Production process and production device of unclosed coating type rubber pipe

A technology of production process and production device, which is applied in the field of production process and production device of non-closed clad rubber tube, can solve the problems such as failure to achieve sealing effect and failure to achieve non-closure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The production process of a non-closed coated rubber tube of this embodiment includes the following steps

[0027] A. Use a mold equipped with a spiral rubber extrusion port to extrude the rubber material into a non-closed ring-shaped rubber tube;

[0028] B. A powder injection port is provided in the gap between the adjacent pipe walls of the ring-shaped rubber tube, and the powder injection port sprays powder so that a powder barrier is formed between the adjacent pipe walls of the ring-shaped rubber tube;

[0029] C. The ring-shaped rubber tube with powder barrier is formed by a vulcanizing device;

[0030] D. The ring-shaped rubber tube formed by the vulcanizing device passes through a circulating water tank at room temperature to wash away the powder compartment and at the same time cool down and shape;

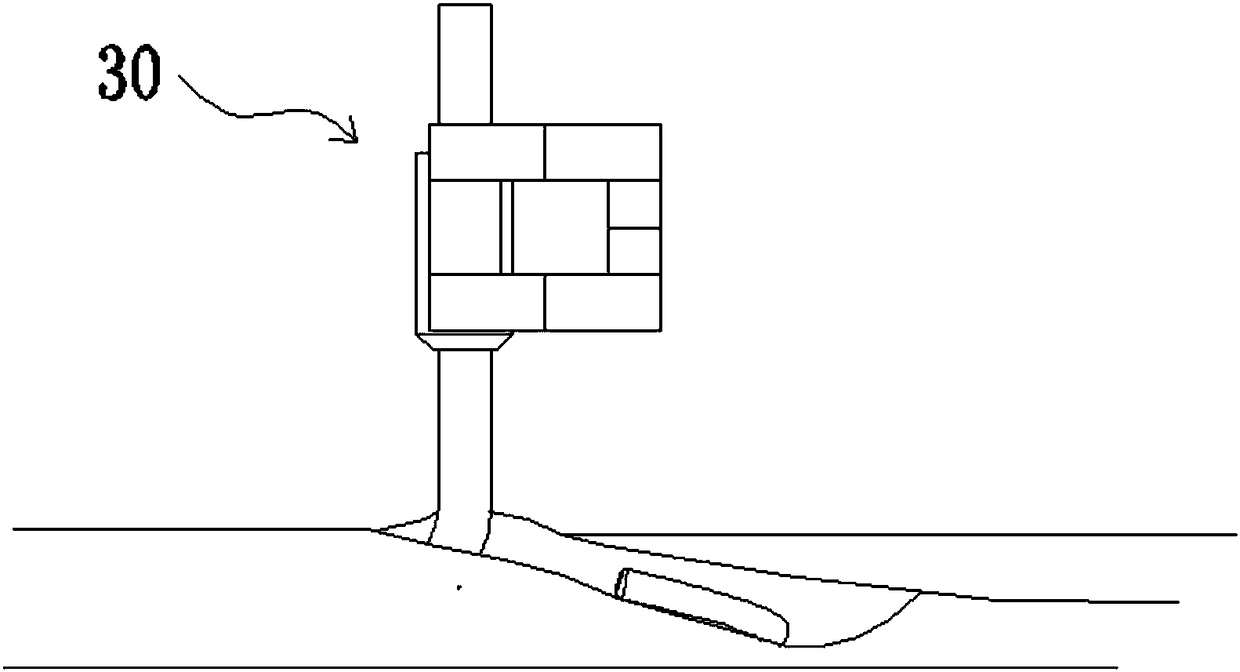

[0031] E. The ring-shaped rubber tube after cooling and shaping passes through the mouth-turning device, and the rubber tube wall covered on the outer layer is turned into ...

