Patents

Literature

40results about How to "Increase bumpiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

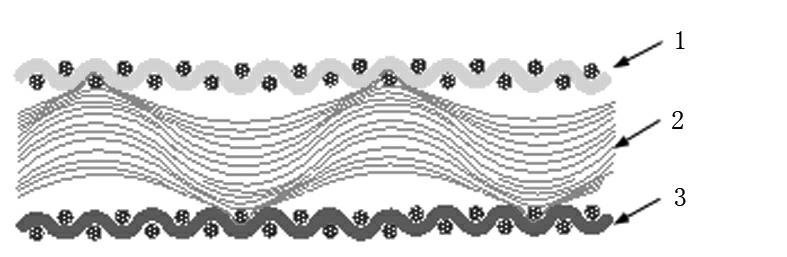

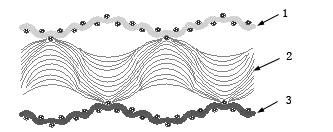

Novel moisture absorption temperature regulation antibacterial summer quilt and production technology thereof

InactiveCN102488426ASoft touchStrong hygroscopicityMulti-ply fabricsVegetal fibresPolyesterAcrylic fibre

The invention belongs to the textile field, and particularly relates to a novel moisture absorption temperature regulation antibacterial summer quilt and production technology thereof. The fabric structure of the summer quilt is formed by three layers, an upper surface layer adopts Outlast acrylic fibers, a lower surface layer adopts bamboo pulp fibers, and a middle layer adopts moisture absorption perspiration discharging polyester filament. The health care summer quilt has hot wet comfort of moisture absorption and temperature regulation, has an antibacterial function simultaneously, has good hygiene, unique and elegance appearance and strong washability, is formed in one-step in the production process, saves cost and energy, and has high additional value.

Owner:HENAN INST OF ENG

Application of expanded glass beads in sand-in-water base paint, sand-in-water base paint, preparation method and sand-in-water coating

The invention relates to application of expanded glass beads in sand-in-water base paint, the sand-in-water base paint, a preparation method and a sand-in-water coating. The sand-in-water base paint is prepared from components in parts by weight as follows: 20-30 parts of deionized water, 0.2-0.3 part of a dispersing agent, 0.2-0.5 part of a defoaming agent, 1.0-2.0 parts of an anti-freezing agent, 1.0-2.0 parts of a coalescing agent, 1-5 parts of expanded glass beads, 1-5 parts of titanium dioxide, 1-8 parts of kaolin, 0.8-2.0 parts of cellulose, 1.0-2.0 parts of a pH regulator, 20-40 parts of an emulsion, 0.1-0.5 part of a preservative, 5-10 parts of a 10wt% protective glue solution, 0.1-0.5 part of a thickening agent and 40-50 parts of quartz sand. The expanded glass beads are added tothe sand-in-water base paint, the specific gravity of particles in the sand-in-water base paint is reduced, the suspension property of particles in the base paint is improved, so that the particle suspension property in the sand-in-water coating prepared from the sand-in-water base paint is improved, the size of sand-in-water particles in shear and granulation processes is more uniform, the coverage rate of finished sand-in-water products is increased, and the spray consumption of the sand-in-water coating is reduced.

Owner:北京莱恩斯新材料科技有限公司

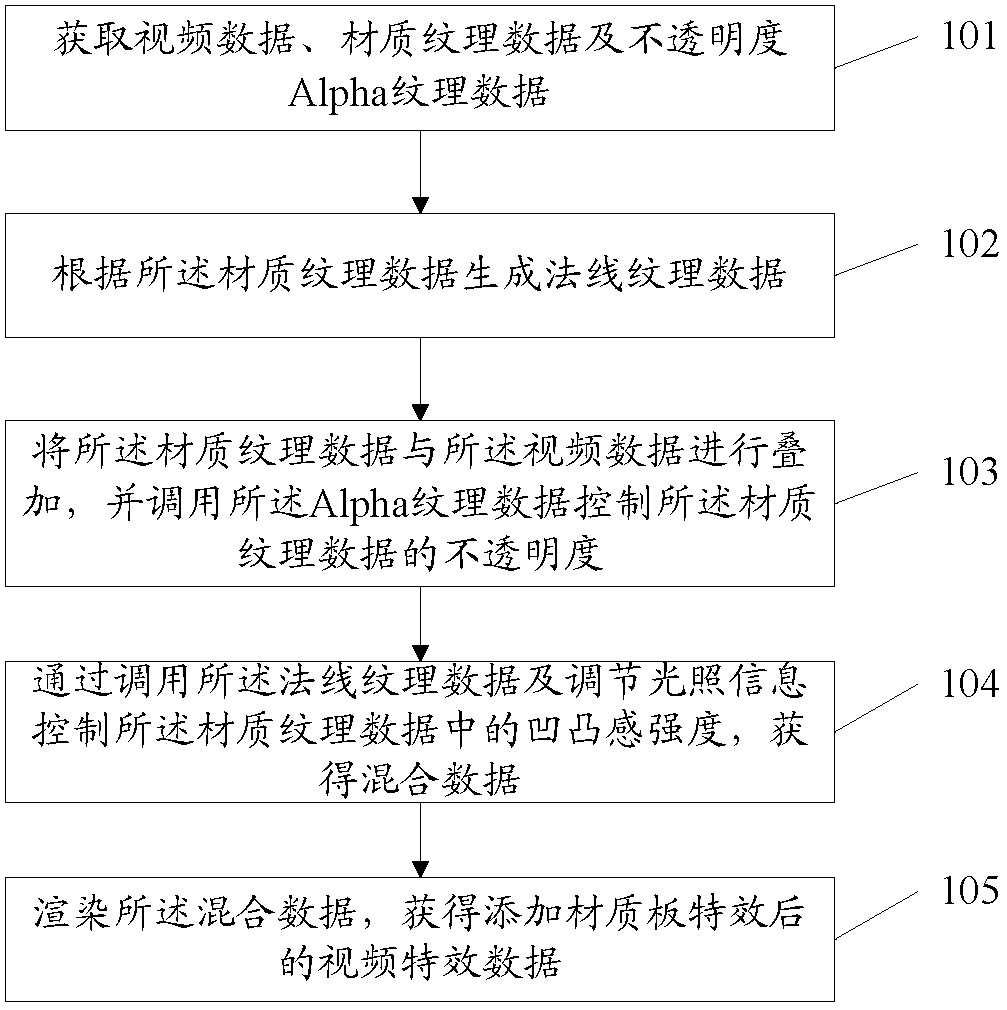

Method for realizing special effects of material boards

InactiveCN102800118AIncrease bumpinessImprove picture qualityTelevision system detailsColor television detailsData controlPattern recognition

The invention discloses a method for realizing special effects of material boards. The method comprises the following steps of: acquiring video data, material texture data and nontransparency Alpha texture data; generating normal texture data according to the material texture data; superposing the material texture data and the video data and calling the nontransparency Alpha texture data to control nontransparency of the material texture data; controlling the strength of concave-convex impression in the material texture data by calling the normal texture data and adjusting illumination information, and acquiring blended data; and rendering the blended data and acquiring video special-effect data after being added with the special effects of the material boards. By the method, the quality of pictures is greatly improved, and concave-convex impression of the pictures is improved.

