Construction platform and construction method of pebble bed large-scale deep water foundation

A construction platform and deep-water foundation technology, applied in infrastructure engineering, water conservancy engineering, artificial islands, etc., can solve problems such as construction deviation, impact on construction period, stagnation, etc., and achieve the effect of ensuring stability, saving resources, and accurate limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

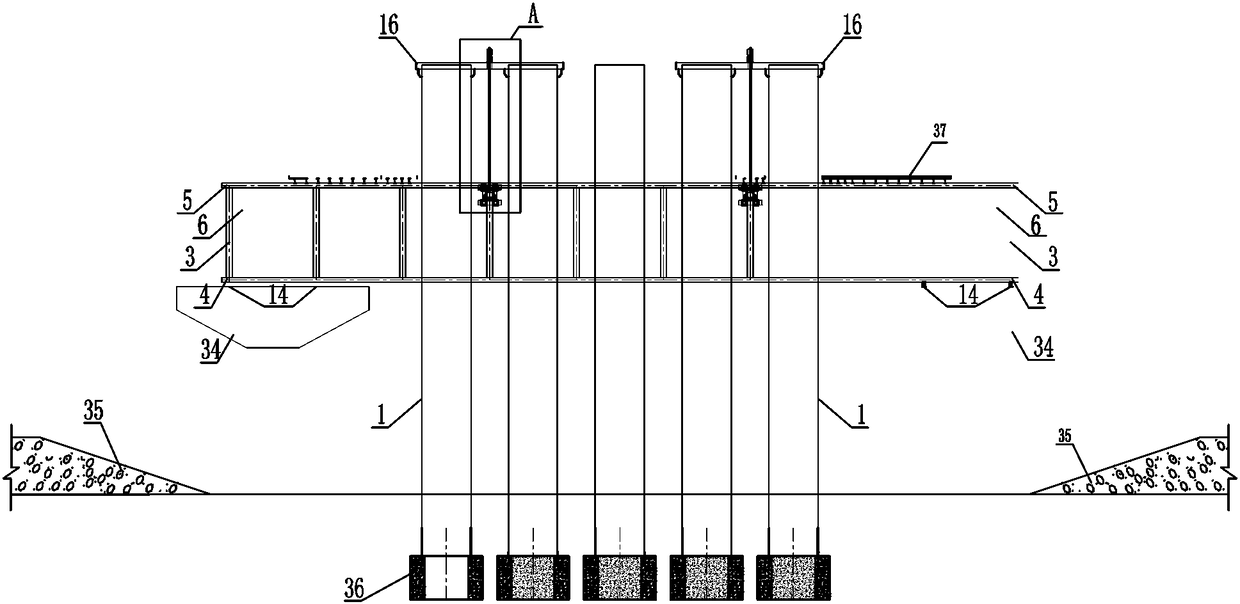

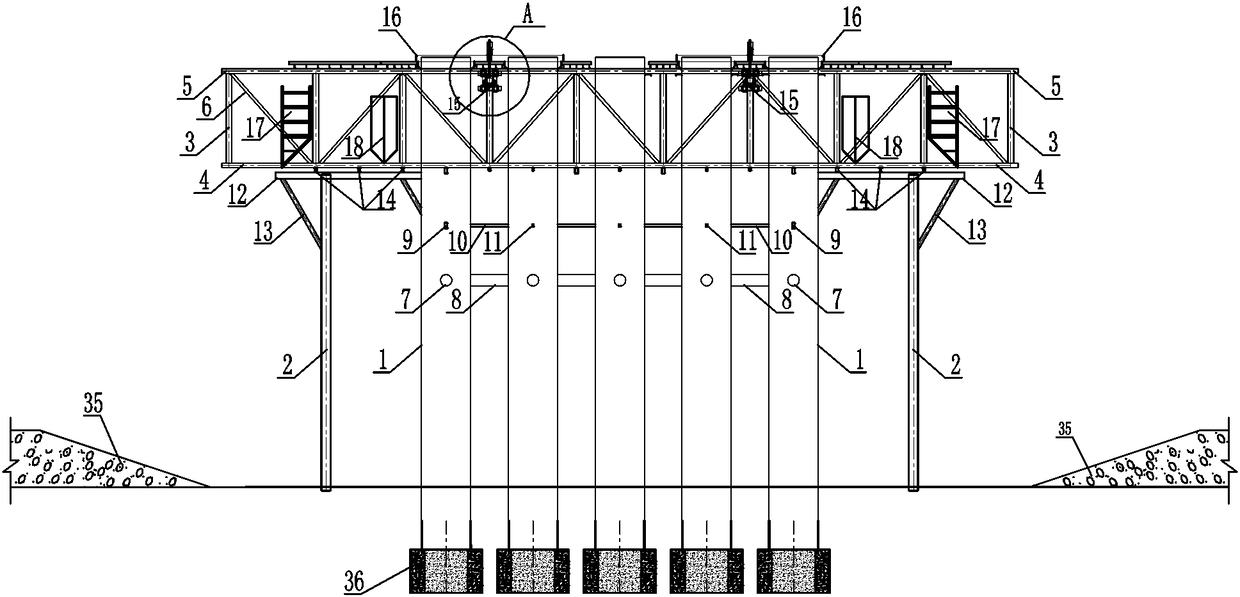

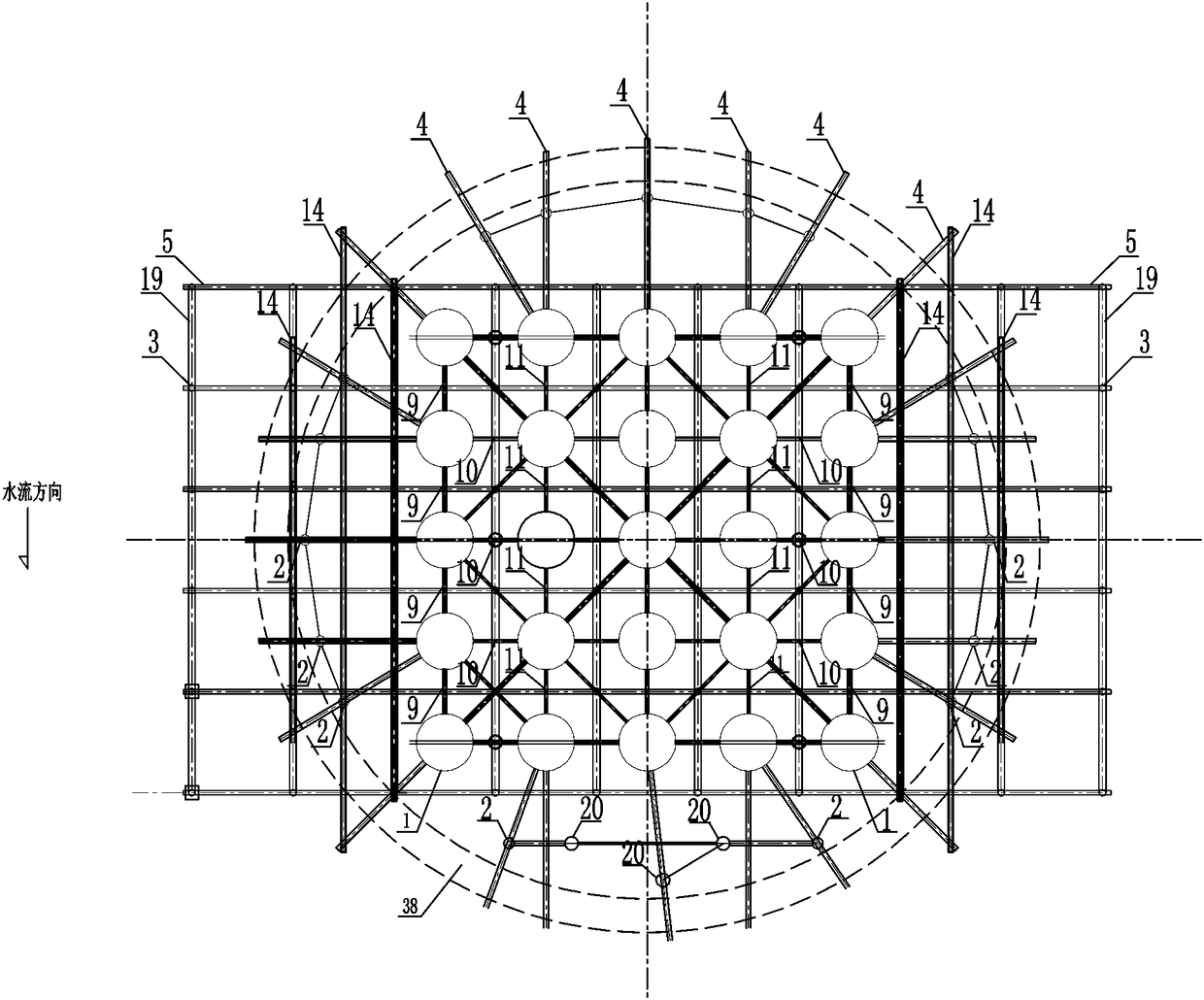

[0042] The construction method of the large-scale deep water foundation construction platform of pebble layer comprises the following steps:

[0043] Step1: Use the chain bucket ship and suction dredger to carry out rough leveling and fine leveling of the cofferdam bottom foundation to reach the design bottom elevation of the cofferdam bottom sealing concrete;

[0044] Step2: Use the first steel pipe vertical rod 3, the second steel pipe vertical rod 6, the first double I-shaped steel pad beam 4, and the second double I-shaped steel pad beam 5, and assemble 5-7m high steel on two large barges 34 The space truss structure in which the casing 1 is positioned constitutes a construction platform, and a plurality of second steel pipe auxiliary piles 20 are respectively inserted and driven on the upper and lower reaches of the platform, wherein the downstream second steel pipe auxiliary piles 20 are used as auxiliary piles for the subsequent cofferdam assembly platform;

[0045] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com