Wind turbine generator set bearing mechanical fault diagnosis method considering multi-class objectives

A technology for wind turbines and bearing machinery, applied in mechanical bearing testing, complex mathematical operations, etc., can solve problems such as errors, misidentification of fault samples without training, and impact on equipment reliability, so as to prevent false modals and modal aliasing Effects with low impact and few modalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The invention is a method for diagnosing mechanical faults of wind turbine bearings in consideration of multi-category targets, comprising the following steps:

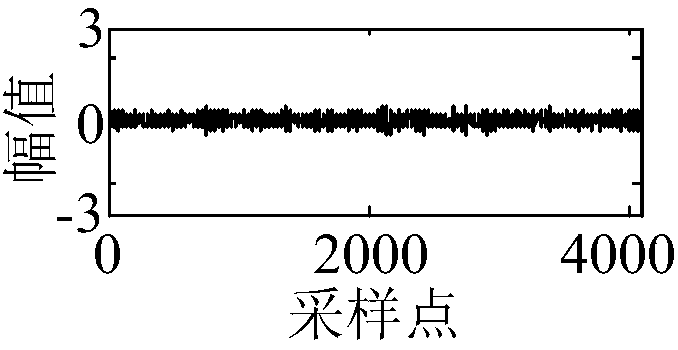

[0087] 2) Wind turbine bearing vibration signal acquisition

[0088] Acceleration sensors are used to collect wind turbine bearing normal state signals, rolling element fault vibration signals, inner ring fault vibration signals and outer ring fault signals, and the above signals are recorded by a 16-channel data recorder. The signal sampling frequency is 12 kHz, and the signal length is 4096 sampling points;

[0089] 2) Wind turbine bearing vibration signal processing

[0090] In order to extract effective fault feature information and take into account the modulation characteristics of the bearing vibration signal, the empirical wavelet transform is used for bearing fault diagnosis. Then, a set of orthogonal filter banks is constructed based on the segmented intervals, so as to decompose the complex bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com