Owner:CHINA DIGITAL VIDEO BEIJING

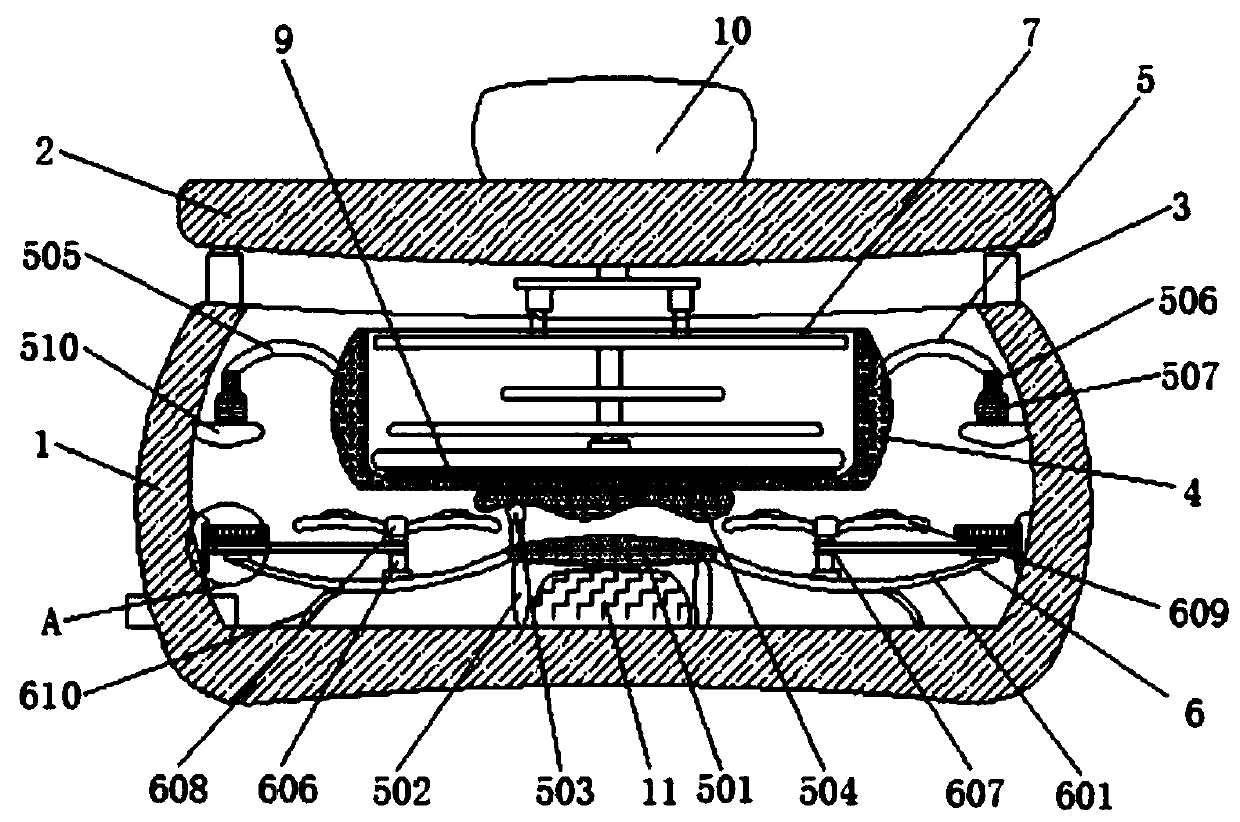

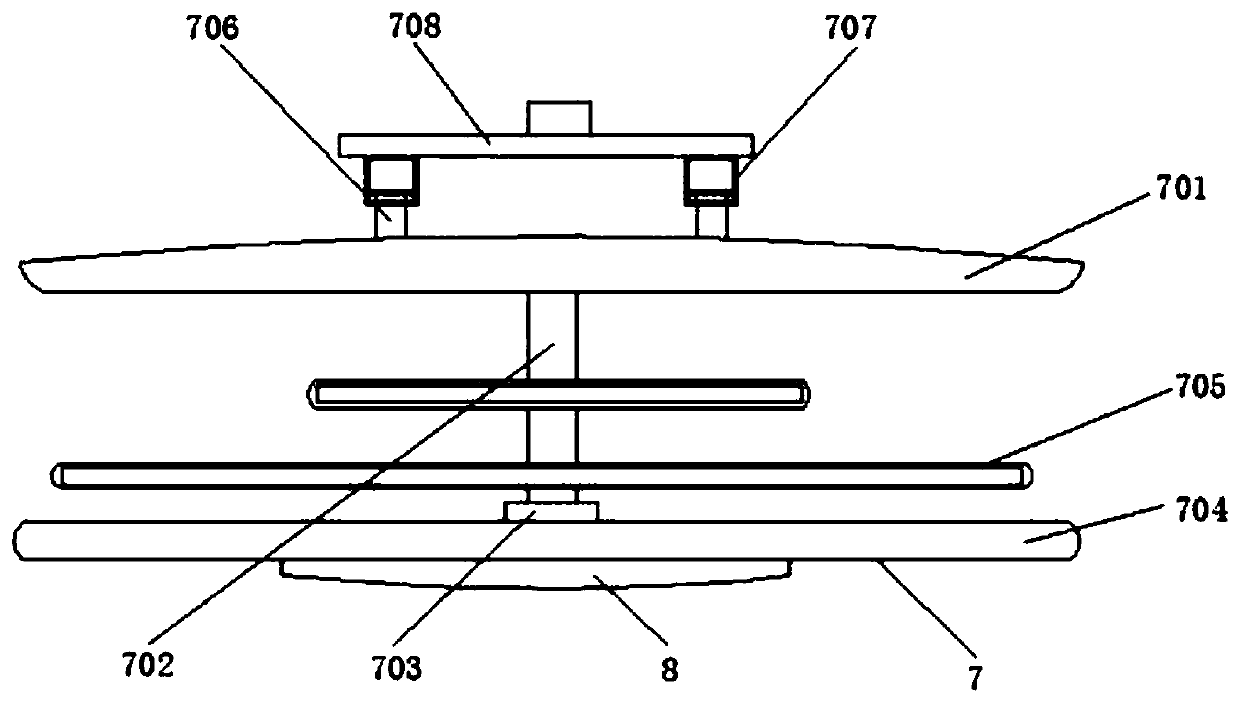

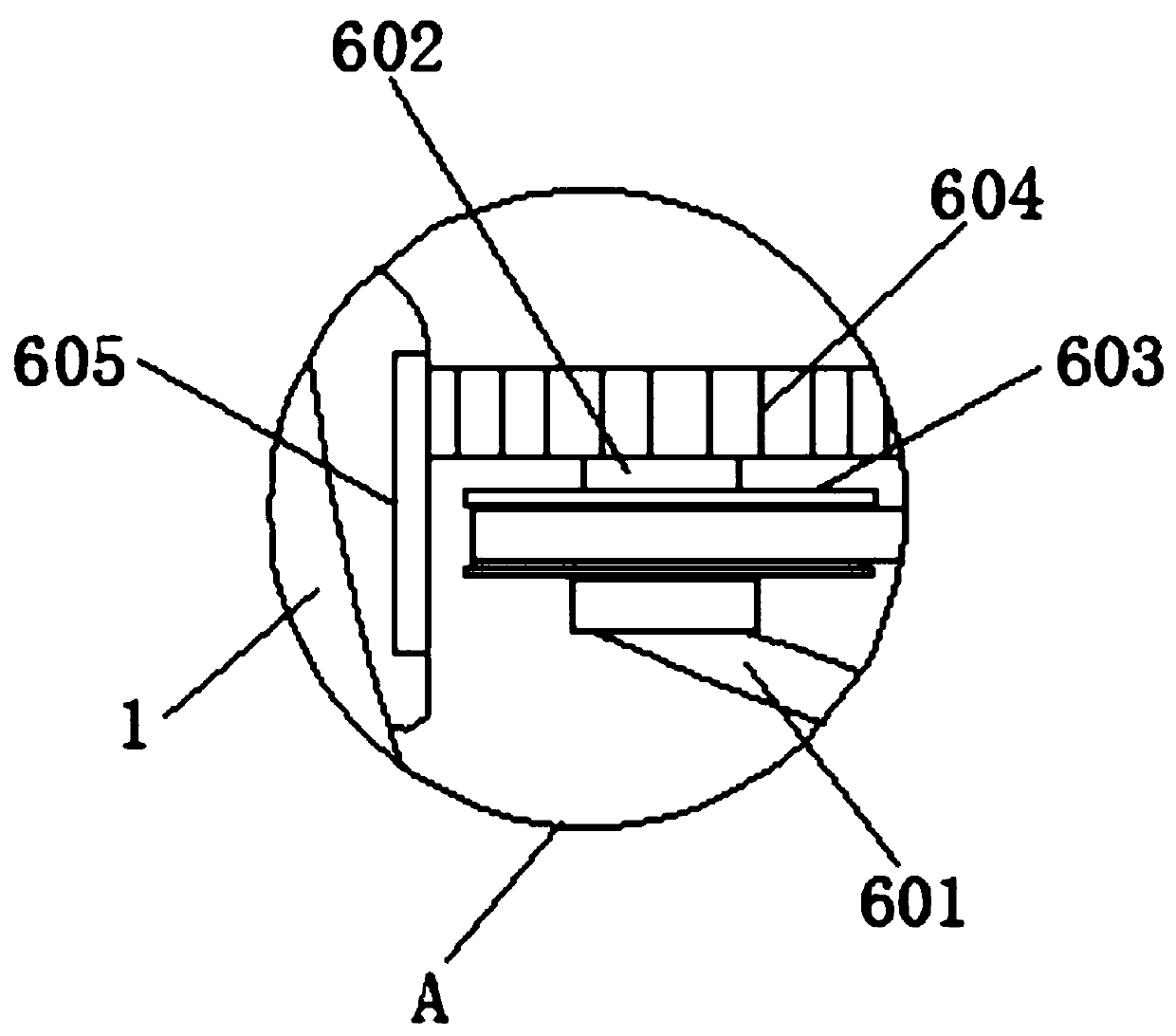

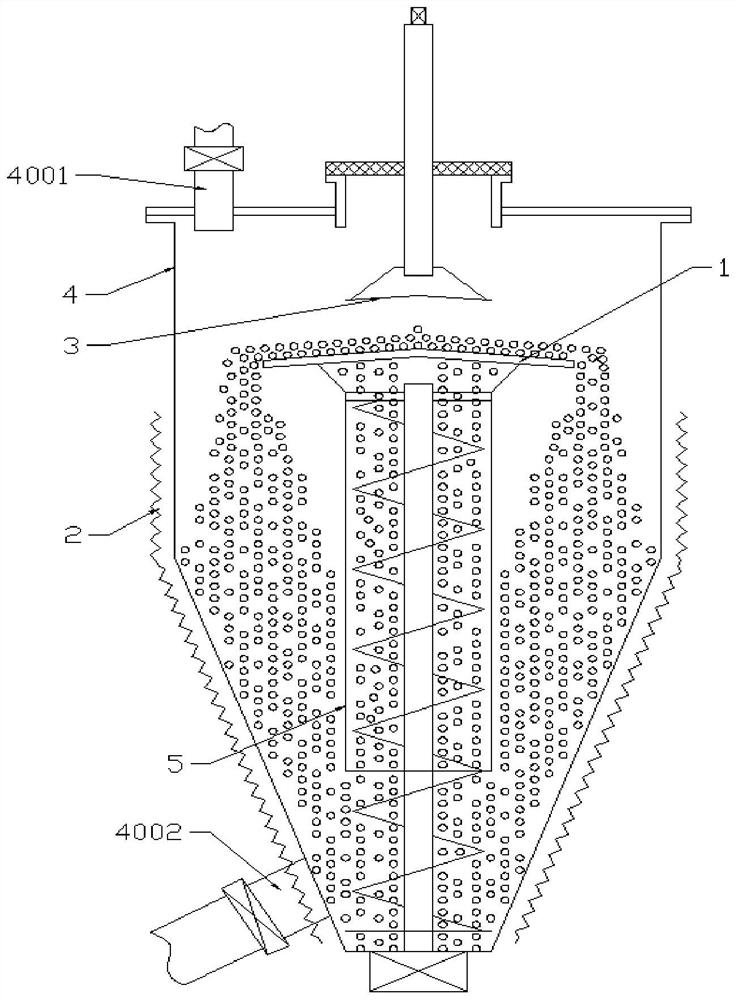

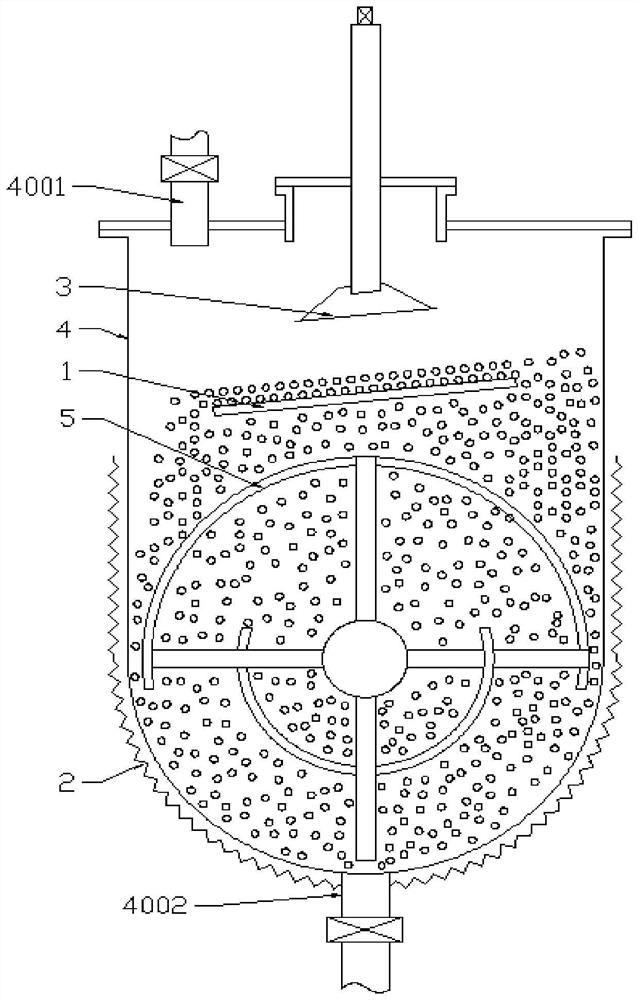

Razor clam cleaning device and cleaning method for promoting sand spitting and water flow scouring by reciprocating sloshing

The invention provides a razor clam cleaning device and a razor clam cleaning method for promoting sand spitting and water flow scouring by reciprocating sloshing, and relates to the field of aquaticproduct cleaning equipment, thereby solving problems that the interior of the razor clam is not easy to clean and the surface is not easy to clean. The razor clam cleaning device comprises an erectingand washing box, the top of the erecting and washing box is welded to the bottom of a top frame plate through an electric telescopic rod, a motor box is welded to the top of the top frame plate, a shaking filter box is arranged in the erecting and washing box, and a bearing and washing mechanism is arranged at the bottom of the top frame plate and located in a shaking and washing box. According to the razor clam cleaning device, an underwater motor drives the shaking filter box to move up and down along with the motor, so that razor clams placed in the shaking filter box shake up and down, and sand in the razor clams can be spit out more quickly; a reciprocating rod is inserted to move up and down in a fixed sleeve, water flow pushing blades drive surrounding water flow to rush to the razor clams to turn over the razor clams, so that sand is flushed cleanly.

Owner:绍兴津源午马机械股份有限公司

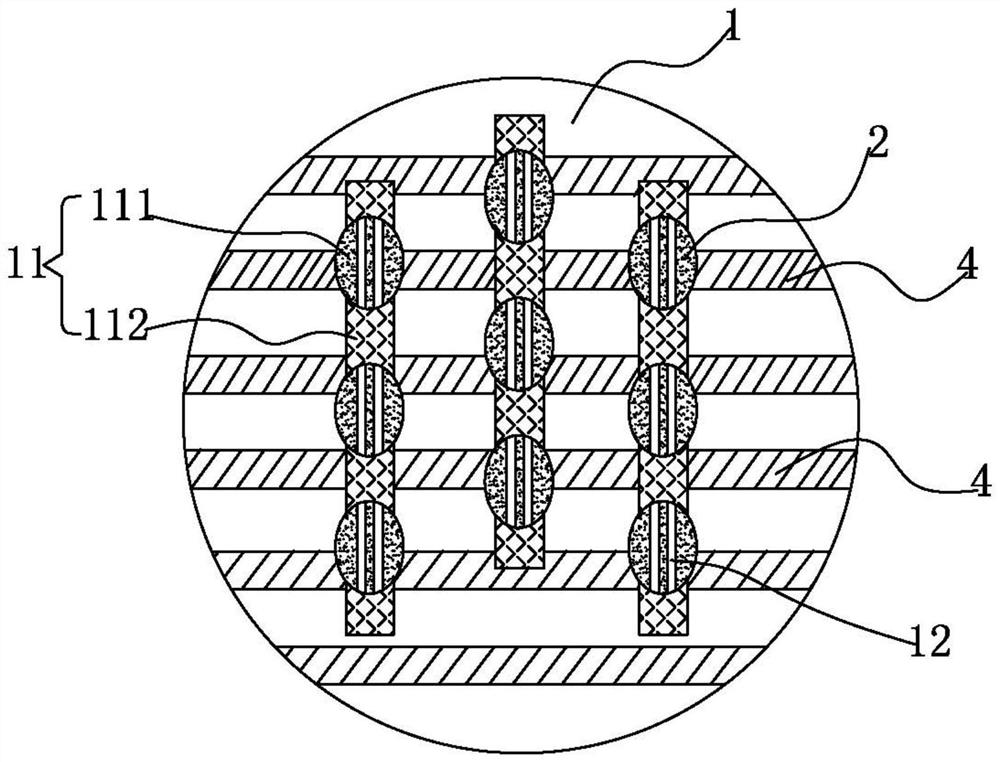

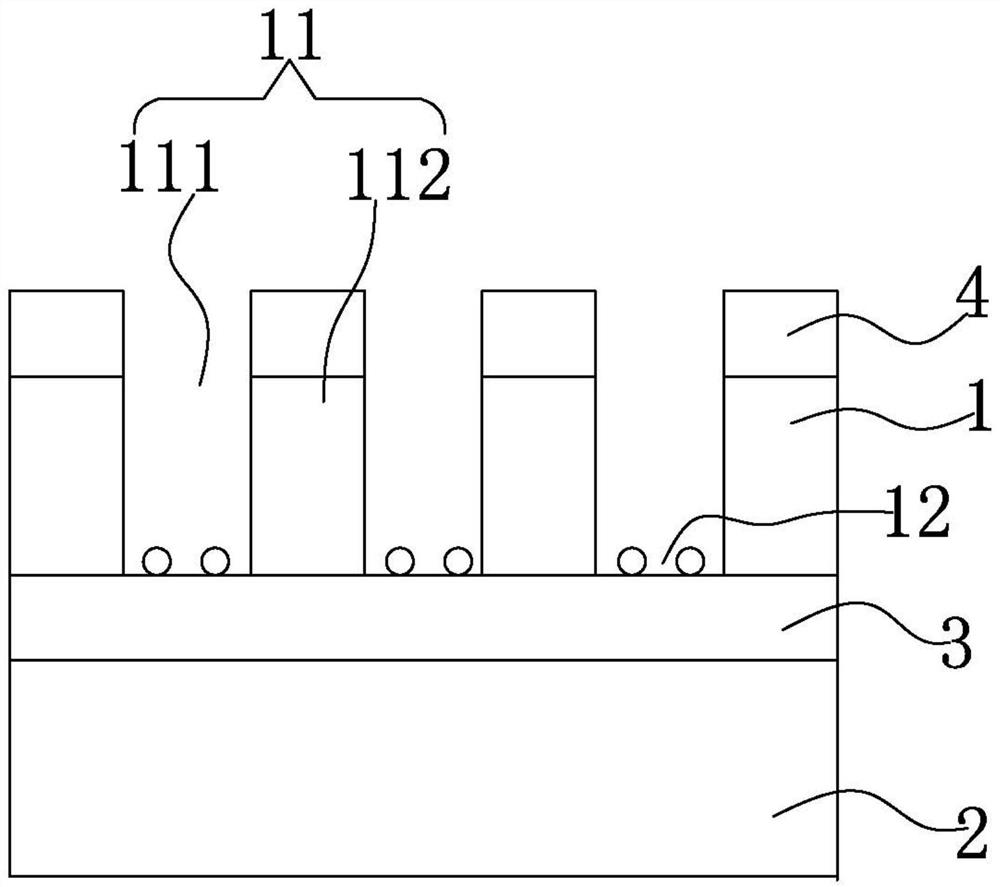

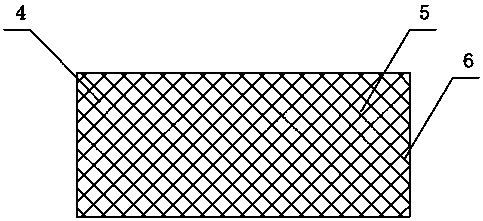

Fabric with open mesh structures and preparation method of fabric

The invention relates to the technical field of fabrics, in particular to a fabric with open mesh structures. The fabric comprises a surface layer, a bottom layer, a connecting layer and a jacquard layer, wherein the surface layer comprises a plurality of first yarns; the plurality of first yarns are interwoven to form the surface layer; the plurality of mesh structures are formed on the surface layer; each mesh structure comprises a plurality of open meshes and a plurality of closed meshes; the bottom layer comprises a plurality of second yarns; the plurality of second yarns are interwoven to form the bottom layer; the connecting layer comprises a plurality of third yarns; the plurality of third yarns are interwoven to form the connecting layer; the connecting layer is used for connecting the surface layer and the bottom layer; the jacquard layer comprises a plurality of fourth yarns which are interwoven; and the jacquard layer is formed on the surface layer. The fabric is integrally woven and is attractive, novel, high in interestingness, good in air permeability, high in stereoscopic impression and obvious in touch feeling, and the preparation process is greatly simplified, so that the production efficiency is improved and the production cost is reduced.

Owner:FUJIAN SINCETECH NEW MATERIAL TECH +1

Method for preparing coating powder by adopting plasma vapor deposition process

ActiveCN113215552ANo mutual adhesionGood dispersionVacuum evaporation coatingSputtering coatingNanoparticlePhysical chemistry

The invention discloses a method for preparing coating powder by adopting a plasma vapor deposition process. The coating powder comprises a base material and one or more coating materials deposited on the surface of the base material. The preparation method of the coating powder comprises the following steps of: depositing one or more coating materials on the surfaces of base material particles by adopting a plasma enhanced chemical vapor deposition process, wherein the plasma enhanced chemical vapor deposition process is carried out in a fluidized plasma vapor deposition furnace. The base material powder in the invention is in fluidized cyclic motion in the vapor deposition process, the coating materials are relatively uniformly distributed in the deposited composite powder in a nano particle form, and the coating materials rapidly generate a compact accumulation layer on the surfaces of the base material particles, so that the base material and the coating are firmly combined together, no mutual bonding phenomenon exists among the composite powder particles, and good dispersity is achieved.