Embodiment 2

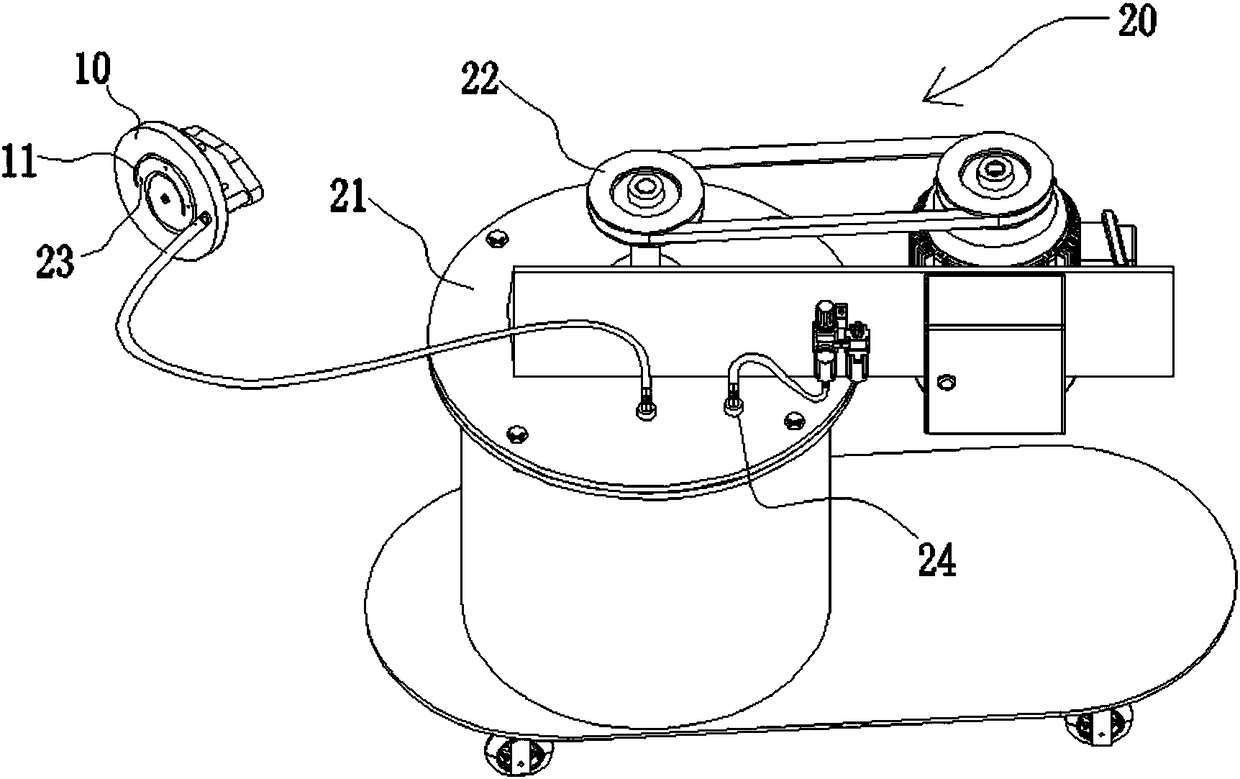

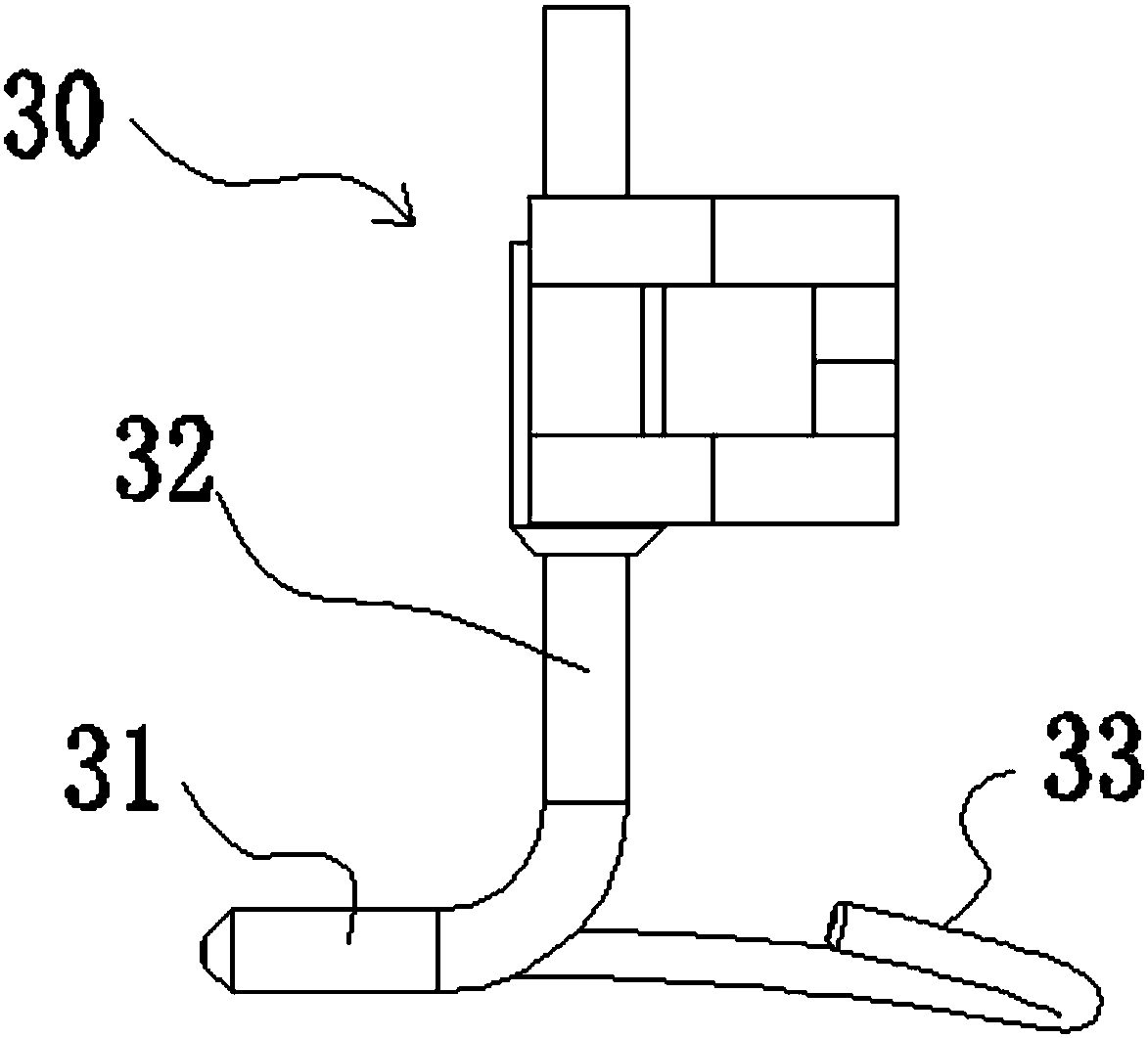

[0040] Such as figure 1 , 2 , 3, and 4, the production device of a non-closed coated rubber tube in this embodiment includes an extrusion die 10, a powder spraying device 20, a vulcanizing device, a cooling water tank at room temperature, a turning device 30, a pressure Tightening device and heating and baking setting device, the extrusion die 10 is provided with a spiral rubber extrusion port 11; the powder spraying device 20 includes a powder storage box 21, a powder lifter 22 and a powder outlet 23. Powder is stored in the powder storage box 21, and the powder booster 22 is in communication with the powder outlet 23, and the powder outlet 23 is arranged in the gap of the spiral rubber extrusion port 11 on the extrusion die 10; The mouth-turning device 30 includes a deflector 31, an open vertical pipe 32 and a mouth-turning device 33, and the mouth-turning device 33 is provided with a downwardly curved portion. The powder storage tank 21 is also connected with an air inlet 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com