Method for preparing coating powder by adopting plasma vapor deposition process

A plasma gas, vapor deposition technology, applied in coating, ion implantation plating, metal material coating process, etc., to achieve the effect of good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

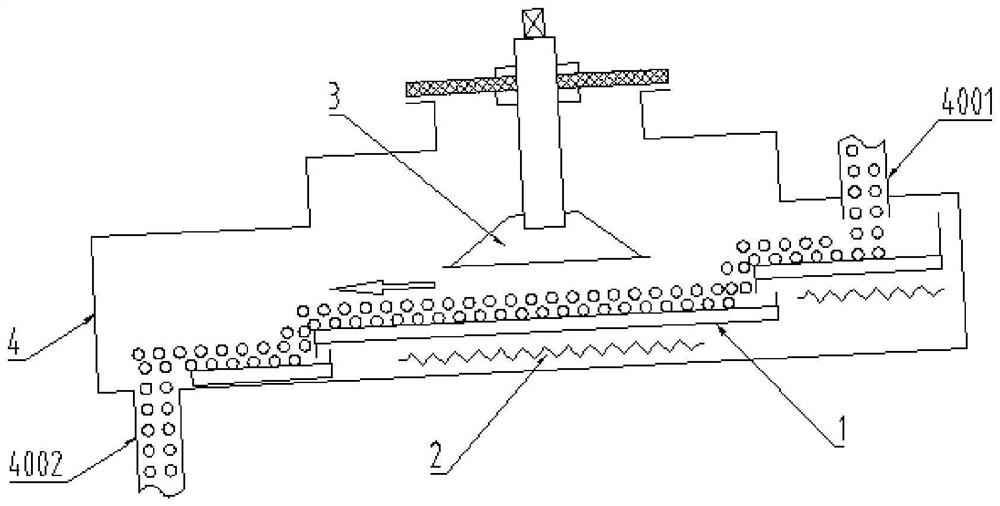

[0032] Such as figure 1 As shown, the present embodiment provides a fluidized plasma vapor deposition furnace. The furnace body 4 is provided with a feed port 4001 and a discharge port 4002. A positive electrode plate 3 and a negative electrode plate 1 are provided inside the furnace body 4. The positive electrode plate The number of 3 is more than 1, and each positive plate can be connected to the working gas and the plasma generator separately. The positive plate 3 is set above the negative plate 1 and keeps a certain working distance from the negative plate 1. The parallel space or nearly parallel space between them is the deposition area. A feed plate and a discharge plate are respectively connected between the negative plate 1 and the feed port 4001 and the discharge port 4002. The feed plate, the discharge plate and the negative plate 1 are connected to a vibrating device, which has the function of vibrating material delivery. An electric heating element 2 is arranged b...

Embodiment 2

[0038] This embodiment provides a method for preparing coating powder by plasma vapor deposition process, which is completed based on the fluidized plasma vapor deposition furnace in Example 1. The powder is artificial graphite particles, D50=15 μm, and the coating material is nanometer Silicon, the source gas is silane SiH 4 , the specific deposition process includes the following steps:

[0039] S1. Put 93kg of artificial graphite particles into the hopper at the upper end of the feed port 4001 of the fluidized plasma vapor deposition furnace, wait for the feed, and vacuumize the deposition furnace until the pressure in the furnace is 0.01 to 2 Torr;

[0040]S2. Power on the electric heating element, raise the temperature of the deposition furnace to 500°C, make the feed plate, negative plate and discharge plate in the state of vibrating feeding, open the feed port 4001 and the discharge port 4002, and the artificial graphite particles will flow in a controlled manner Seque...

Embodiment 3

[0045] This embodiment provides a method for preparing coating powder by plasma vapor deposition process, which is completed based on the fluidized plasma vapor deposition furnace in Example 1. The powder is artificial graphite particles, D50=15 μm, and the coating material is nanometer Silicon and nano-carbon, the source gas is silane SiH 4 and propylene, the specific deposition coating process includes the following steps:

[0046] S1. Put 85 kg of artificial graphite particles into the hopper at the upper end of the feed inlet 4001 of the fluidized plasma vapor deposition furnace, wait for the feed, and vacuumize the deposition furnace until the pressure in the furnace is 0.01 to 2 Torr;

[0047] S2. Power on the electric heating element, raise the temperature of the deposition furnace to 500°C, make the feed plate, negative plate 1 and discharge plate in the state of vibrating feeding, open the feed port 4001 and the discharge port 4002, and the flow of artificial graphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com