Owner:株洲弗拉德科技有限公司

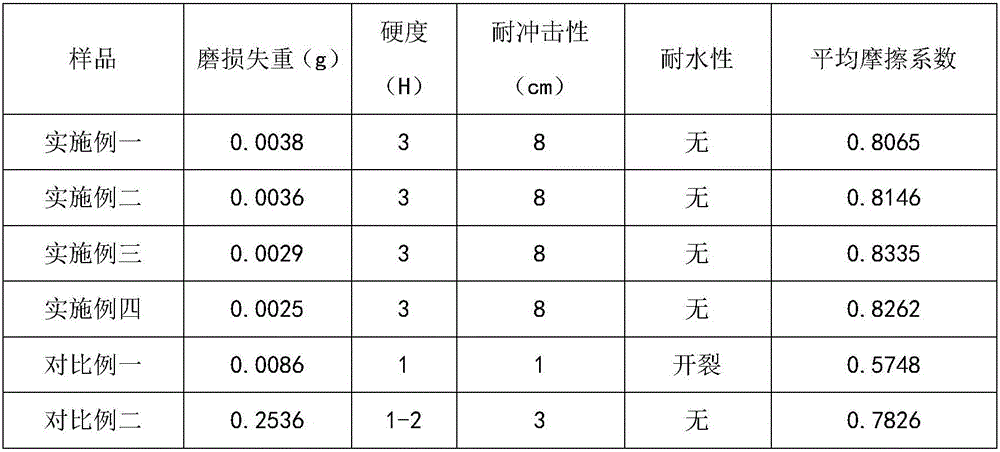

Heavy-duty anti-skid lane paint

The invention discloses a heavy-duty anti-skid lane paint. In the prior art, the most of the lane paint has the following advantages that the materials in the formula have significant odor and toxicity, the construction process is complex, and the construction time is long. The purpose of the present invention is to solve the advantages in the prior art. The technical scheme is that the heavy-duty anti-skid lane paint comprises components A, B and C, wherein the component A comprises 0.5-1.5% of a dispersant, 0.5-1.5% of a wetting agent, 0.5-1.5% of a defoamer, 0.5-1.5% of a thickening agent, 0.5-1.5% of a leveling agent, 20-37% of deionized water, 50-70% of a curing agent, 6-12% of pigment paste, and 2-5% of a water reducing agent, the component B comprises an aqueous acrylic amino resin, and the component C comprises 10-15% of white cement, 12-25% of barium sulfate, 6-13% of titanium dioxide, 13-20% of quartz powder, and 27-59% of large color particles. According to the present invention, the heavy-duty anti-skid lane paint with characteristics of environmental protection, no toxicity, spray molding in one time and construction time saving is prepared.

Owner:苏州大乘环保新材有限公司

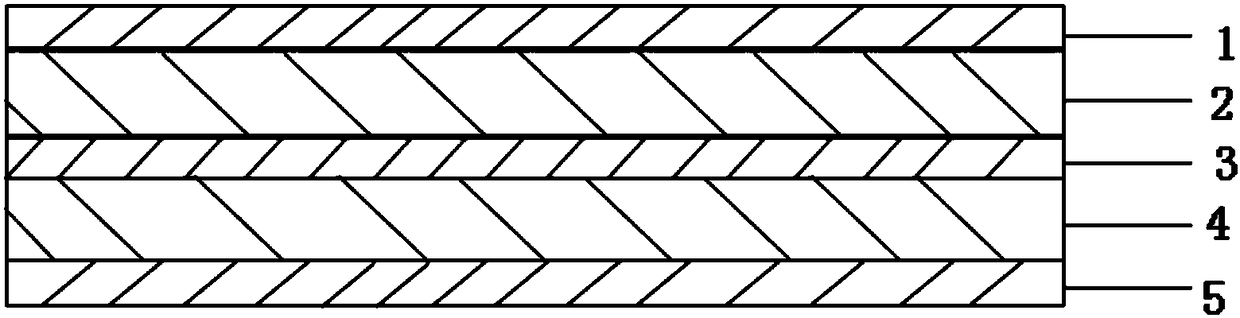

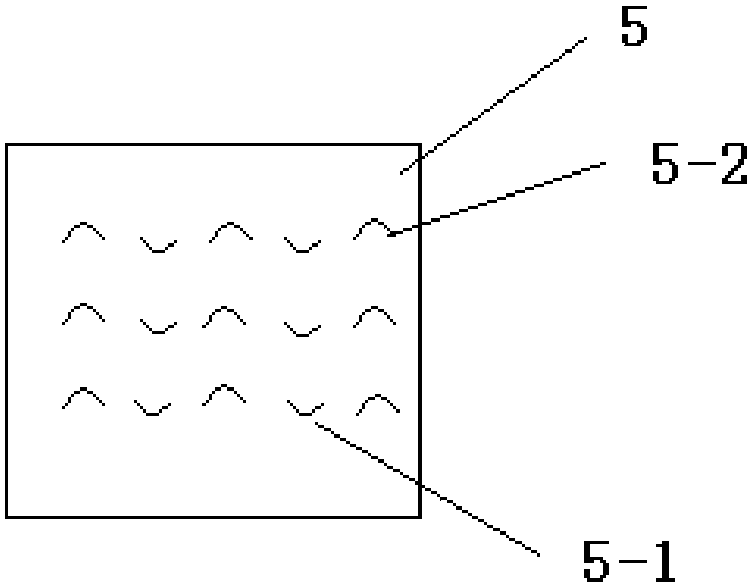

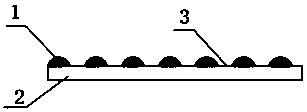

Non-sticking yogurt cover film

PendingCN108190235AReduce usageAvoid accumulationSynthetic resin layered productsDomestic containersPolyesterCopper foil

The invention relates to a non-sticking yogurt cover film. The non-sticking yogurt cover film comprises five layers of structures which are the ink layer, the polyester layer, a sticking later, a polyethylene layer and a coating in sequence from top to bottom. The thickness of the coating is 3-5 [mu]m, a plurality of concave particles and convex particles are arranged on the surface of the inner side of the coating, and the concave particles and the convex particles are arranged at intervals. According to the non-sticking yogurt cover film, the structure is simple, the design is compact, the polyester layer and the polyethylene layer are composited into a main body, and using of a copper foil layer is reduced, sanitary and convenient effects are achieved, the piercing effect is good, the concave-convex sense of the inner layer is improved through arrangement of the concave particles and the convex particles on the surface of the inner side of the coating, surface tensile force is removed, and yogurt is prevented from being accumulated on the surface.

Owner:JIANGSU SUNKEY PACKAGING

Method for preparing coating powder by adopting plasma vapor deposition process

ActiveCN113215533ANo mutual adhesionGood dispersionVacuum evaporation coatingSputtering coatingNanoparticlePhysical chemistry

The invention discloses a method for preparing coating powder by adopting a plasma vapor deposition process. The coating powder comprises a base material and one or more coating materials deposited on the surface of the base material. The preparation method of the coating powder comprises the following steps of: depositing one or more coating materials on the surfaces of base material particles by adopting a plasma enhanced chemical vapor deposition process, wherein the plasma enhanced chemical vapor deposition process is carried out in a fluidized plasma vapor deposition furnace. The base material powder in the invention is in fluidized motion in the vapor deposition process, the coating materials are relatively uniformly distributed in the deposited composite powder in a nano particle form, and the coating materials rapidly generate a compact accumulation layer on the surfaces of the base material particles, so that the base material and the coating are firmly combined together, the composite powder particles are not bonded with one another, and the coating powder has good dispersity.

Owner:株洲弗拉德科技有限公司

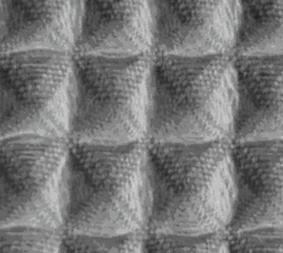

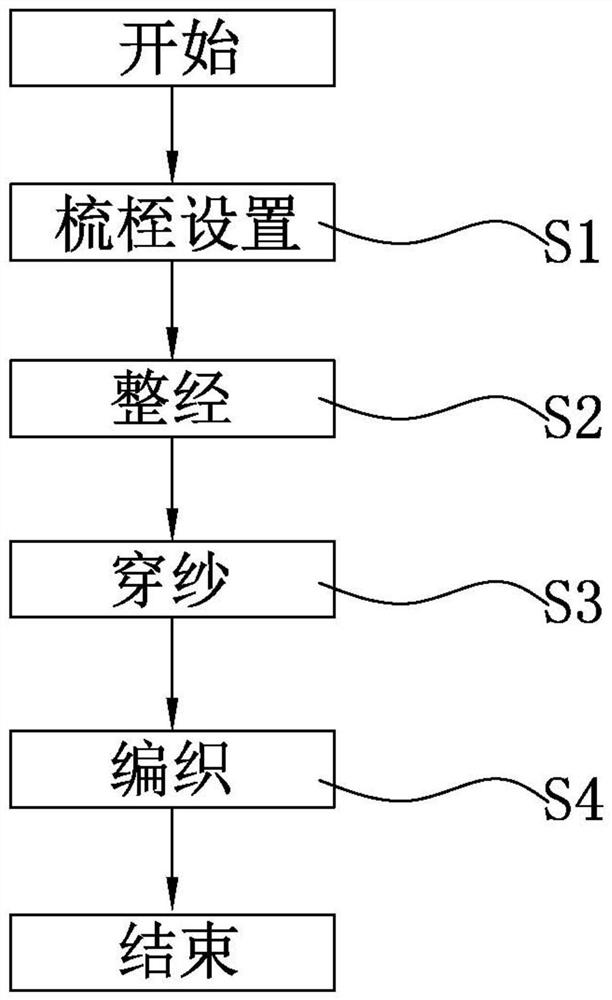

Novel textilene dew fabric and preparation method thereof

InactiveCN110438623AIncrease bumpinessHas anti-skid effectFilament/thread formingCarpetsAntioxidantDioctyl terephthalate

The invention provides a novel textilene dew fabric and a preparation method thereof. The novel textilene dew fabric is made from warps and wefts by weaving, at least one of the warps and the wefts ismade of specially-made dew filaments, each dew filament comprises a first core layer wrapped by a first coating layer, each first coating layer is coated with a second coating layer, and water drop shaped convex dots are arrayed at intervals on each second coating layer. Each second coating layer is prepared from, by weight, 20-30 parts of polyvinyl chloride, 10-15 parts of dioctyl terephthalate,0.5-2 parts of soybean oil, 2-4 parts of a calcium-zinc stabilizing agent, 2-5 parts of rubber, 15-20 parts of nanocalcium, 0.1-1 part of an antioxidant, 0.1-1 part of an anti-ultraviolet agent and 0.5-1 part of a compound lubricant. The novel textilene dew fabric is made by interweaving of the dew PVC coating filaments, concave-convex effects of the fabric can be enhanced, an anti-slip functionand attractiveness are achieved, and the fabric is especially applicable to table mats, floor mats and wall decoration.

Owner:浙江圣特斯林纺织有限公司

Preparation method for sound absorbing material

The invention relates to a preparation method for a sound absorbing material, belonging to the field of materials. According to the invention, natural loofah sponge is utilized as a carrier material;the loofah sponge has developed pores, good adsorption capacity and good load performance, and is subjected to treatment by hydrogen peroxide and mixing with and soaking in a soaking solution; throughtreatment by the soaking solution, maleic anhydride has improved ability in grafting to loofah sponge, and the modification of maleic anhydride improves the bonding of loofah sponge and polyethyleneimine; then through pre-carbonization, an additive is pyrolyzed to generate gas, and a porous structure is formed on the surface of polyethyleneimine; the polyethyleneimine contains carbon nanotubes and is then combined with a mixture, so polyethyleneimine is redissolved in water; added tartaric acid is complexed with excess ferrous ions and chromium ions and deposits on a pre-carbonized surface oris grafted inside the loofah sponge, so porosity is improved; and finally, spray drying is performed to improve surface concave-convex performance, so attractive performance is further improved.

