Cooling device for die casting machine and cooling method thereof

A cooling device and die-casting machine technology, applied in the field of cooling devices, can solve the problems such as difficulty in setting the feeding rhythm and feeding cycle reasonably, the workpiece cooling time is not fixed, and the air cooling effect is not obvious, and the air cooling effect is obvious and the production The effect of high efficiency and increased cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. However, the examples are merely exemplary and do not limit the scope of the present invention in any way. Those skilled in the art should understand that the details and forms of the scheme of the present invention can be modified or replaced without departing from the scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

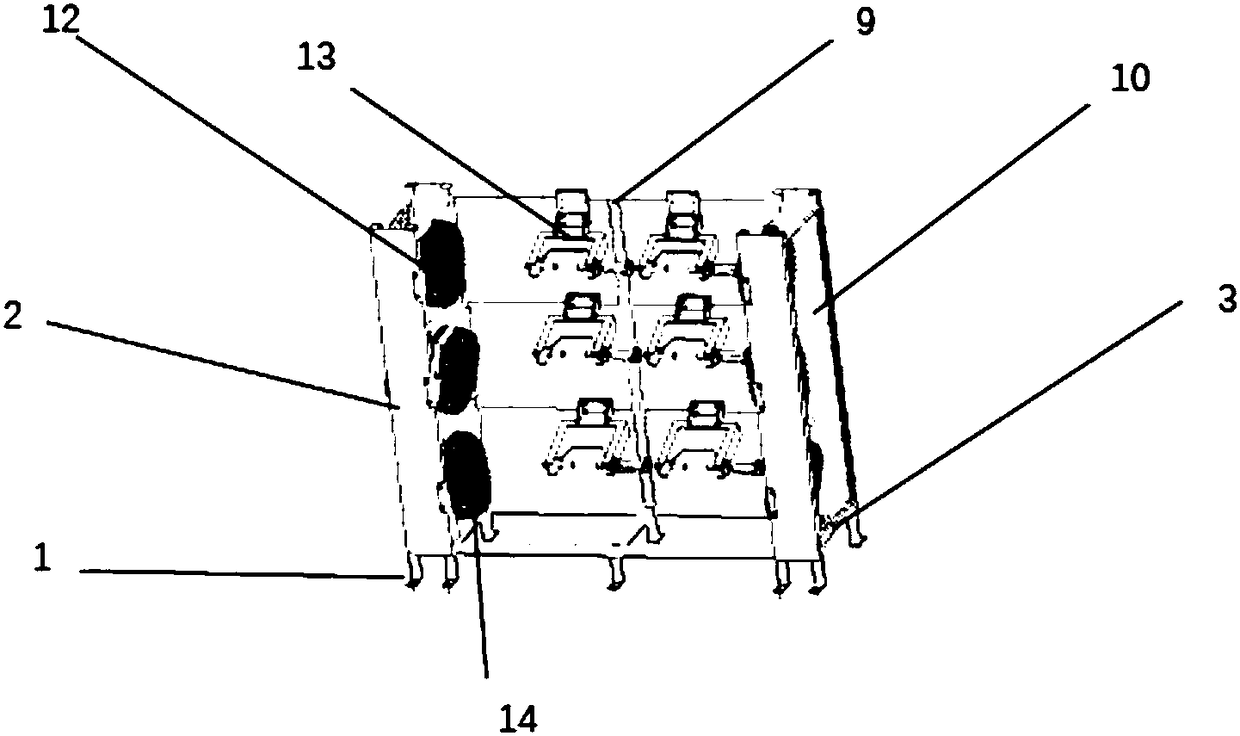

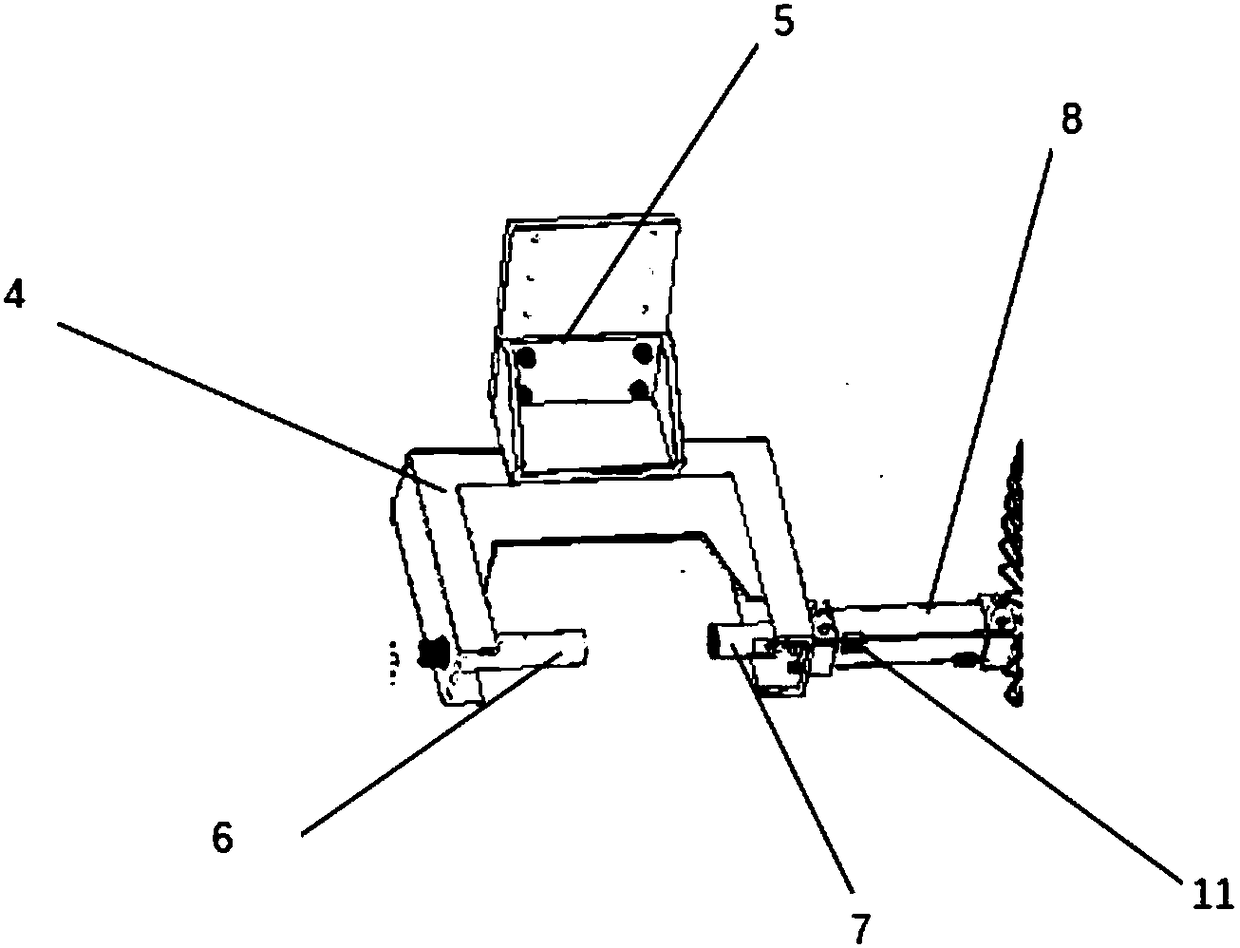

[0024] Such as figure 1 and figure 2 As shown, the present invention discloses a cooling device for a die-casting machine. The cooling device for a die-casting machine includes a cooling jaw 13, a cooling bracket 9, and an air-cooled fan group 12; the cooling jaw 13 includes a channel steel compartment 4, Workpiece fixing cylinder 8, collet 6 and jacking block 7; said workpiece fixing cylinder 8 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com