Patents

Literature

35results about How to "Slide down smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

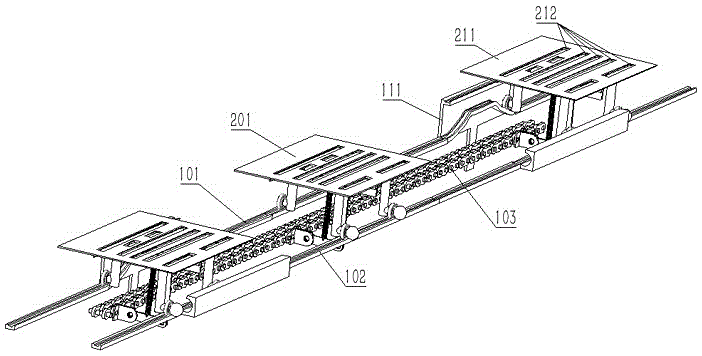

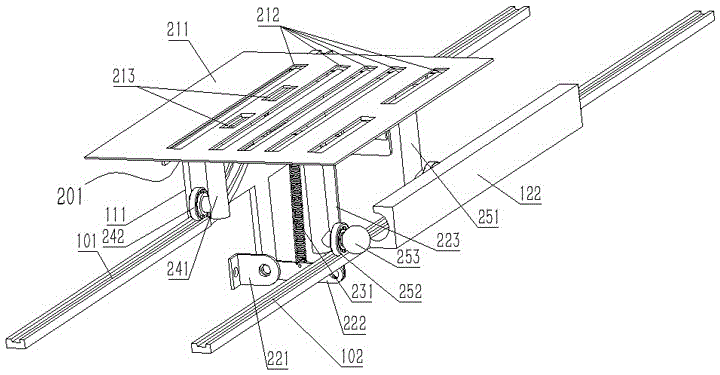

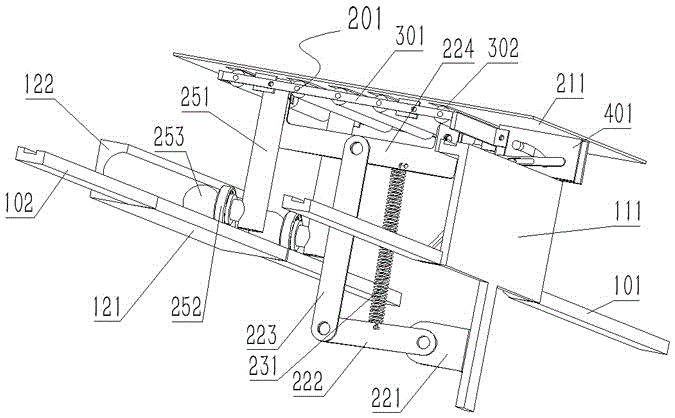

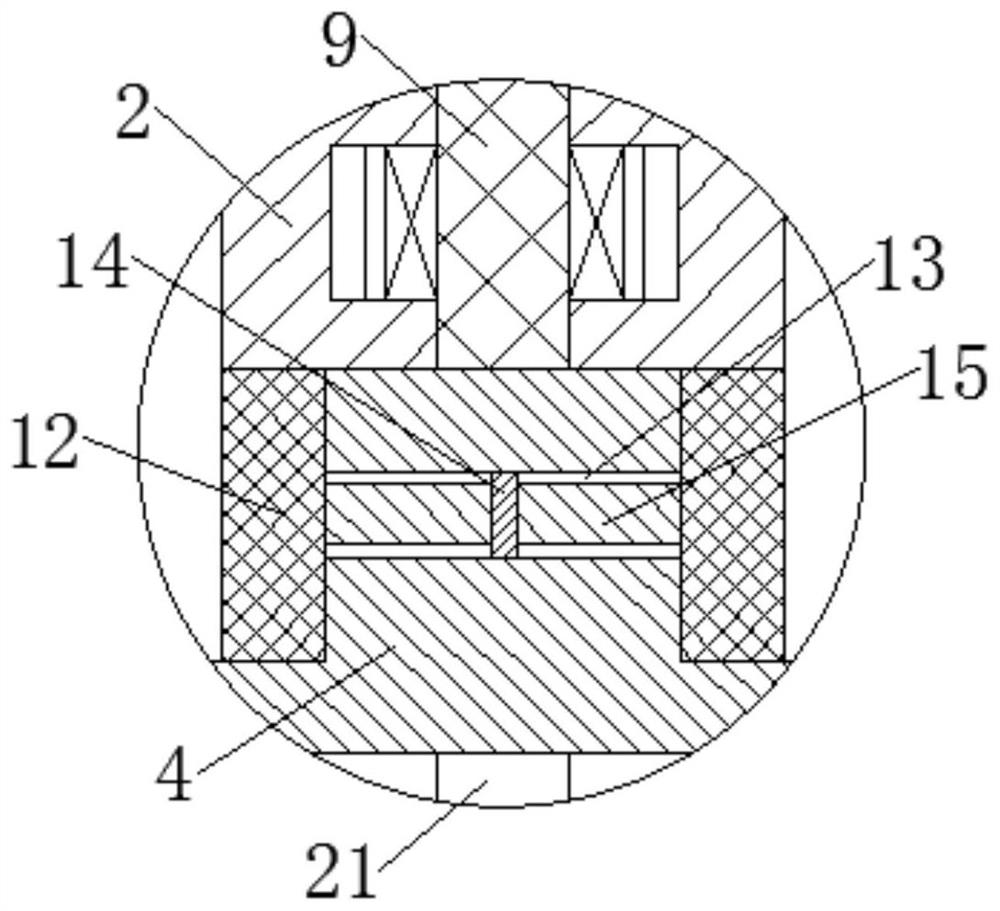

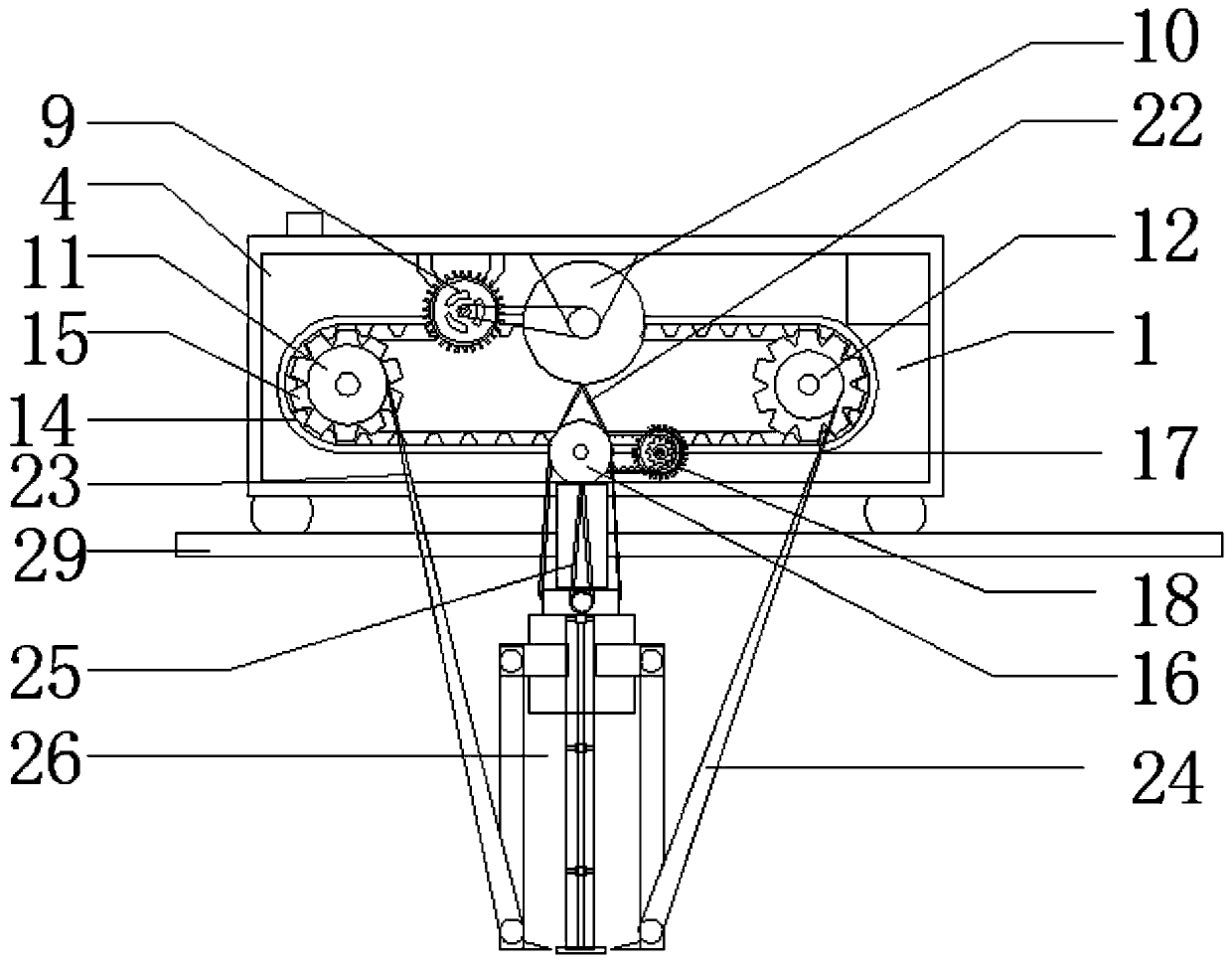

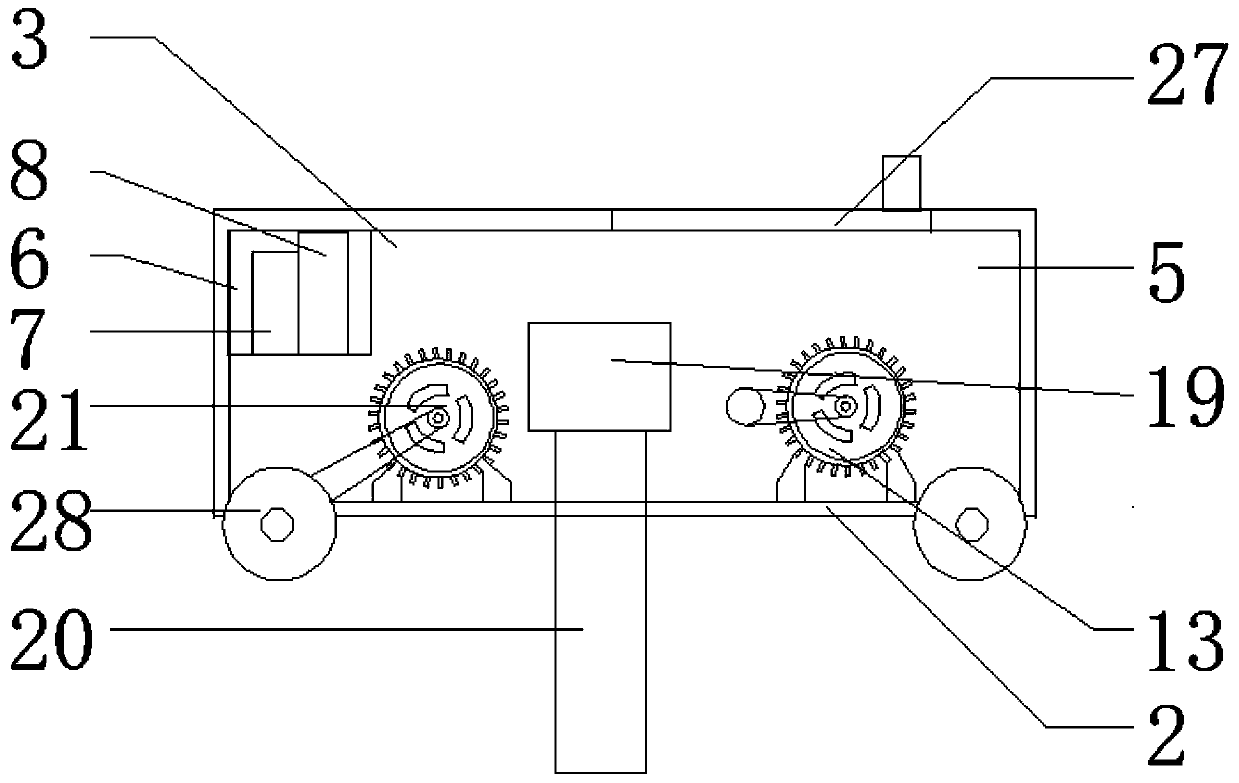

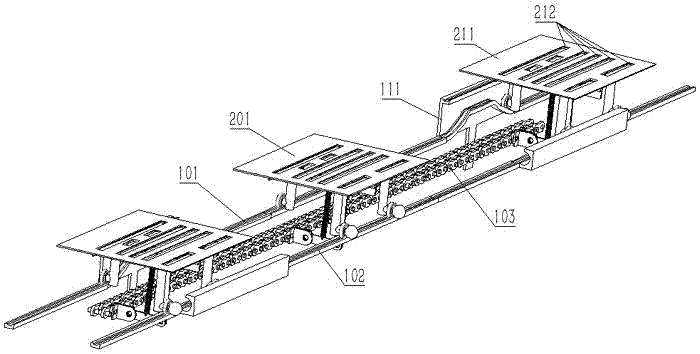

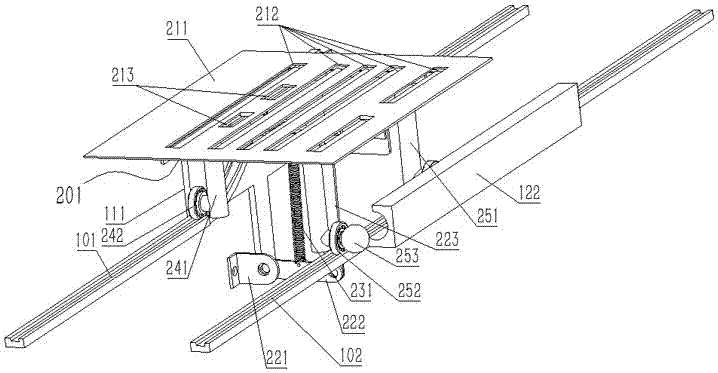

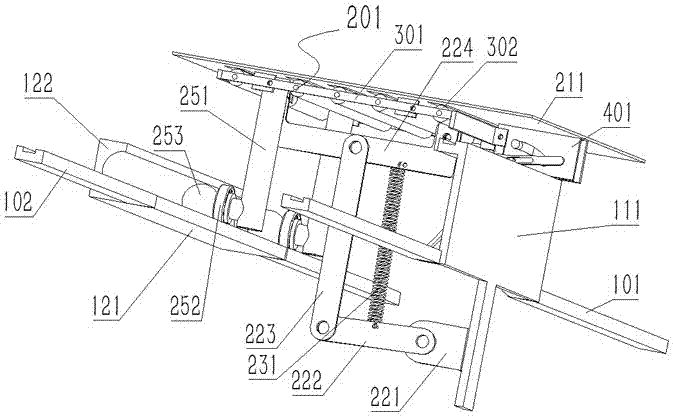

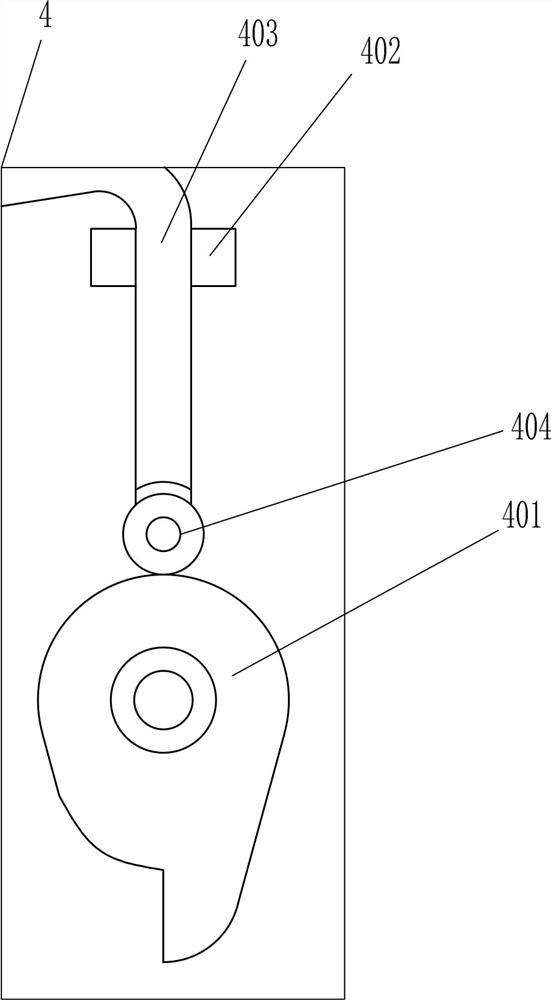

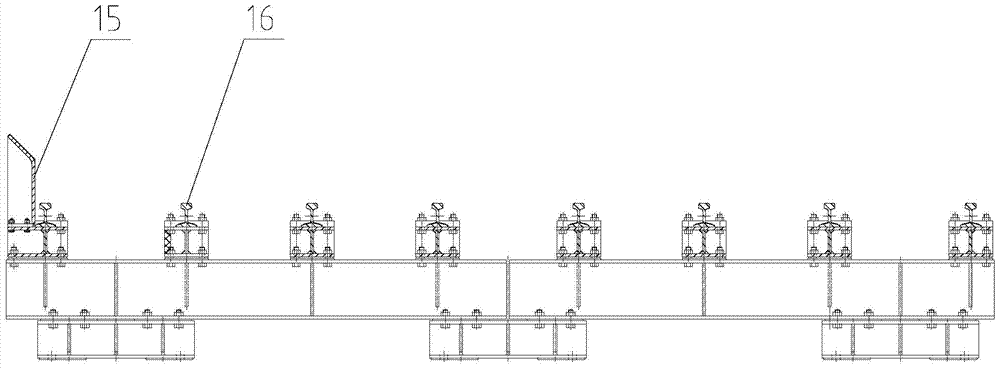

Carrying device and logistics sorting device with carrying device

InactiveCN105083957AReduce frictionReduce frictional resistanceConveyor partsLogistics managementFriction force

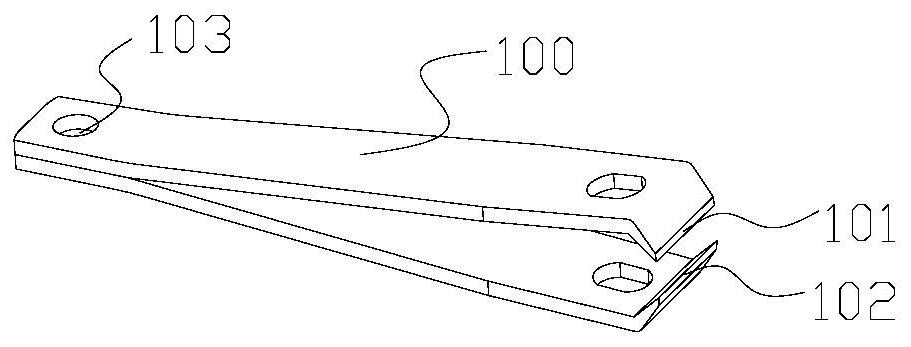

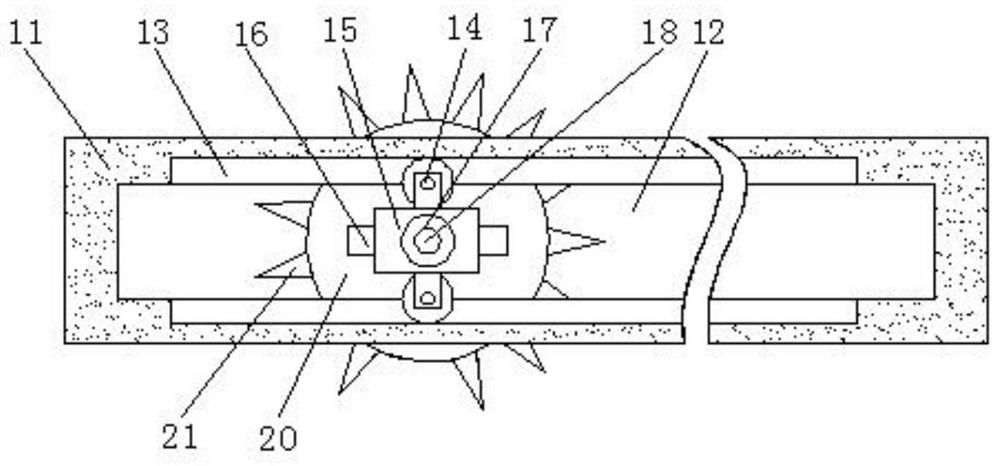

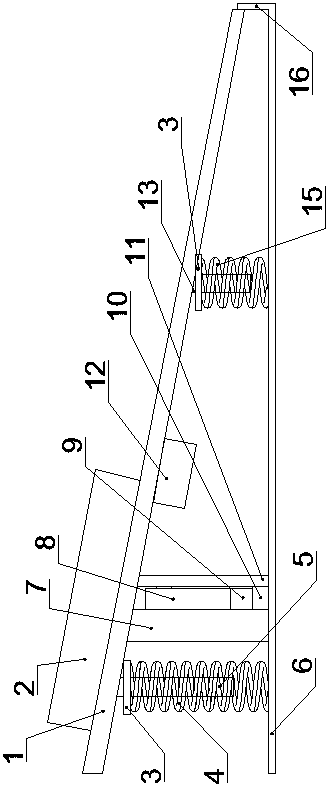

The invention discloses a carrying device and a logistics sorting device with the carrying device. A frame body is connected to the lower portion of a tray of the carrying device. A sliding roller extending forwards and backwards is arranged on the frame body. The right side of the frame body is hinged to the tray around a front and back colored axis. An ejecting structure driving the sliding roller to be exposed out of the upper portion of the tray through the frame body when the tray tips over is arranged between the left side of the frame body and supporting legs. Thus, after the carrying device reaches a sorting port, the supporting legs and the tray will rotate relative to each other around the axis extending forwards and backwards while the tray tips over; and at the moment, the frame body also drives the sliding roller to move upwards relative to the tray under the action of the ejecting structure till the tray tips over in place, the sliding roller is driven by the frame body to be completely exposed out of the top face of the tray, and therefore the roller surface of the sliding roller can replace the top face of the tray to make contact with goods, the contact area between the carrying device and the goods is reduced, friction force borne by the goods in the tip-over pour-out process is reduced, and friction resistance is reduced when the goods slide downwards from the tray.