Owner:赵顺全

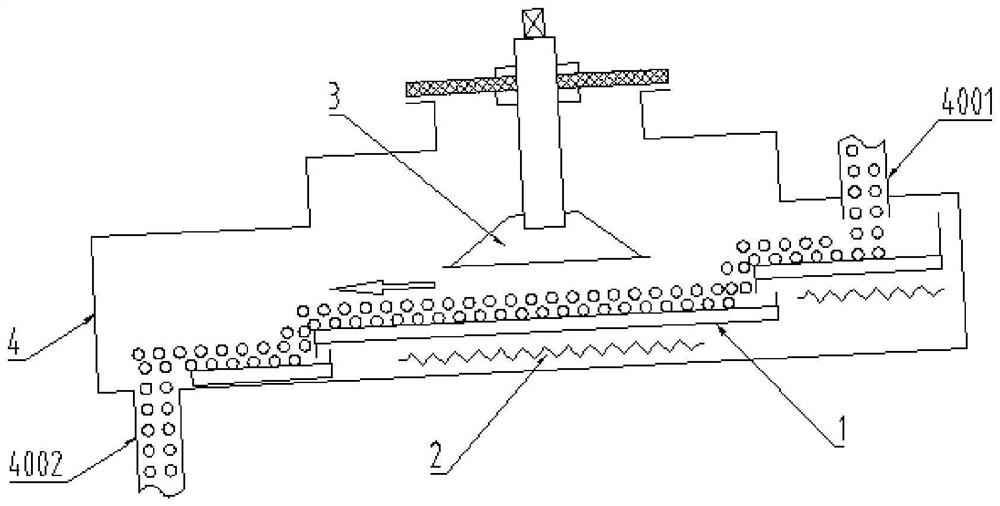

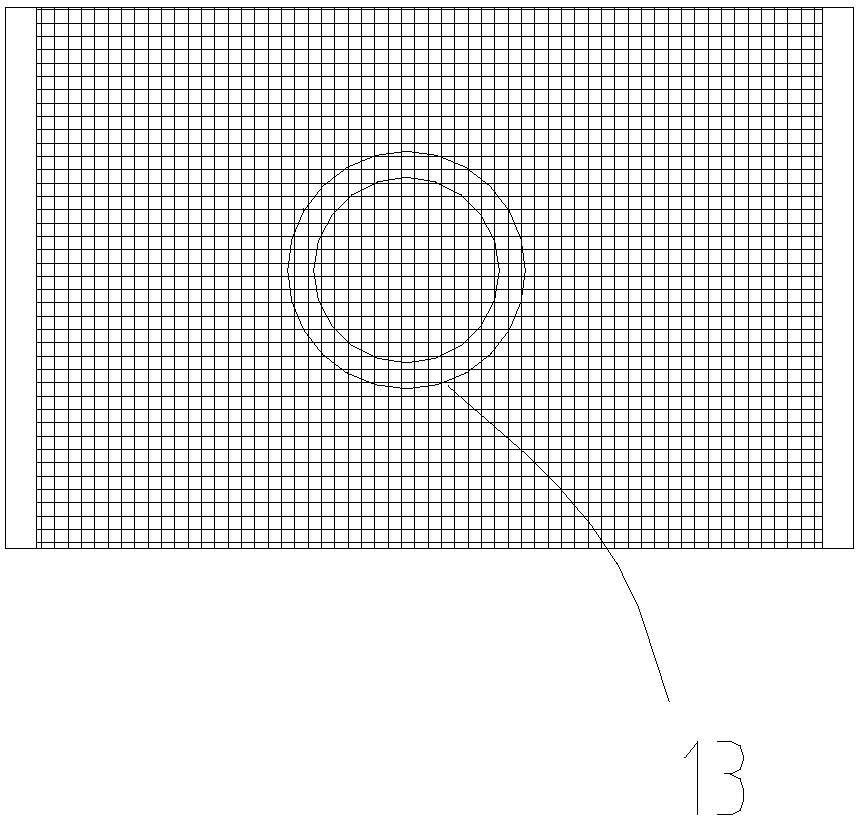

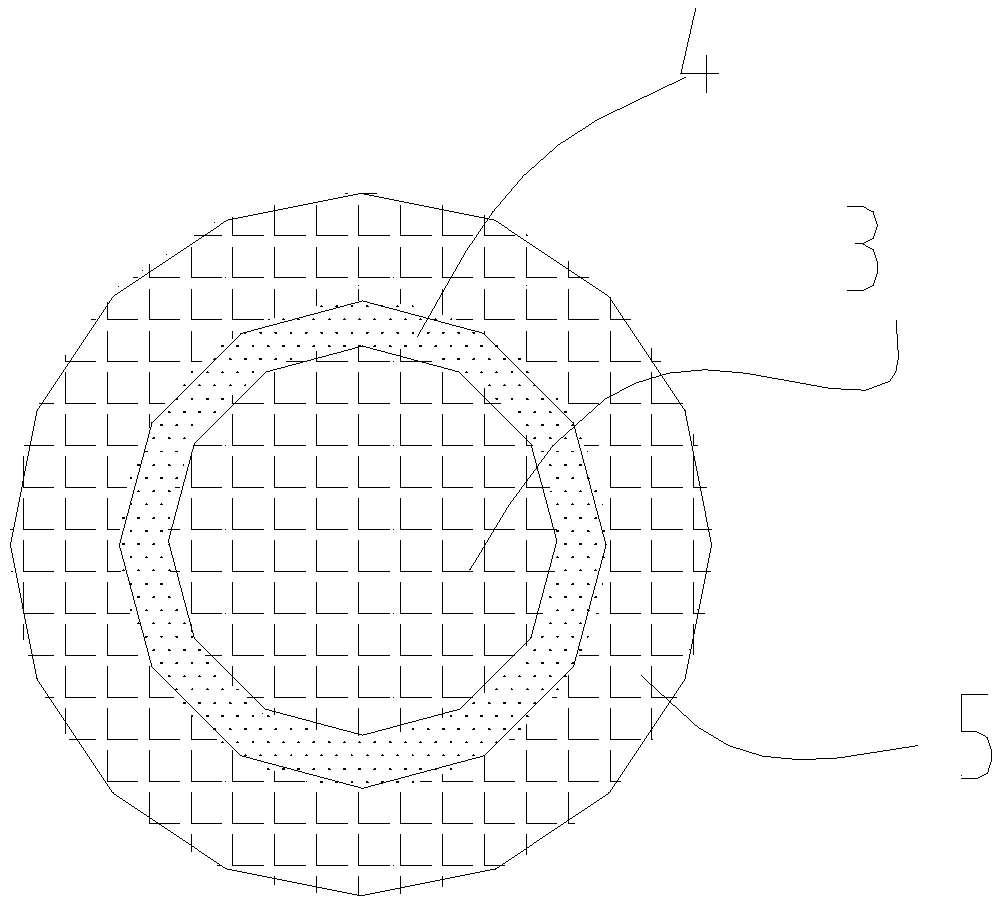

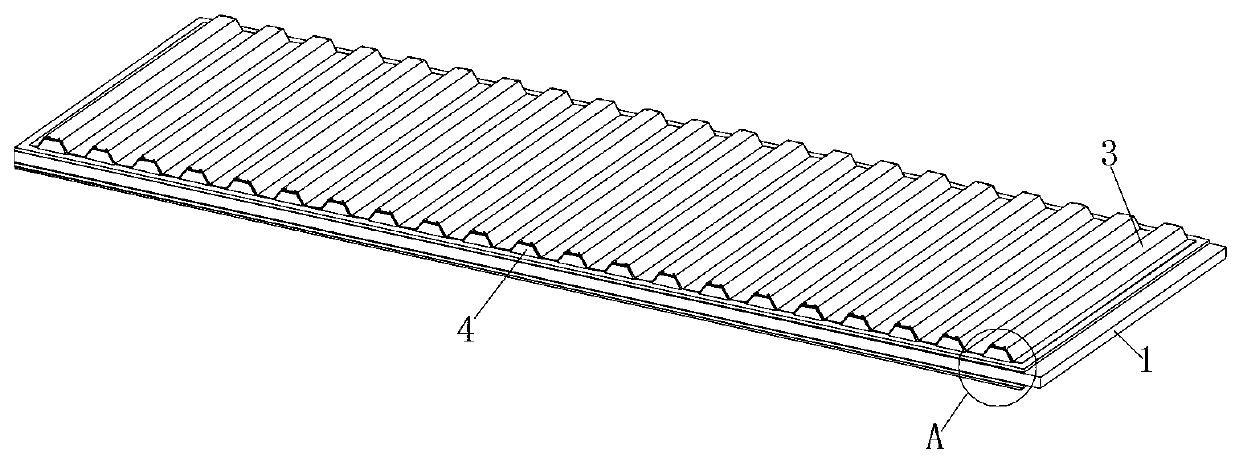

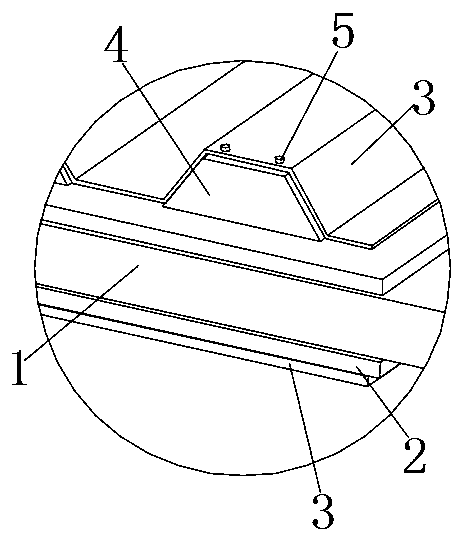

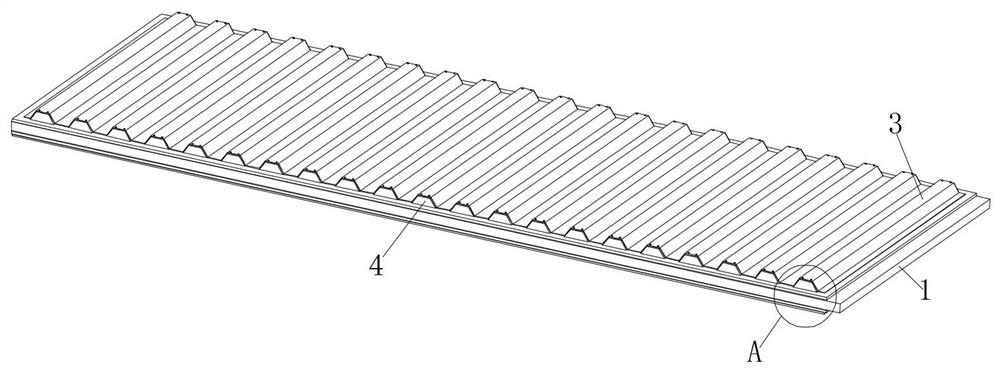

Forming process of conveyor belt

ActiveCN110774507AIncrease bumpinessExtended service lifeBeltsDomestic articlesVulcanizationConveyor belt

The invention discloses a forming process of a conveyor belt. The forming process specifically comprises the following steps: S1, raw material mixing; S2, stopping; S3, mixed glue cooking; S4, calendaring; S5, strip billet cooling; S6, strip billet bottom cover glue attaching; S4, trapezoidal block attaching; S8, strip billet surface cover glue attaching; S9, conveyor belt forming; and S10, vulcanizing treatment. A plurality of trapezoidal blocks are additionally arranged at equal distance to increase a concave and convex feeling of a conveyor belt surface, so that a conveyor belt is not liable to slip while conveying goods; meanwhile, surface cover glue is in contact with the trapezoidal blocks, and is fixed with the trapezoidal blocks through bolts, so that corresponding bolts on damagedpositions can be unscrewed after local cover glue of the surface is damaged by rubbing, and cover glue on the damaged positions is cut off for adding and supplementing local cover glue while the whole conveyor belt does not need to replace, and therefore, financial resources are saved, and the service life of the conveyor belt is prolonged.

Owner:湖南宝烽设备股份有限公司

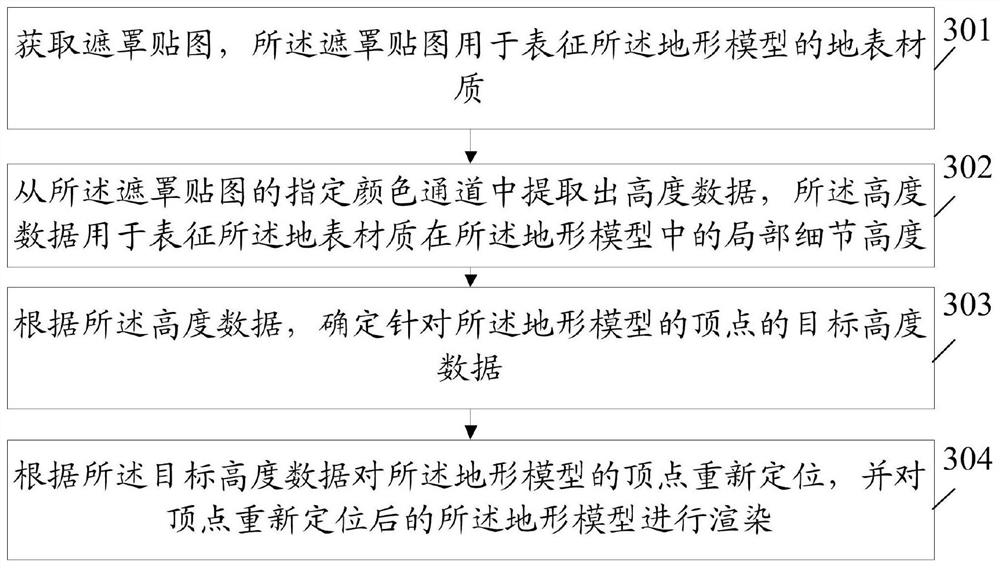

Terrain model rendering method and device, electronic equipment and storage medium

PendingCN113546410AIncrease credibilityIncrease bumpinessVideo games3D-image renderingTerrainComputer graphics (images)

The embodiment of the invention provides a terrain model rendering method and device, electronic equipment and a storage medium, and the method comprises the steps: obtaining a mask map which is used for representing the surface material of a terrain model; extracting height data from a specified color channel of the mask map, wherein the height data is used for representing the local detail height of the earth surface material in the game scene; determining target height data for a vertex of the terrain model according to the height data; and repositioning the vertexes of the terrain model according to the target height data, and rendering the terrain model after the vertexes are repositioned. According to the embodiment of the invention, the vertex of the terrain model is repositioned and then rendered by using the height data in the mask map, and a more real visual effect at each visual angle is obtained.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Application of expanded vitrified microspheres in sand-in-water base paint, sand-in-water base paint, preparation method and sand-in-water coating

