A one-way flow valve

A flow valve, one-way technology, applied in the field of hydraulic valve manufacturing, can solve the problems of not suitable for low-pressure hydraulic systems, large output flow changes, large flow resistance, etc., and achieve the effect of low cost, large flow area and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

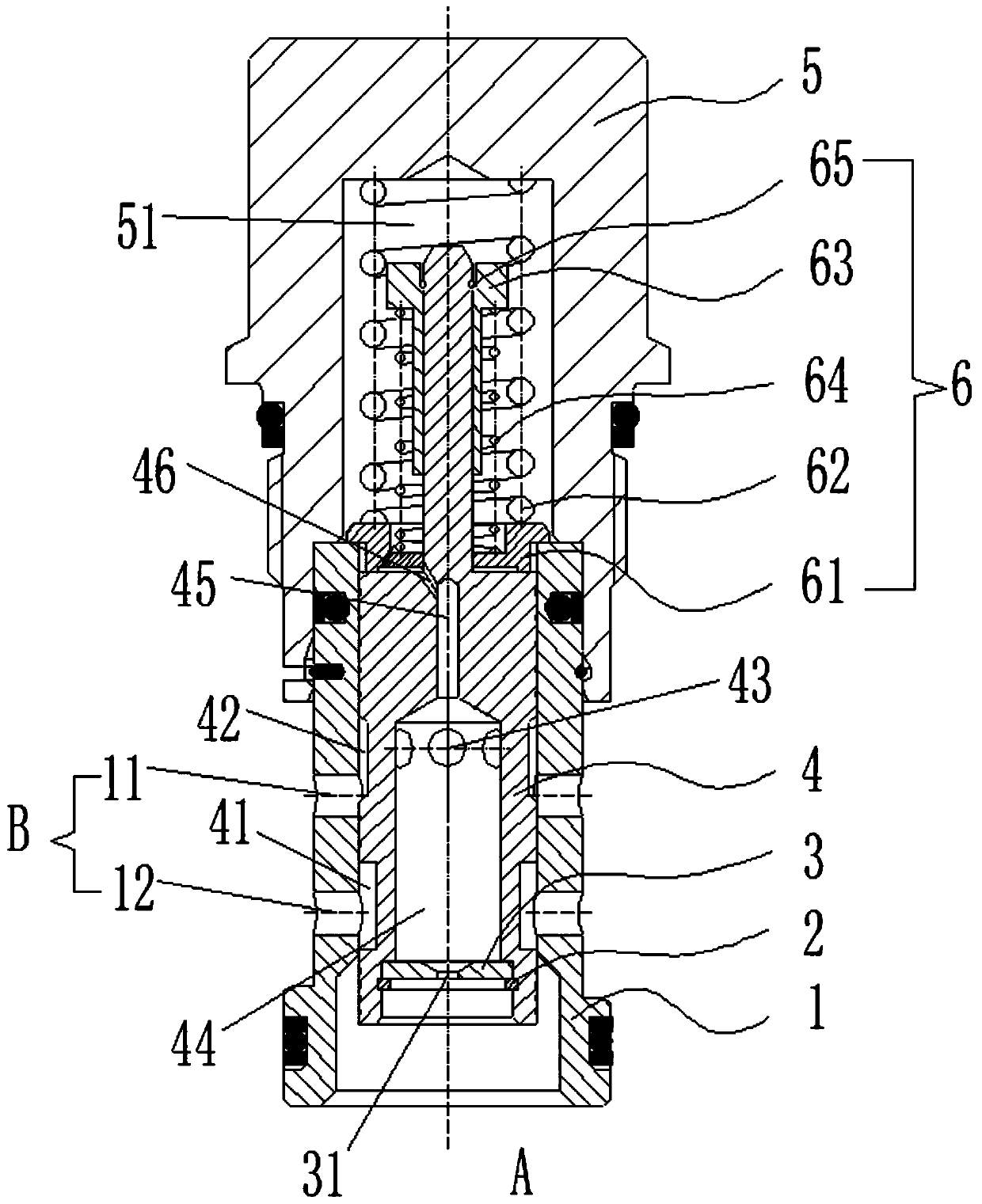

[0019] Such as figure 1 Shown is the structural representation of the present invention,

[0020] A one-way flow valve, comprising a valve body 1 with a stepped through hole inside, the valve body 1 is provided with an oil port A and an oil port B, and the oil port A is located at the large aperture of the stepped through hole of the valve body 1 , the oil port B is composed of the first flow hole 11 and the second flow hole 12 on the side wall of the valve body 1, and the first flow hole 11 and the second flow hole 12 are evenly distributed along the circumference of the valve body 1 , the first flow hole 11 is located above the second flow hole 12; the main valve core 4 is slidably arranged in the valve body 1, and the main valve core 4 is provided with a communication flow chamber 44 and a first flow channel, The flow cavity 44 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com