Production output device for precision frames used for diodes

A technology of output devices and diodes, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of cost increase, waste of resources, and messy stacking, etc., and achieve the effect of reducing production costs, improving yield rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

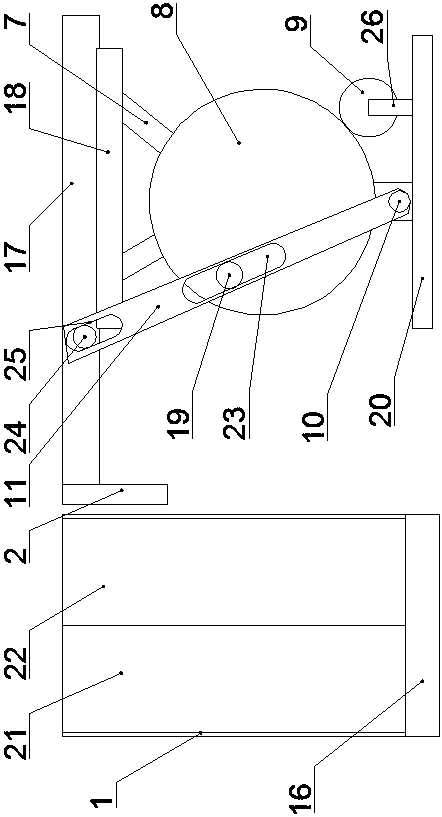

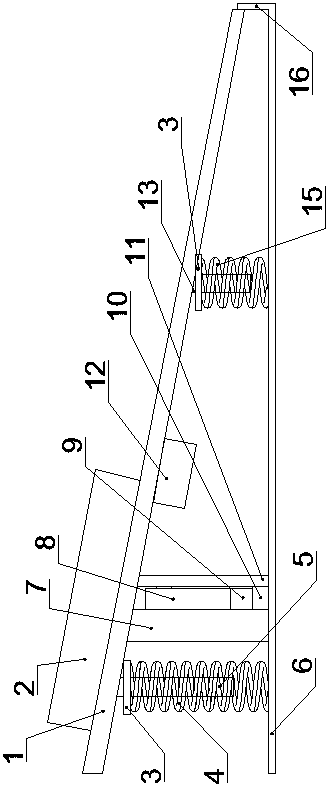

[0017] Example: such as Figure 1-2 As shown, a precision frame production and output device for diodes according to the present invention includes a conveying device and a pushing device. The conveying device includes a first bottom plate 6 arranged horizontally front and rear, and a baffle is provided on the front end of the first bottom plate 6 16. The baffle plate 16 and the first bottom plate 6 are integrally formed, and the first bottom plate 6 is provided with a slideway plate 1 with a low front and a high rear. The eaves on the front end surface of the road plate 1 are higher than the upper end surface of the baffle plate 16, and the surface of the slideway plate 1 is vertically provided with a first guide post 5 and a second guide post 13, and the lower ends of the first guide post 5 and the second guide post 13 are Both are suspended in the air, and the upper ends of the first guide post 5 and the second guide post 13 are fixedly provided with an annular stopper 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com