Owner:北京莱恩斯新材料科技有限公司

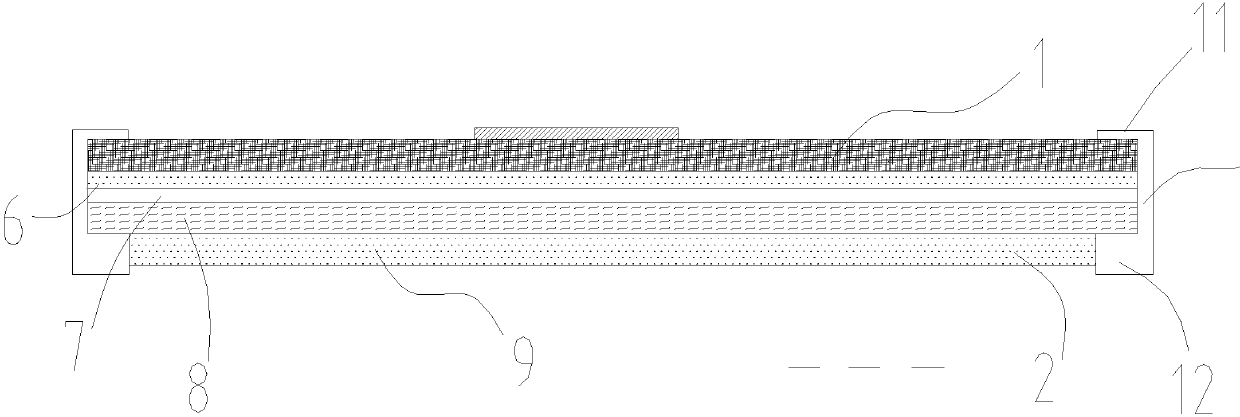

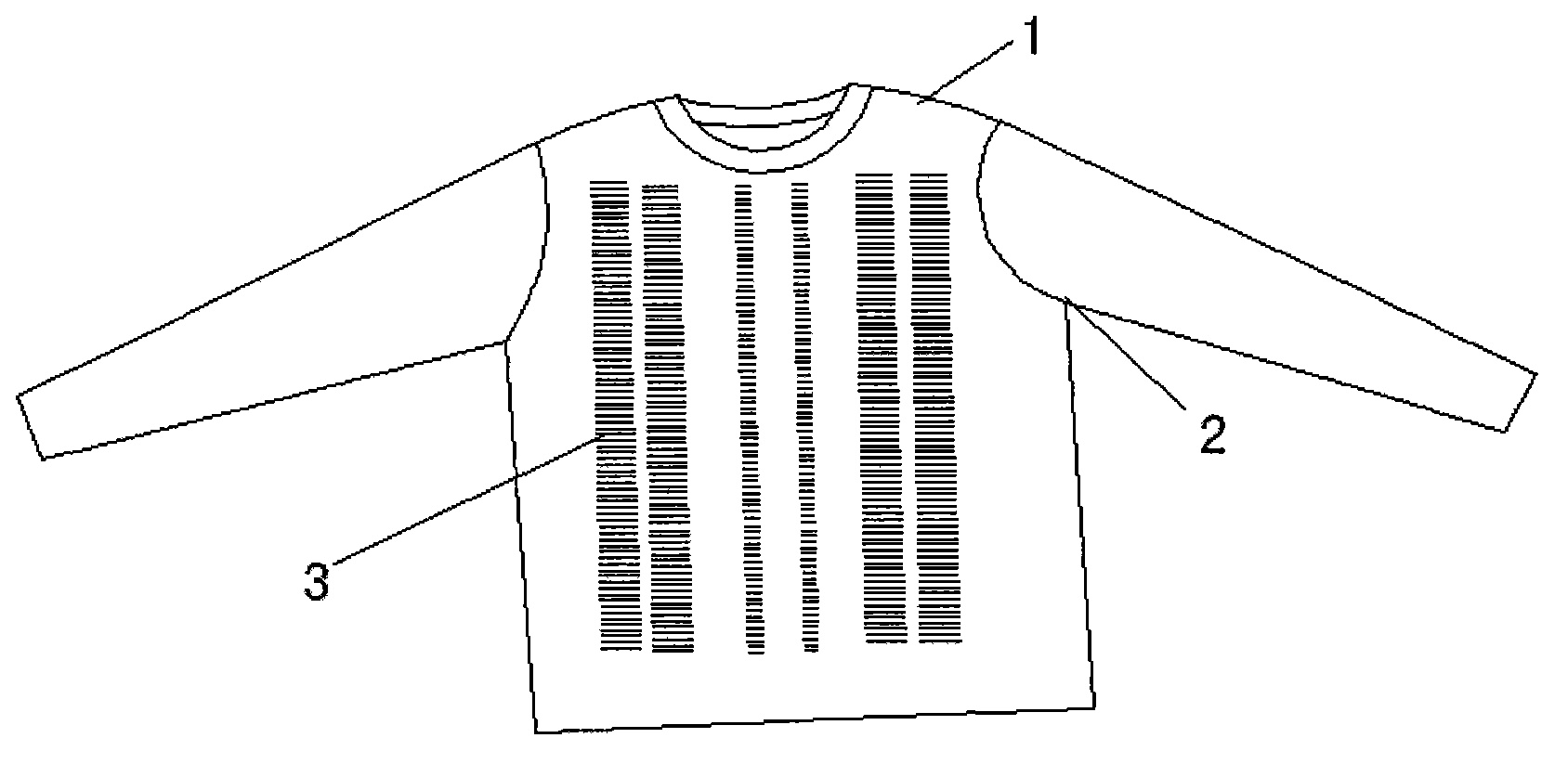

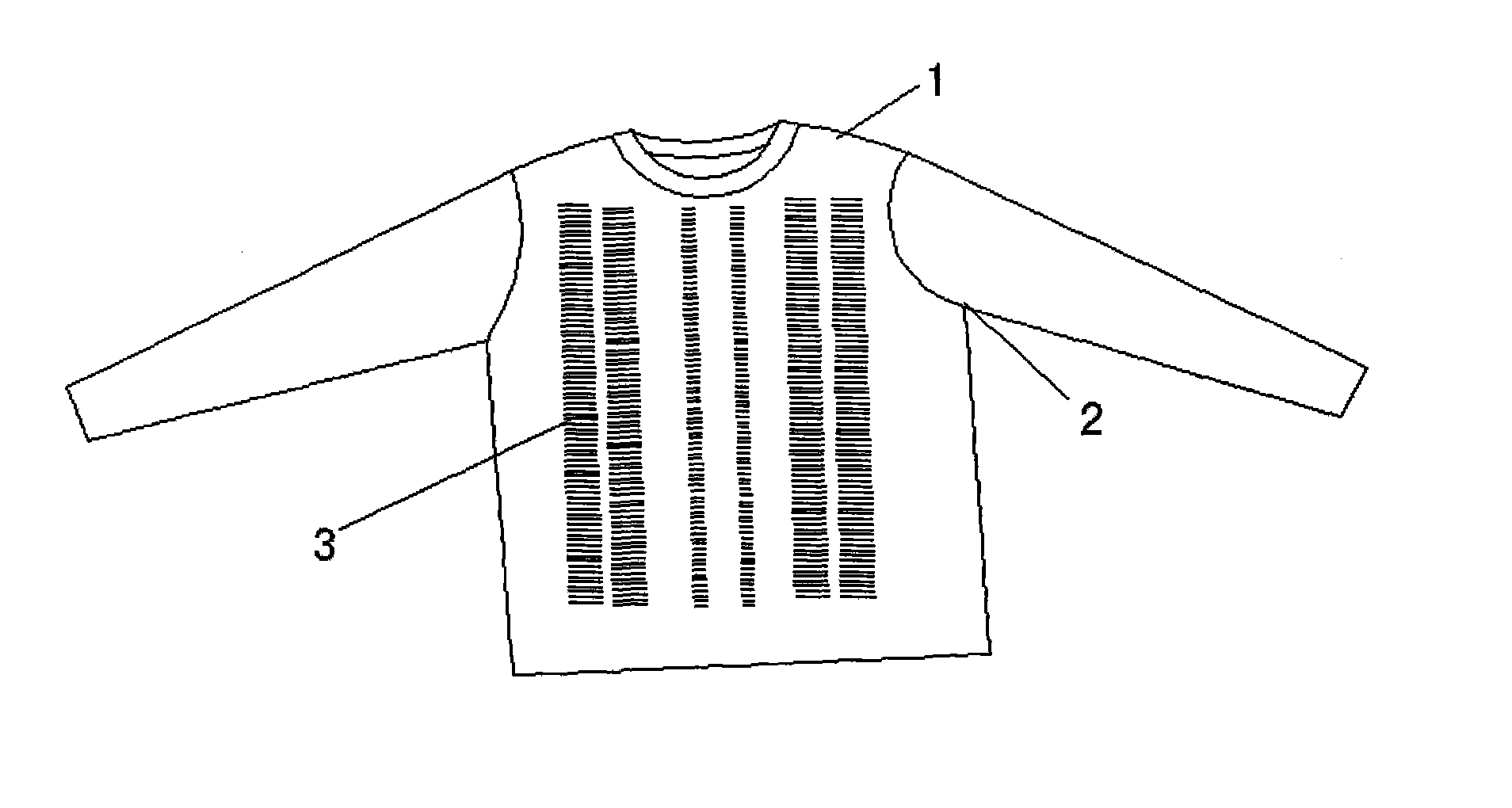

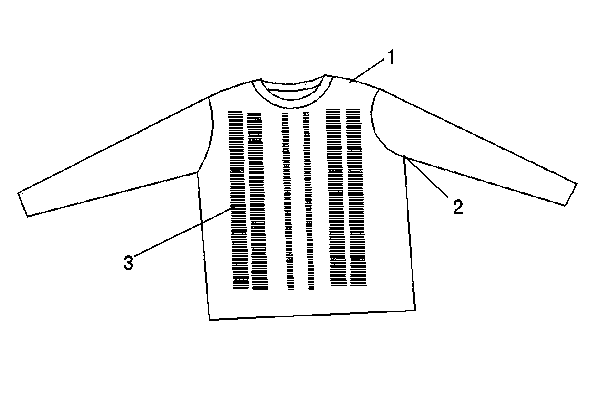

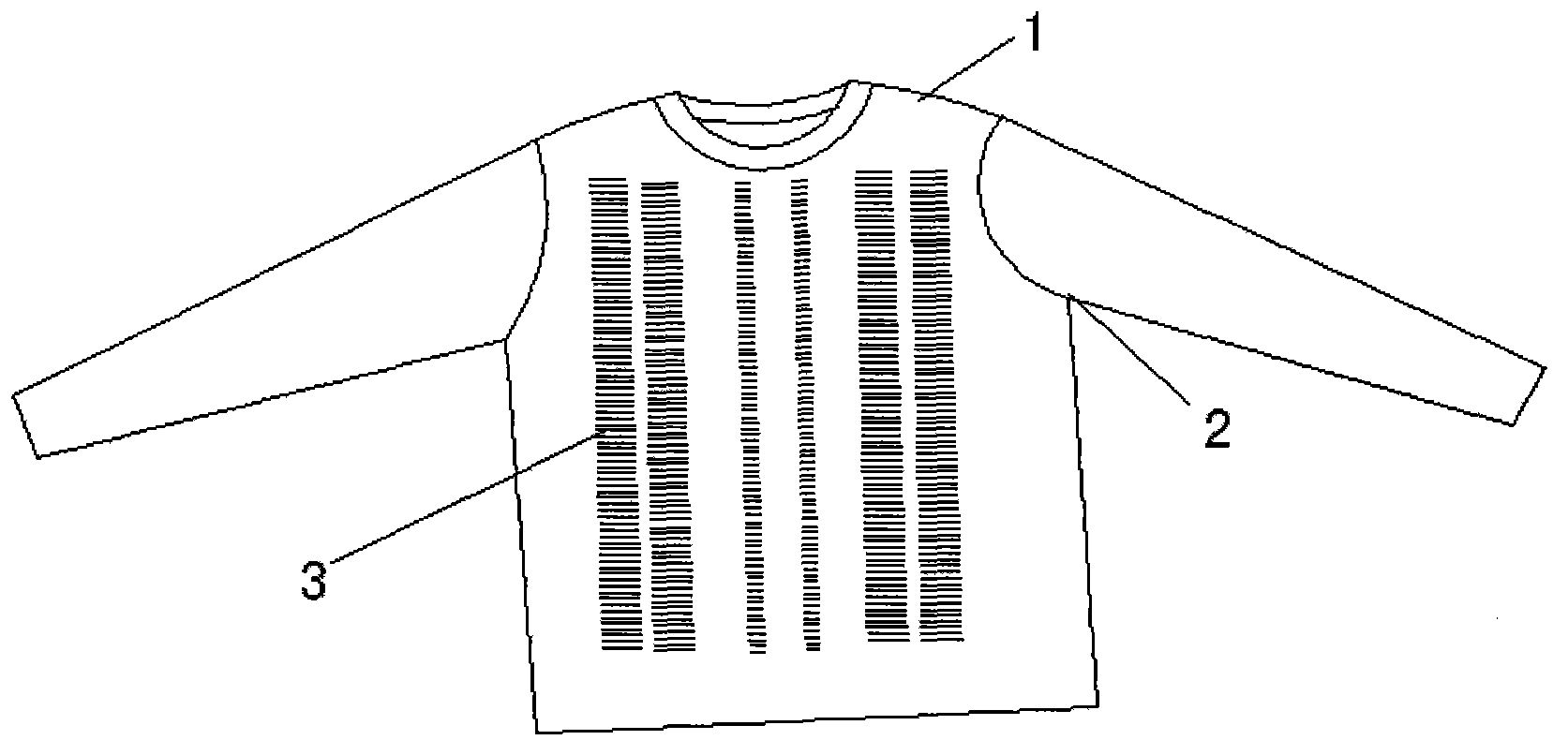

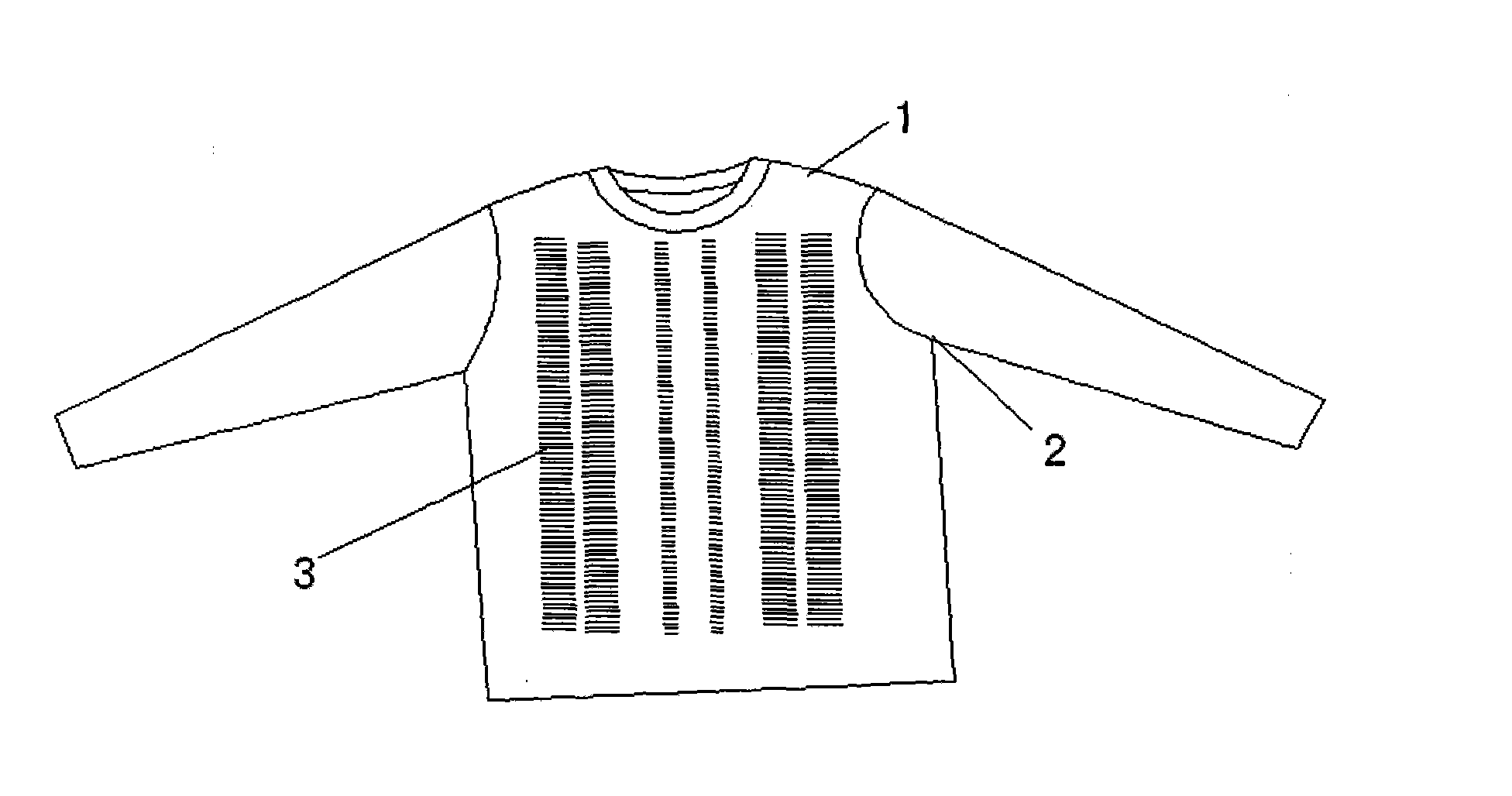

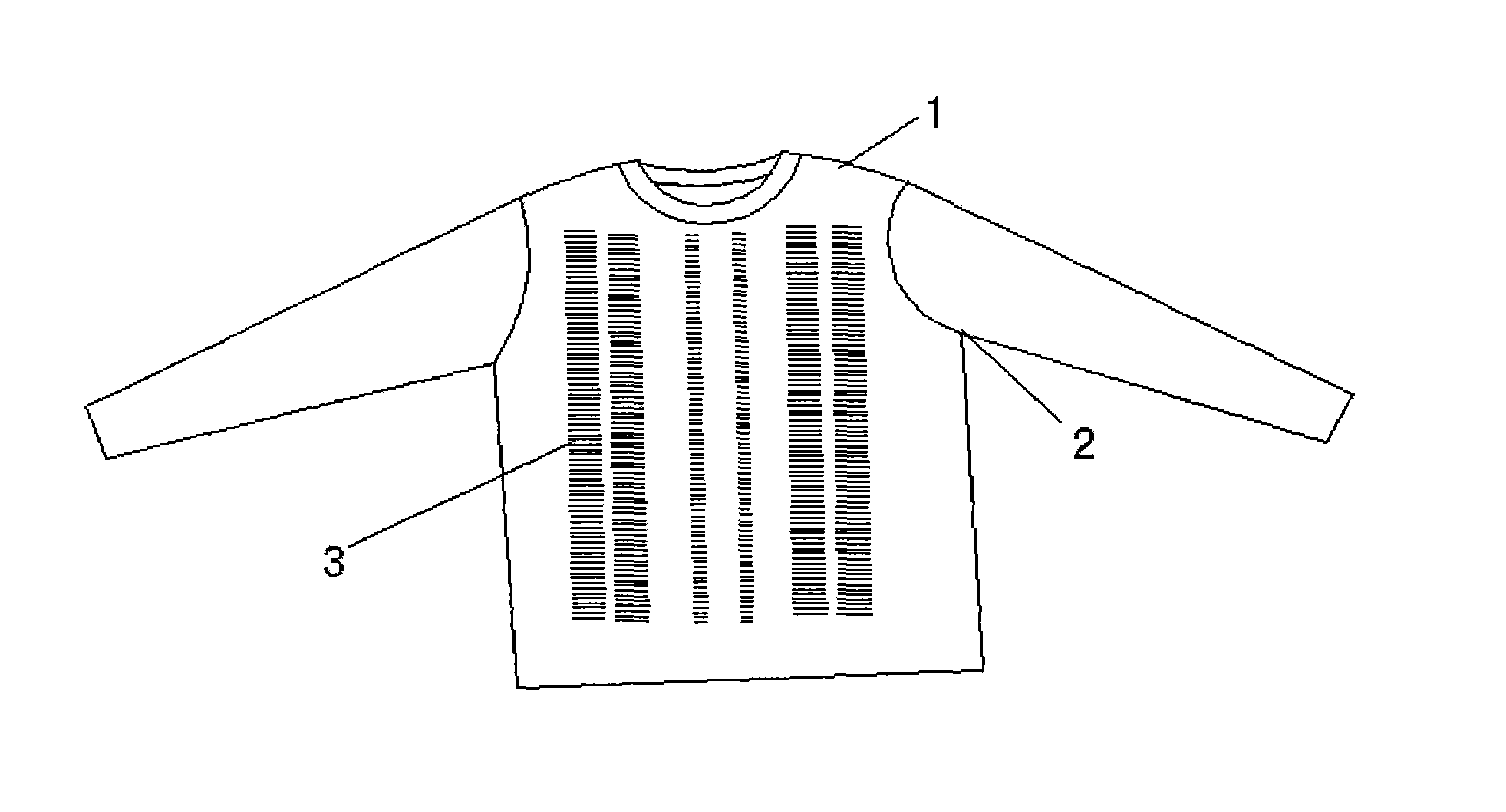

Elastic fabric garment with good air permeability

InactiveCN103799040AIncrease bumpinessPromote circulationProtective garmentSpecial outerwear garmentsEngineeringFilament yarn

The invention relates to an elastic fabric garment with the good air permeability. The elastic fabric garment comprises a garment body (1). Air holes (2) are formed in the shoulder portions and the oxter portions of the garment body (1) and six strip-shaped breathable nets (3) are arranged on the front part of the garment body (1). The garment body (1) is made of fabric which is warp knitting fabric. The