Owner:HENAN UNIV OF SCI & TECH

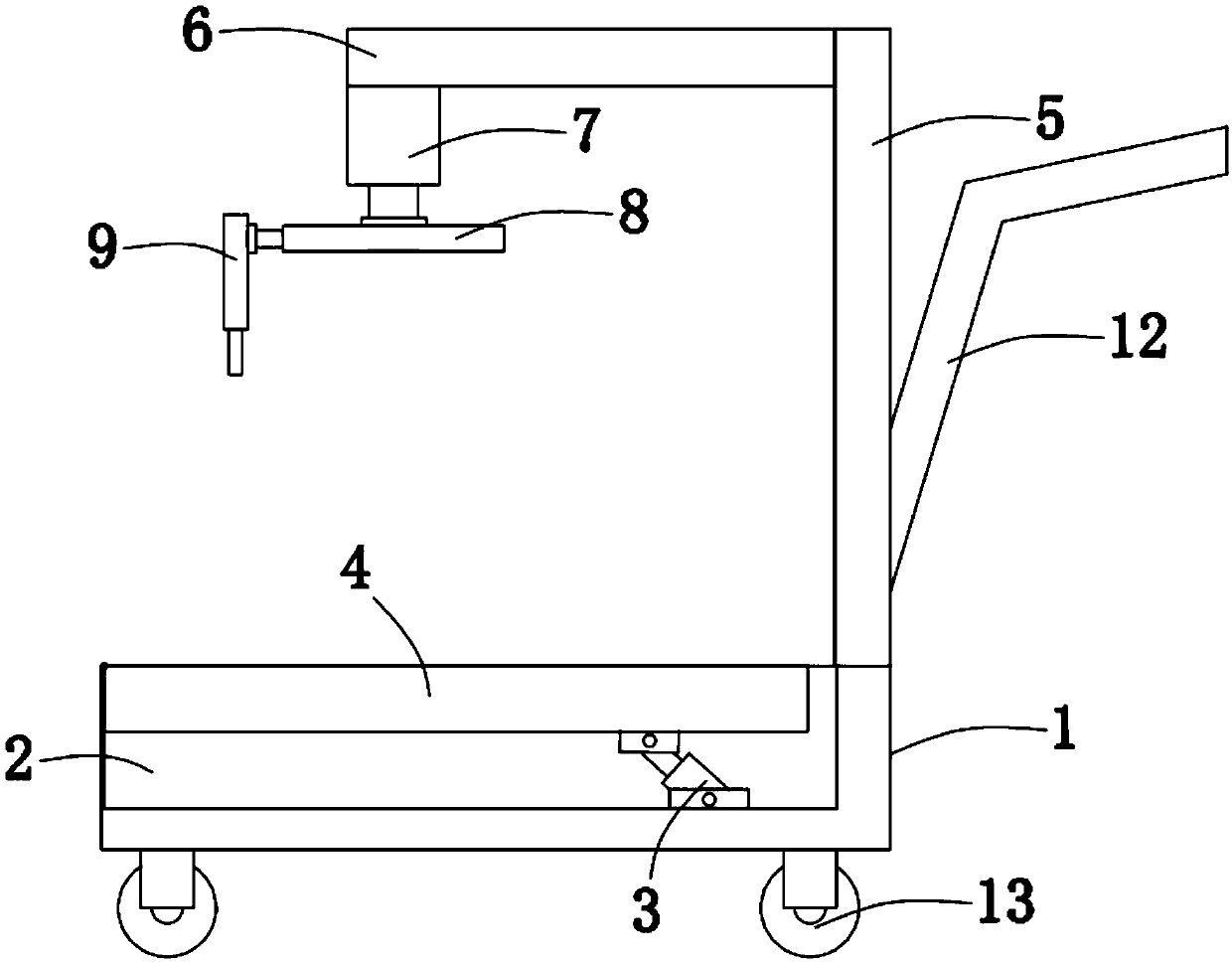

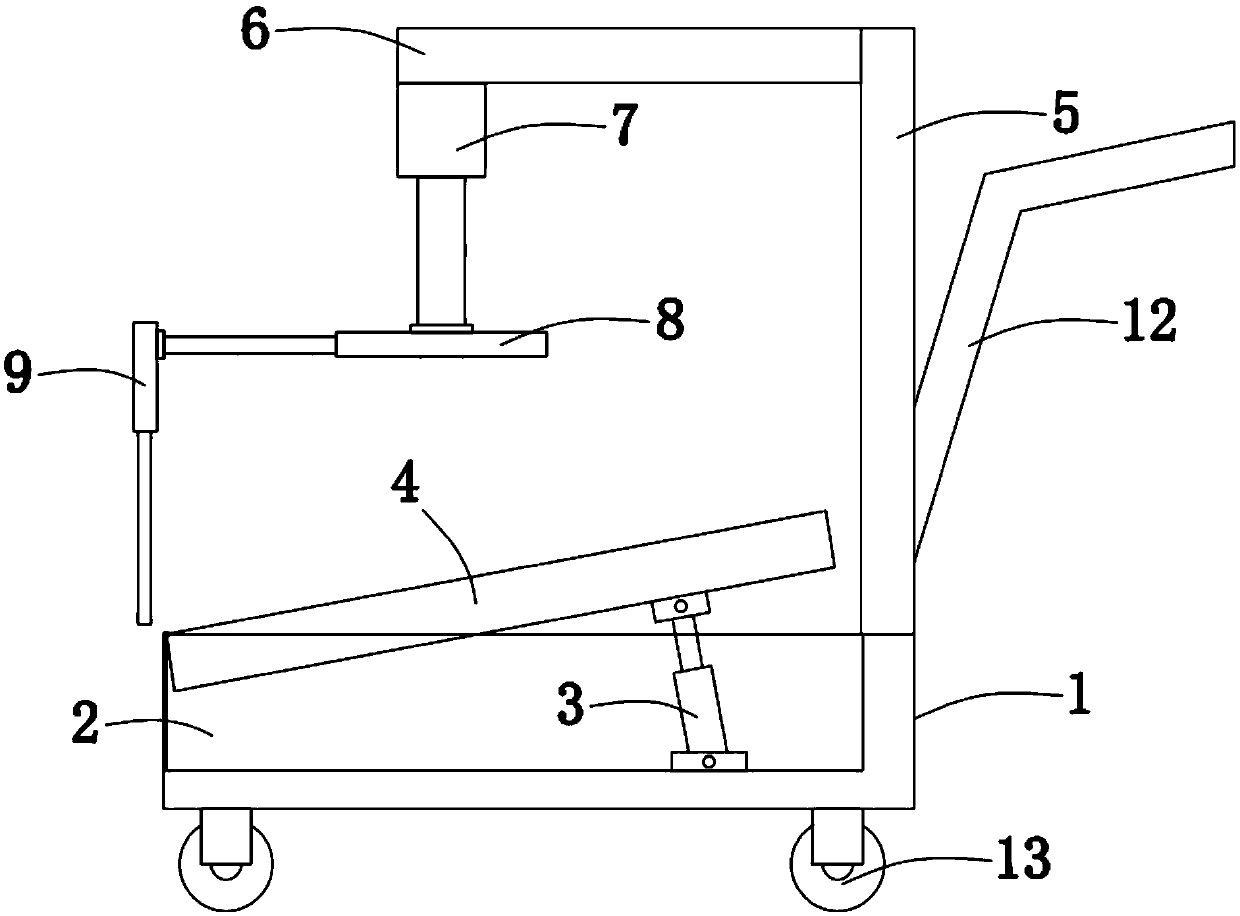

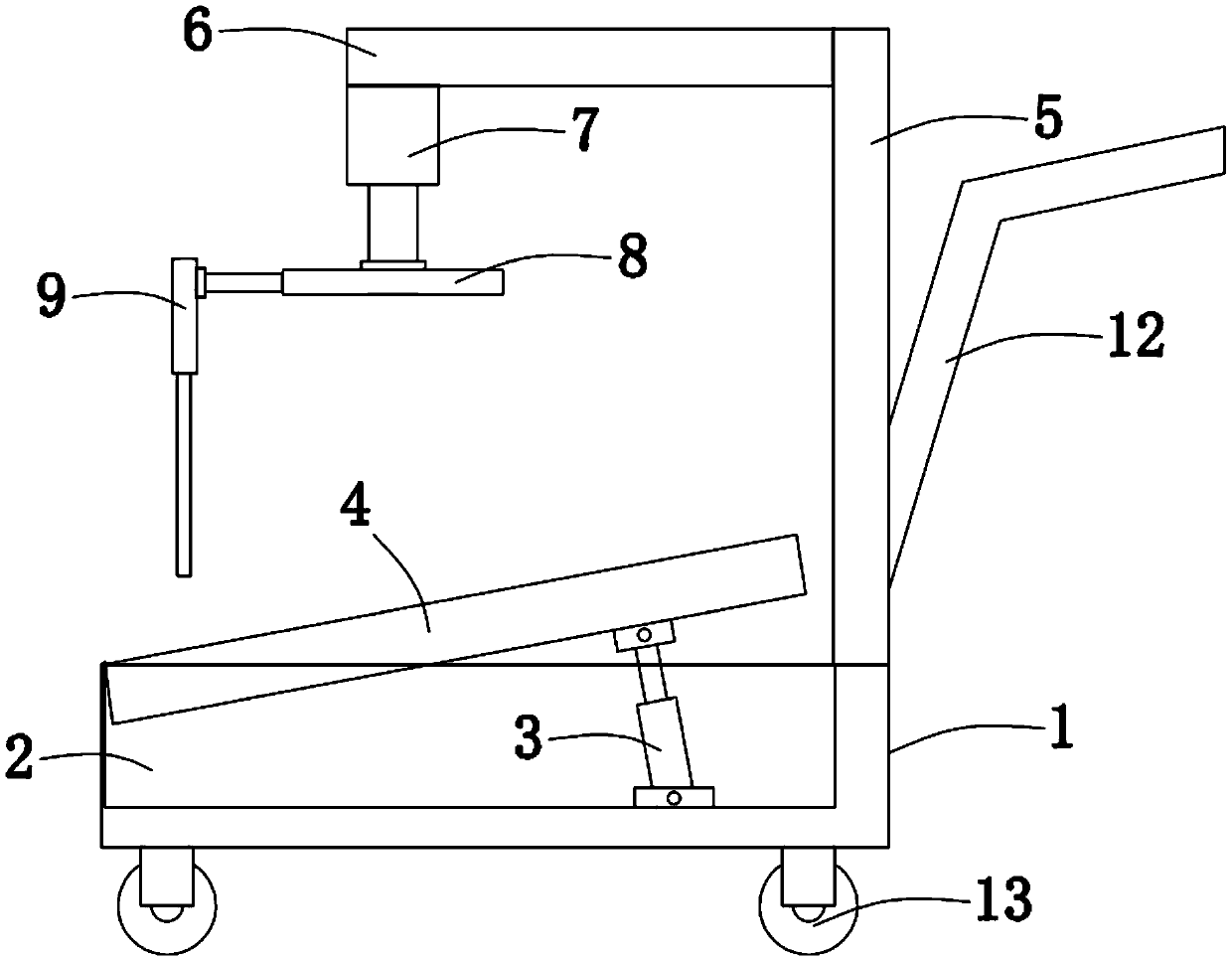

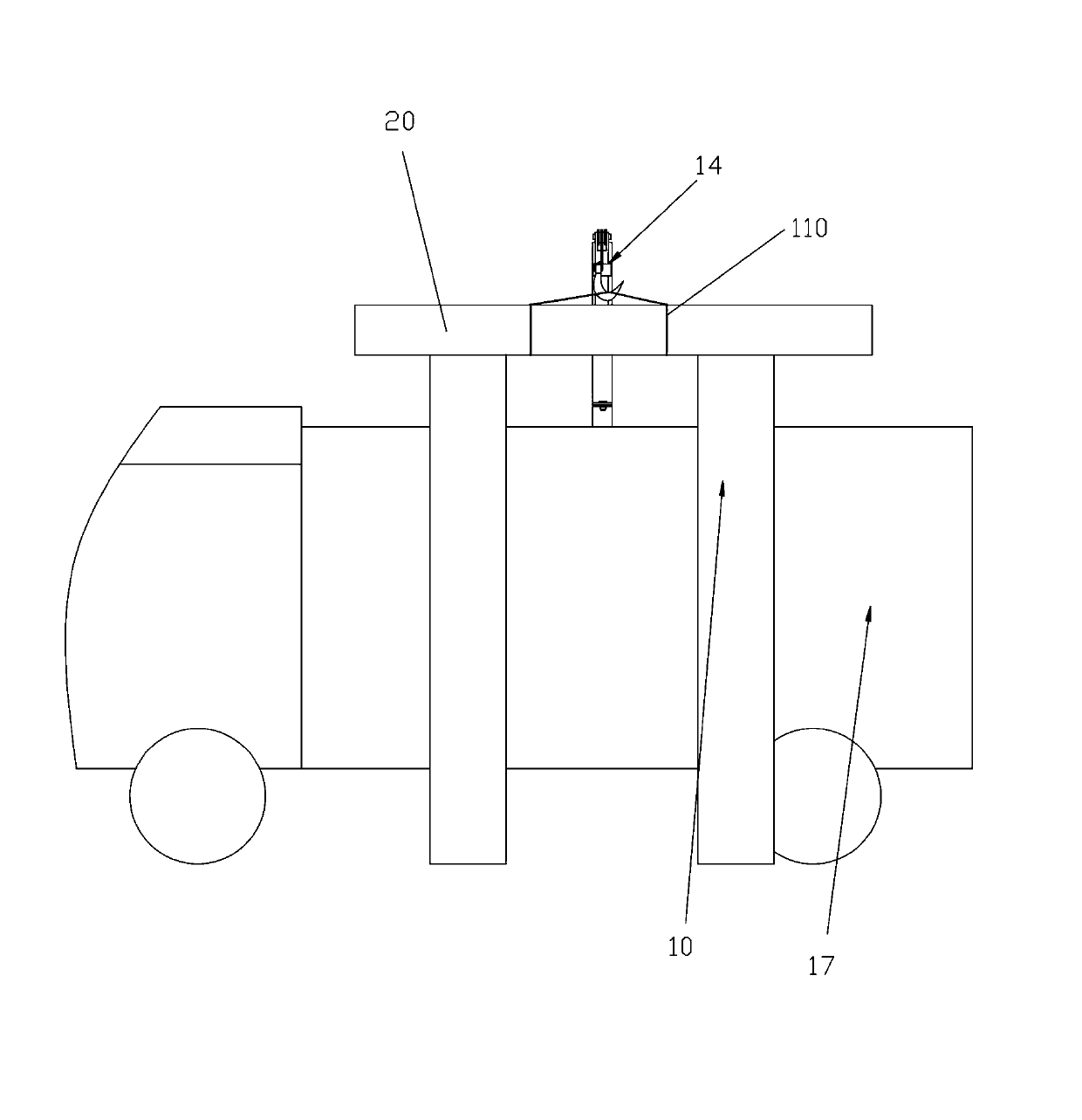

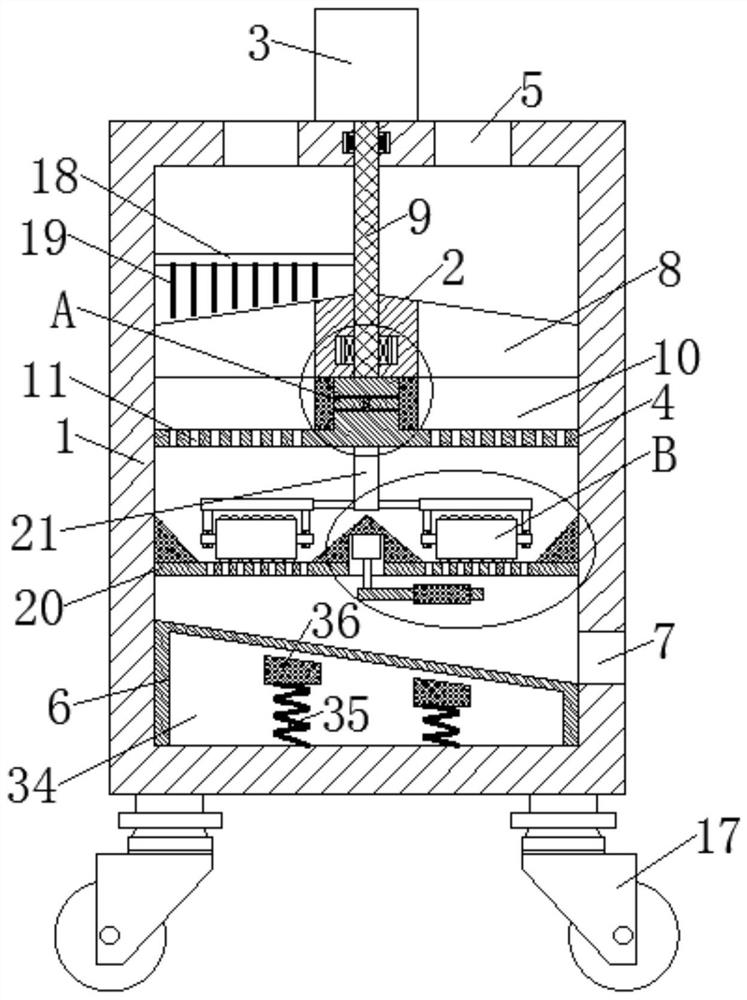

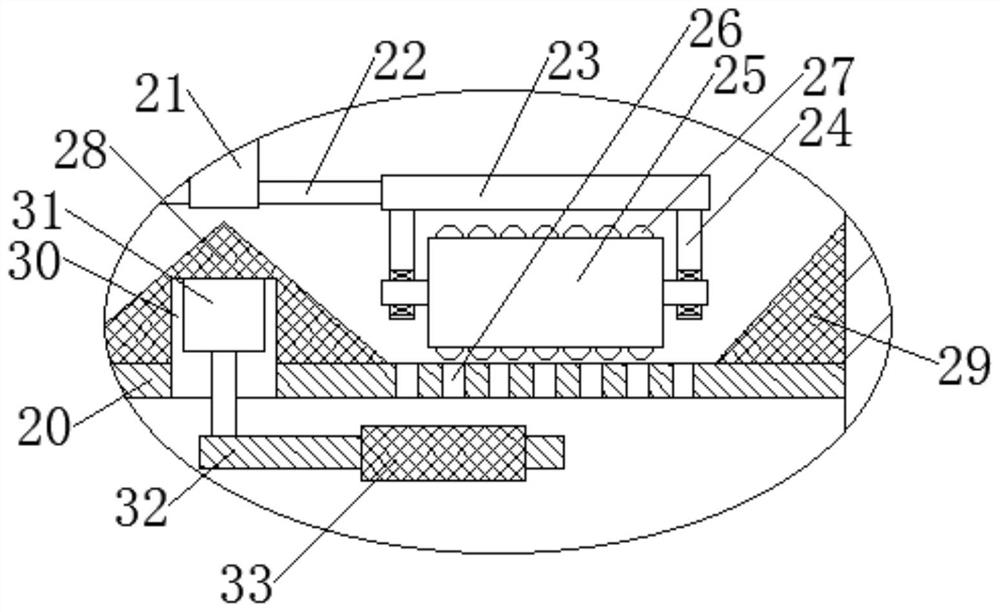

Goods moving device for storage

ActiveCN109532979AChange the damagePlay the role of limiting and preventing fallingSupporting partsHand carts with multiple axesHydraulic cylinderEngineering

