Non-sticking yogurt cover film

A technology of yogurt and covering film, which is applied in the field of packaging bags, can solve the problems of easy sticking yogurt, etc., and achieve the effect of reducing the use of copper foil layer, compact design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

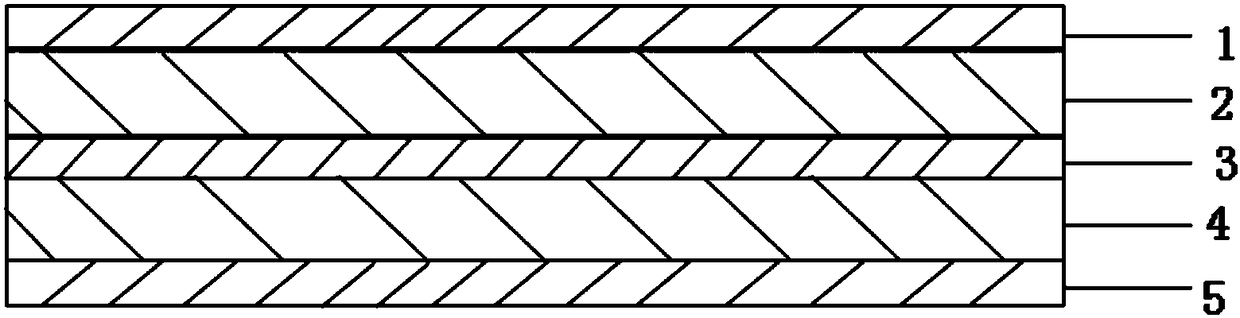

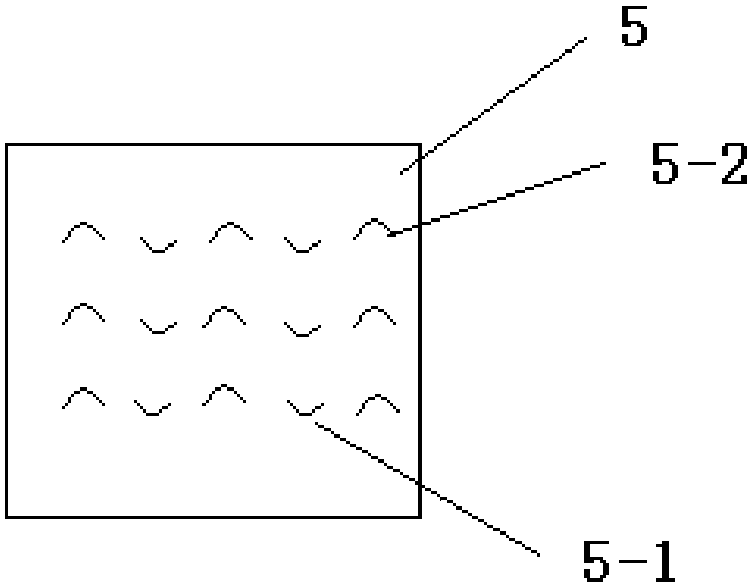

[0014] Such as Figure 1-Figure 2 As shown, a non-stick yogurt cover film includes five layers from top to bottom: ink layer 1, polyester layer 2, adhesive layer 3, polyethylene layer 4 and coating 5, the thickness of coating 5 3-5 μm, the inner surface of the coating 5 is provided with several concave particles 5-1 and convex particles 5-2, the concave particles 5-1 and convex particles 5-2 are arranged at intervals, the concave particles 5-1 and the convex particles 5-2 are all circular, the polyester layer 2 has a thickness of 10-15 μm, the polyethylene layer 4 has a thickness of 60-65 μm, and the coating 5 is made of polyurethane compounds.

[0015] The present invention uses polyester layer 2 and polyethylene layer 4 as the main body, adding adhesive 766 as an adhesive layer in the composite process to connect polyester layer 2 and polyethylene layer 4 together, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com