law of yarn laying is 1-0 / 2-3, 75D / 36 T400 polyester fiber fully-drawn filament yarn is adopted in surface yarn, FDY 84D / 36F polyester filament yarn is adopted in ground yarn, the T400 polyester fiber fully-drawn filament yarn is hollow, and the section of the T400 polyester fiber fully-drawn filament yarn is of a cross shape. The elastic fabric garment is good in air permeability, the fabric adopted in the garment is good in elasticity, comfortable, durable, soft, stiff, smooth and good in drapability.

Owner:马军锋

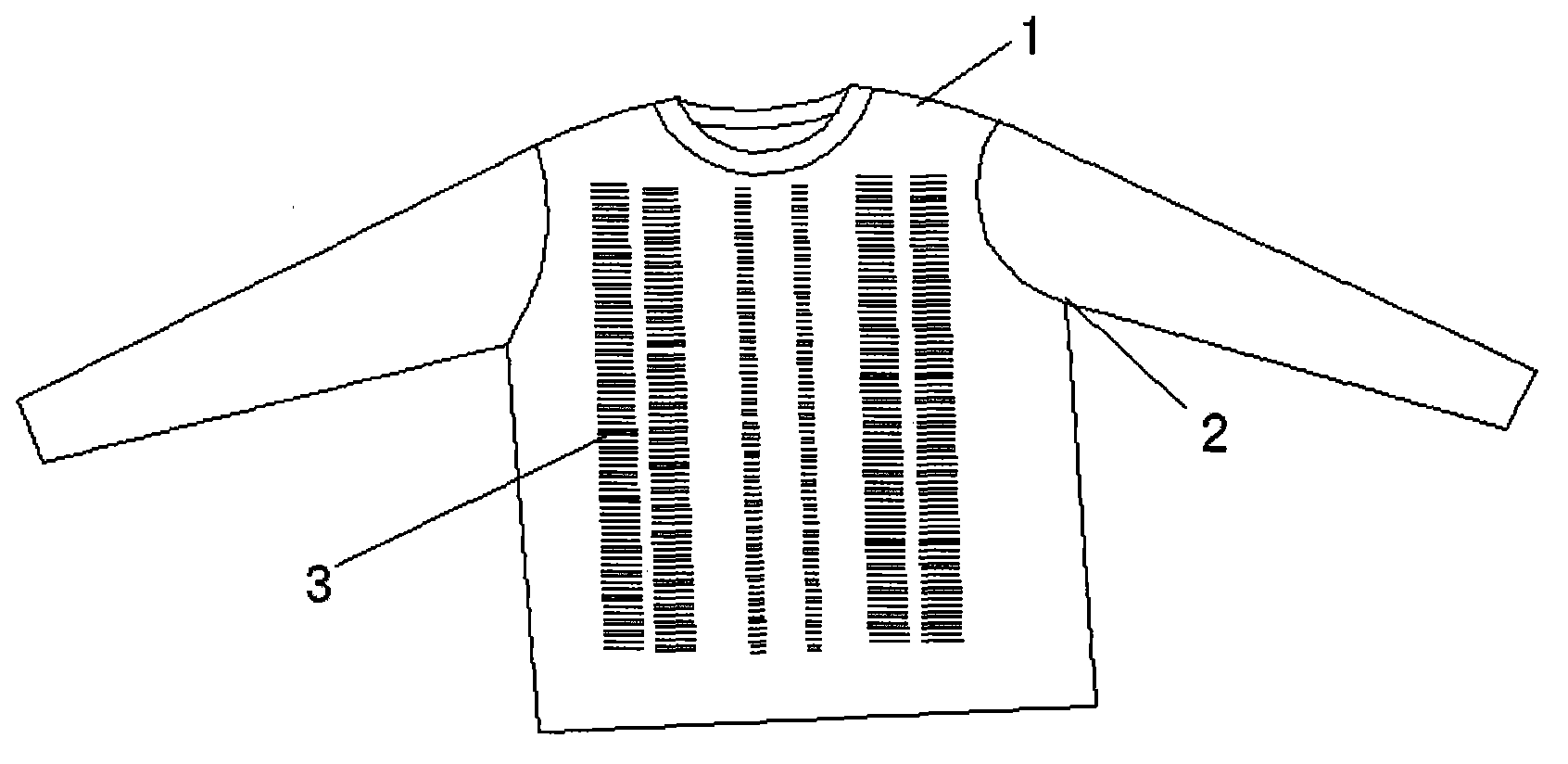

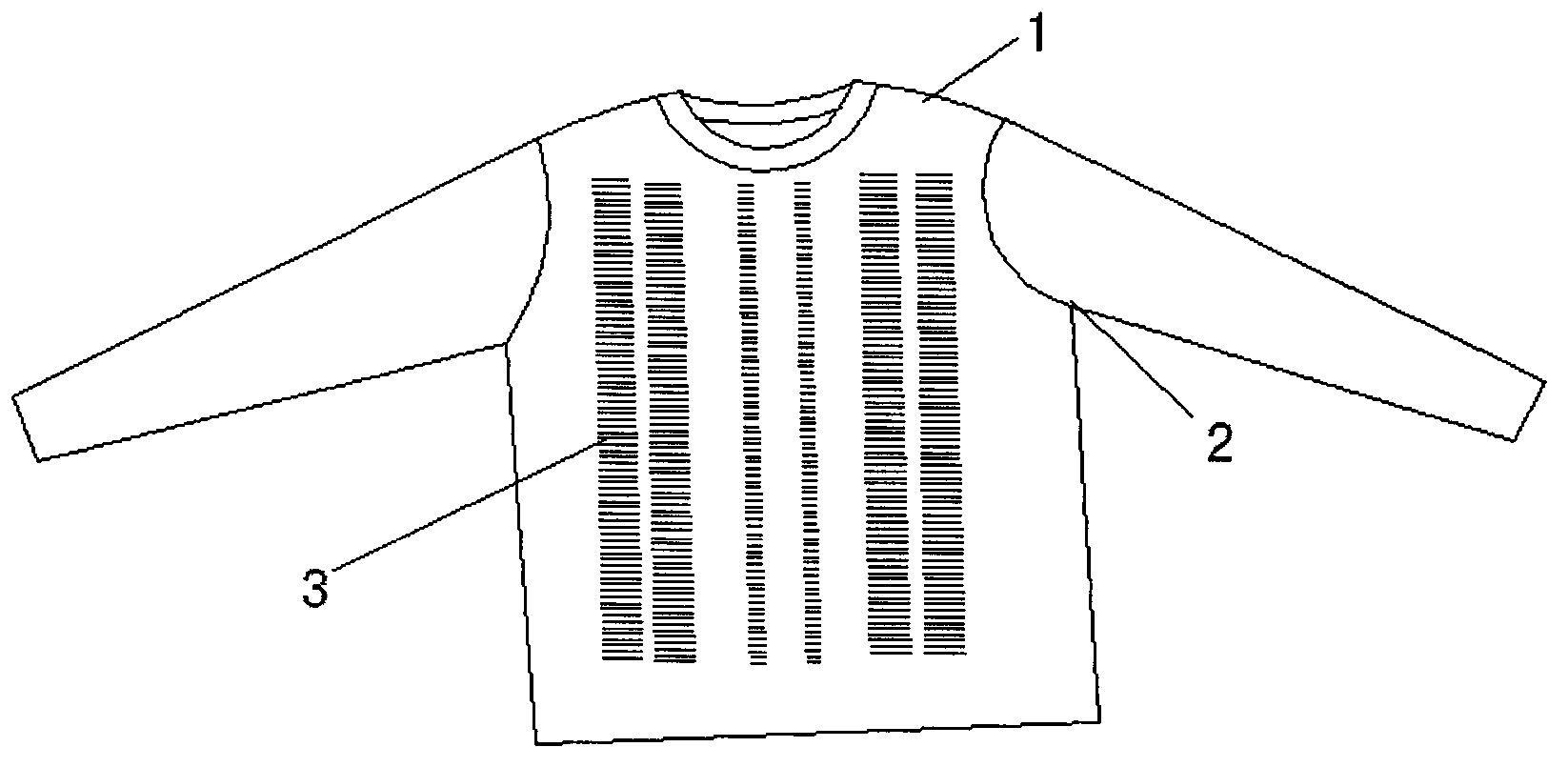

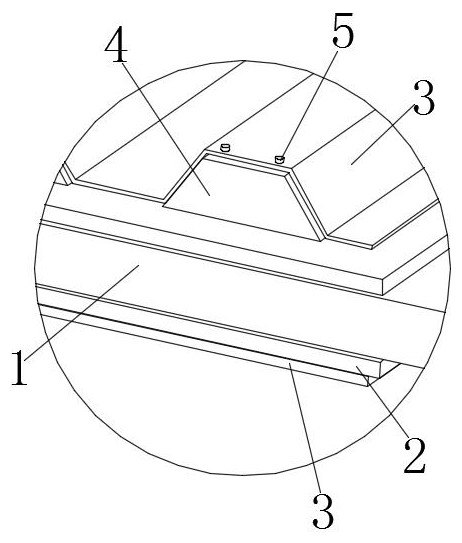

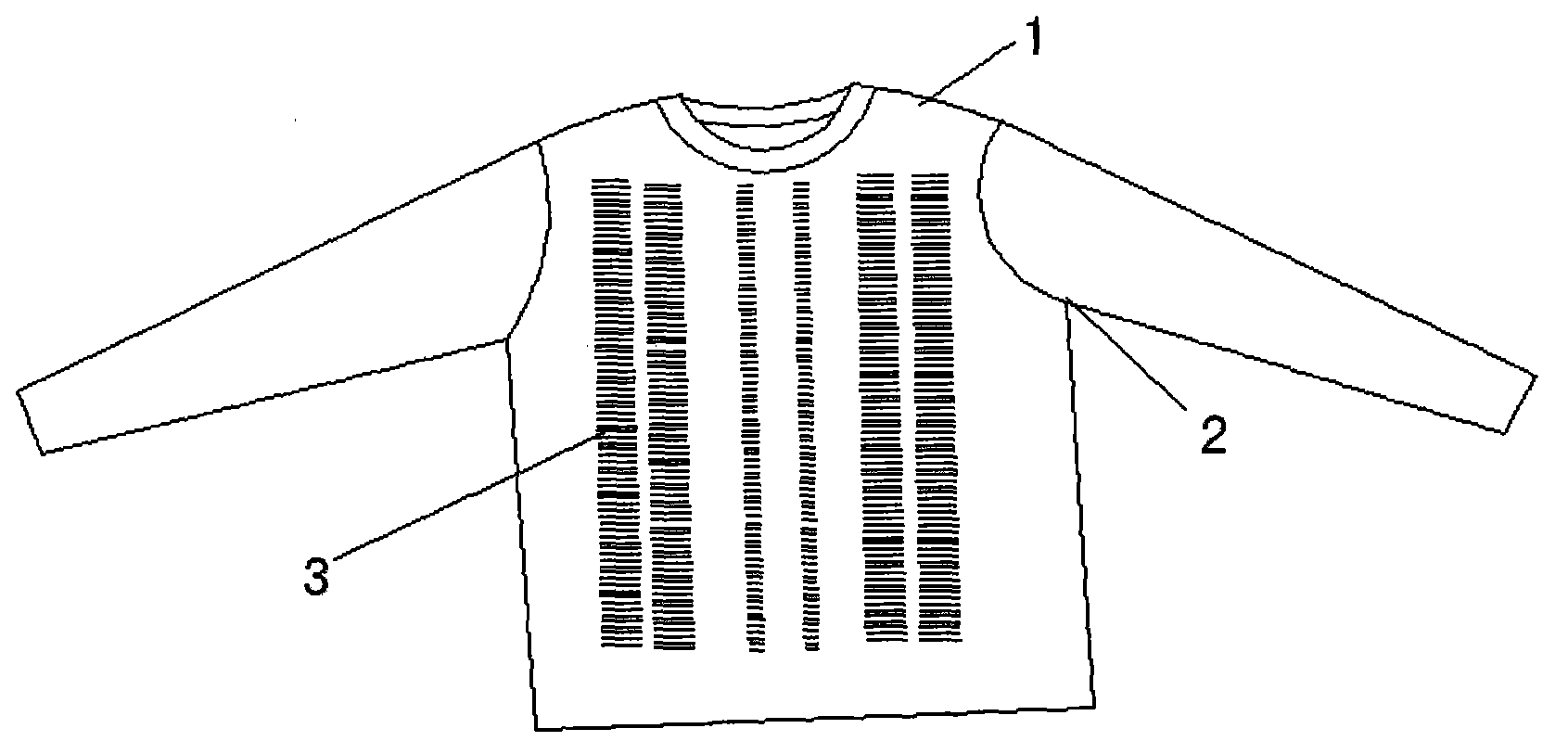

Antibacterial and crease-resistant garment with good air permeability

InactiveCN103799048AGood air permeabilityAvoid the growth of bacteriaProtective garmentSpecial outerwear garmentsEngineeringFiber