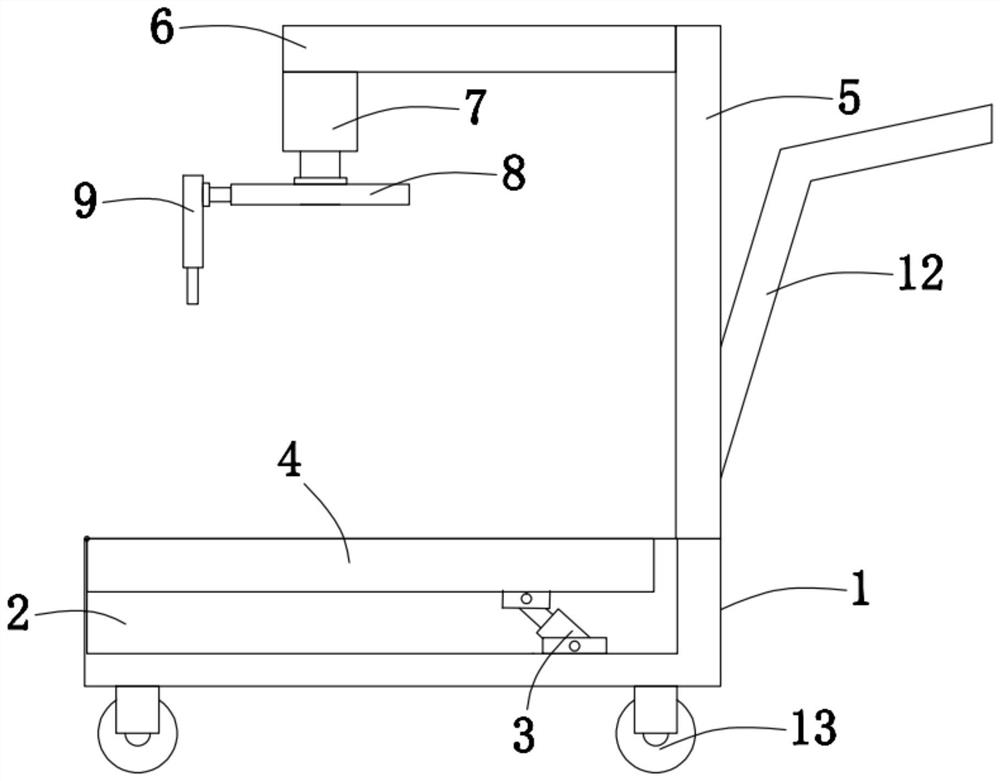

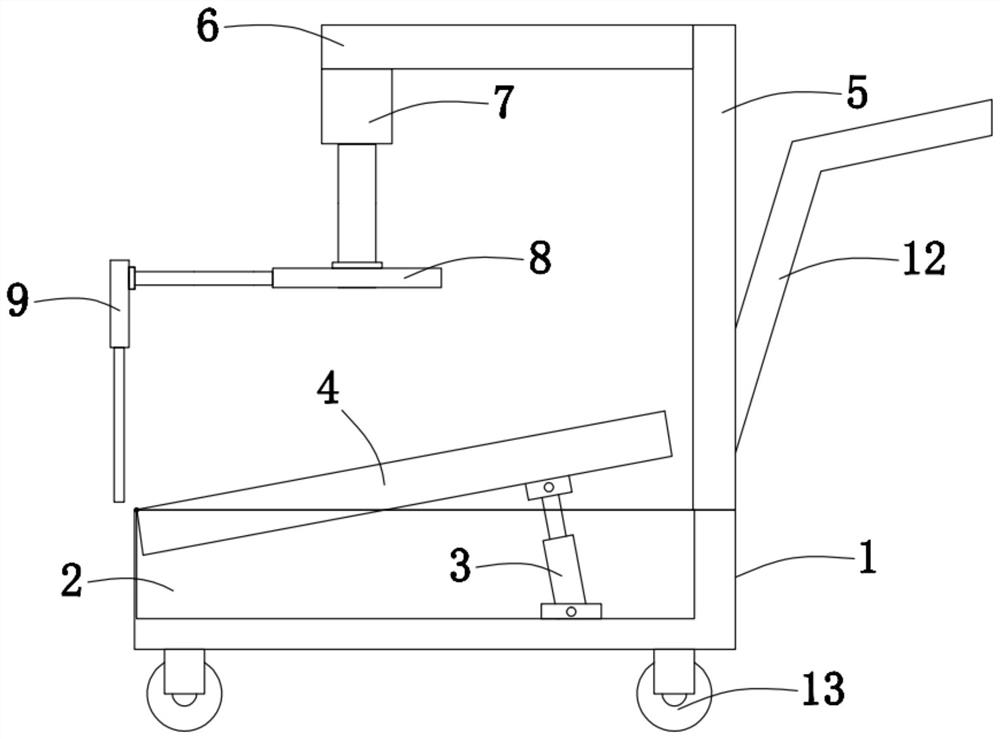

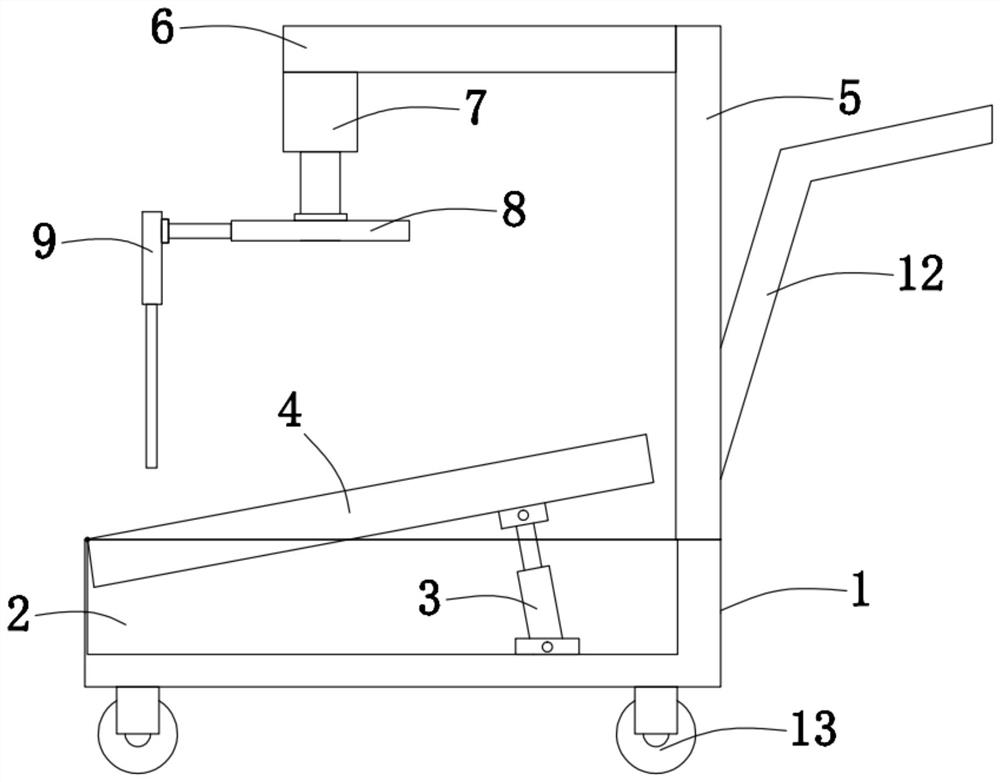

The invention discloses a goods moving device for storage, which comprises a base, wherein a cavity is formed in the upper end of the base, a first hydraulic cylinder is movably connected in the lowerend of the right side of the cavity through a pin shaft, the output end of the first hydraulic cylinder is pin-connected with a supporting seat through a connecting lug, the left side end of the supporting seat moves to the left end of the cavity through the pin shaft, the right side of the upper end of the base is provided with a vertical bracket, the left end of the vertical bracket is connected with a transverse bracket, the output end of a second hydraulic cylinder is provided with a first telescopic device, two sides of one end of the first telescopic device is fixedly connected a secondtelescopic device, the lower end of the opposite side of the second telescopic device on the two sides is hinged with a gear lever, and one end of the first telescopic device is further provided withtwo groups of elastic belts. According to the goods moving device for storage, the device is easy and convenient to use in moving goods in the storage, and the phenomenon that the goods are damaged due to the fact that all the goods are dumped at one time when the traditional transport trolley is unloaded is changed.

Owner:周永俊

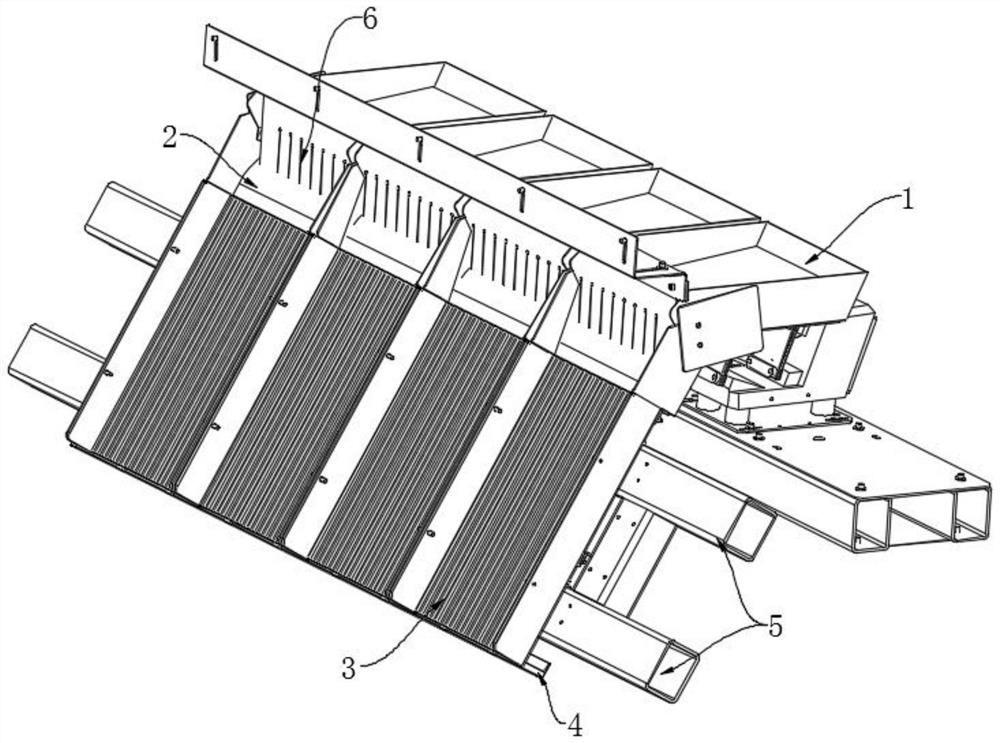

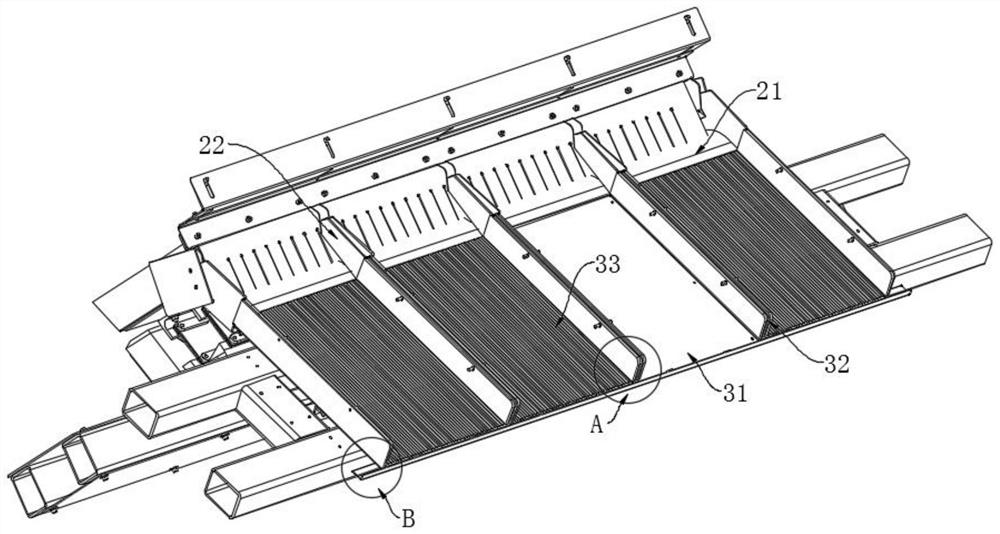

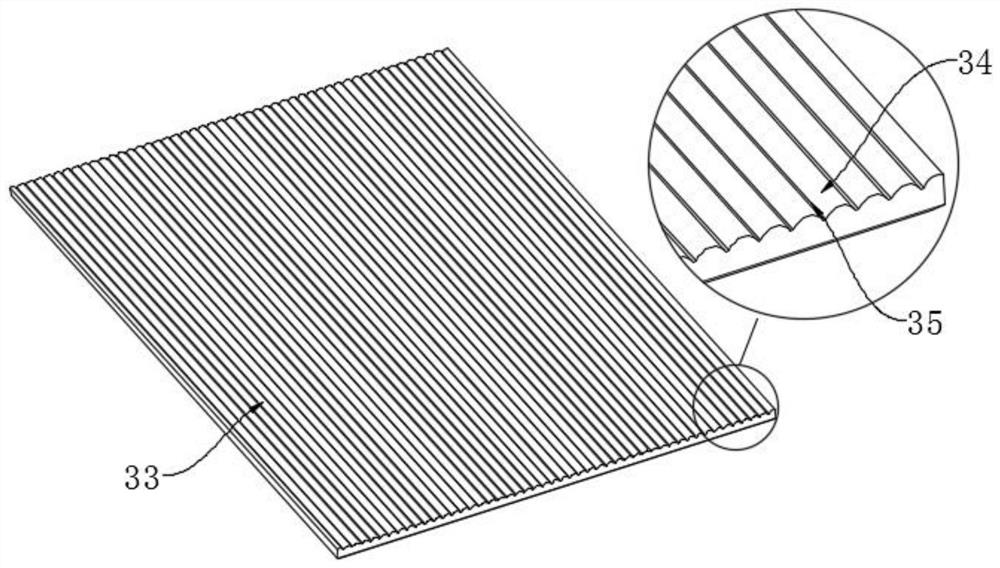

Material conveying device of glass sorting machine

The invention discloses a material conveying device of a glass sorting machine. The material conveying device comprises a vibration disc assembly, a feeding slide way assembly and a material conveying slide way assembly which are sequentially connected, and a flow guide assembly arranged at the discharging end of the material conveying slide way assembly. The material conveying slide way assembly comprises a plurality of slide ways arranged adjacently, each slide way comprises a supporting plate arranged obliquely, material conveying baffles arranged on the two sides of the supporting plate and a glass sliding plate fixed to the plate face of the supporting plate, and the glass sliding plates are matched with the supporting plates in size. The surface of the glass sliding plate is of a corrugated structure, and a water flow channel is formed between every two adjacent arc-shaped protruding parts. The arc-shaped protruding parts on the surfaces of the glass sliding plates enable the traditional surface contact between the glass and the plate surface to be changed into point contact, so that the adsorption force between the glass and the plate surface is reduced, and the glass can smoothly slide down from the glass slideway; and meanwhile, the plate surface made of the glass material has the characteristics of strong sliding guiding performance, difficulty in abrasion and strong durability.

Owner:ANHUI VISION OPTOELECTRONICS TECH

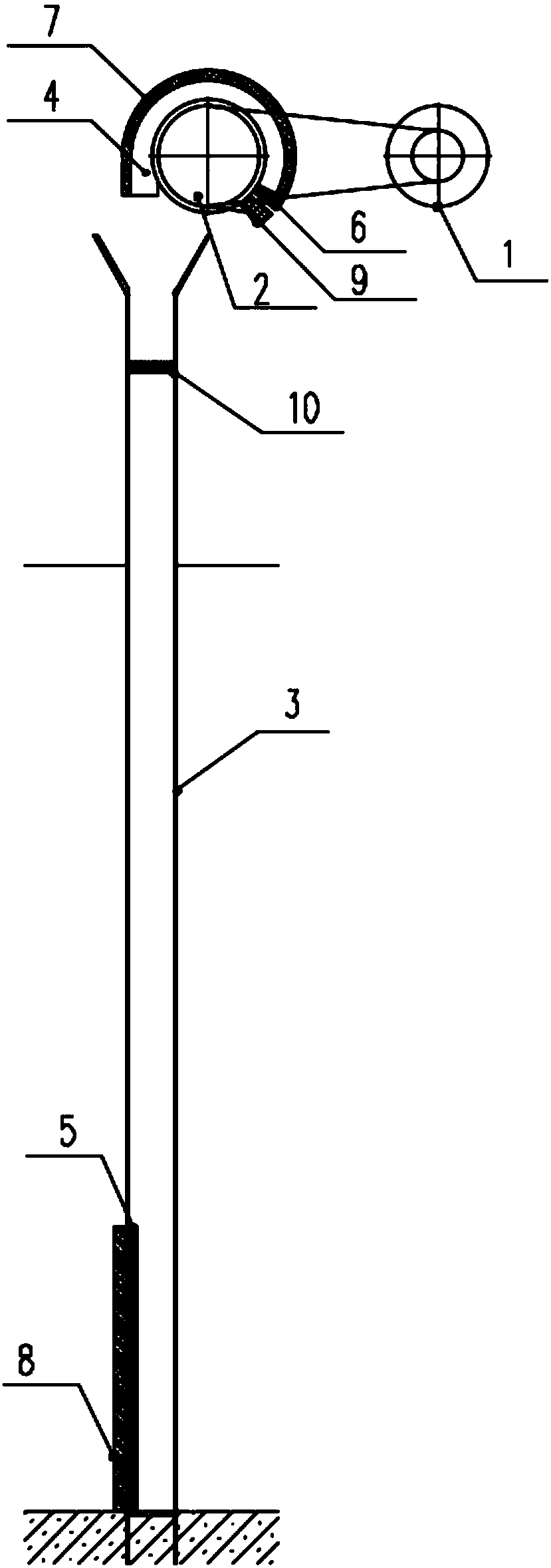

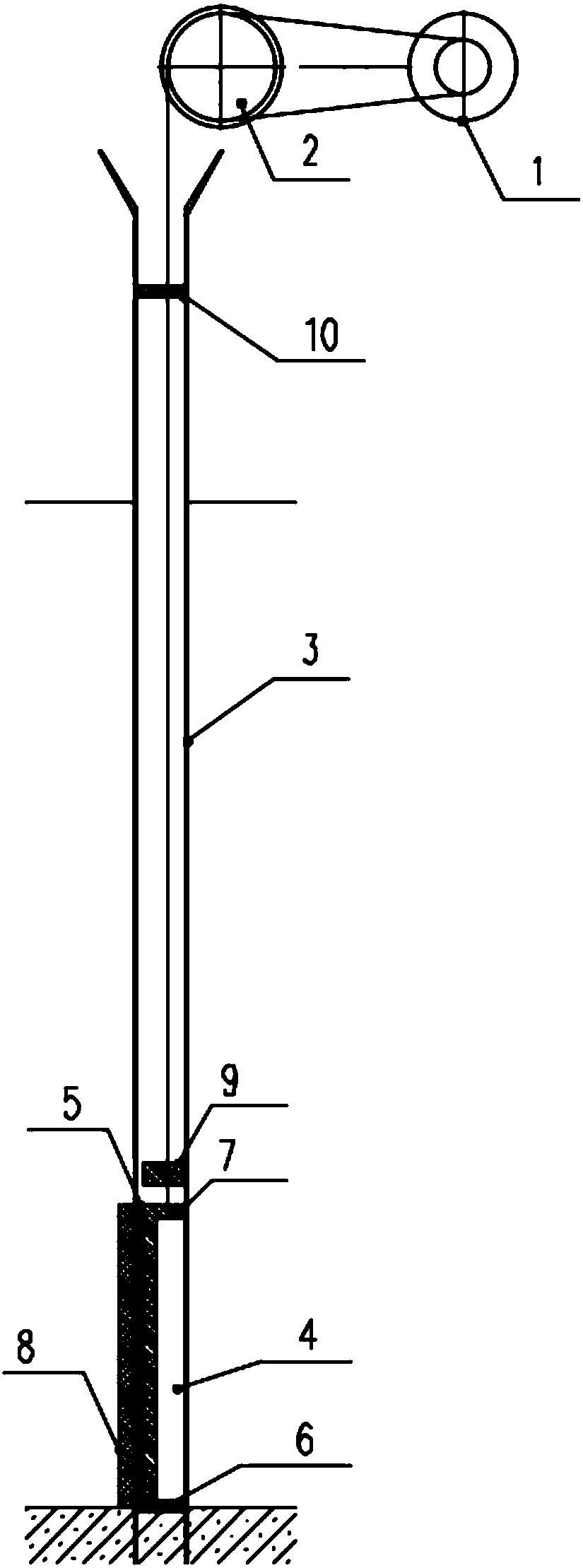

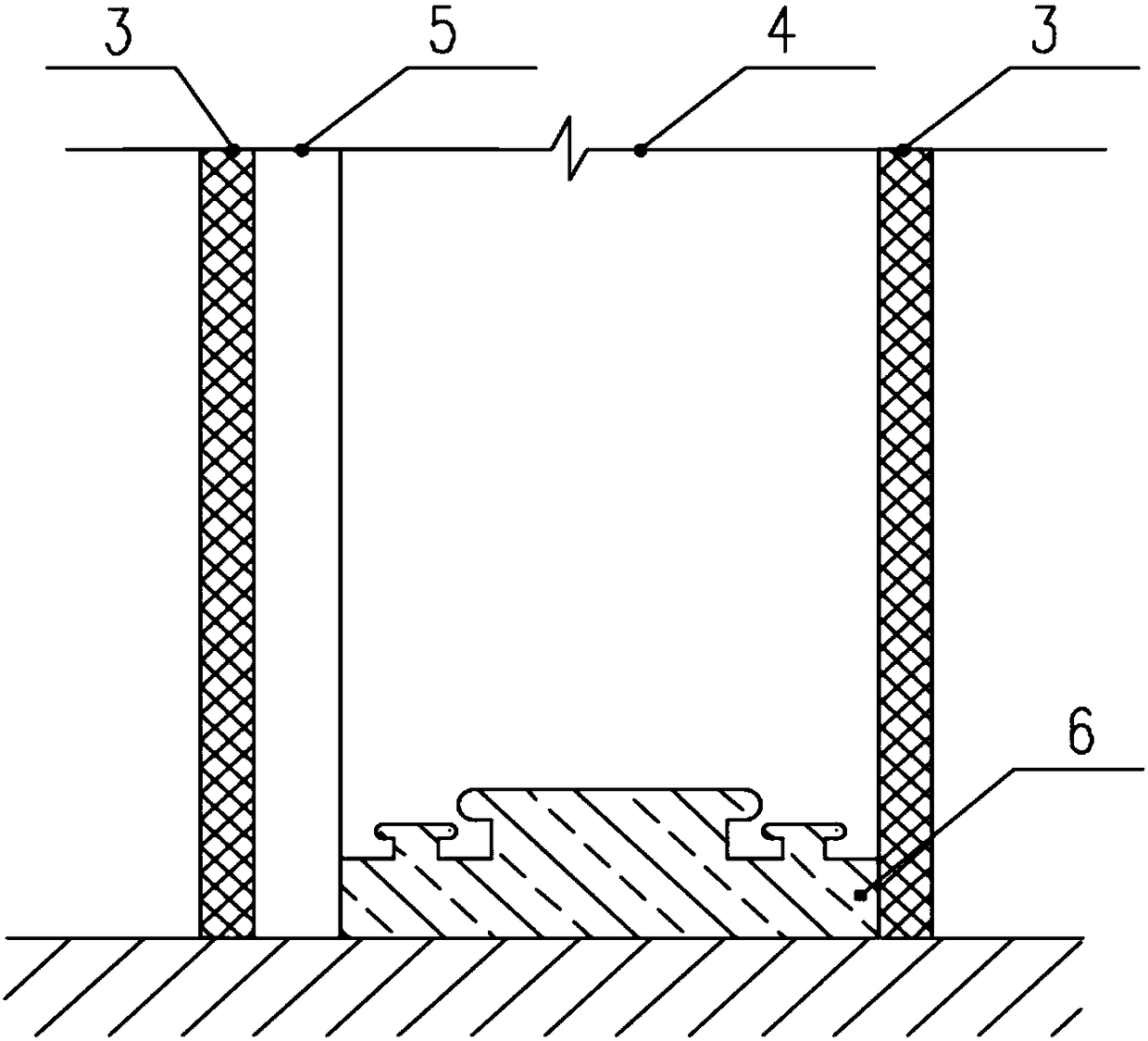

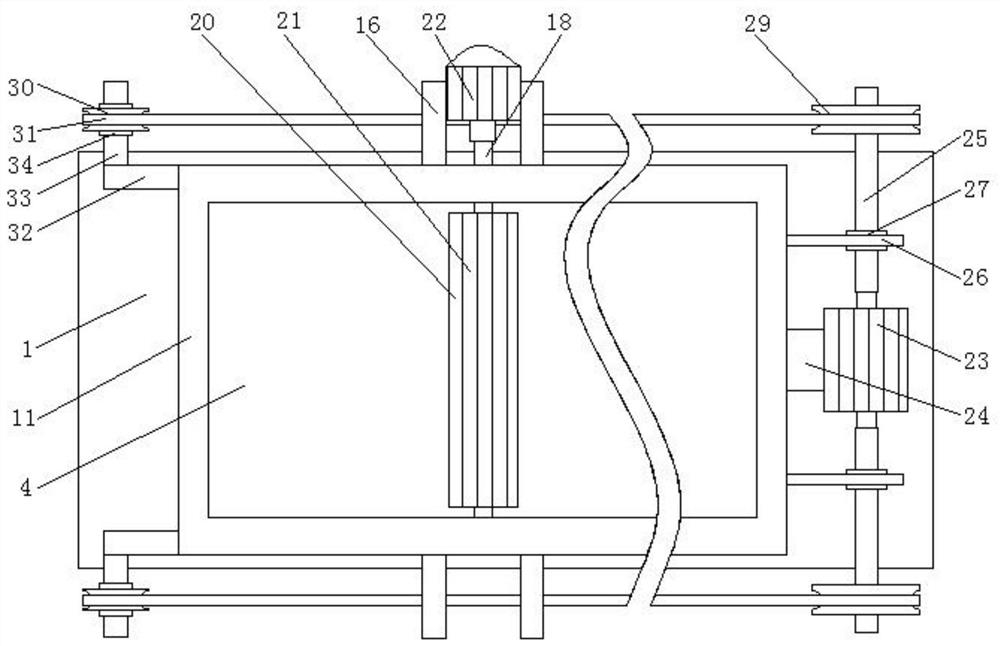

Magnetic-extruding-type automatic lifting flood-proofing baffle system and building waterproofing method

