A Rigidity Enhancement Device for Inner Hole of Thin-wall Rotary Structural Part

A technology with increased rigidity and a rotating body, applied in the direction of expanding mandrels, etc., can solve the problems of poor versatility and limitation of tooling shape, and achieve the effect of improving versatility and expanding the machinable area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

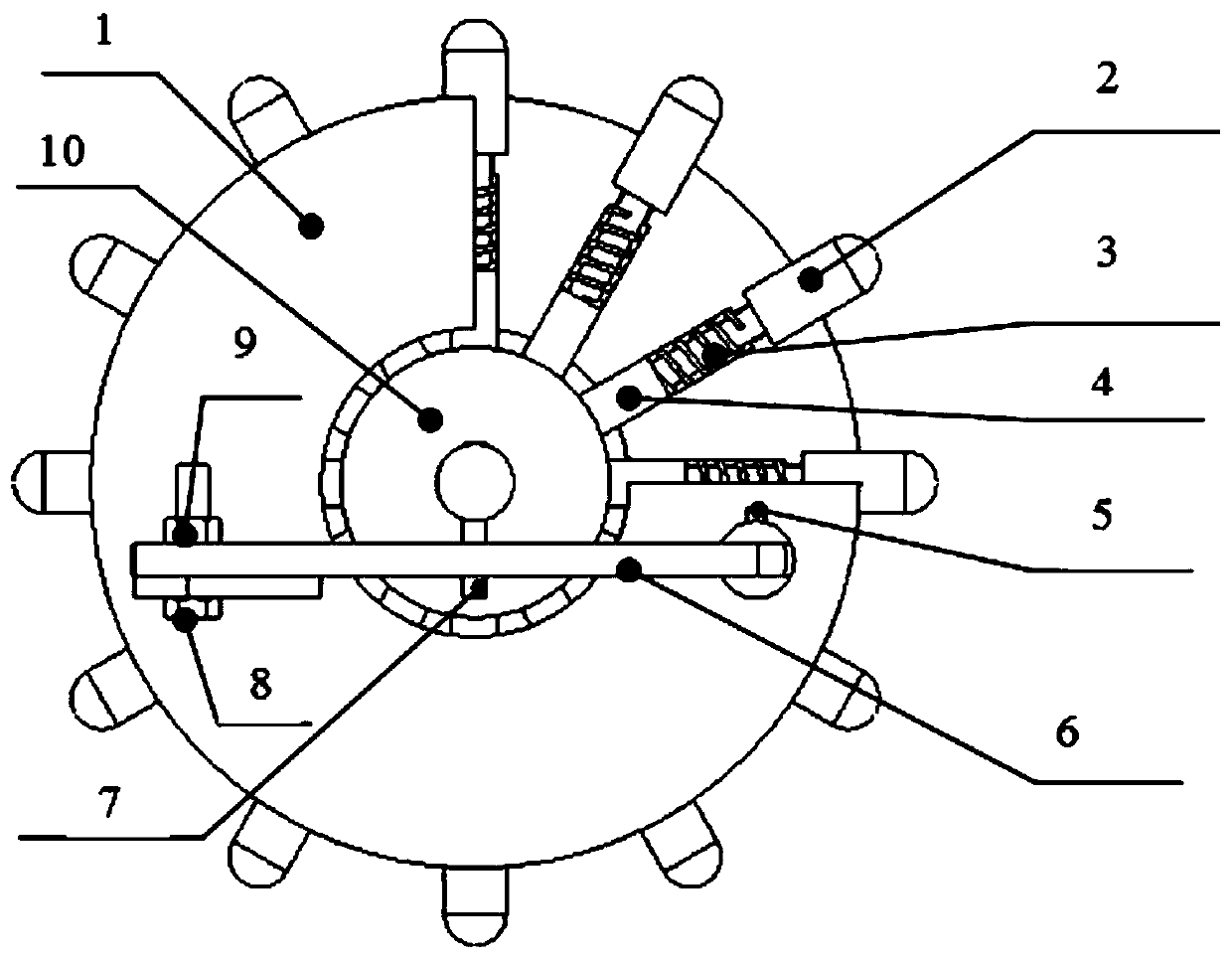

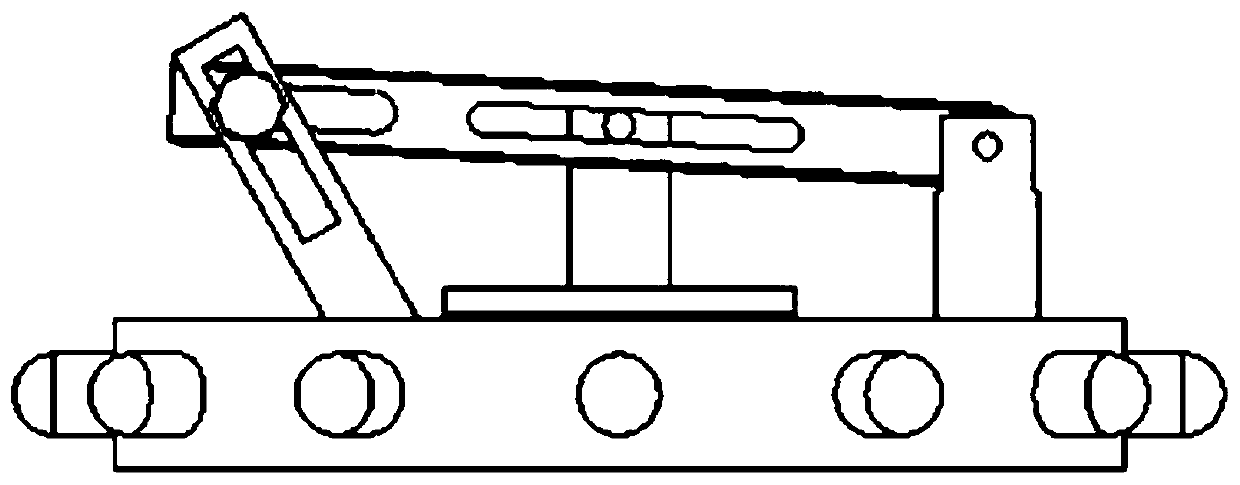

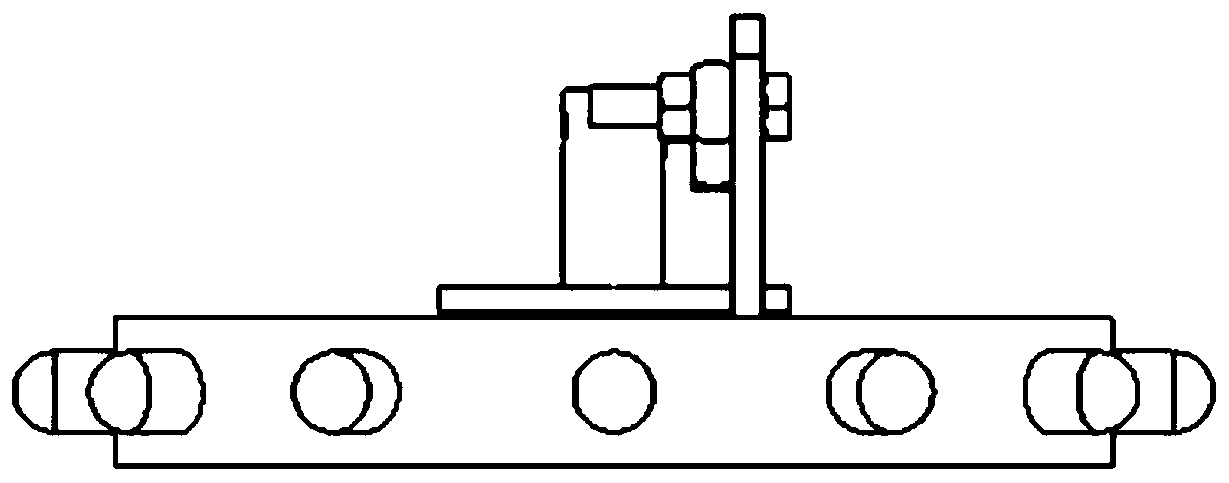

[0016] A device for enhancing the rigidity of the inner hole of a thin-walled rotary structure, comprising: a disc 1, a top post 2, a spring 3, a radial thrust shaft 4, a pin 5, a handle 6, a pin 2 7, a bolt 8, a nut 9 and Axial thrust shaft 10.

[0017] The disc 1 is in the shape of a cylinder, and 12 step-shaped through holes are evenly distributed on the cylindrical surface of the disc 1. There is a cylinder on the end face of the disc 1, and there is a groove on the end face of the cylinder. The pin hole of the groove, there is also an inclined square on the end surface of the disc 1, and a waist-shaped groove is arranged on the end surface; one end of the top column 2 is a hemispherical surface, and the other end surface has a threaded hole, and the top column 2 is 12 in total; There are 12 springs 3 in total; the radial thrust shaft 4 is a stepped shaft, the end face of one end is a cylinder with an inclined plane, and the other end has threads; the pin-5 is a cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com