Full-wedge type anti-explosion container

A container and wedge type technology, applied in the field of full wedge type explosion-proof container, can solve the problems of failure, excessive deformation of end caps, and large number of parts, so as to achieve the effect of increased pressing force and good protection against explosion impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

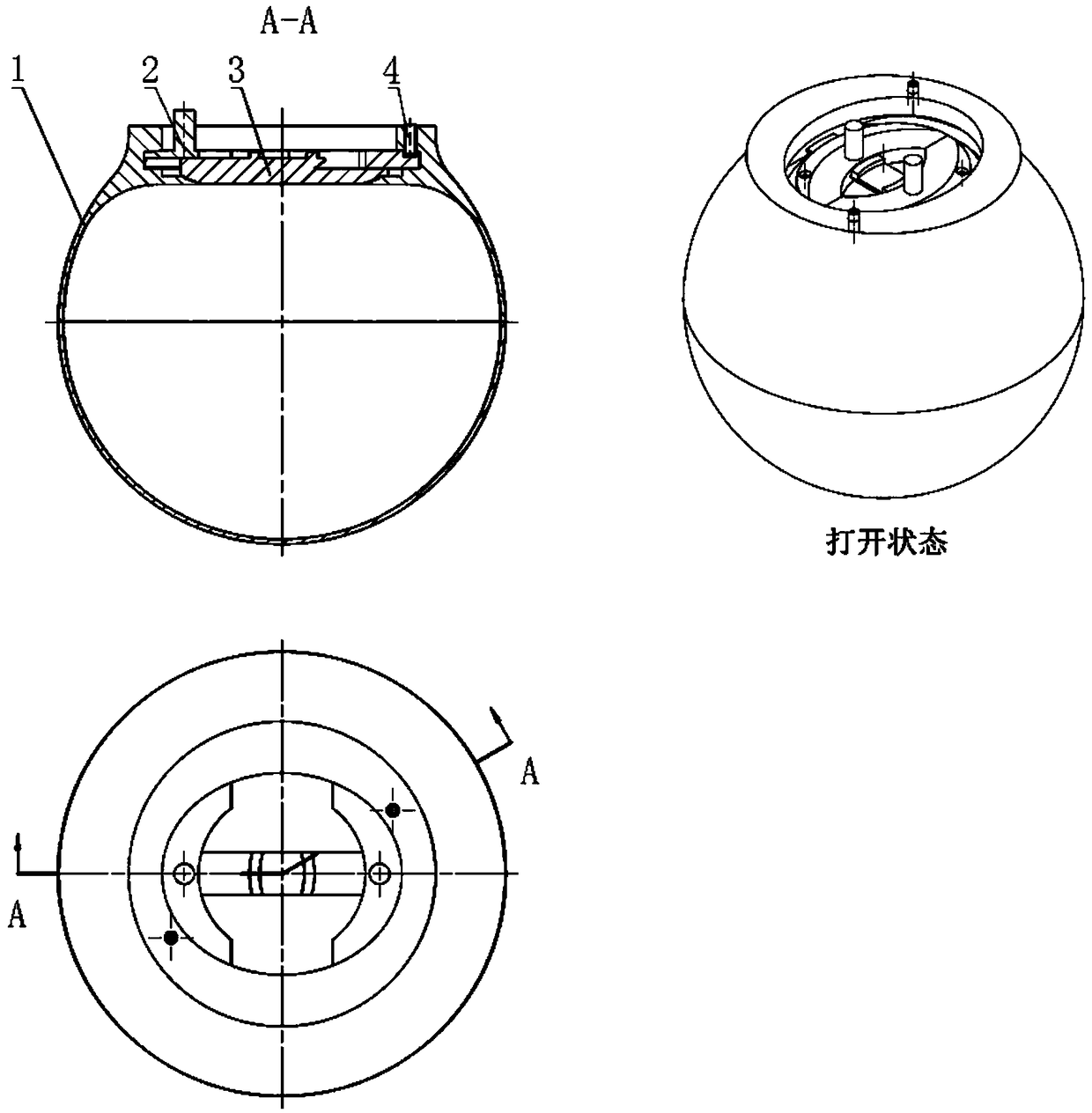

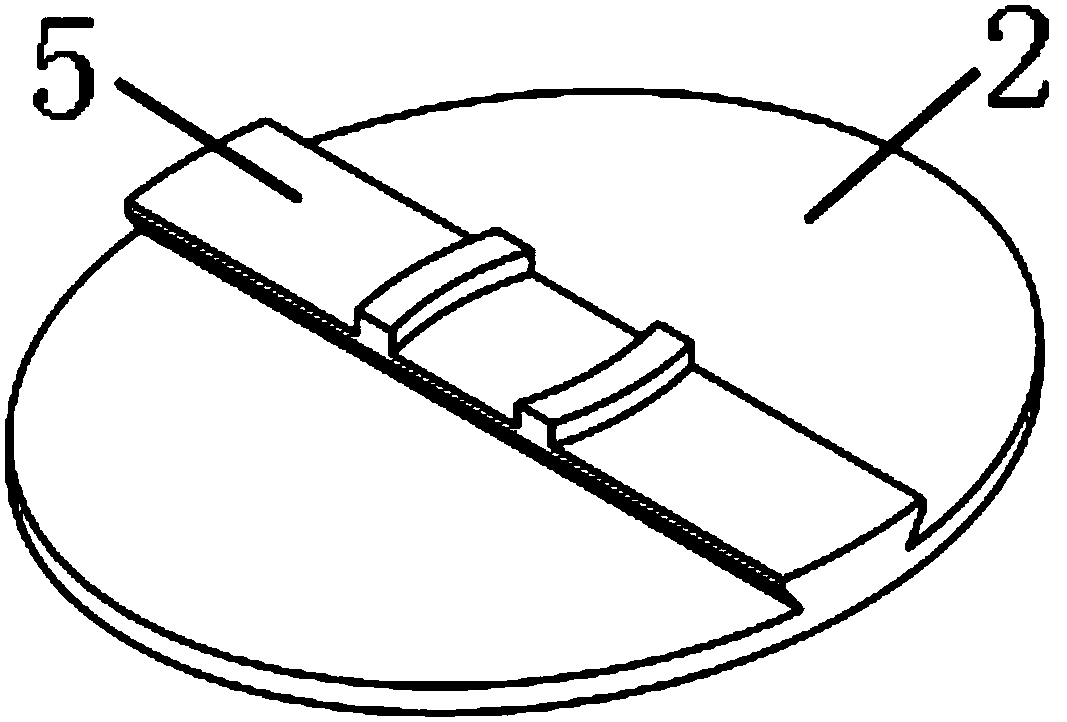

[0018] as attached figure 1 As shown, a full wedge anti-explosion container is mainly composed of a shell 1, a cover plate 2, a wedge 3 and a locking member 4, and the whole structure is only composed of six parts.

