Hanger for metal pipe and vehicle with hanger

A technology for metal pipes and spreaders, applied in the field of spreaders and vehicles, can solve the problems of high labor intensity, low work efficiency, and high labor costs, and achieve the effects of reducing labor intensity, simple installation, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

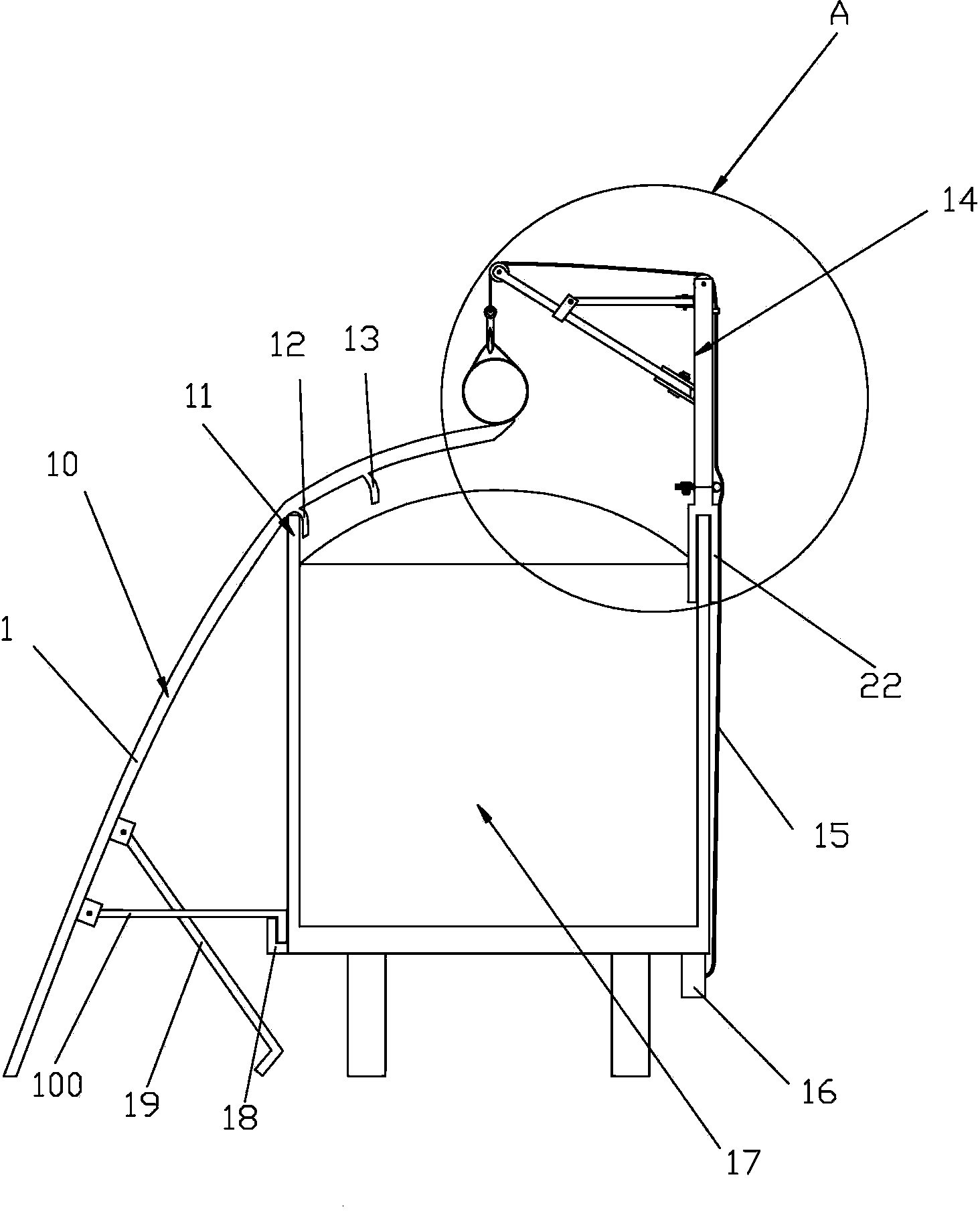

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a vehicle equipped with a spreader specially used for metal pipes includes a carriage 17 and a spreader specially used for metal pipes 20 mounted on the carriage 17 . The spreader includes a crane 14 for lifting the metal pipe 20 and two slide rails 10 for the metal pipe 20 to slide. This hoist 14 comprises the fixed bar 28 that is installed on the compartment 17 side walls, the turret 29 that is installed on this fixed bar 28 and the driving mechanism 16 that is installed in this compartment 17 bottoms (as figure 1 and figure 2 shown). The driving mechanism 16 comprises a rope winding mechanism and a motor connected with the rope winding mechanism. The motor is connected with a controller for controlling the rotation of the motor. The controller is provided with a remote control receiver. An adapted remote control, which is provided with a forward rotation button for contro...