The invention relates to an antibacterial and crease-resistant garment with good air permeability. The antibacterial and crease-resistant garment with good air permeability comprises a garment body (1), wherein shoulders and underarms of the garment body (1) are provided with air-permeable holes (2), six belt-shaped air-permeable nets (3) are arranged in the front face of the garment body (1), the garment body (1) is made of fabric, the fabric is composed of a front face crease-resistant layer, a middle bonding layer and a back face antibacterial layer, the crease-resistant layer is made of polyurethane materials with a memory function, the bonding layer is a thermosetting type mucilage glue layer, and the antibacterial layer is a fabric layer containing nanometer bamboo carbon fibers. The antibacterial and crease-resistant garment has good air permeability.

Owner:陈国银

Garment having good air permeability and weft fibers arranged irregularly

The invention relates to a garment, in particular to a garment having good air permeability and weft yarn fibers arranged irregularly. The garment comprises a garment body (1), wherein the shoulder portions and oxter portions of the garment body (1) are provided with air holes (2), and the front portion of the garment body (1) is provided with six strip-shaped ventilation nets (3). The garment body (1) is made of fabrics which are formed by warp yarn fibers and weft yarn fibers in an interwoven mode, part of the weft yarn fibers are arranged regularly in the weft direction, and the other part of the weft yarn fibers are arranged irregularly in the weft direction; when the warp yarn fibers pass through the wrap yarn fibers which are arranged irregularly, every five weft yarn fibers cross one weft yarn fiber in a partitioned mode at a time; when the warp yarn fibers pass through the wrap yarn fibers which are arranged irregularly, four to eight weft yarn fibers cross in a partitioned mode at a time in the weft direction. The garment has the good air permeability.

Owner:杨洁

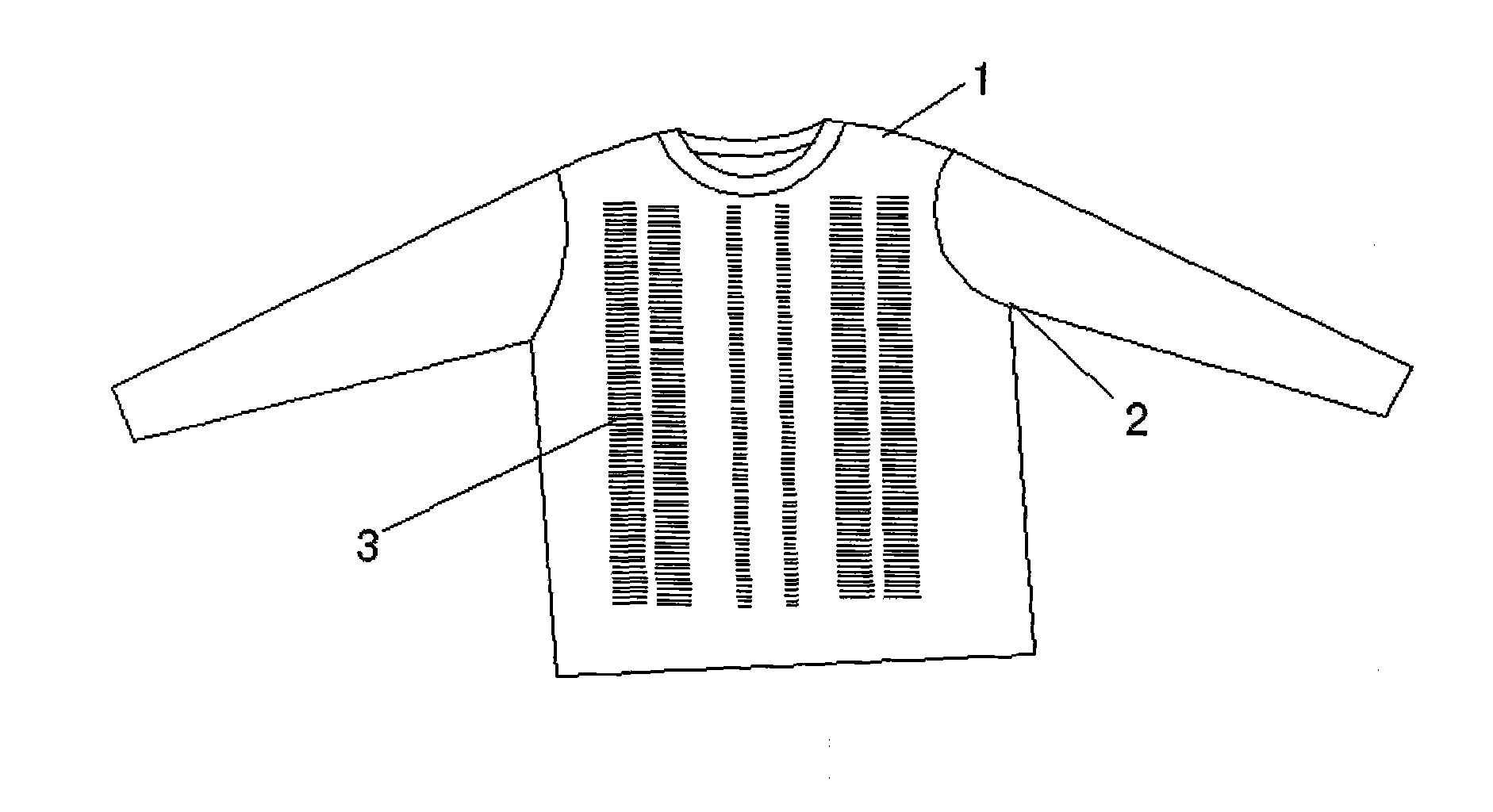

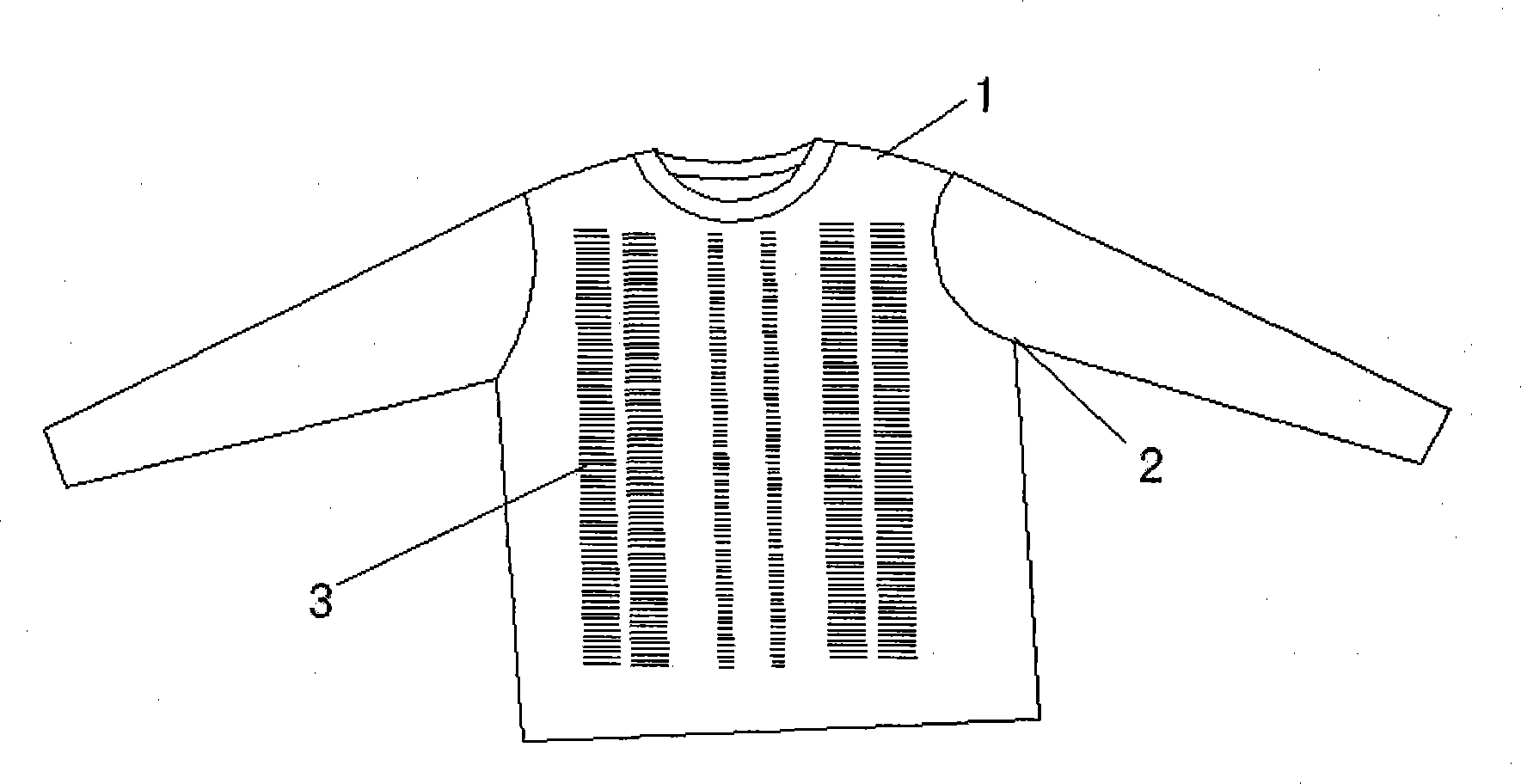

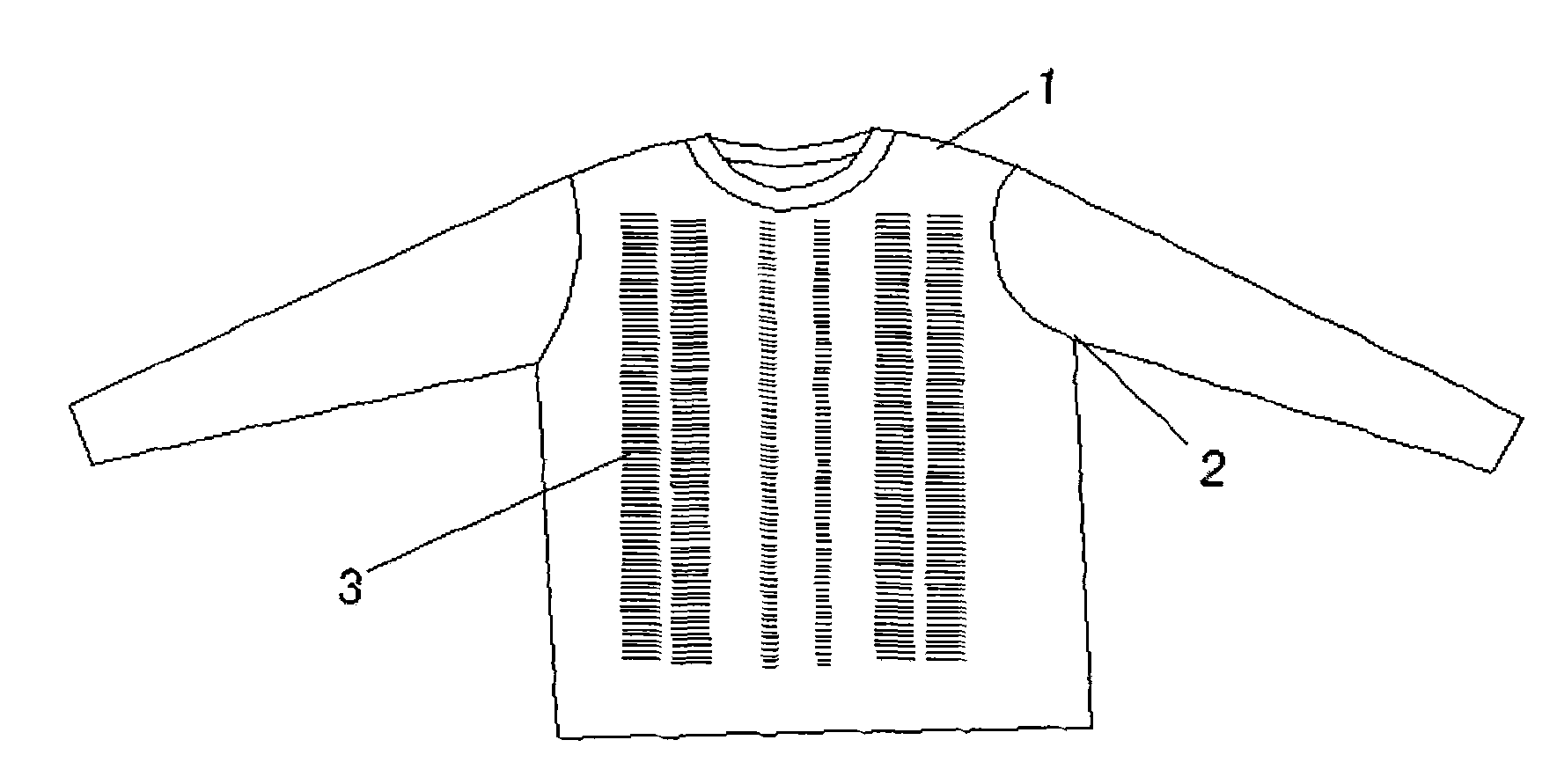

Wear-resistant and washable garment having good air permeability

InactiveCN103519393AIncrease bumpinessPromote circulationWoven fabricsProtective garmentPolyesterWear resistant

The invention relates to a garment, in particular to a wear-resistant and washable garment having good air permeability. The wear-resistant and washable garment comprises a garment body (1), the shoulder portions and oxter portions of the garment body (1) are provided with air holes (2), and the front portion of the garment body (1) is provided with six strip-shaped ventilation nets (3). The garment body (1) is made of fabrics comprising warp yarns and weft yarns, the warp yarns and the weft yarns are mutually interwoven up and down to form a grid structure, tissue of the grid structure is tabby or cross grain tissue, and a plurality of highlight polyester yarns parallel to the weft yarns are arranged at intervals in the direction of each warp yarn. The wear-resistant and washable garment is good in air permeability, resistant to wear and washable.