PendingCN108397116AStrong sealingImprove resilience to flood damageFlood panelsPower-operated mechanismAutomatic controlWaterproofing

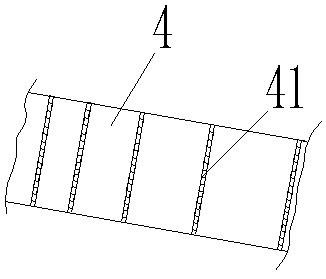

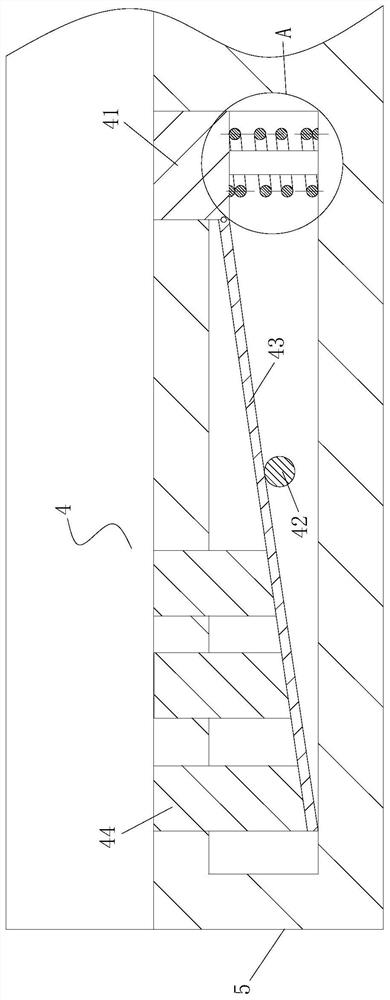

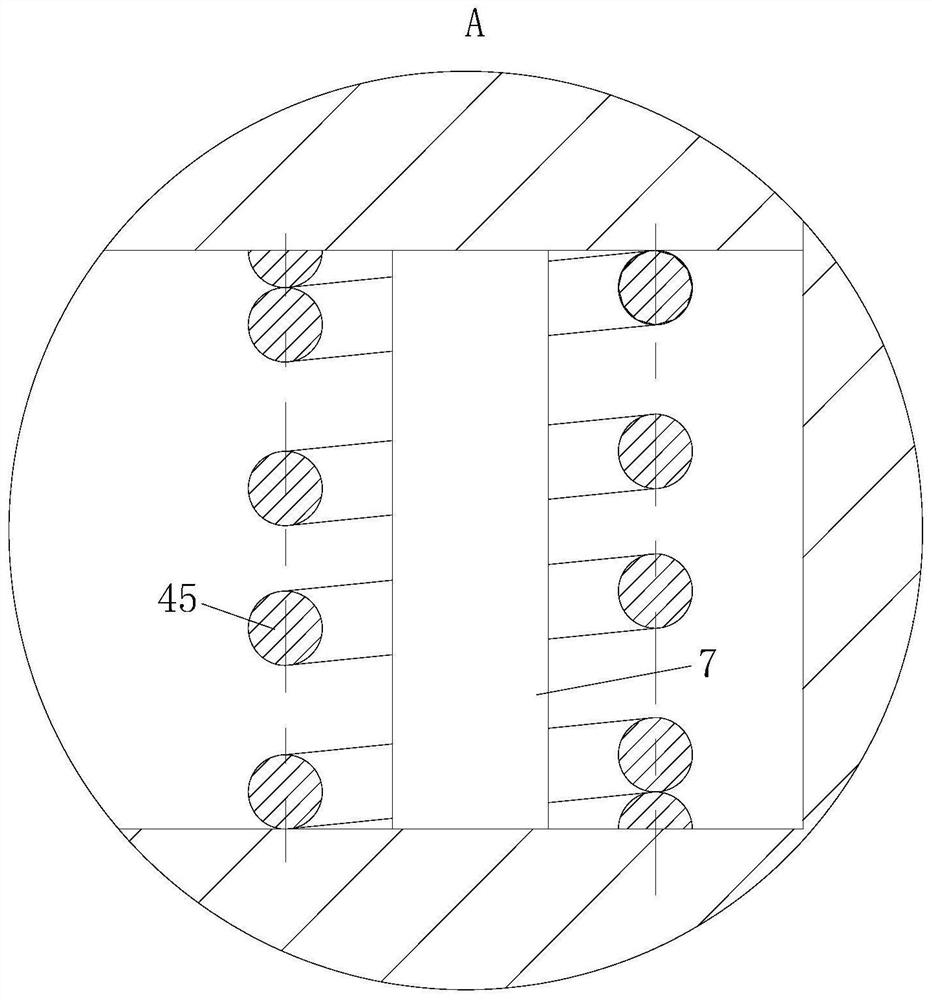

The invention discloses a magnetic extruding type automatic lifting flood-proofing baffle system, and further discloses a building waterproofing method. the magnetic extruding type automatic lifting flood-proofing baffle system comprises a motor (1), a sliding channel (3), a rope chain, a flood-proofing baffle (4) and a coiling drum assembly (2), and further comprises a control center, a series-connection electromagnetic strip (9), a sliding channel electromagnetic strip (8), a baffle electromagnetic strip (7) and a water level detecting device; the control center is connected with the series-connection electromagnetic strip (9), the sliding channel electromagnetic strip (8), the baffle electromagnetic strip (7), the motor (1) and the water level detecting device; the baffle electromagnetic strip (7) is arranged on the outer side of the flood-proofing baffle (4), the series-connection electromagnetic strip (9) is arranged on the top face of the flood-proofing baffle (4), and the series-connection electromagnetic strip (9) and the baffle electromagnetic strip (7) are the same in magnetic pole; and the sliding channel electromagnetic strip (8) is vertically arranged on the outer sideof the sliding channel (3). According to the magnetic extruding type automatic lifting flood-proofing baffle system, the baffle can be automatically controlled to fall to realize waterproofing without slotting, and sealing is good.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Hanger for metal pipe and vehicle with hanger

The invention relates to a hanger for a metal pipe (such as a stainless steel pipe and an aluminum alloy pipe) and a vehicle with the hanger. The vehicle comprises a compartment and the hanger which is installed on the side wall of the compartment, wherein the hanger comprises a hoisting machine, the hoisting machine comprises a fixed rod which is arranged on one side wall of the compartment, a rotary rack which is arranged on the fixed rod and a drive mechanism which is arranged on the bottom of the compartment, the lower end of the fixed rod is provided with four clamping feet, the hanger also comprises two slide rails, each slide rail comprises an oblique panel, a loading fastener and an unloading fastener, the lower side of the bottom surface of the oblique panel is movably provided with a first clamping hook and a second clamping hook, and the compartment is provided with limiting grooves which are matched with the first clamping hook and the second clamping hook for use. The compartment is provided with the hanger, so that the working personnel can be reduced, and the labor cost can be reduced. The workload of the working personnel can be alleviated, and the labor intensity can be alleviated. The loading and unloading time can be shortened, and the working efficiency can be greatly increased.

