Freeze dryer

A freeze-drying machine and freeze-drying technology, which is applied in the field of freeze-drying machines, can solve the problems of inconvenient assembly and transportation, difficult manufacturing and assembly, and large space occupation, and achieve the effects of avoiding pollution risks, saving manufacturing materials, and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

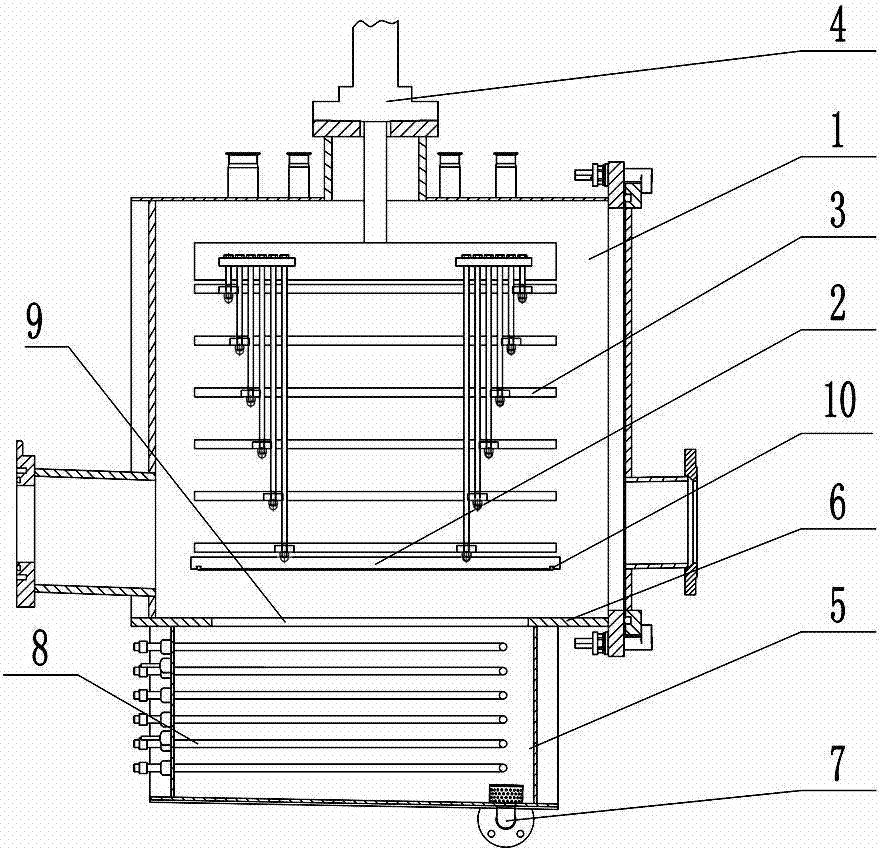

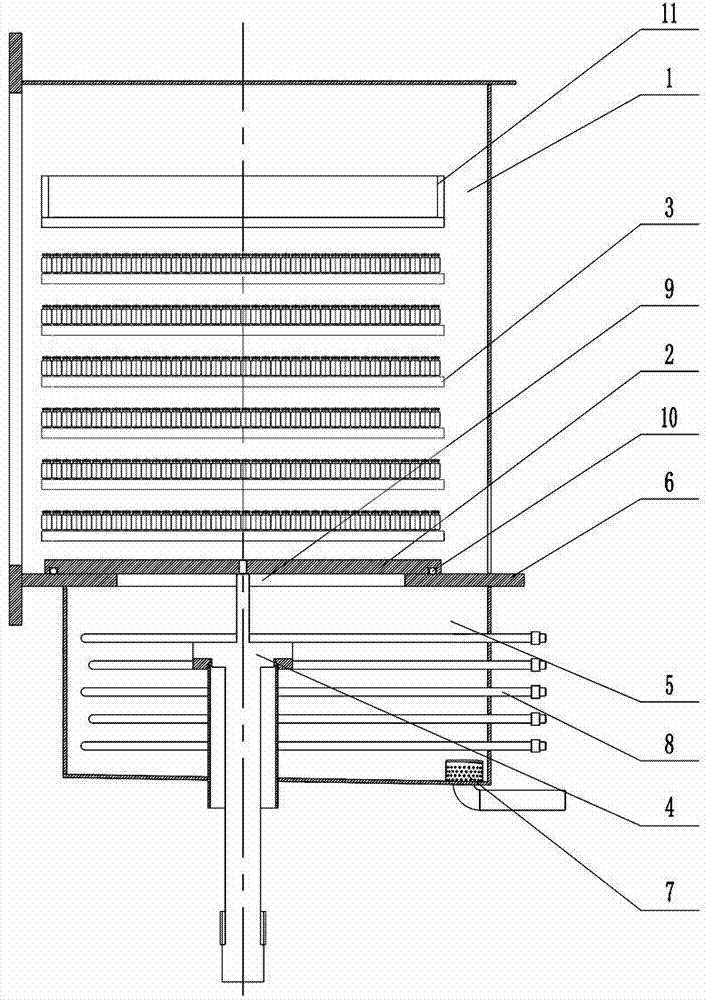

[0029] Such as figure 1 As shown, the lyophilizer of the present invention includes a freeze-drying chamber 1 and a cold trap chamber 5, and a coil 8 for refrigeration is provided in the cold-trap chamber 5; Above the multiple freeze-dried slabs 3, the top of the freeze-dried chamber 1 is provided with a lifting drive 4 for driving the support plate 2 and the freeze-dried slabs 3 up and down. The lifting drive 4 in this embodiment is an oil cylinder. During work, after the bottle body in a half-stoppered state completes freeze-drying on the freeze-drying plate layer 3, the support plate 2 and each freeze-drying plate layer 3 will move down under the drive of the lifting drive member 4, so that each freeze-drying plate layer The layers 3 are close to each other for