Refrigerator compressor control method

A technology of a refrigerator compressor and a control method, which is applied to household refrigeration devices, lighting and heating equipment, cooling fluid circulation devices, etc. Improve customer experience and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

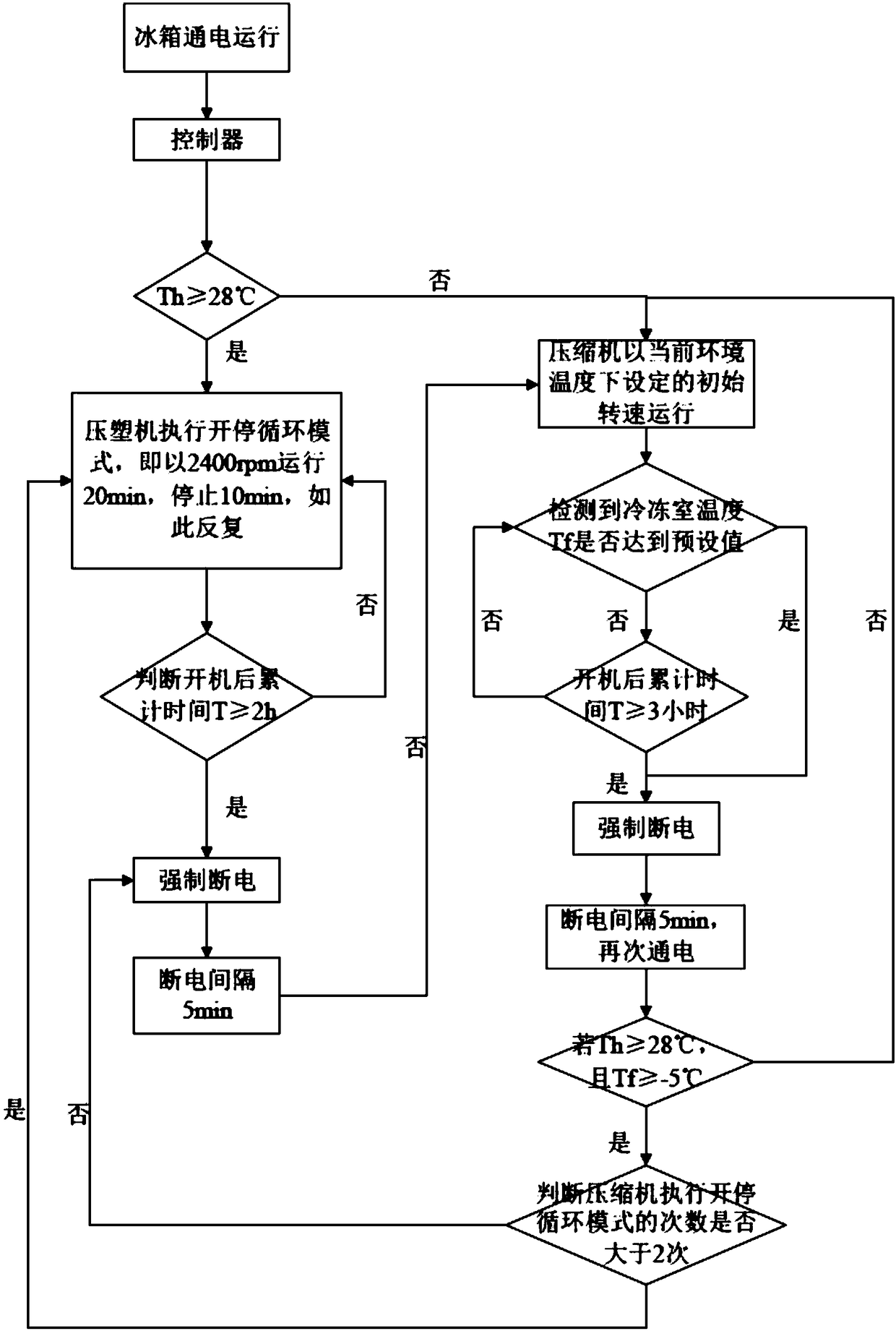

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

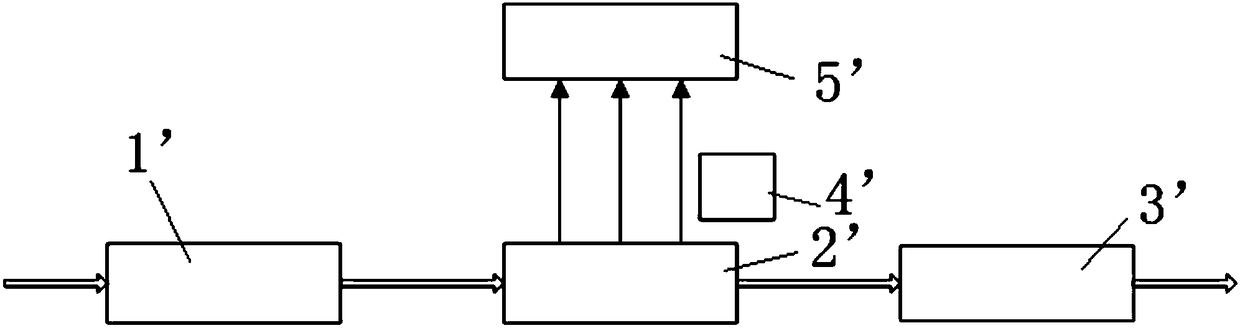

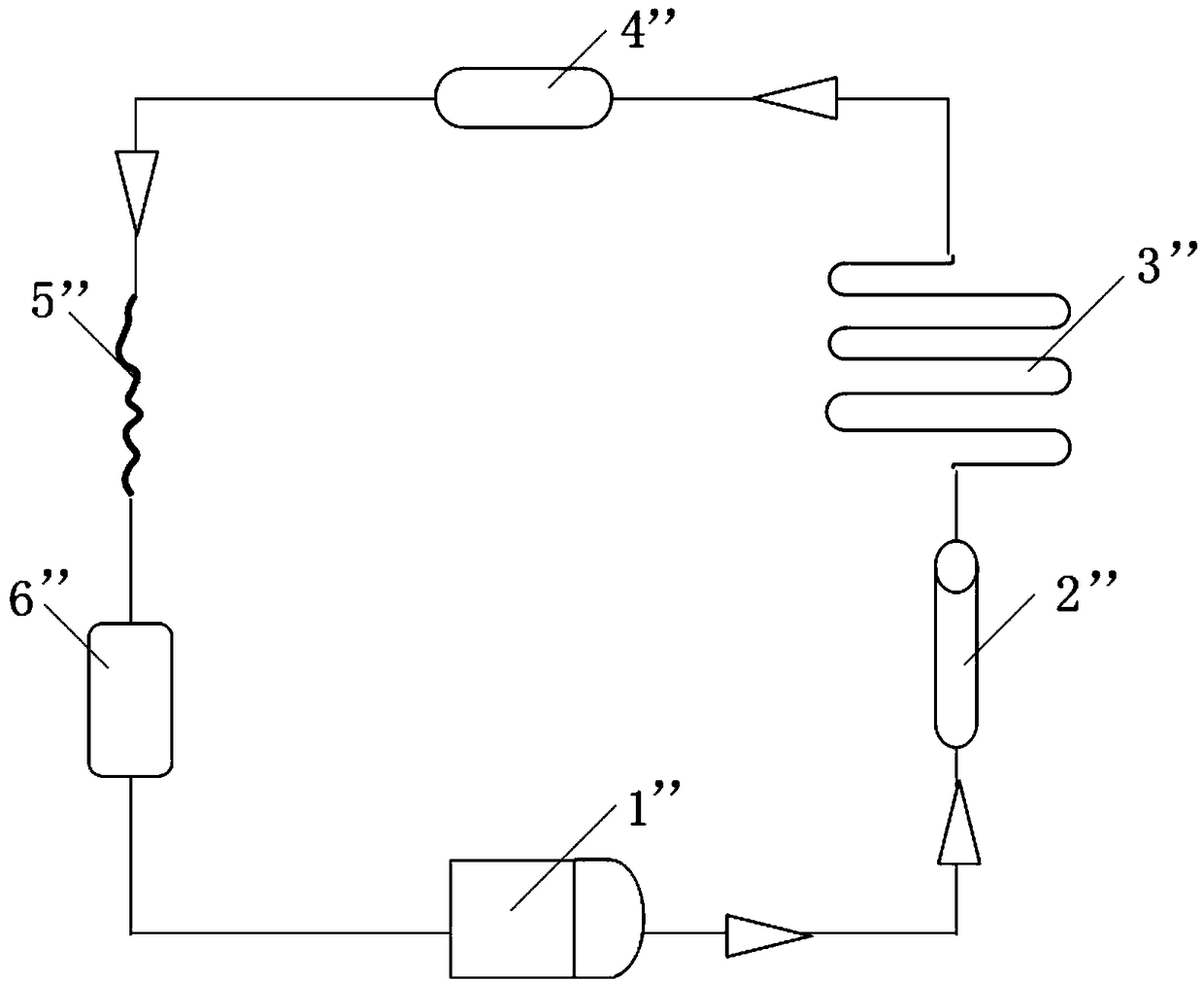

[0038] This embodiment is applied to adopt figure 2 In the refrigeration cycle system where the pipeline of the refrigerator integrated embedded condenser is located, a refrigerator compressor control method is provided in this embodiment, which is applied to the compressor 1" of the frequency conversion air-cooled refrigerator. It is mainly for the refrigerant ( Refrigerant) first flows through the anti-condensation pipe 2" and then flows through the integrated embedded condenser 3" inverter air-cooled refrigerator. By optimizing the control program of the inverter compressor, the temperature on the surface of the beam or vertical beam of the refrigerator at the initial stage of power-on is reduced. problems, thereby improving user experience and reducing the risk of the freezer door seal being so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com