Embodiment 2

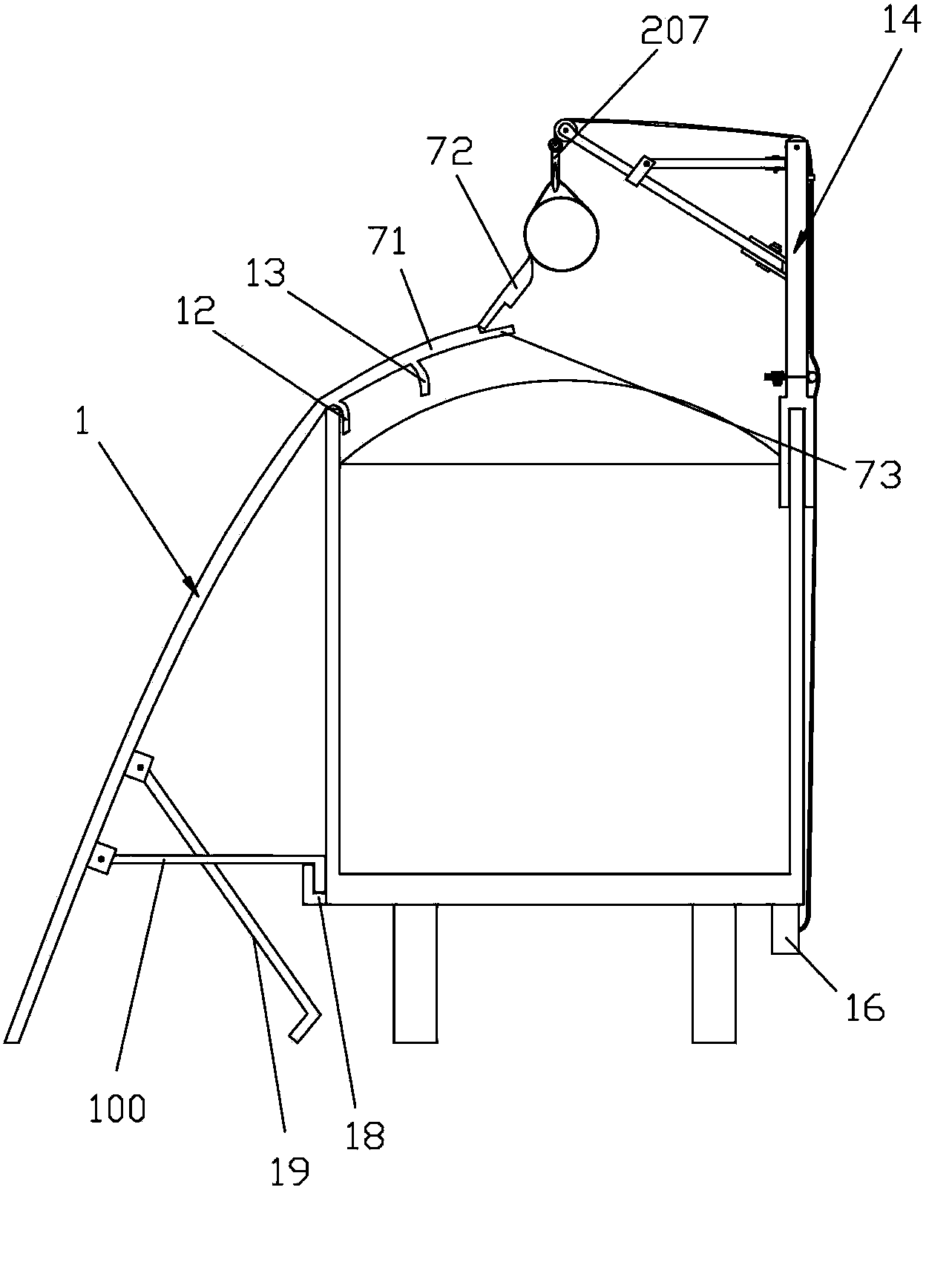

[0043] Such as Figure 9 and Figure 10 As shown, on the basis of the first embodiment above, the difference between the second embodiment and the first embodiment is that the inclined plate 1 includes an extension plate 71 and a rotating plate 72 that can rotate around the extension plate, and the extension plate 71 is provided with There is an extension block 73 on which the rotating plate 72 is located. When the metal pipe 20 is unloaded from the vehicle, the hook 207 lifts the metal pipe 20 from the compartment 17, and the rotating plate 72 will be pushed up by the metal pipe 20. Thus turning up, when the metal pipe 20 is out of contact with the rotating plate 72, the rotating plate 72 is turned down to the original position under its own gravity. After such a structure is set, the metal pipe 20 can be placed more smoothly. On the rotating plate 72, slide the slide rail 10 smoothly.