Owner:GOOMAX METEL CO LTD FUJIAN

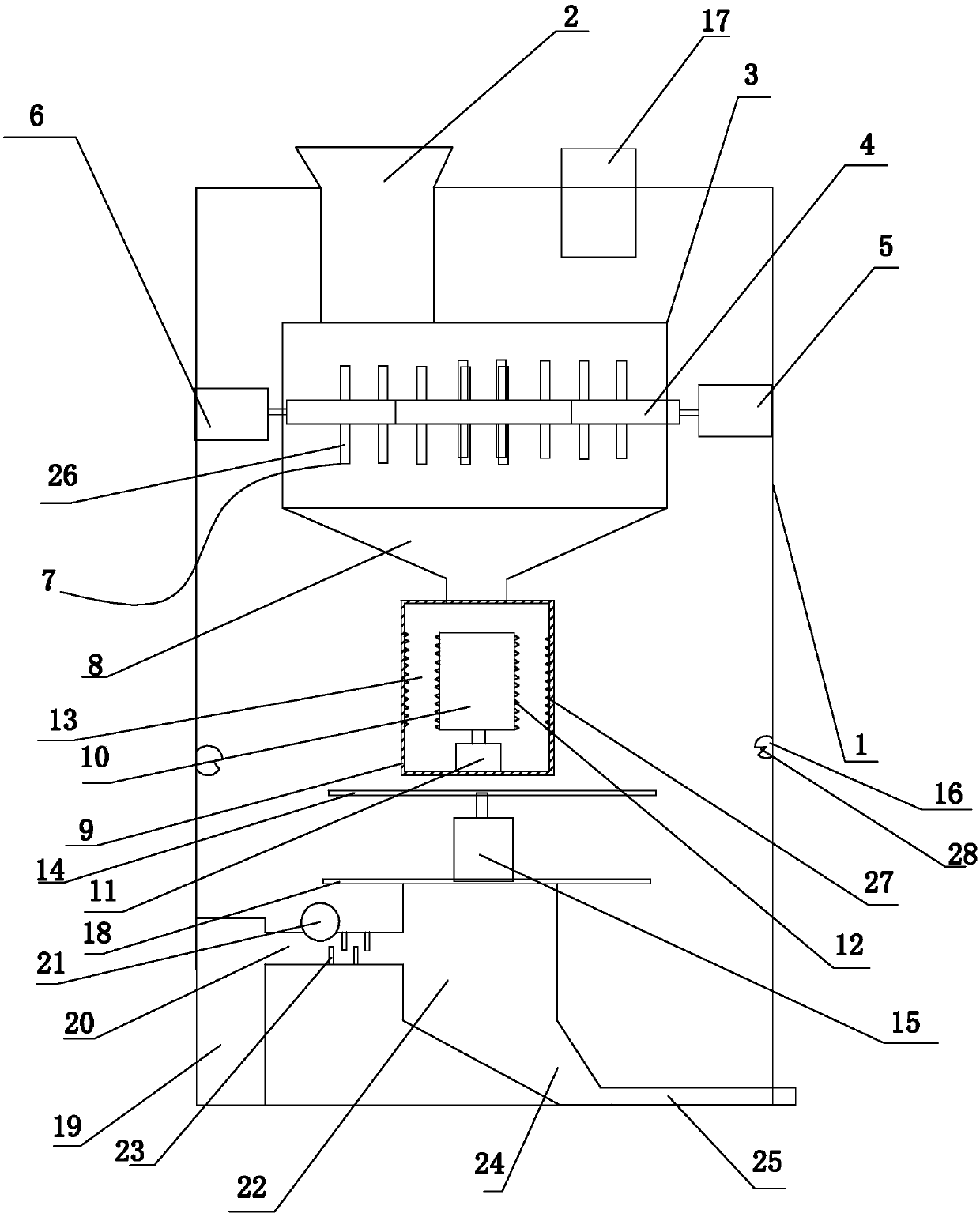

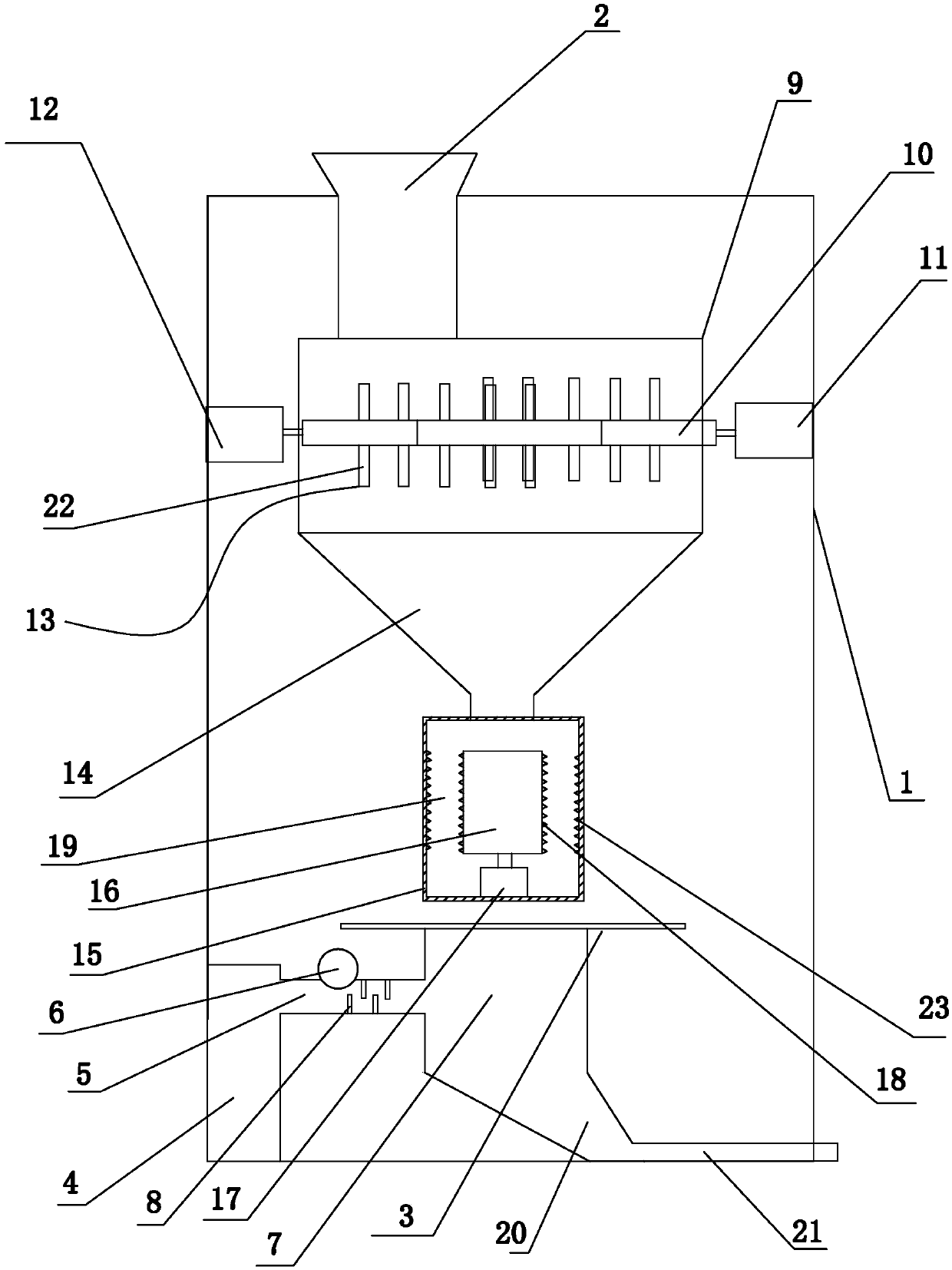

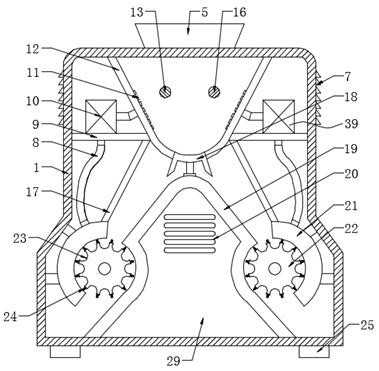

Raw material processing device for activated carbon production

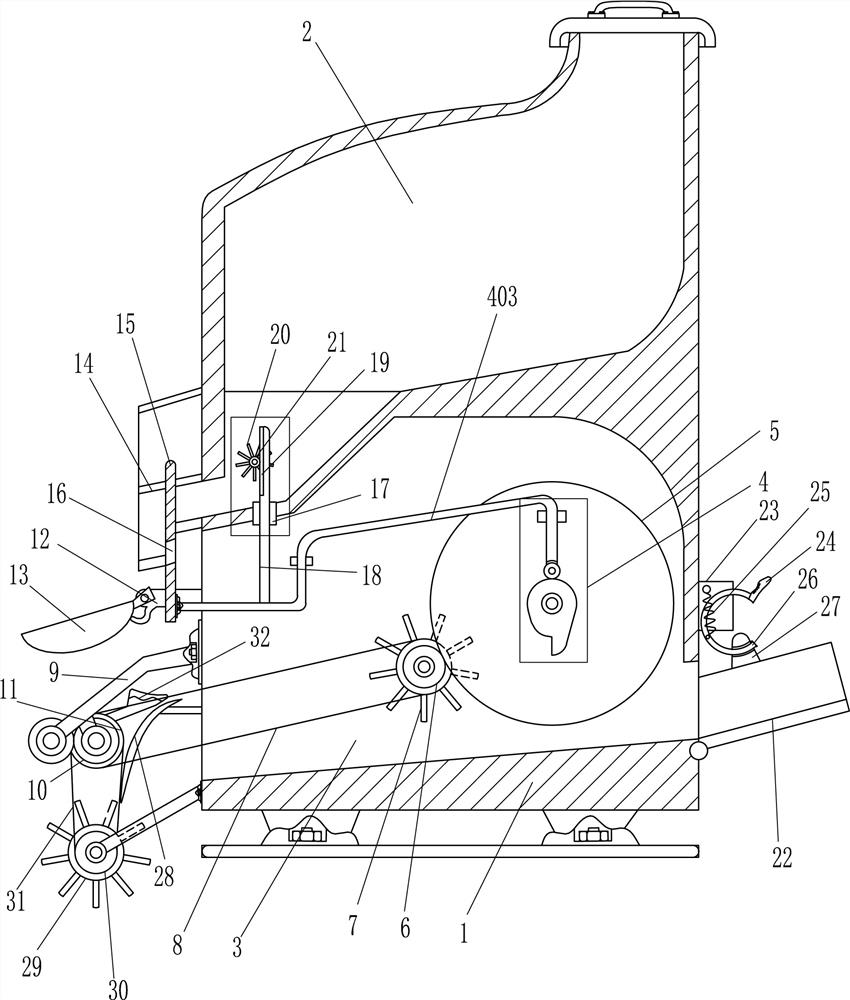

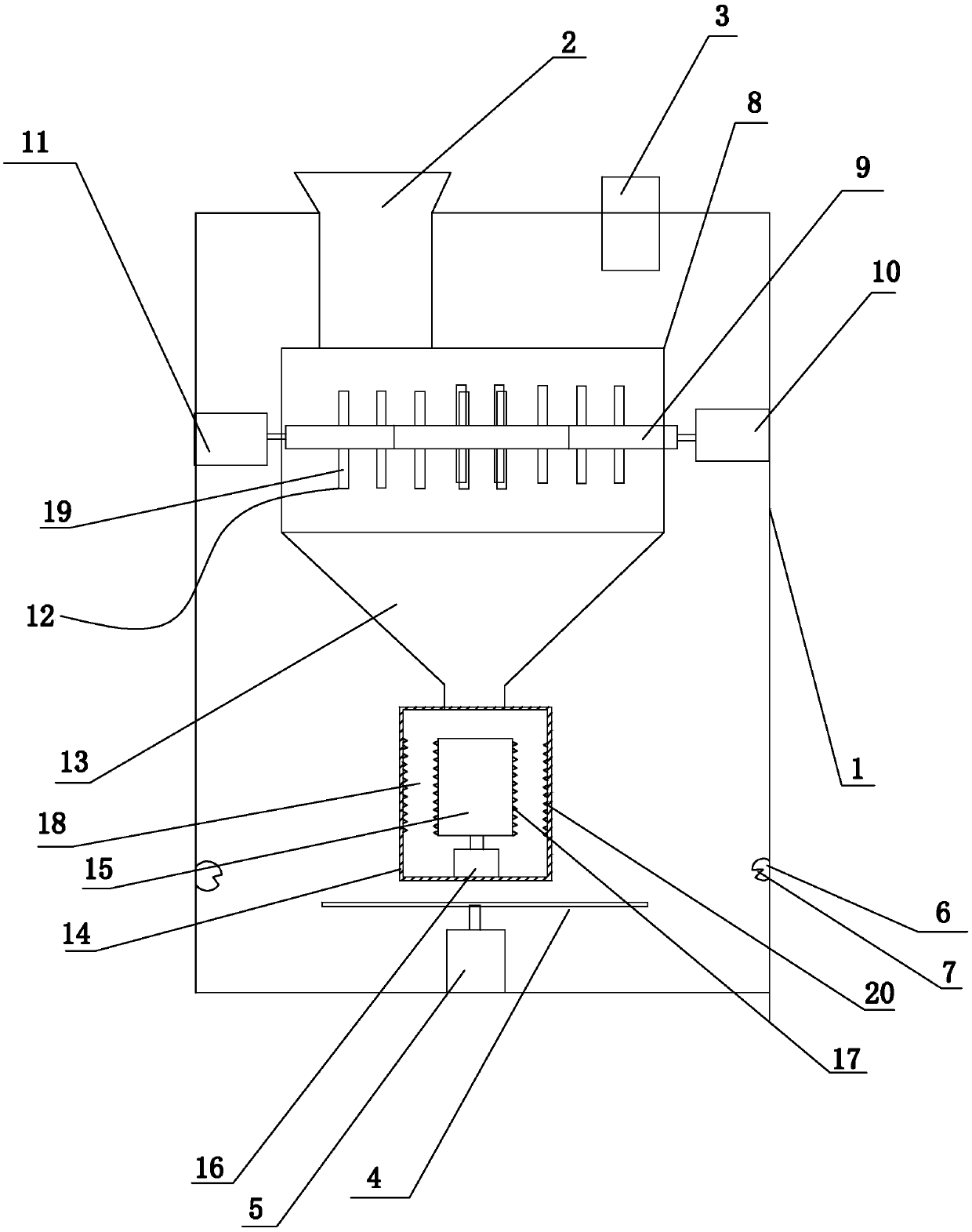

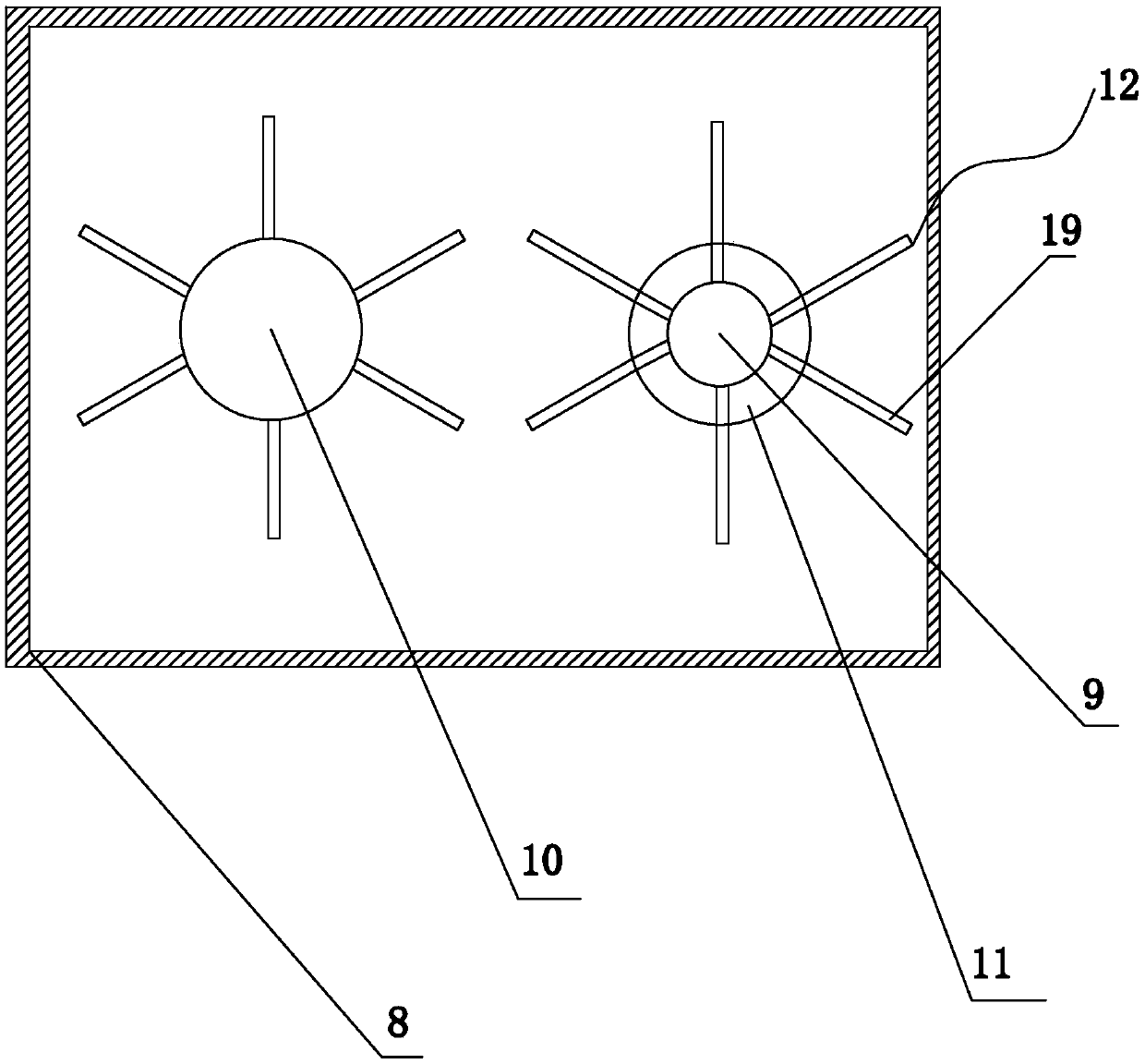

InactiveCN109622195ASmash thoroughlyImprove crushing efficiencyDirt cleaningGrain treatmentsActivated carbonEngineering

The invention discloses a raw material processing device for activated carbon production. The device comprises a machine frame (1), wherein a feeding channel (2) is formed in the machine frame (1), and an upper layer crushing mechanism, a lower layer crushing mechanism, a drying mechanism and a dust removal mechanism are sequentially arranged from top to bottom in the machine frame (1), wherein the upper layer crushing mechanism is used for crushing activated carbon raw materials, and the lower layer crushing mechanism is used for crushing the activated carbon raw materials. According to the device, the structure is simple, the crushing efficiency is high, dust impurities on the activated carbon raw materials can be effectively removed, and the crushing and drying processes can be carriedout in the same equipment.

Owner:宁波越茂活性炭有限公司

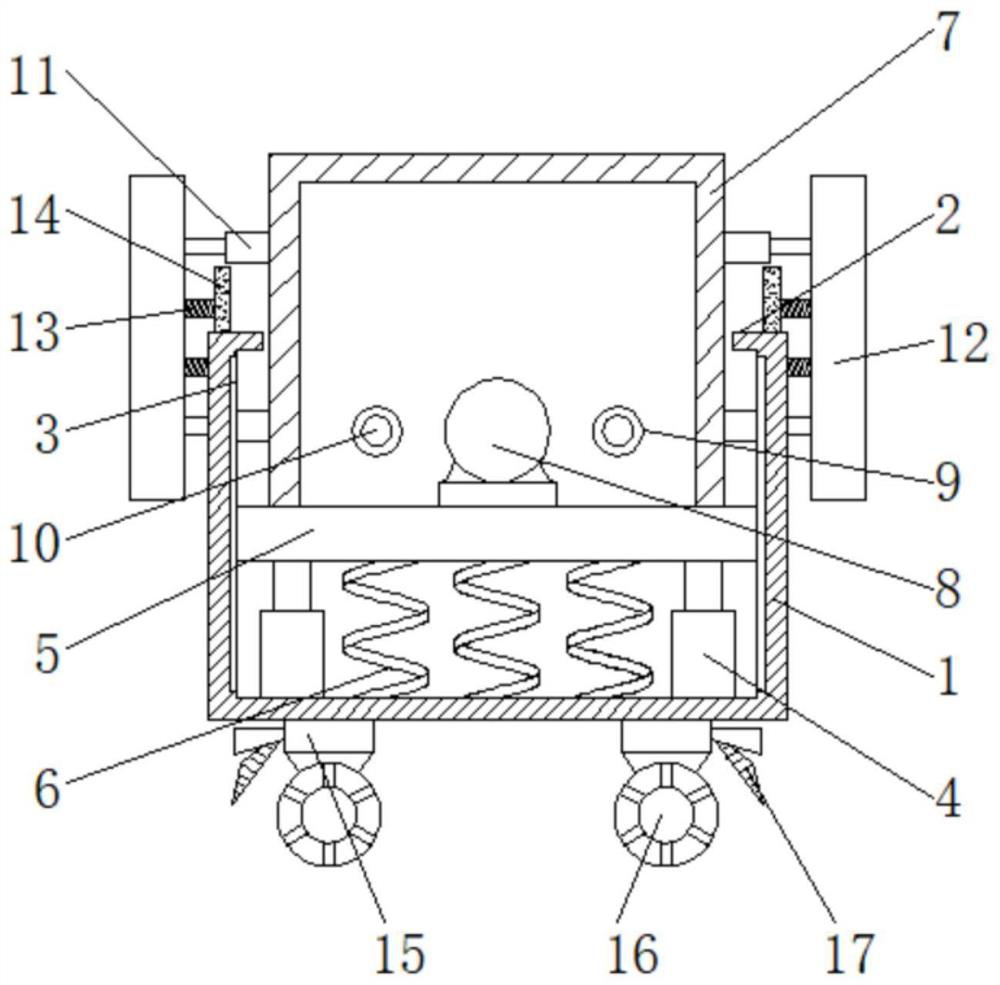

Moving auxiliary device for mounting electromechanical equipment

InactiveCN112178423AEffective clampingReduce extrusion deformationMeasurement devicesStands/trestlesStructural engineeringMechanical engineering

Owner:广州鼎奥科技有限公司

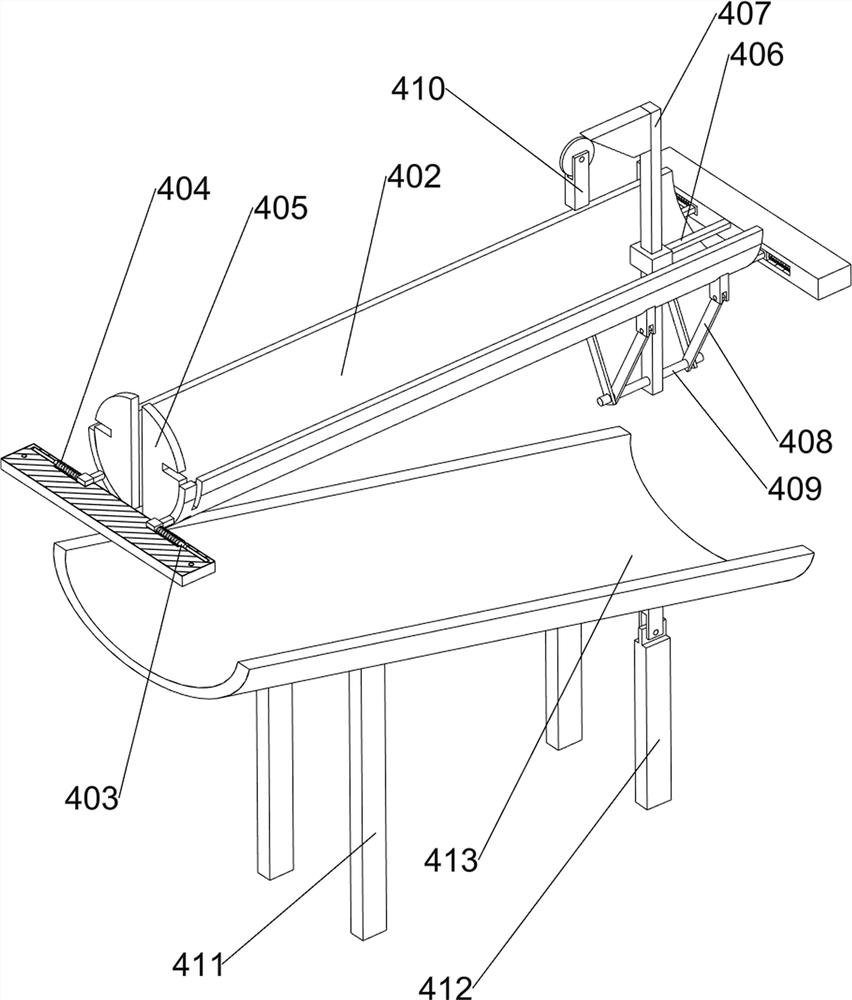

Sliding-board-type automatic cake panning machine

The invention relates to a sliding-board-type automatic cake panning machine. The machine comprises a working table, a baking pan, a cake shoveling mechanism, a portal frame, a cake spreading assembly, a cleaning mechanism, a cake shoveling mechanism and a cake stacking mechanism. The baking pan is hinged to the middle of the upper end of the working table, the cake shoveling mechanisms are installed on racks of the two sides of the backing pan, and the cake stacking mechanism is hinged to the working table of the vertical side of the baking pan in the horizontal direction; the portal frame which crosses the baking pan is fixedly installed at the upper end of the working table, and the cake spreading assembly is in driving installation on the portal frame and can horizontally move along the portal frame in the horizontal direction; the cleaning mechanism is installed on the working table below the portable frame of the horizontal side of the caking pan in the horizontal direction. Themaking device achieves full-closed and full-automatic processing and cannot be influenced by external environments such as blowing and raining, the hygiene of food materials is guaranteed, and the food safety is guaranteed; most importantly, since machine operation is not influenced by individual difference of operators, the taste is uniformly controlled by a program, and it is guaranteed that each piece of Chinese hamburger is delicious in taste.

Owner:马士通安全设备(天津)有限公司

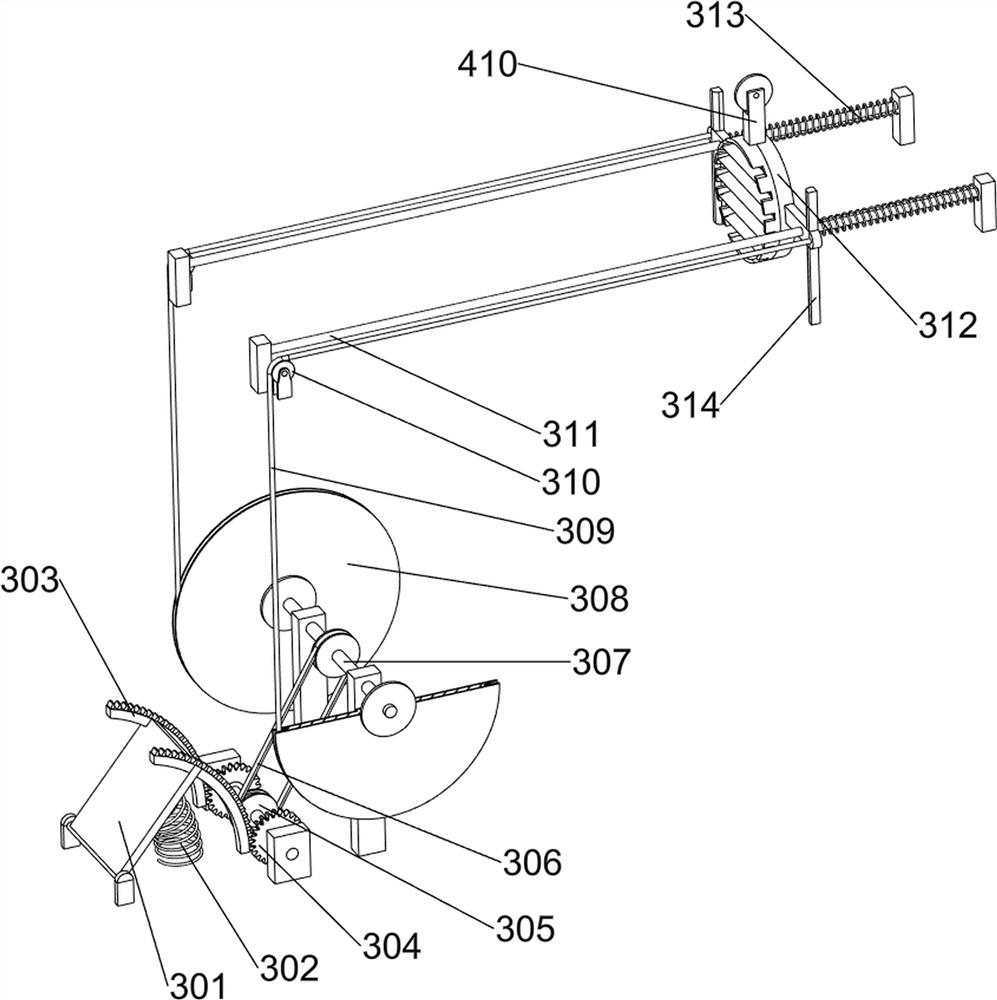

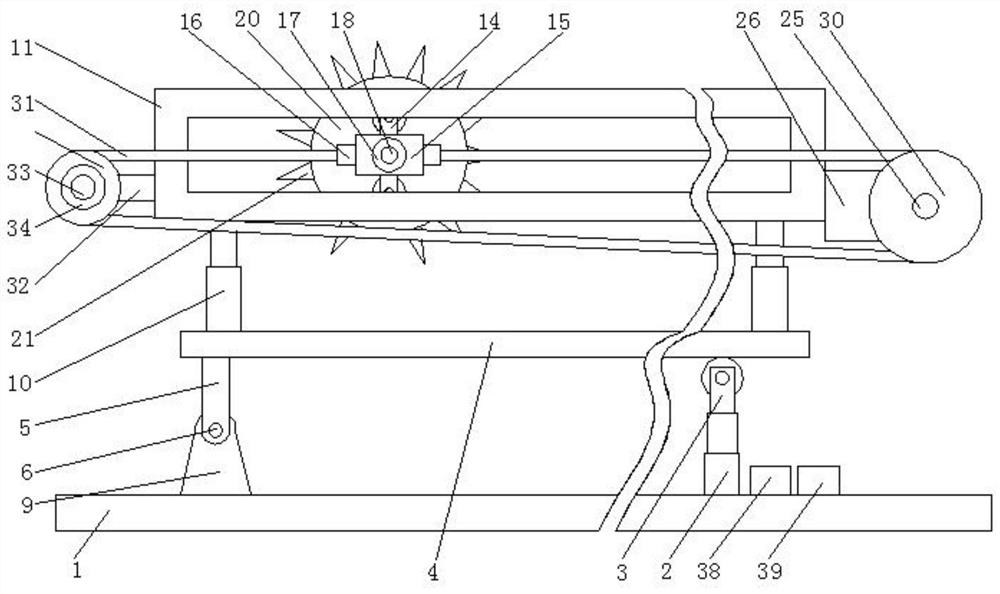

Radish slitting equipment for food processing

InactiveCN112549142AGuaranteed separation effectSave human effortMetal working apparatusIndustrial engineeringFood processing

The invention relates to slitting equipment, in particular to radish slitting equipment for food processing. According to the radish slitting equipment for food processing, radish slitting can be conducted automatically and efficiently, and conveying and collecting are convenient. According to the technical scheme, the radish slitting equipment for the food processing comprises a base, and first supporting frames are arranged on the two sides of the upper portion of the base; a driving assembly arranged on one side of the base; a cutting assembly arranged between the upper sides of the first supporting frames on the two sides; a blanking assembly arranged between the upper sides of the first supporting frames on the two sides; and a discharging assembly arranged in the middle of the upperside of the base. According to the radish slitting equipment for food processing provided by the invention, by treading a pedal, first pull ropes on the front side and the rear side are driven to movedownwards, a cutter is driven to move rightwards, and meanwhile push rods on the left side and the right side are driven to move rightwards.

Owner:陈源

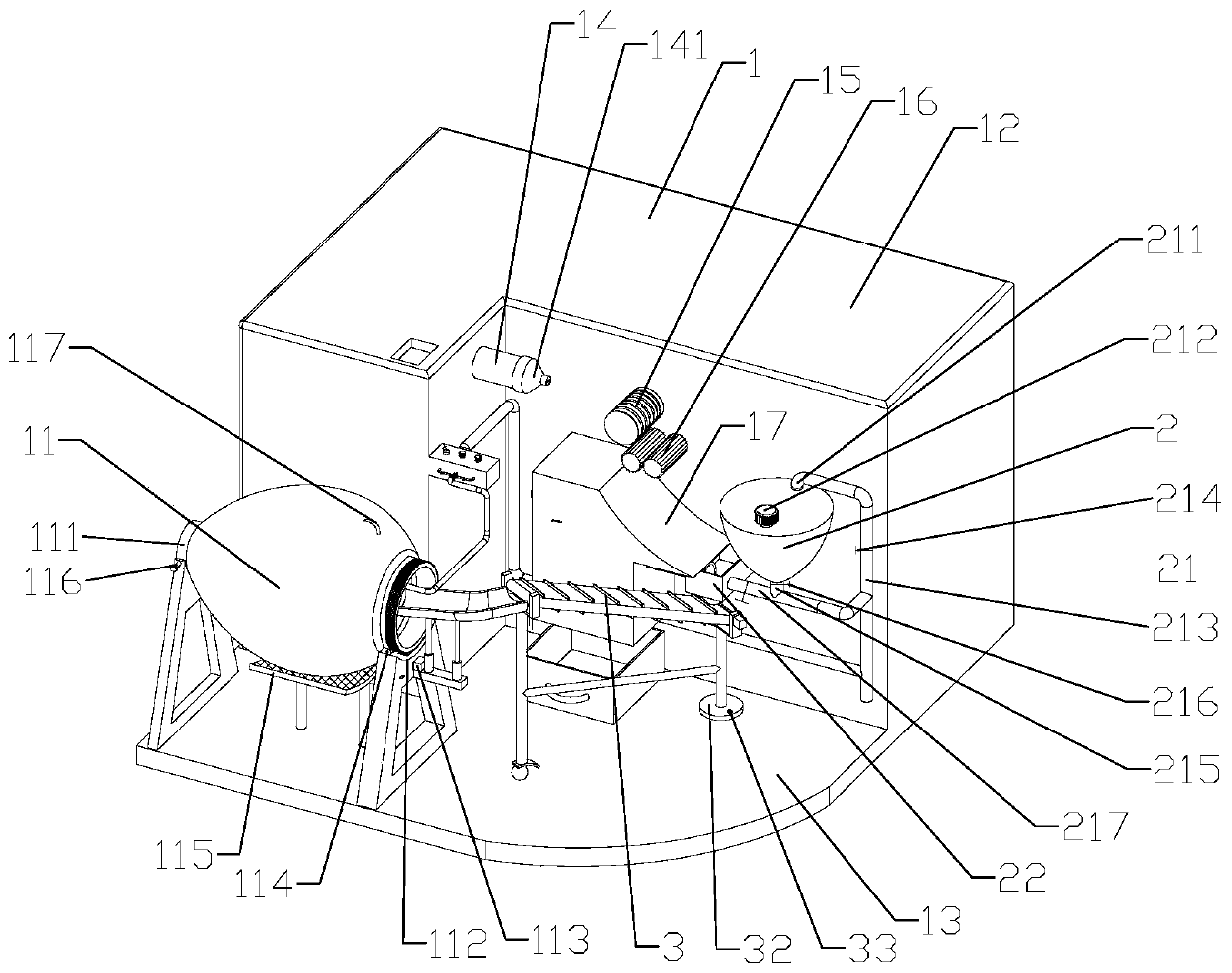

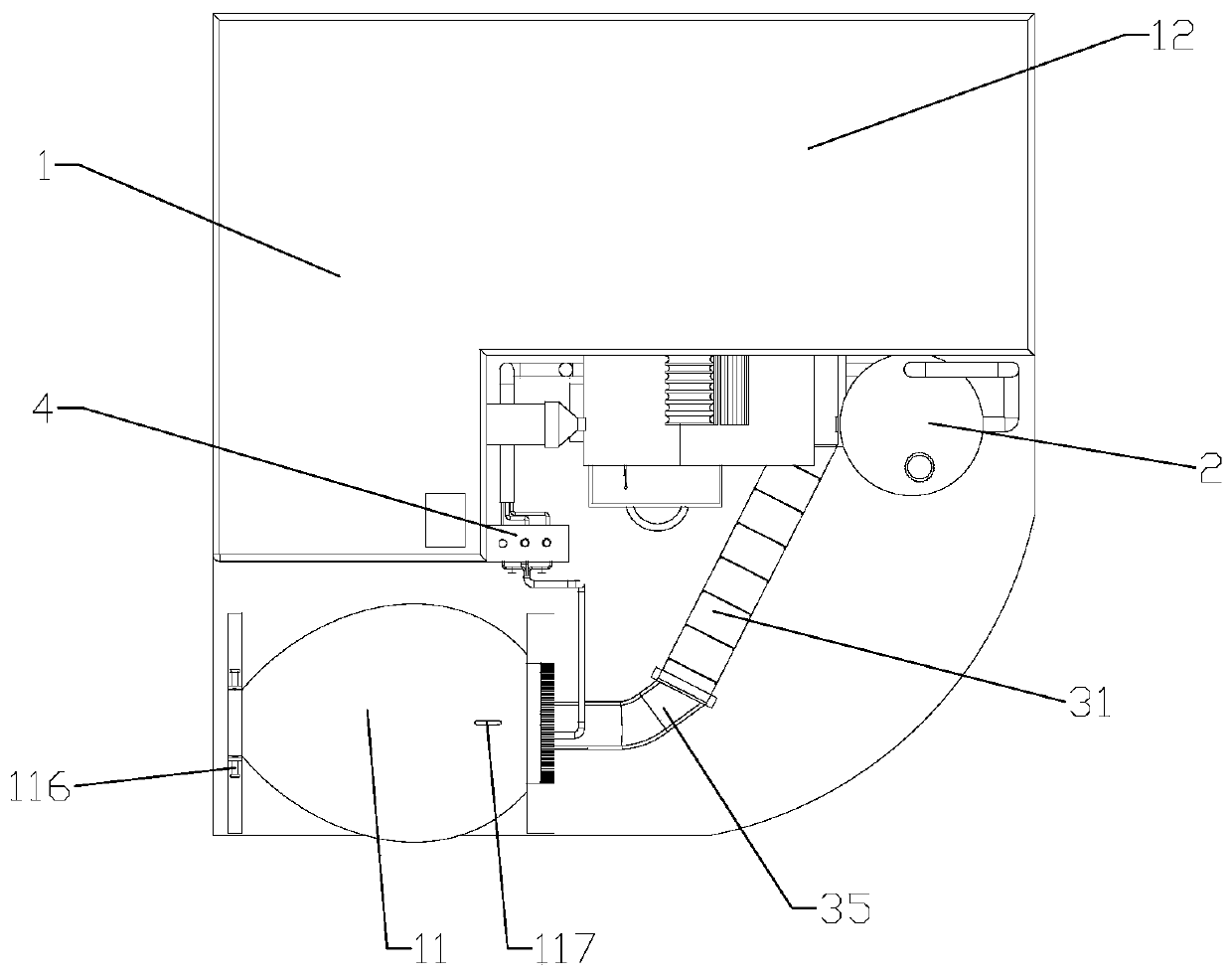

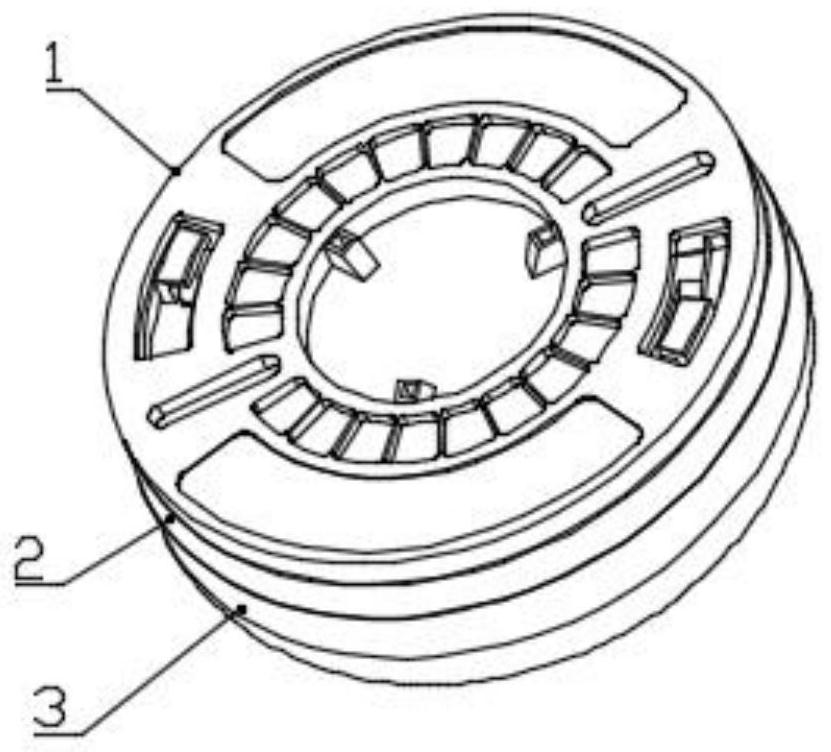

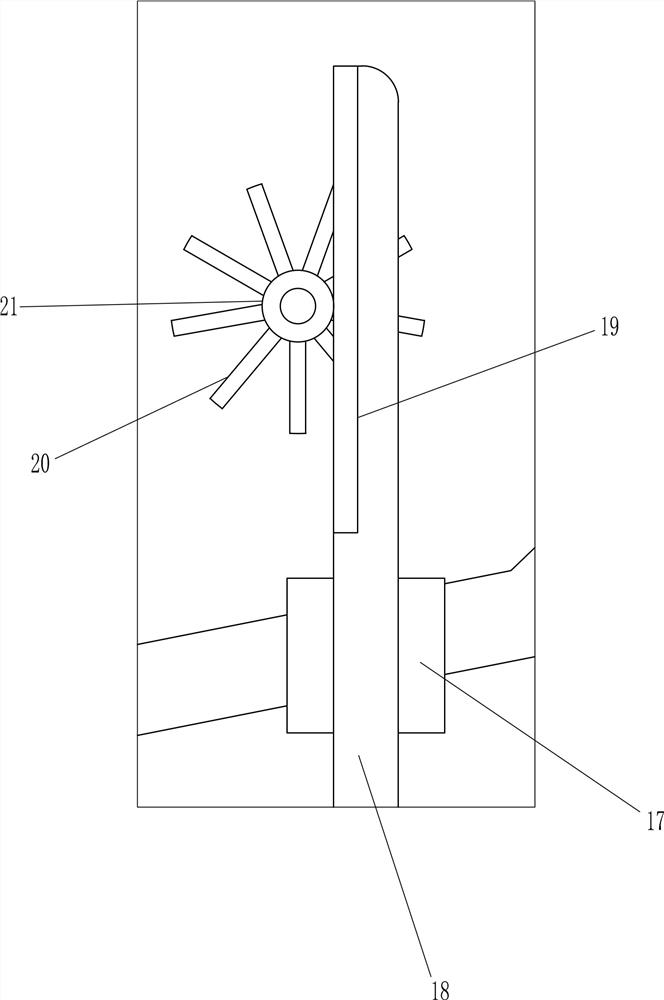

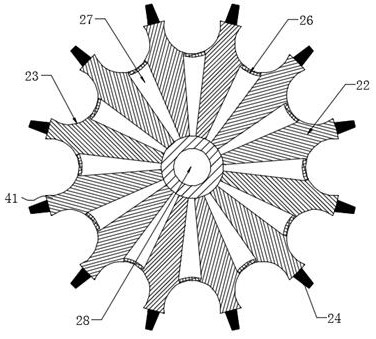

Full-automatic pill making machine

PendingCN109730930AWon't stickDusting effect is goodPharmaceutical product form changeEngineeringMaterial supply

The invention discloses a full-automatic pill making machine. The pill making machine comprises a pill making machine body and a coating machine pot body, wherein the pill making machine body comprises a machine main body, a base, a strip extruding outlet, a transition wheel and a pill extruding roller. The full-automatic pill making machine further comprises a powder spreading device, a pill conveying mechanism and a polishing and drying assisting device; the powder spreading device is used for coating the surface of just-prepared pills with powder; the pill conveying mechanism is used for conveying the coated pills into the coating machine pot body; the polishing and drying assisting device is used for material supply for coloring, polishing and drying of the pills in the coating machinepot body. The full-automatic pill making machine can achieve automatic powder spreading, powder collecting and automatic conveying and assist a coating machine in polishing and drying the pills.

Owner:潍坊鑫起机械科技有限公司

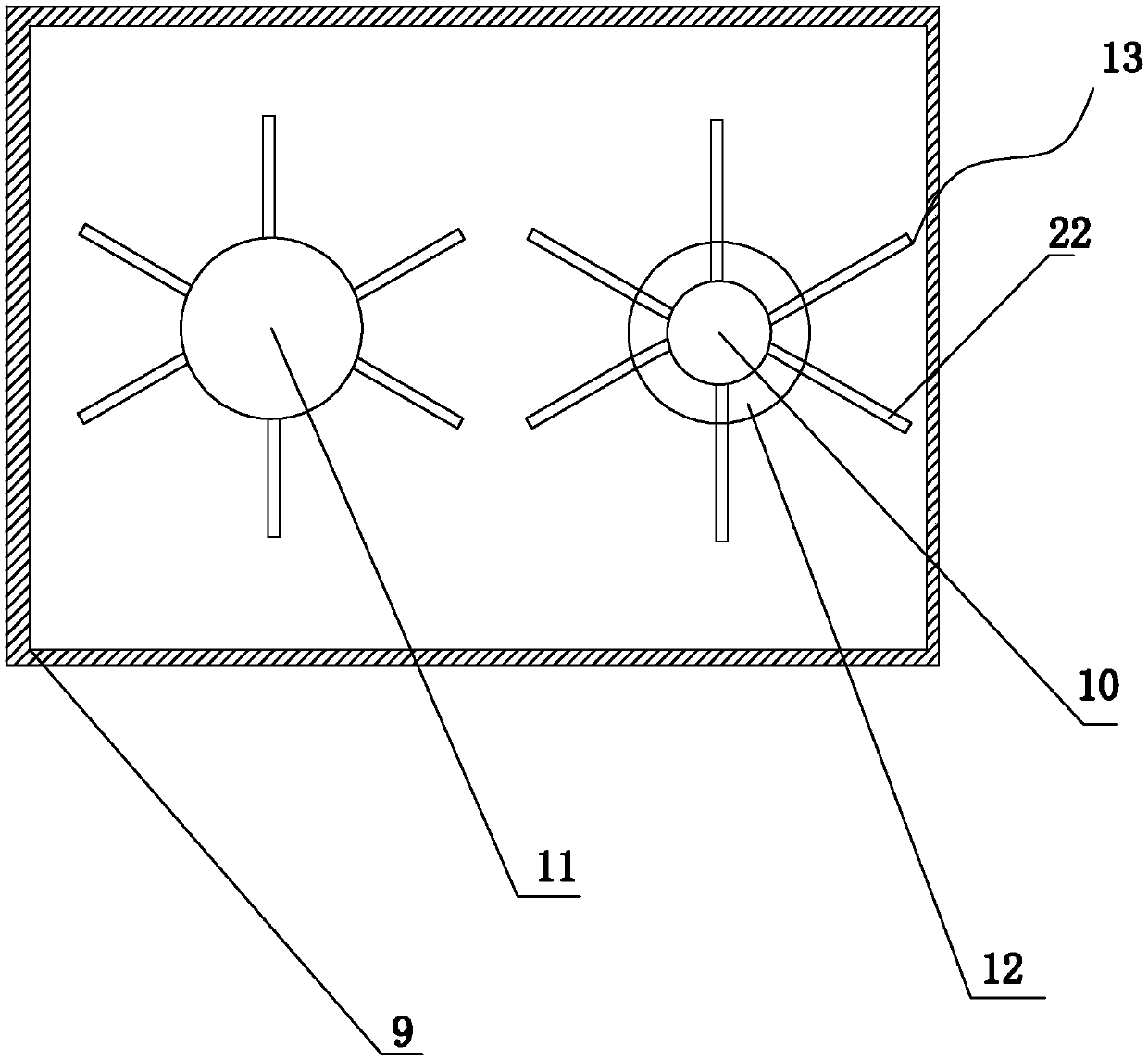

Activated carbon crushing device with dust removal function

InactiveCN109622196AAvoid enteringImprove crushing efficiencyDirt cleaningGrain treatmentsActivated carbonEngineering

The invention discloses an activated carbon crushing device with a dust removal function. The device comprises a machine frame (1), wherein a feeding channel (2) is formed in the machine frame (1), anupper layer crushing mechanism, a lower layer crushing mechanism and a dust removal mechanism are sequentially arranged from top to bottom in the machine frame (1), a bearing platform (3) is arrangedbelow the lower crushing mechanism, a plurality of through holes are formed in the bearing platform, the dust removal mechanism comprises a dust collection cabinet body (4), a dust conveying pipe (5), a dust collector (6) and a dust collection channel (7), the dust collection channel (7) and the bearing platform (3) are fixedly connected, the middle part of the dust collection channel (7) communicates with the dust conveying pipe (5), the output end of the dust conveying pipe (5) is connected with the dust collection cabinet body (4), the dust conveying pipe (5) communicates with the dust collector (6), and a plurality of stop pieces (8) are arranged in the dust conveying pipe (5). The device is simple in structure, high in crushing efficiency and capable of effectively removing dust impurities on activated carbon raw materials.