Owner:吴建平

Moisture-guiding and air-permeable garment with good air permeability

The invention relates to a moisture-guiding and air-permeable garment with good air permeability. The moisture-guiding and air-permeable garment with good air permeability comprises a garment body (1), wherein shoulders and underarms of the garment body (1) are provided with air-permeable holes (2), six belt-shaped air-permeable nets (3) are arranged in the front face of the garment body (1), the garment body (1) is made of fabric, the fabric comprises warp and weft, the warp is made of spun rayon yarns, the weft is made of blended yarns of jute / Richcel fibers, and the warp is perpendicular to the weft. The moisture-guiding and air-permeable garment has good air permeability.

Owner:杨洁

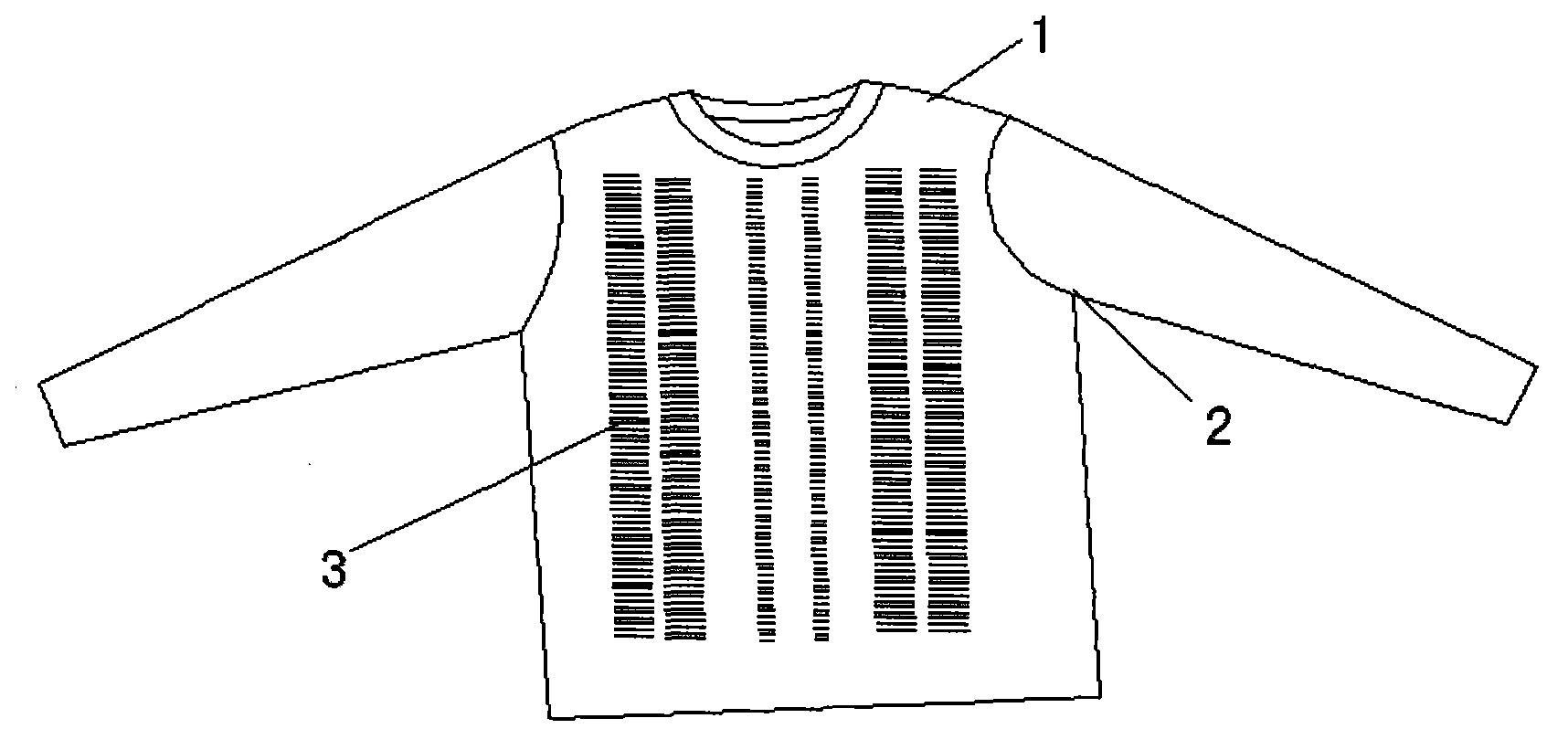

Garment with good air permeability and size stability

InactiveCN103799089AIncrease bumpinessPromote circulationWoven fabricsProtective garmentPolyesterYarn

The invention relates to a garment with the good air permeability and size stability. The garment comprises a garment body (1). Air holes (2) are formed in the shoulder portions and the oxter portions of the garment body (1) and six strip-shaped breathable nets (3) are arranged on the front part of the garment body (1). The garment body (1) is made of fabric interwoven from warps and wefts, the warps and the wefts are arranged in the mode of two warps up and two wefts down, each warp is 50D / 72F polyester low stretch yarn, each weft is 5D / 36F polyester low stretch yarn, and the warps and the wefts are of a twill weave structure. The garment is good in air permeability and size stability.

Owner:赵万兴

Machine-woven and knitted composite garment with good air permeability

InactiveCN103799033AIncrease bumpinessPromote circulationProtective garmentSpecial outerwear garmentsEngineeringWoven fabric

The invention relates to a machine-woven and knitted composite garment with good air permeability. The machine-woven and knitted composite garment with good air permeability comprises a garment body (1), wherein shoulders and underarms of the garment body (1) are provided with air-permeable holes (2), six belt-shaped air-permeable nets (3) are arranged in the front face of the garment body (1), the garment body (1) is made of fabric, one face of the fabric is machine-woven fabric, and the other face of the fabric is knitted fabric. The machine-woven and knitted composite garment has good air permeability, shows two different styles, and is novel and unique.

Owner:沈卫军

Anti-oil fabric garment with good air permeability

InactiveCN103519451AIncrease bumpinessPromote circulationProtective garmentSpecial outerwear garmentsPolyesterEngineering

The invention relates to a garment, in particular to an anti-oil fabric garment with good air permeability. The anti-oil fabric garment with good air permeability comprises a garment body (1), wherein ventilation holes (2) are formed in shoulder portions and oxter portions of the garment body (1), six strip-shaped ventilating nets (3) are arranged on the front part of the garment body (1), the garment body (1) is made of fabrics, the fabrics comprises three layers, the first layer and the third layer are Teflon coatings, the second layer is textile fabrics, and the textile fabrics are nylon waterproof shell fabric or polyester shell fabric. The anti-oil fabric garment has good air permeability, and has the functions of water resistance, oil prevention, and oil resistance.

Owner:JIANGSU ZHENXIN IND

Luminous fabric garment with good air permeability

InactiveCN103799062AIncrease bumpinessPromote circulationProtective garmentSpecial outerwear garmentsYarnEngineering

Owner:黄文平

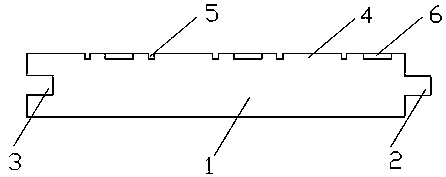

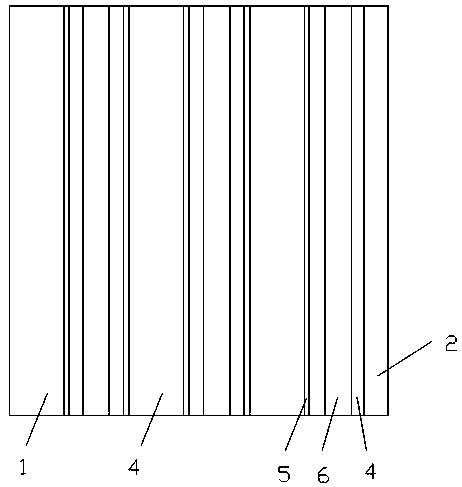

Anti-skid fluorescent plastic wood floor

PendingCN108331297AIncrease bumpinessPlay a role in anti-slipLighting elementsFlooringEngineeringRoad surface

The invention discloses an anti-skid fluorescent plastic wood floor. The anti-skid fluorescent plastic wood floor comprises a rectangular board body, one side of the board body is a tenon, and the other side of the board body is a groove matched with the tenon. The anti-skid fluorescent plastic wood floor is characterized in that the surface of the board body is strip-shaped board surfaces, channels are formed between the board surfaces, and fluorescent belts are embedded in the board surfaces. Compared with a traditional technology, the board body is designed in the form that the board surfaces and channels are phase-to-phase, the concave and convex feeling of feet when a pedestrian walks is improved, and an anti-skid function is achieved; and at the same time, a fluorescent belt design is added on the board surfaces, so that the pedestrian can see clearly the road surface when walking at night, and the safety for nighttime walk improved.

Owner:YIXING HUALONG NEW MATERIAL LUMBER CO LTD

Elastic fabric garment having good air permeability

InactiveCN103519384AIncrease bumpinessPromote circulationWarp knittingProtective garmentEngineeringFilament yarn

The invention relates to a garment, in particular to an elastic fabric garment having good air permeability. The elastic fabric garment comprises a garment body (1), the shoulder portions and oxter portions of the garment body (1) are provided with air holes (2), and the front portion of the garment body (1) is provided with six strip-shaped ventilation nets (3). The garment body (1) is made of fabrics, the fabrics are double-face warp knitting fabrics satisfying the weaving rule of 1-0 / 5-6, bottom yarns are polyester filament yarns and spandex yarns FDY84D / 36F, and surface yarns are polyester low stretch yarns and spandex yarns 75D / 144F. The elastic fabric garment has the good air permeability. The fabrics will not wrinkle easily, the garment will not easily retract after being hung, and drapability is good.

Owner:许永新

A conveyor belt forming process

ActiveCN110774507BIncrease bumpinessExtended service lifeBeltsDomestic articlesVulcanizationConveyor belt

The invention discloses a molding process of a conveyor belt, which specifically includes the following steps: S1: raw material mixing; S2: parking; S3: heat mixing of mixed rubber; S4: calendering; S5: cooling of the belt blank; S6: bottom cover of the belt blank Glue attachment; S7: Trapezoidal block attachment; S8: Belt blank surface cover adhesive attachment; S9: Conveyor belt forming; Make the conveyor belt not easy to slip when transporting goods, and at the same time contact the trapezoidal block through the surface cover rubber and fix it with bolts, so that after the surface part of the cover rubber is damaged by friction, the bolt corresponding to the damaged position can be unscrewed and the damaged position can be cut The cover glue can be added to the partial cover glue without replacing the entire conveyor belt, which saves money and improves the service life of the conveyor belt.

Owner:湖南宝烽设备股份有限公司

Fabric structure reinforced garment having good air permeability

InactiveCN103519373AGood air permeabilityExpand the range of tearingWeft knittingGarmentsYarnEngineering

The invention relates to a garment, in particular to a fabric structure reinforced garment having good air permeability. The fabric structure reinforced garment comprises a garment body (1), the shoulder portions and oxter portions of the garment body (1) are provided with air holes (2), and the front portion of the garment body (1) is provided with six strip-shaped ventilation nets (3). The garment body (1) is made of fabrics comprising at least two kinds of raw material yarns, one kind is spandex yarns, the melting points of other raw material yarns are higher than that of the spandex yarns, and the fabrics are of adhering structures which are formed by the woven spandex yarns in a melted mode at the interweaving positions of the raw material yarns. The fabric reinforced garment has the good air permeability. In addition, the fabric structure is reinforced.

Owner:华明浩

Foamed satin

The invention discloses foamed satin. The foamed satin comprises a foamed body, a satin surface, a texture, first textile threads, venting holes and second textile threads. The foamed satin has the advantages that the glossy and soft satin surface is adopted as a bottom face of the foamed satin so that the foamed satin causes no irritation to the human skin, correspondingly irritability of the human skin is avoided, the comfort of the foamed satin can be improved at the same time, and people feel more comfortable when wearing clothes made of the foamed satin. Spandex-coated silk is adopted forweaving the satin surface, so that the satin surface is shrunk to form various kinds of regular foam, correspondingly the concave-convex performance of the satin surface can be enhanced, and patternson the satin surface are more stereoscopic at the same time; the clothes are more attractive, correspondingly the sales quantity of the clothes is increased, and improvement of the popularity of goods is facilitated. By forming vent holes in the satin surface, the satin can be breathable and is especially suitable for being used as a raw material of the clothes in summer. Since it is hot in summer, if hot air generated by people is not discharged from the interiors of the clothes in time, the comfort of people wearing the clothes can be affected.

Owner:JIANGSU LIBO TEXTILE

Three-phase braided fabric garment having good air permeability

InactiveCN103519375AGood air permeabilityIncrease density and firmnessWoven fabricsProtective garmentWeft yarnBiomedical engineering

The invention relates to a garment, in particular to a three-phase braided fabric garment having good air permeability. The three-phase braided fabric garment comprises a garment body (1), wherein the shoulder portions and oxter portions of the garment body (1) are provided with air holes (2), and the front portion of the garment body (1) is provided with six strip-shaped ventilation nets (3). The garment body (1) is made of fabrics which are three-phase braided fabrics, the fabrics are formed by yarns in an interwoven mode, the yarns comprise weft yarns, left-leaning warp yarns and right-leaning warp yarns, and the through weaving rule is performed in the left-leaning warp yarns and the right-leaning warp yarns. The three-phase braided fabric garment has the good air permeability. In addition, the fabric structure is reinforced. According to the three-phase braided fabric garment, patterns of the fabrics are changed, consistency and firmness are enhanced, and a sense of depth, stereoscopic impression and rich colors can be produced.

Owner:马军锋

Water absorption and guide garment with excellent breathability

InactiveCN103799019AGood air permeabilityStrong water absorptionProtective garmentSpecial outerwear garmentsPolyesterYarn

The invention relates to a water absorption and guide garment with excellent breathability. The water absorption and guide garment comprises a garment body (1), wherein air holes (2) are formed in the shoulders and the oxters of the garment body (1); six strip-shaped breathable nets (3) are arranged on the front of the garment body (1); the garment body (1) is made of a fabric which is a polyester cotton intertexture; the polyester cotton intertexture consists of polyester yarns and chinlon yarns; the polyester yarns are arranged on the front of the fabric; the chinlon yarns are arranged on the back of the fabric. The water absorption and guide garment has excellent breathability.

Owner:李文标

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com