plugging, and the rubber stopper on the bottle body is completely pressed into the bottle mouth; the support plate 2 is lowered to the bottom of the freeze-drying chamber 1 to support the freeze-dried plate layer 3 ....

Embodiment 2

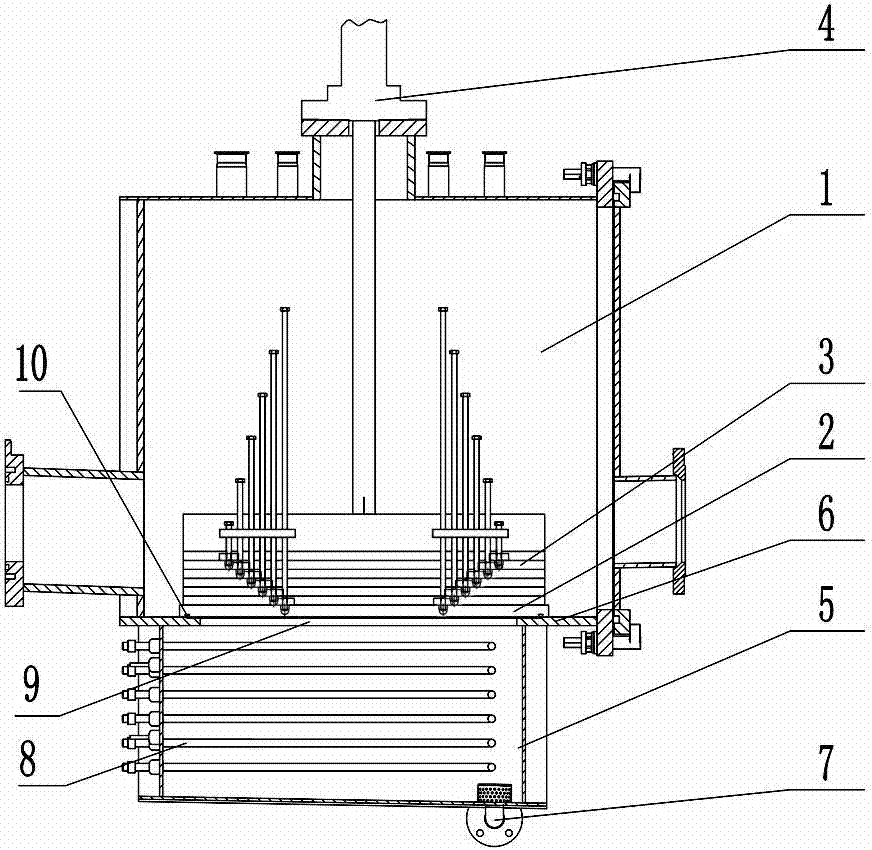

[0035] Such as image 3 and Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that in this embodiment, the lifting drive member 4 is arranged at the bottom of the cold trap chamber 5, when the support plate 2 descends to the bottom of the freeze-drying chamber 1 and covers the through When opening the hole 9, the lift driver 4 exerts a downward pulling force on the support plate 2, driving the support plate 2 to be pressed against the periphery of the through hole 9, thereby obtaining a better sealing and isolation effect, and measuring the pressure of the freeze-drying chamber 1 more accurately. liters, to accurately judge whether the freeze-drying is sufficient (the freeze-drying machine mainly evaporates the water in the mixture in the bottle, and the freeze-drying chamber 1 needs to be sealed before plugging, and the pressure rise of the freeze-drying chamber 1 should be measured, if the freeze-drying chamber 1 If the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com