Belt sanding machine

A technology for grinding machines and abrasive belts, which is applied in the direction of abrasive belt grinding machines, grinding machine parts, grinding machines, etc., can solve the problems of unreasonable structural design of abrasive belt grinding machines, excessive consumption of manpower and material resources, and low grinding efficiency. Efficient structural design, saving grinding time, and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

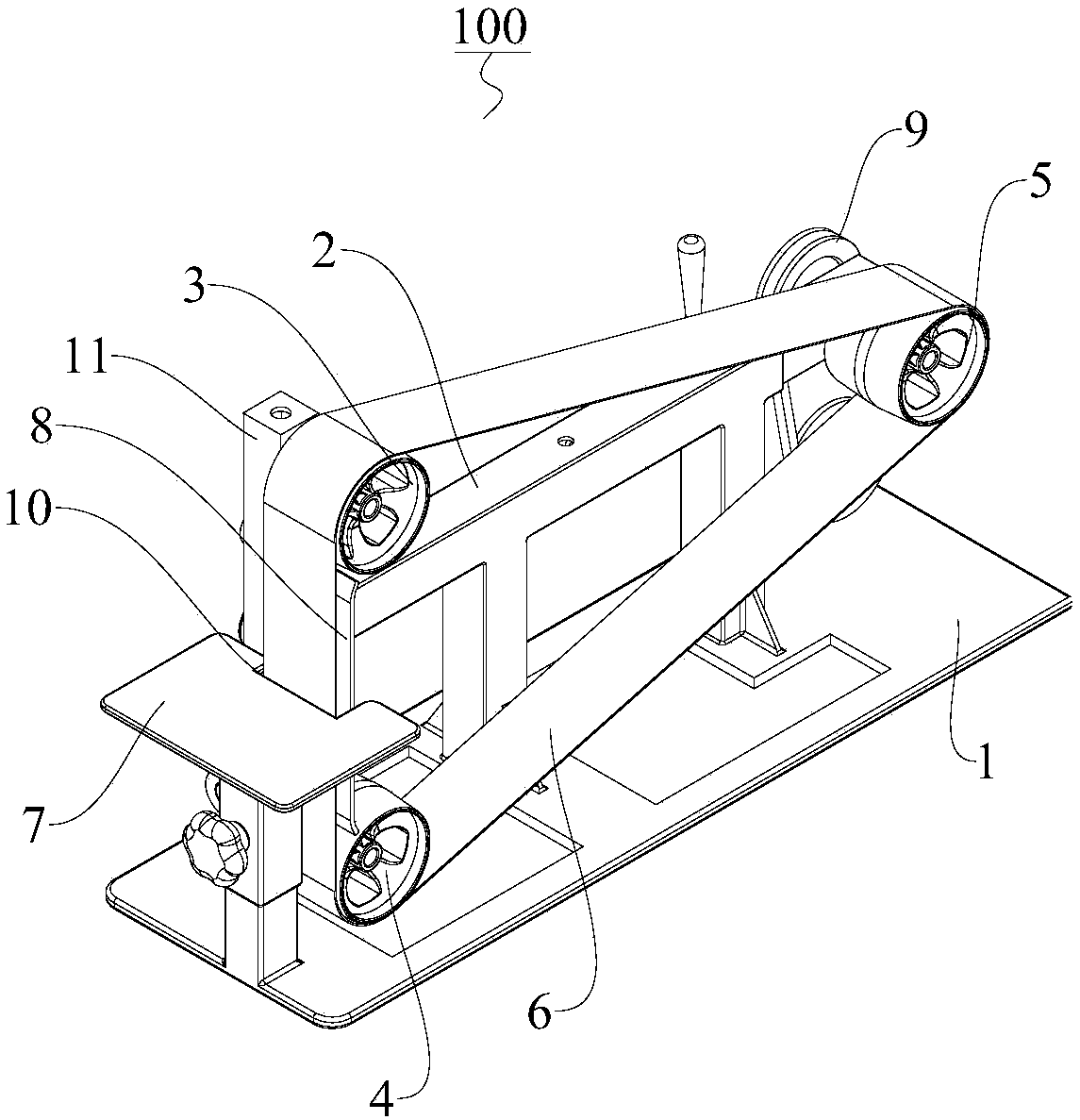

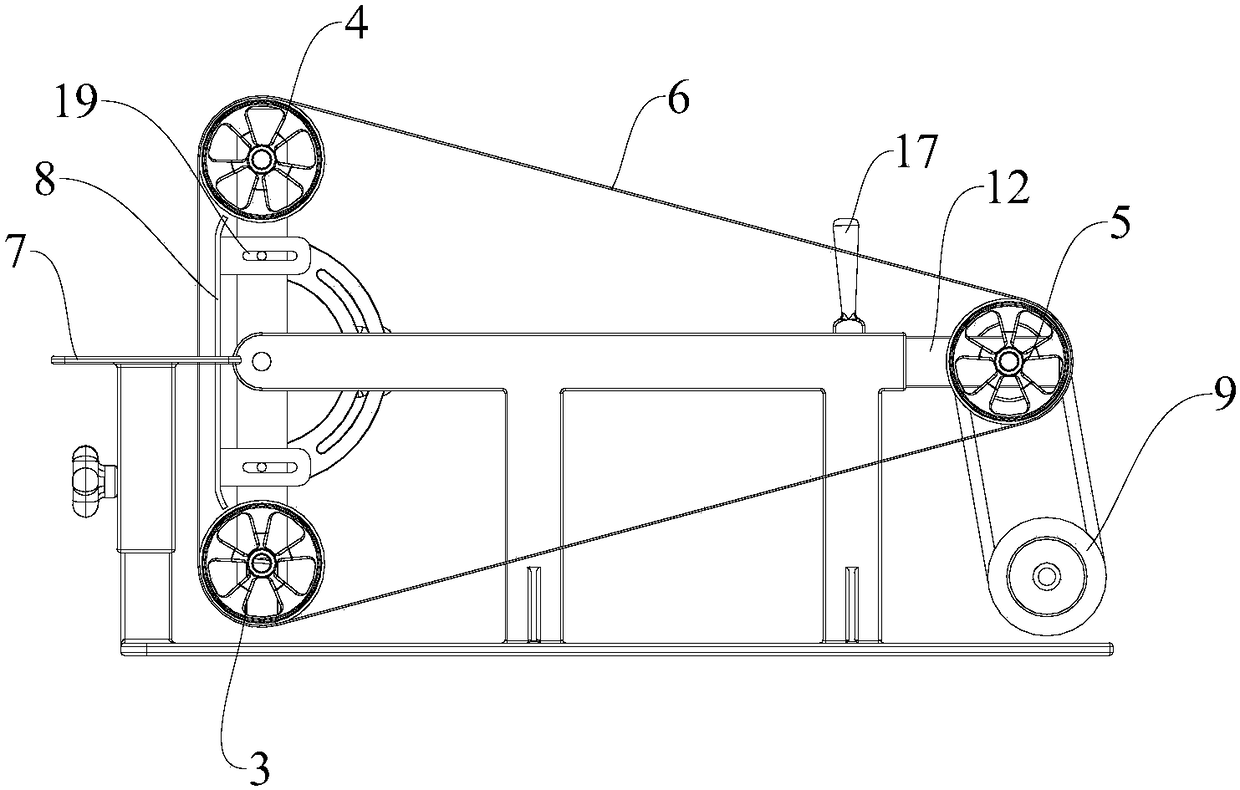

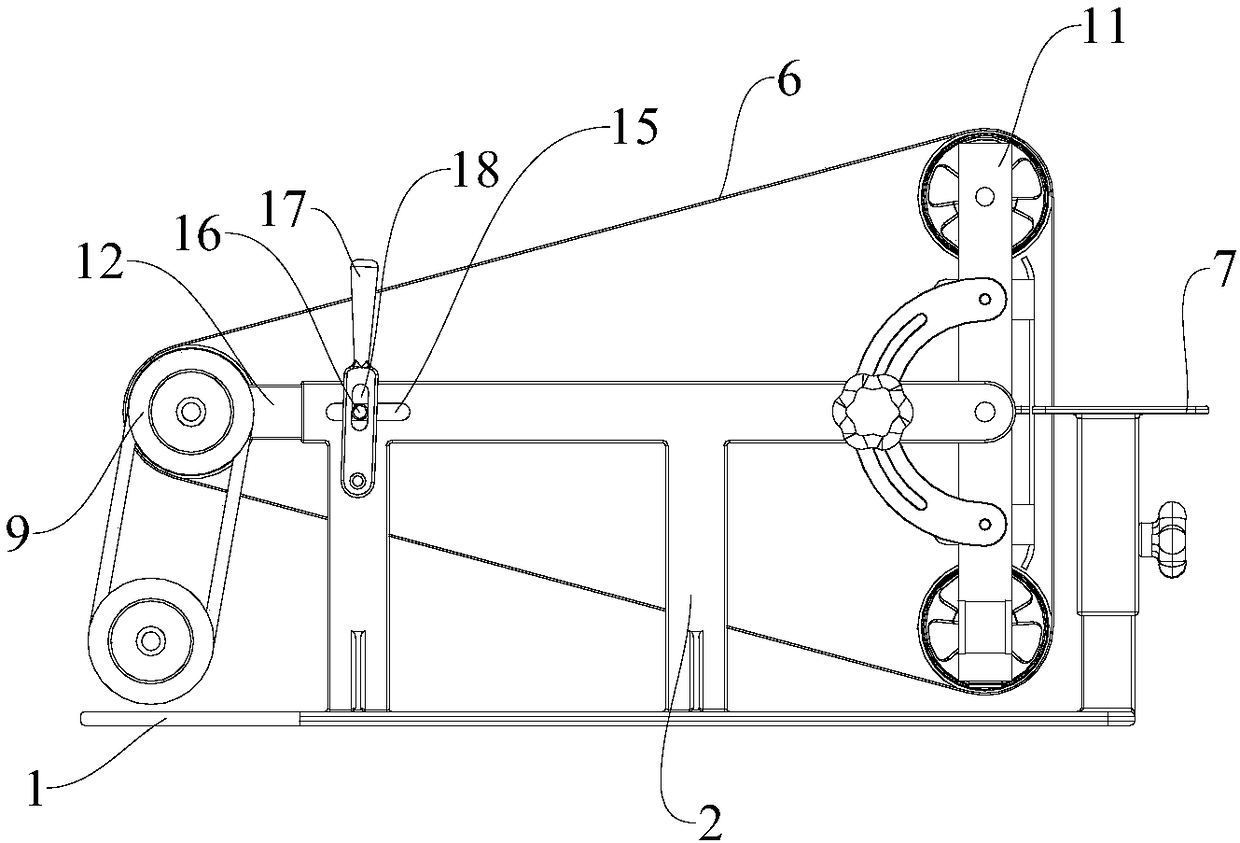

[0020] Such as Figure 1 to Figure 3 As shown, according to an embodiment of the present invention, the abrasive belt sander 100 includes: a base 1, a fixed bracket 2, a first tension pulley 3, a second tension pulley 4, a third tension pulley 5, an abrasive belt 6, a support Platform 7, protection guide plate 8 and driving device 9, fixed bracket 2 is fixed on the base 1; the first tensioning wheel 3 and the second tensioning wheel 4 are arranged in the up and down direction, and the third tensioning wheel 5 is located on the se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap