Supercavitation projectile regarding surface controlling drag reduction

A surface control and supercavitation technology, which is applied in the direction of projectiles, offensive equipment, weapon types, etc., can solve the problems of difficult implementation, high detection requirements of tail bubble sensors, and narrow application range, etc., and achieve easy implementation and intelligentization The effect of a wide range of applications and a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

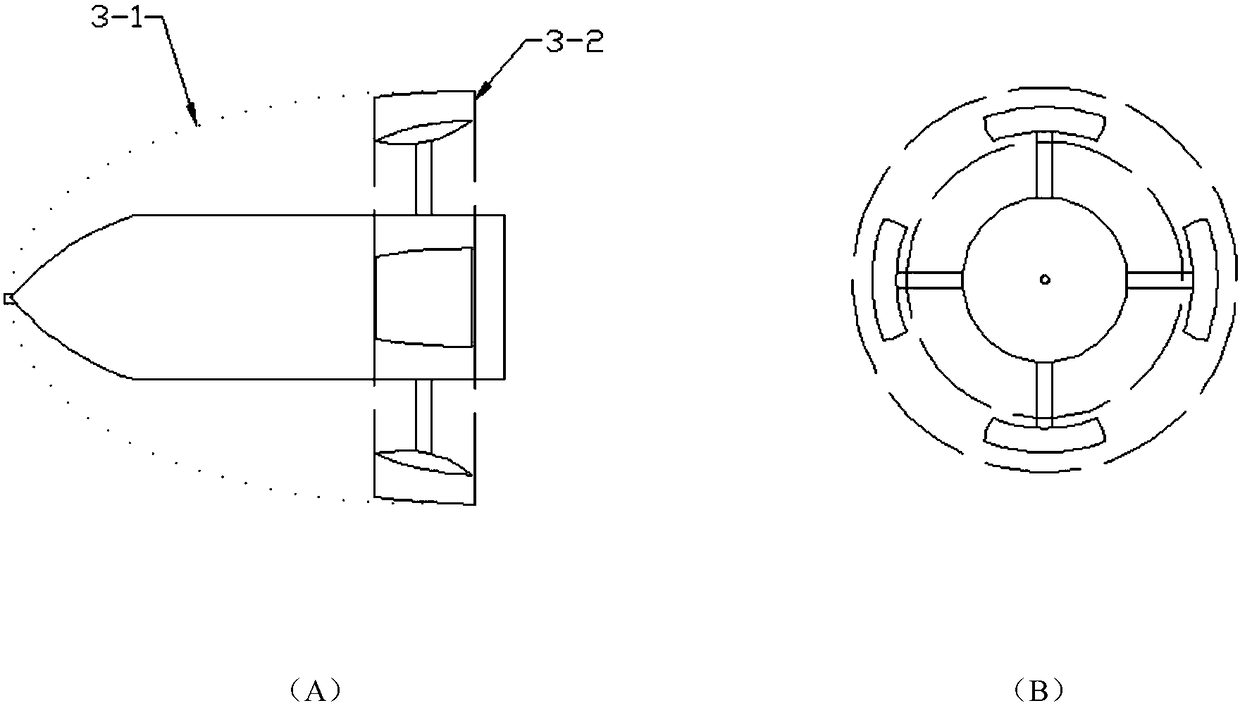

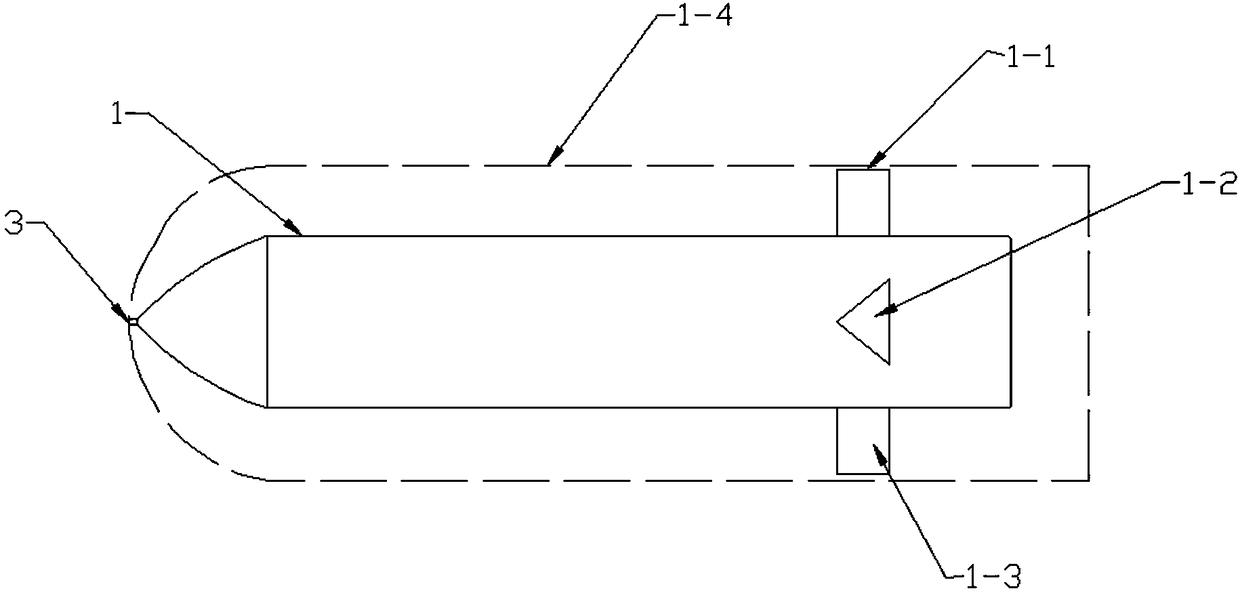

[0019] (1) The projectile body that forms an air cavity in the water, and the air cavity model is determined by the air-water boundary;

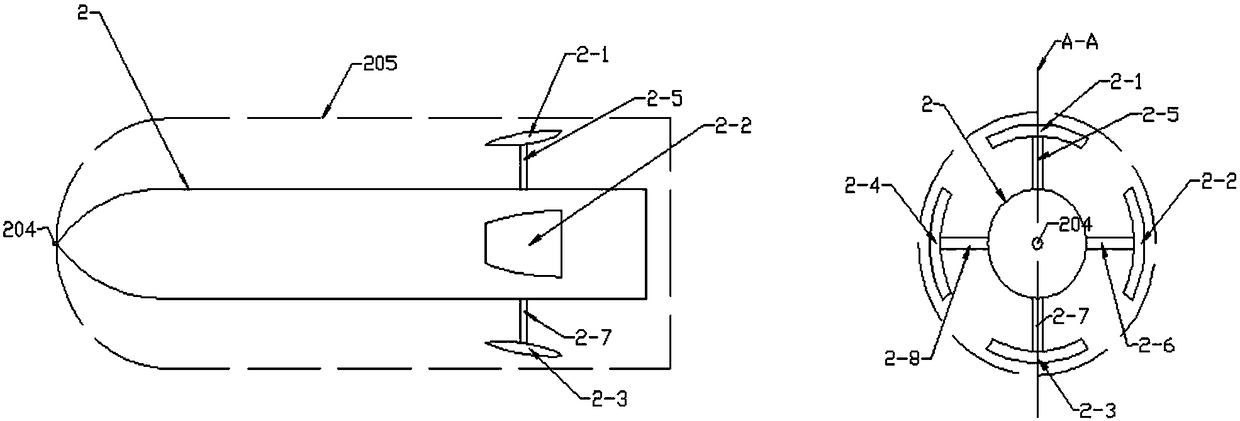

[0020] (2) The snowboard-type buffer connected with the projectile, the bottom of the snowboard-type buffer faces the air-water boundary of the air cavity;

[0021] (3) Drivers and controllers that change the position of the buffer based on the speed of the projectile and the air cavity model.

[0022] One disadvantage of the supercavitating projectile designed in the prior art is that the tail fin is easy to touch the air-water boundary, which increases the water resistance of the projectile's movement. Another disadvantage is that because the position of the tail fin is fixed, it cannot adapt to the change of the cavity shape caused by the change of the projectile speed.

[0023] The supercavitating underwater projectile designed by the present invention can maintain stability in the air cavity without the above-mentioned disadvantages. The tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com