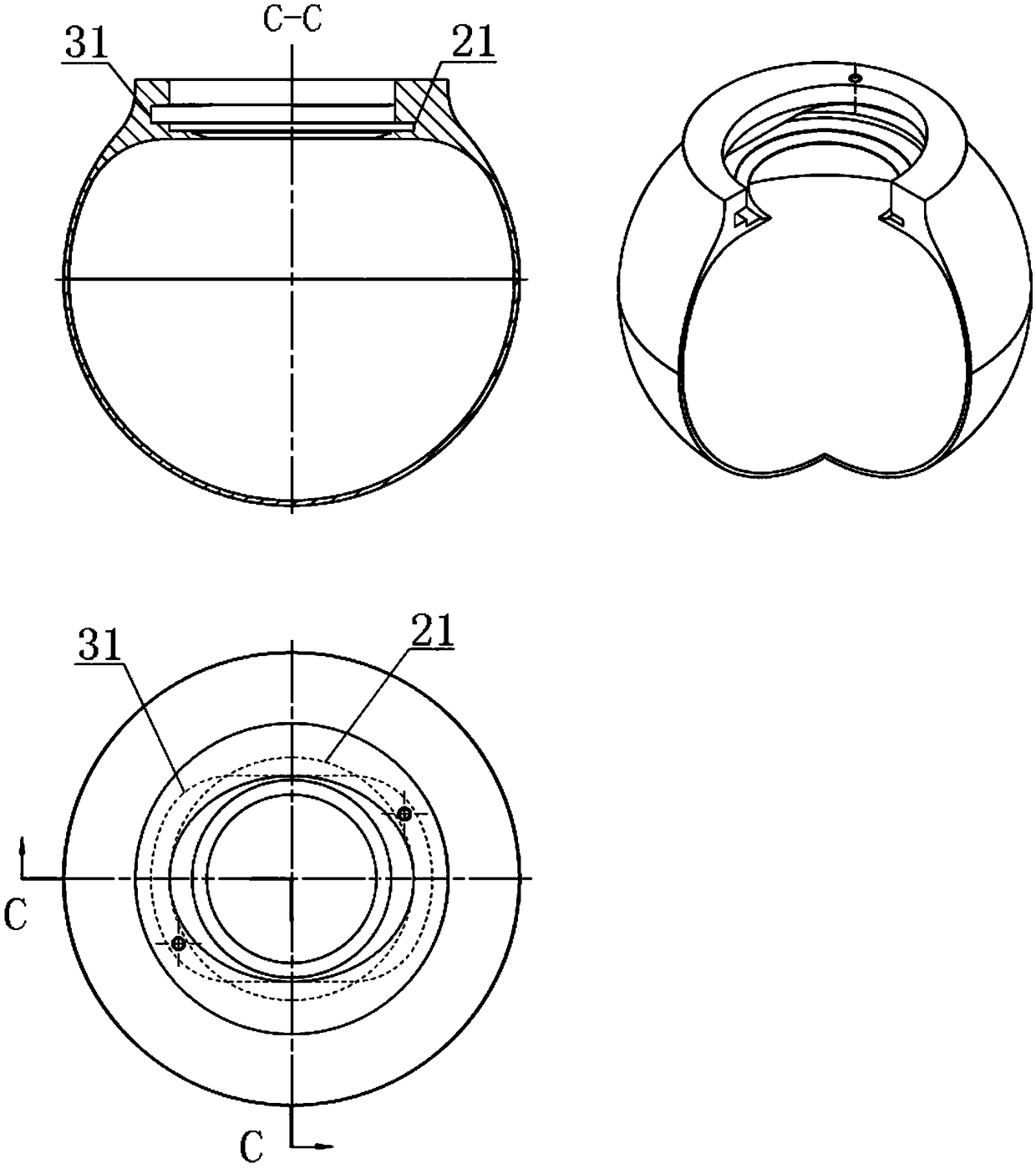

[0019] The shell structure of the full wedge anti-explosion vessel is as attached figure 2 As shown, the shell adopts a spherical design as a whole. According to investigation and analysis, under the same load, the spherical shell has smaller principal stress than other forms of shells such as cylindrical shells. The opening adopts an elliptical opening, and the difference between the long and short axes of the ellipse is fully utilized to realize the axial fixation of the cover plate.

[0020] The flange neck at the upper end of the shell is the key to this design, and the wedge bar slot 31 and the cover plate slot 21 are dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com