Owner:宁波越茂活性炭有限公司

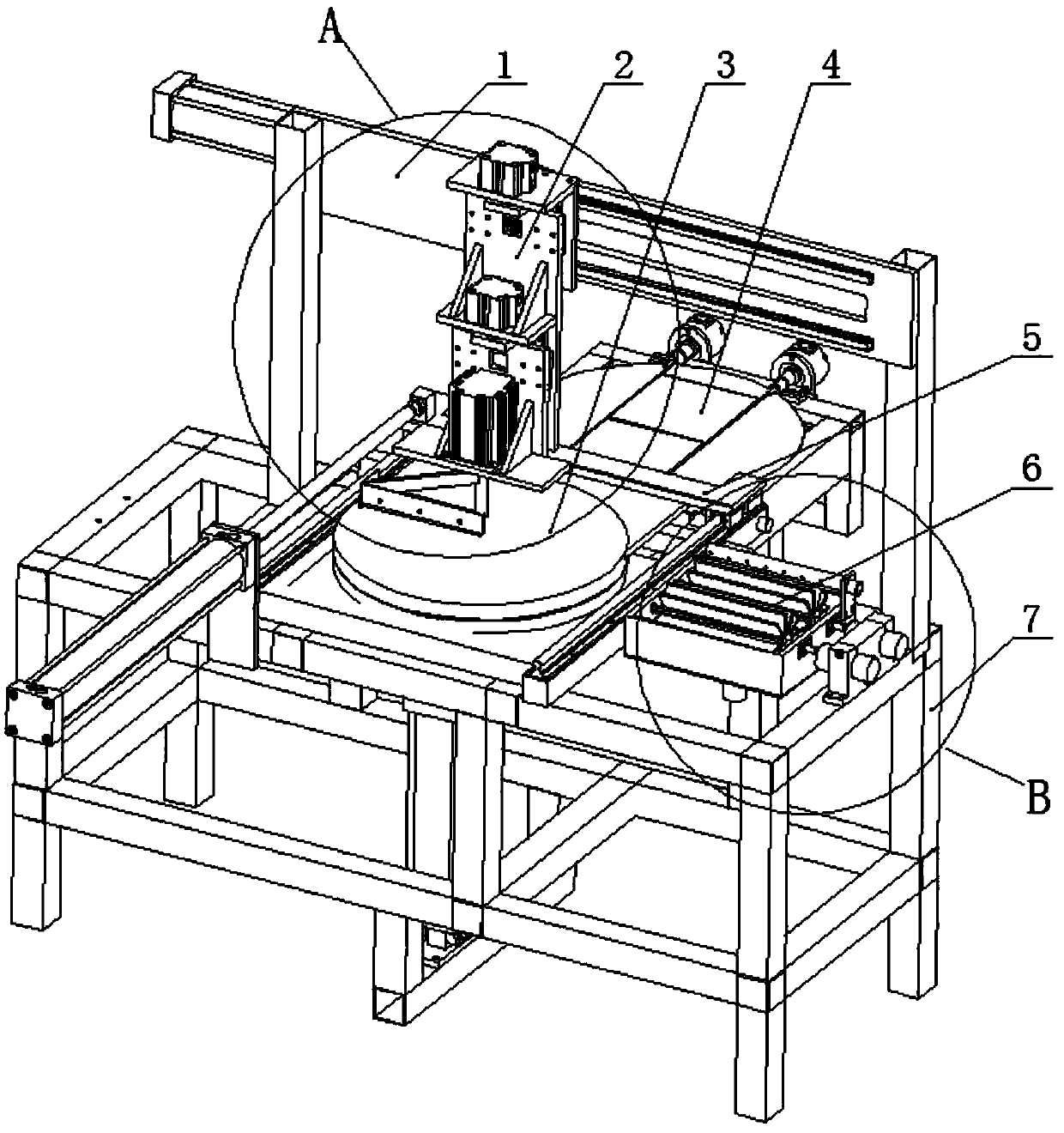

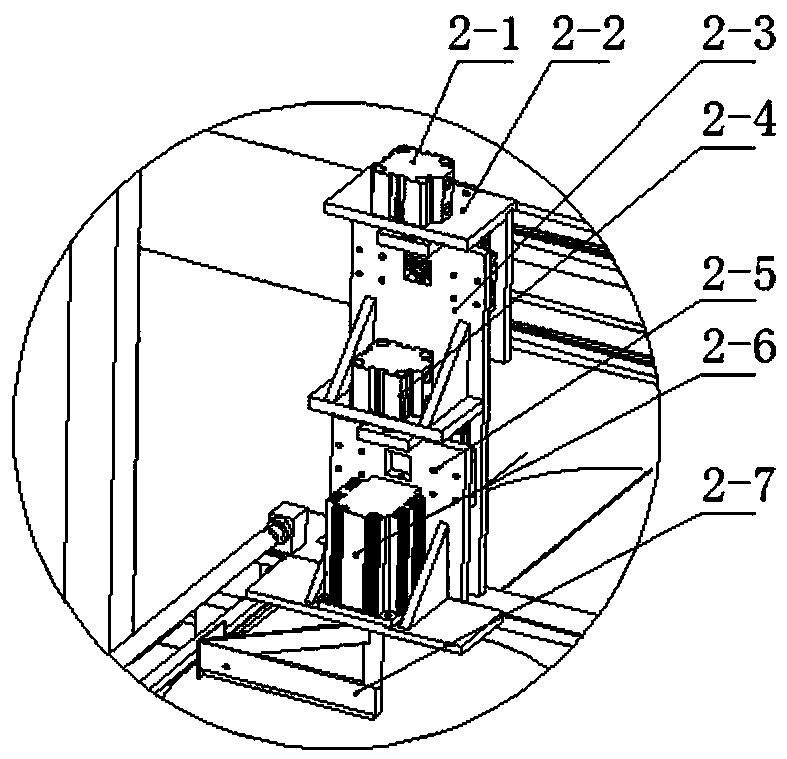

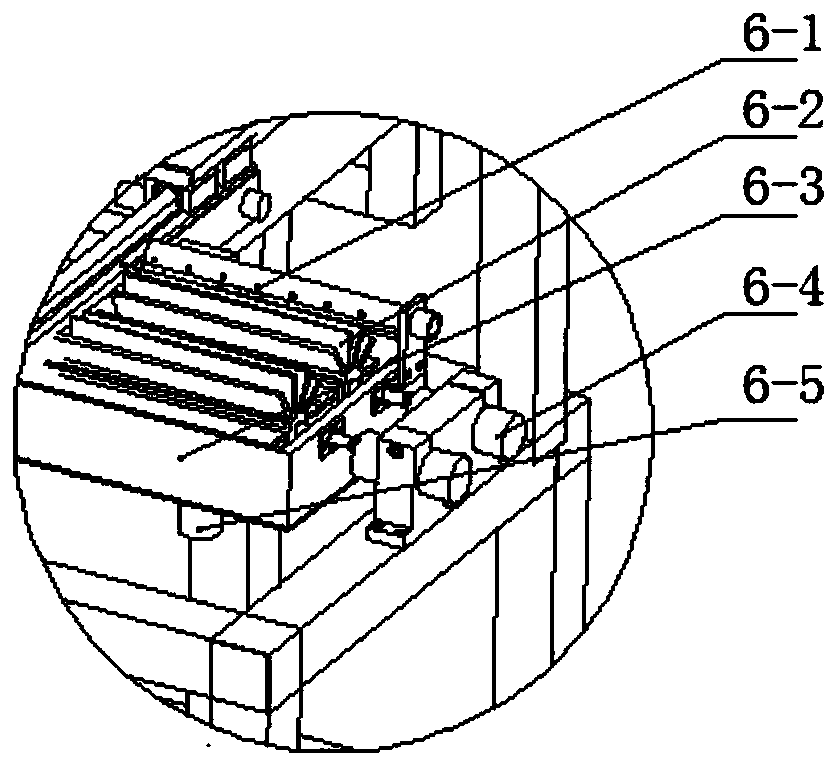

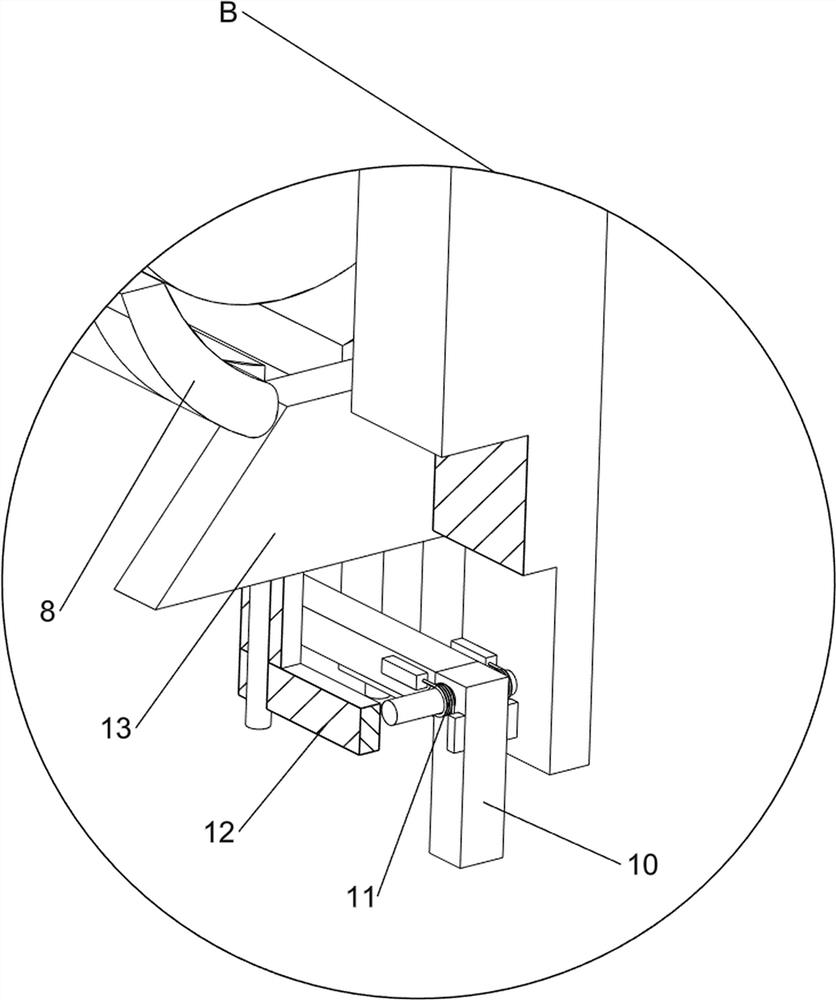

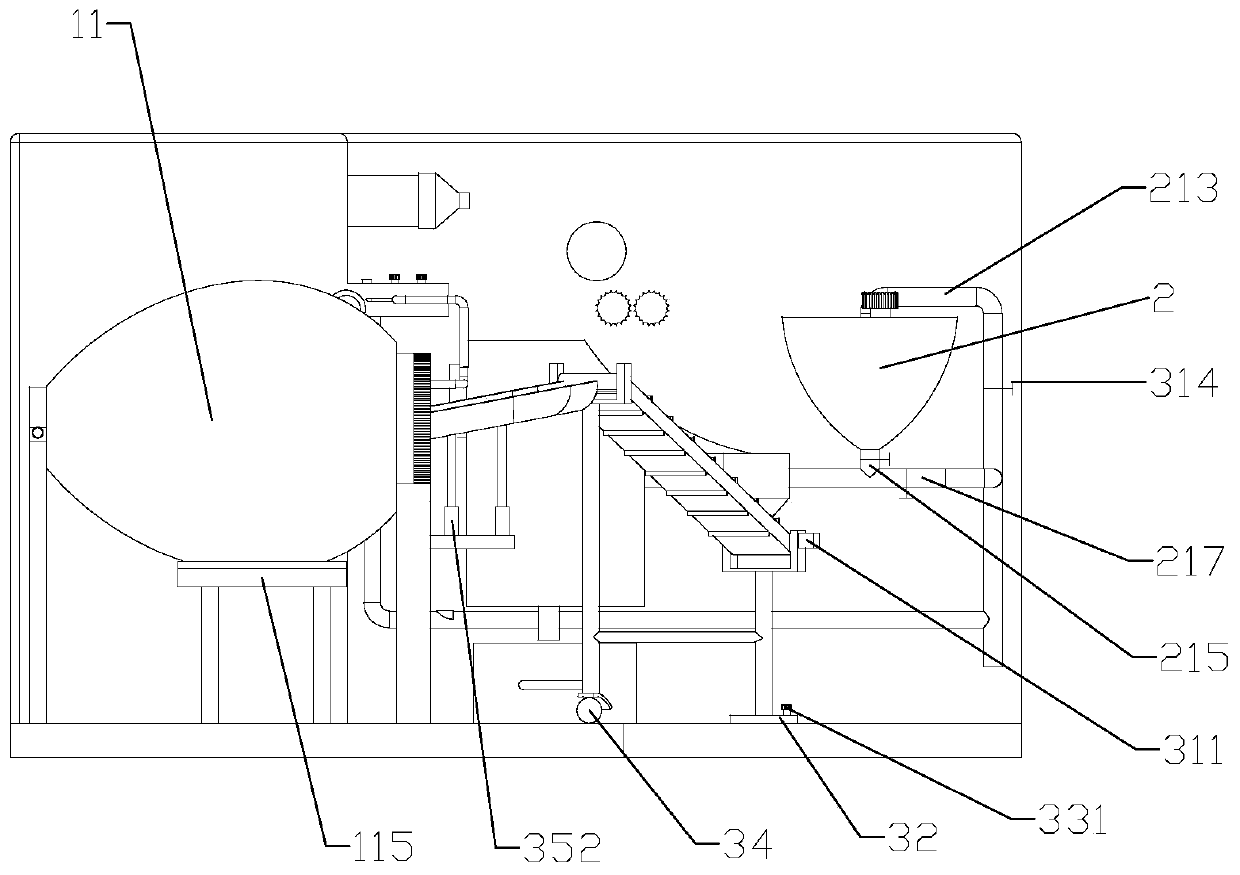

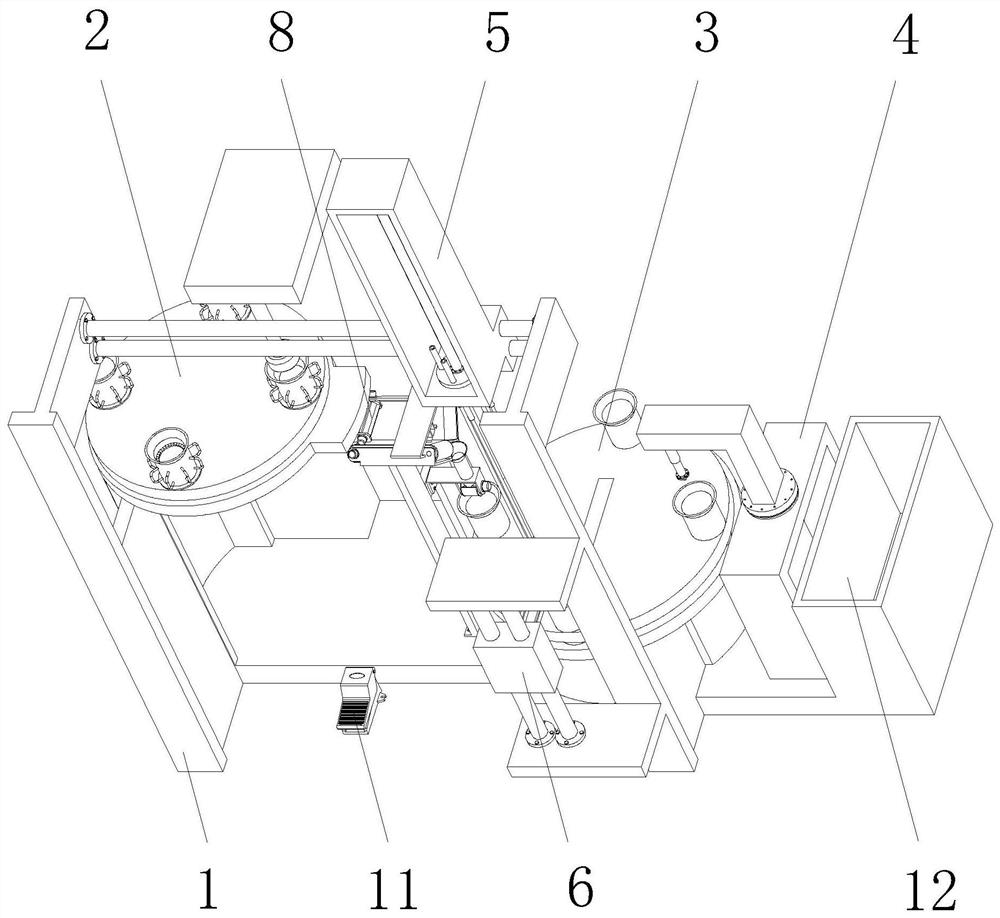

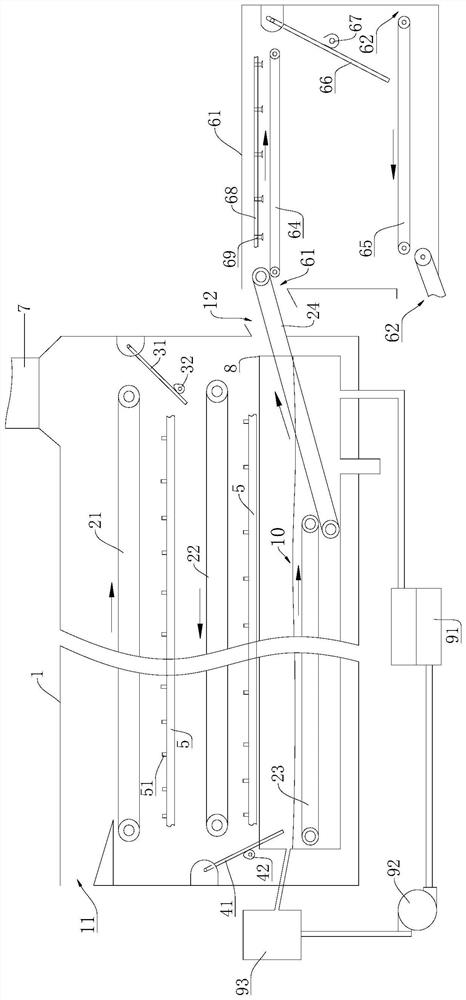

Cultivation seedling to production seedling transferring system for edible fungus cultivation use

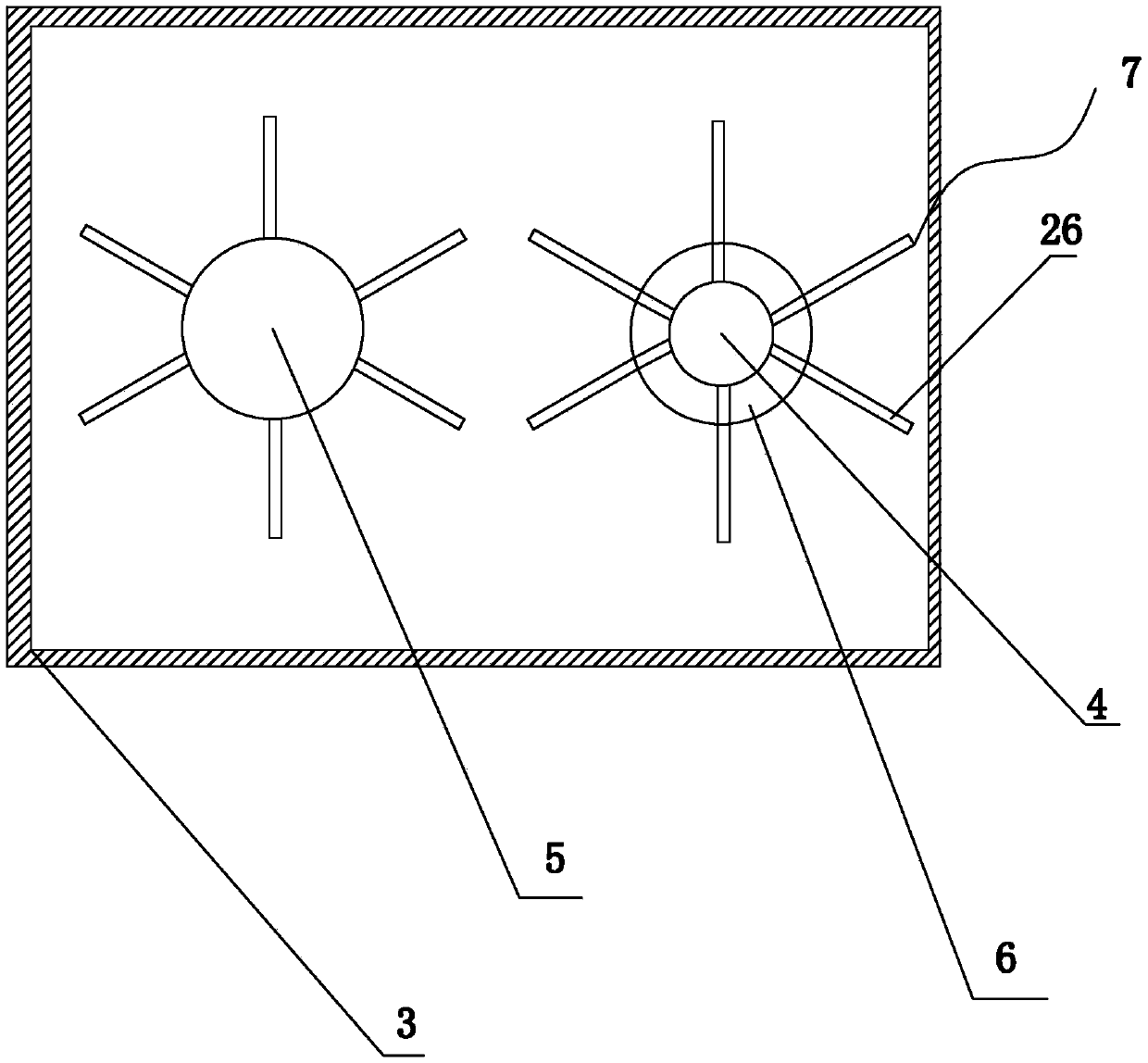

InactiveCN111657057AHigh degree of automationLabor savingCultivating equipmentsMushroom cultivationEngineeringEdible mushroom

The invention discloses a cultivation seedling to production seedling transferring system for edible fungus cultivation use. The cultivation seedling to production seedling transferring system for edible fungus cultivation use comprises a machine frame; a cultivation seedling turntable mechanism, a production seedling turntable mechanism and a metal rod removing mechanism are sequentially arranged, from the left to the right, on the machine frame; a branch conveyor mechanism and a culture material conveyor mechanism are arranged between the cultivation seedling turntable mechanism and the production seedling turntable mechanism; the culture material conveyor mechanism is arranged under the culture material conveyor mechanism; a branch fetching mechanism is arranged in front of the branch conveyor mechanism; and a culture material stamping mechanism is arranged above the cultivation seedling turntable mechanism. The cultivation seedling to production seedling transferring system for edible fungus cultivation completes most of the procedures in the process of transferring the cultivation seedlings to the production seedlings by using automated equipment so that a lot of manpower is saved with production efficiency improved; and thus, cost of employing enterprises can be reduced.