Embodiment 3

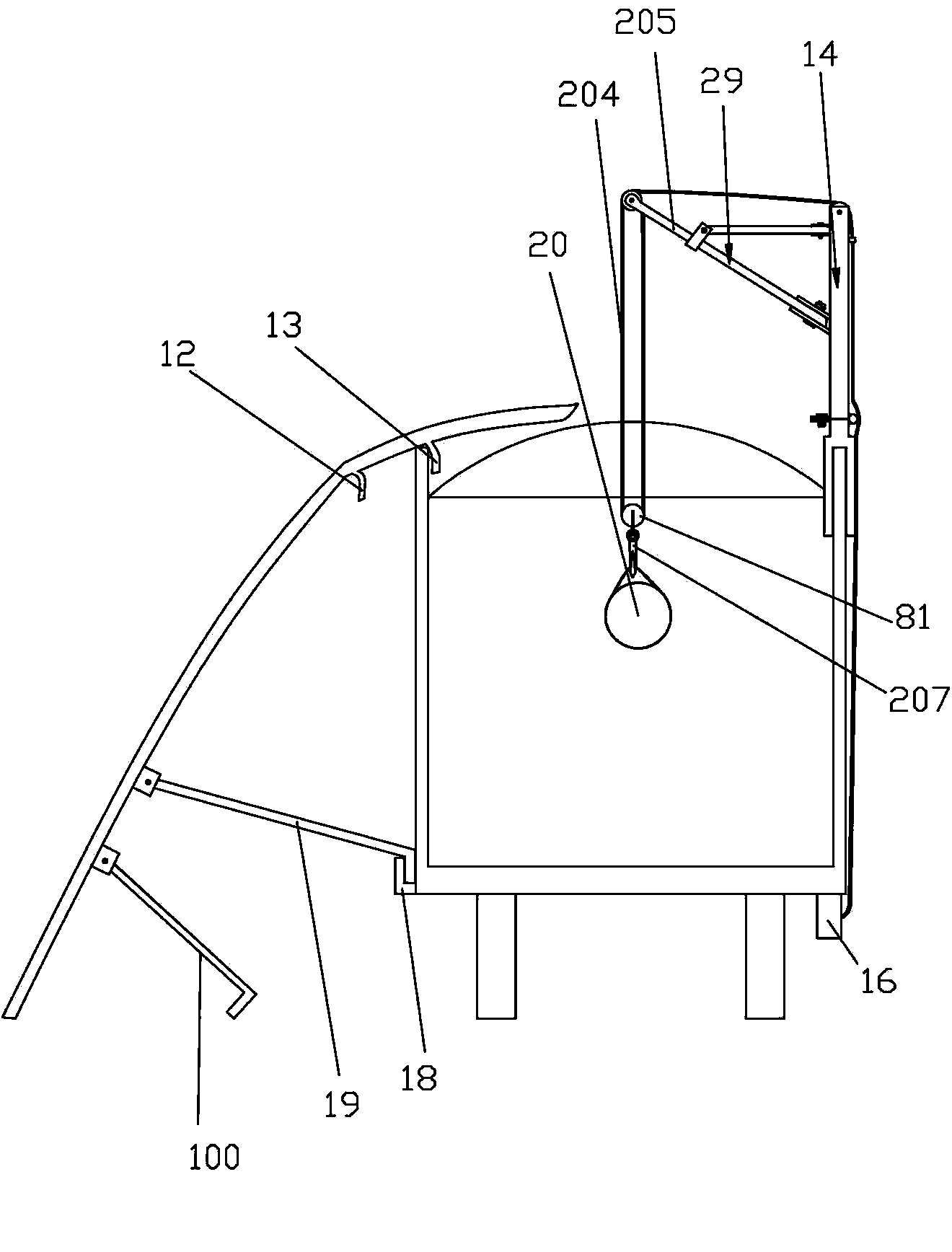

[0045] Such as Figure 11 As shown, on the basis of the first embodiment above, the difference between the third embodiment and the first embodiment is only that the above-mentioned sling also includes a movable pulley 81, the above-mentioned hook 207 is installed on the movable pulley 81, and on the movable pulley 81 The above-mentioned suspension rope 204 is wound, one end of the above-mentioned suspension rope 204 is fixedly connected to the above-mentioned rope winding mechanism, and the other end of the above-mentioned suspension rope 204 is fixedly connected to the diagonal stay rod 205 of the above-mentioned turret 29 . After setting such a structure, the above-mentioned motor only needs to pull half of the gravity of the suspended metal pipe 20, which greatly reduces the requirement on the power of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com