Owner:赵爽

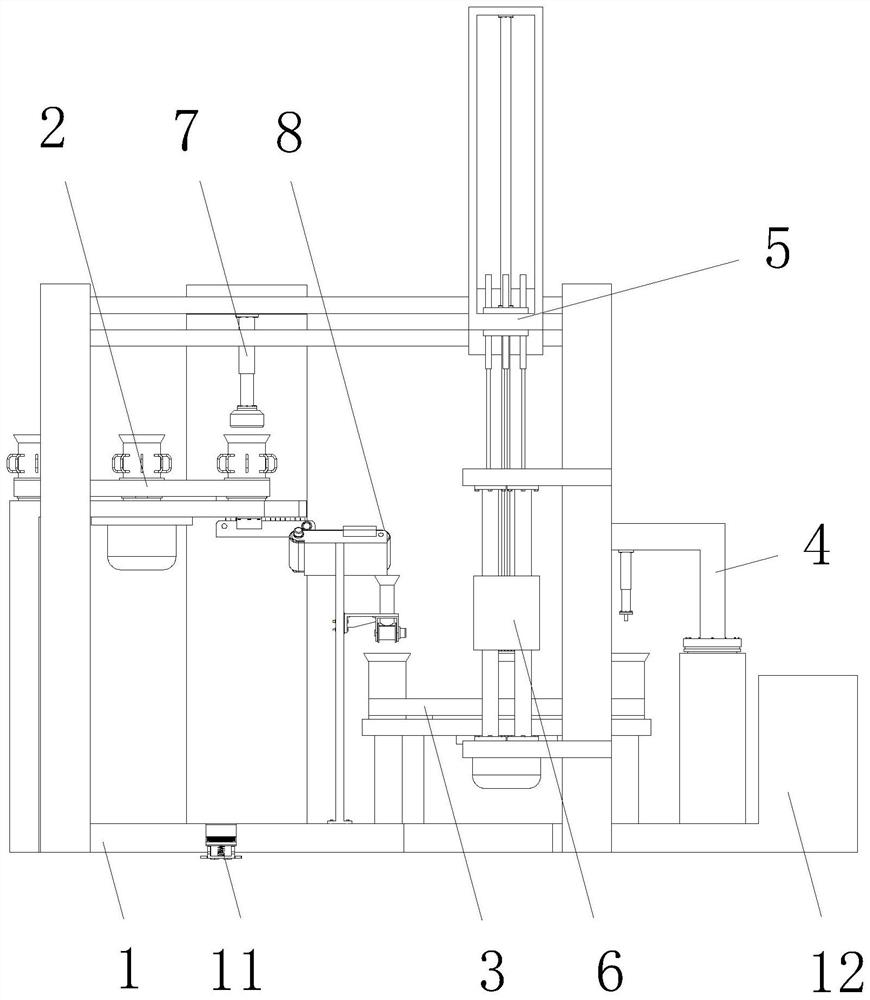

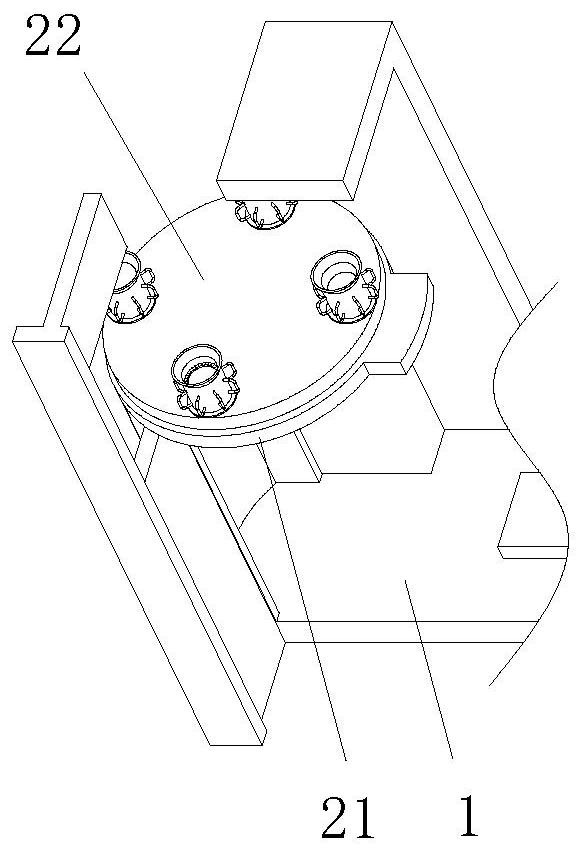

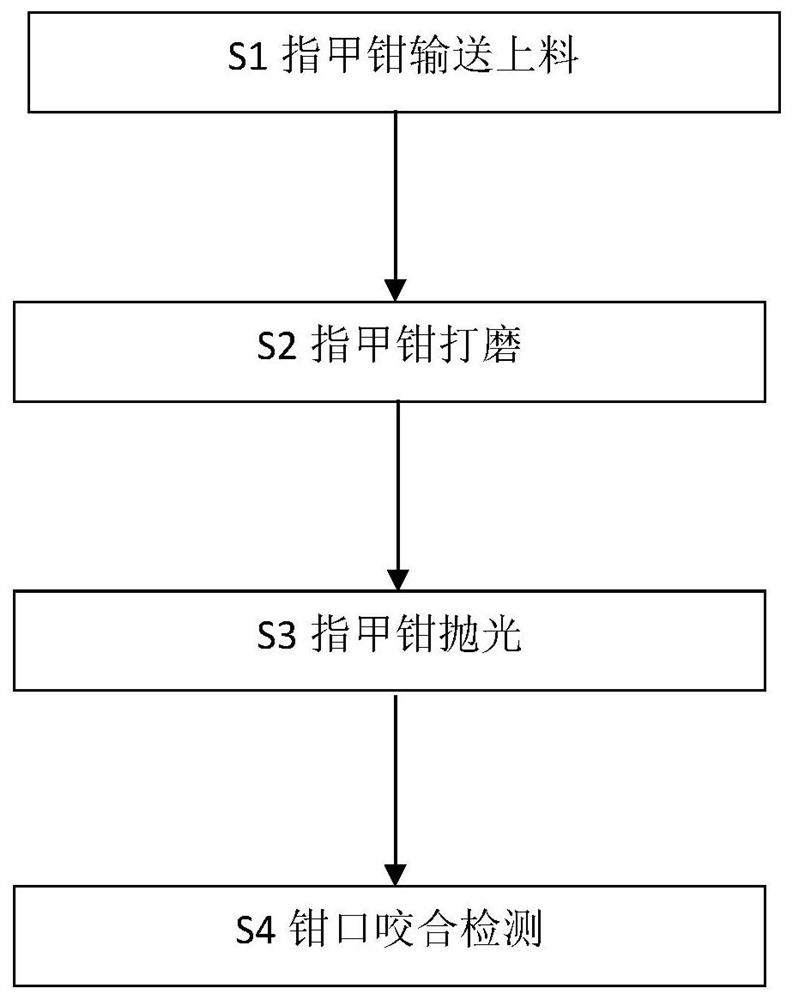

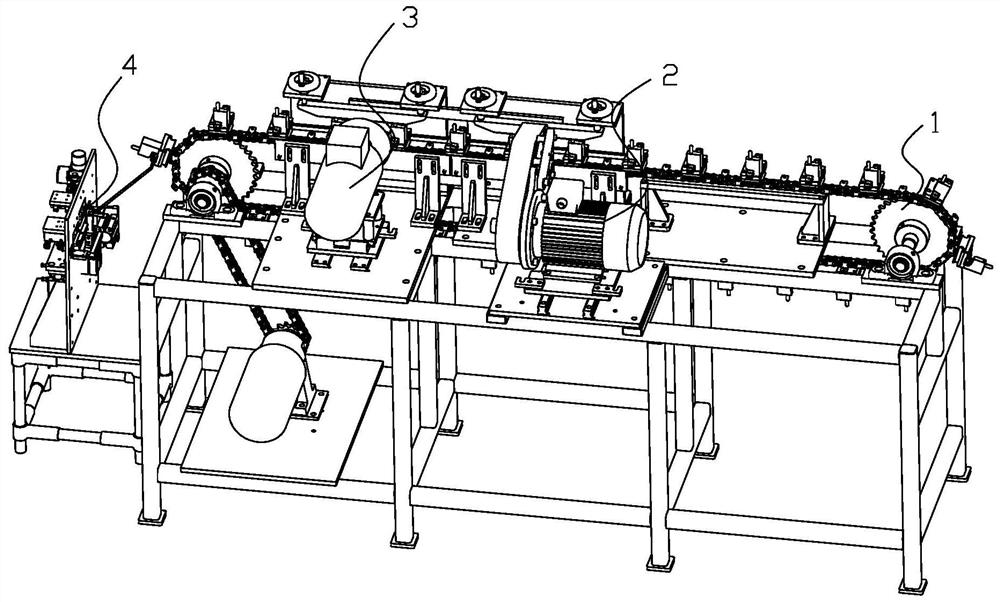

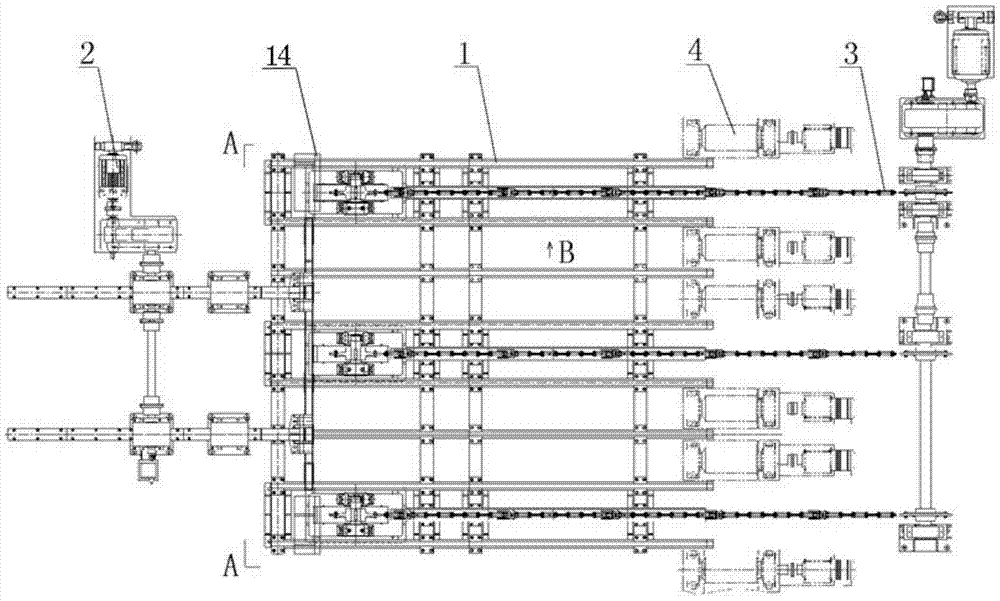

Automatic production method for nail clippers

ActiveCN113231894AEasy to adjustImprove stabilityMachine part testingGrinding carriagesIndustrial engineeringAutomatic processing

The invention belongs to the technical field of automatic production of nail clippers, and discloses an automatic production method of nail clippers. Equipment adopted by the method comprises a rack, a conveying device, a jaw grinding device, a jaw polishing device and a jaw gripping detection device, wherein the conveying device, the jaw grinding device, the jaw polishing device and the jaw gripping detection device are arranged on the rack; the conveying device is transversely and circularly arranged on the rack, and the conveying device is used for conveying the nail clippers; the jaw grinding device is located on the front side of the conveying device, and the jaw grinding device is used for grinding upper clippers and lower clippers of the nail clippers; the jaw polishing device is located on the front side of the conveying device and located on the discharging end side of the jaw grinding device, and the jaw polishing device is used for polishing the upper clippers and the lower clippers of the nail clippers; and the jaw gripping detection device is located on the discharging end side of the conveying device, and the jaw gripping detection device is used for carrying out gripping detection on the upper clippers and the lower clippers of the ground and polished nail clippers. In conclusion, the automatic production method has the advantages that the automatic processing efficiency and the automatic processing precision of the nail clippers are further improved.

Owner:萧县步强新型建材科技有限公司

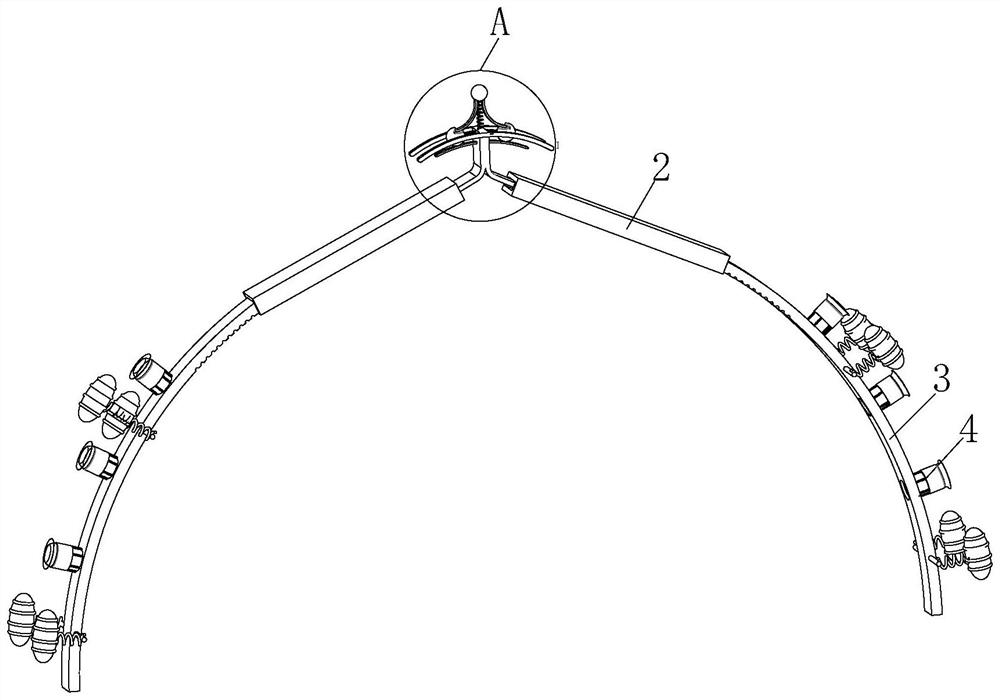

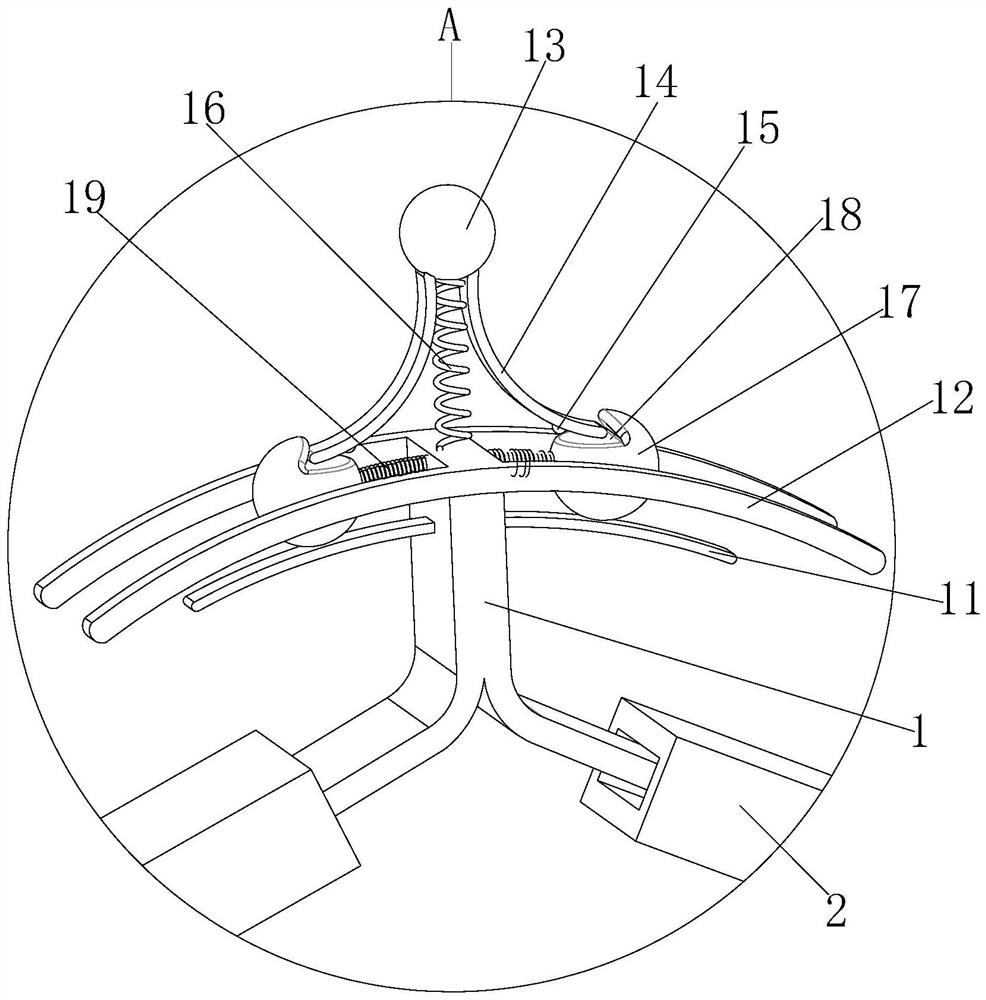

Agricultural greenhouse support

InactiveCN114271132AQuick fixImprove the greenhouse effectRoof coveringClimate change adaptationGreenhouseAgricultural engineering

The invention relates to the technical field of agriculture, and discloses an agricultural greenhouse support which comprises an elastic supporting rod and a rectangular sleeve, the lower end of the elastic supporting rod is divided into two parts, a special-shaped sliding groove penetrating through the two ends of the rectangular sleeve is formed in the rectangular sleeve, a branch at the lower end of the elastic supporting rod is slidably clamped in the special-shaped sliding groove, and an arc-shaped frame is arranged at the lower end of the rectangular sleeve. The upper end of the arc-shaped frame is arranged in the special-shaped sliding groove in a sleeved mode, and an adsorption assembly is arranged on the outer wall of the arc-shaped frame. According to the device, the interior of the fixing sleeve can be in a negative pressure state, a plastic film is adsorbed, the plastic film can be rapidly fixed, the plastic film does not need to be perforated and bound, the greenhouse effect in a greenhouse is better, snow can smoothly slide down along an inclined plane, icing and shielding are prevented, and the device is convenient to use. And the plastic film can be prevented from being scraped.

Owner:浙江极智农业开发有限公司

Ore refining pulverizer for cable production

InactiveCN112718094ASlide down smoothlyAvoid accumulationGrain treatmentsElectric machineEngineering

The invention discloses an ore refining pulverizer for cable production. The ore refining pulverizer comprises a pulverizing cylinder, a discharging plate, a pulverizing motor and a pulverizing disc. During use, to-be-pulverized ore raw materials are added into the pulverizing cylinder through a feeding hole, the pulverizing motor drives an output shaft and the pulverizing disc to rotate synchronously during working, at the initial position, a discharging channel is aligned with a pulverizing groove, at the moment, the distance between a magnetostriction rod and a permanent magnet block is the largest, the magnetostriction rod is shortened, a pulverizing pressing plate is tightly attached to the side, close to the output shaft, of the pulverizing groove, and the ore raw materials enter the pulverizing groove through the discharging channel. Along with rotation of the pulverizing disc, the magnetostriction rod gradually faces the permanent magnet block, so that the magnetostriction rod gradually extends, and then the pulverizing pressing plate is ejected out; and at the moment, the pulverizing groove and the discharging channel are staggered, the top of the pulverizing groove is sealed through the discharging plate, the ores are pulverized along with gradual ejection of the pulverizing pressing plate, and the ores at the pulverizing opening are screened out from first screening holes.

Owner:陈利

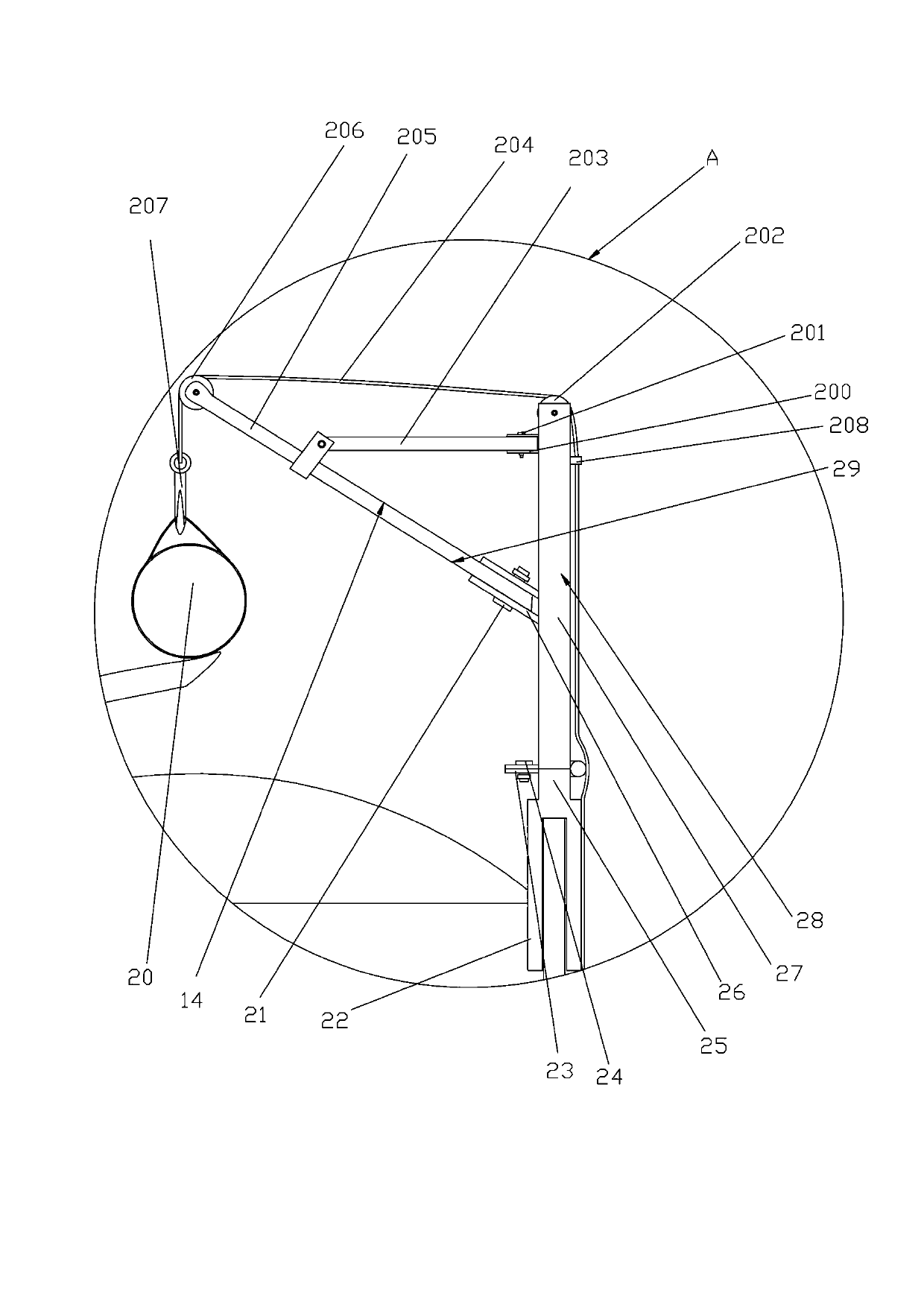

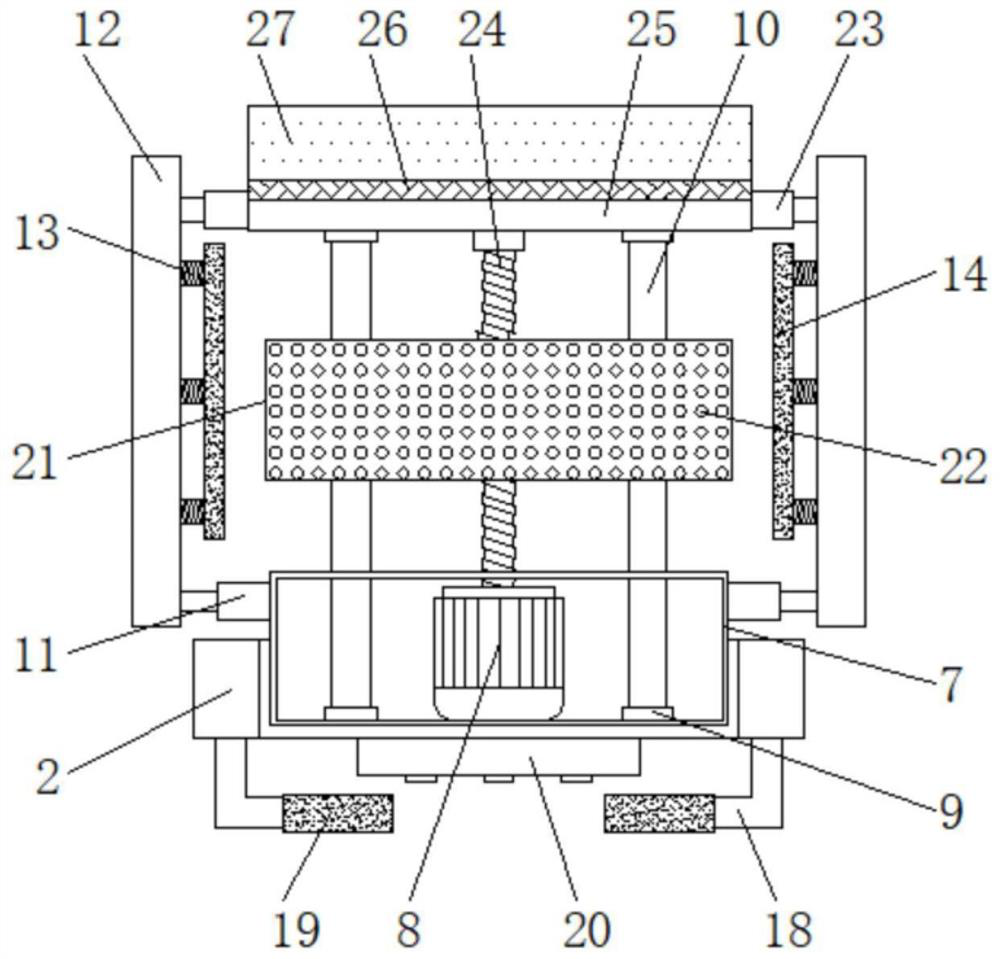

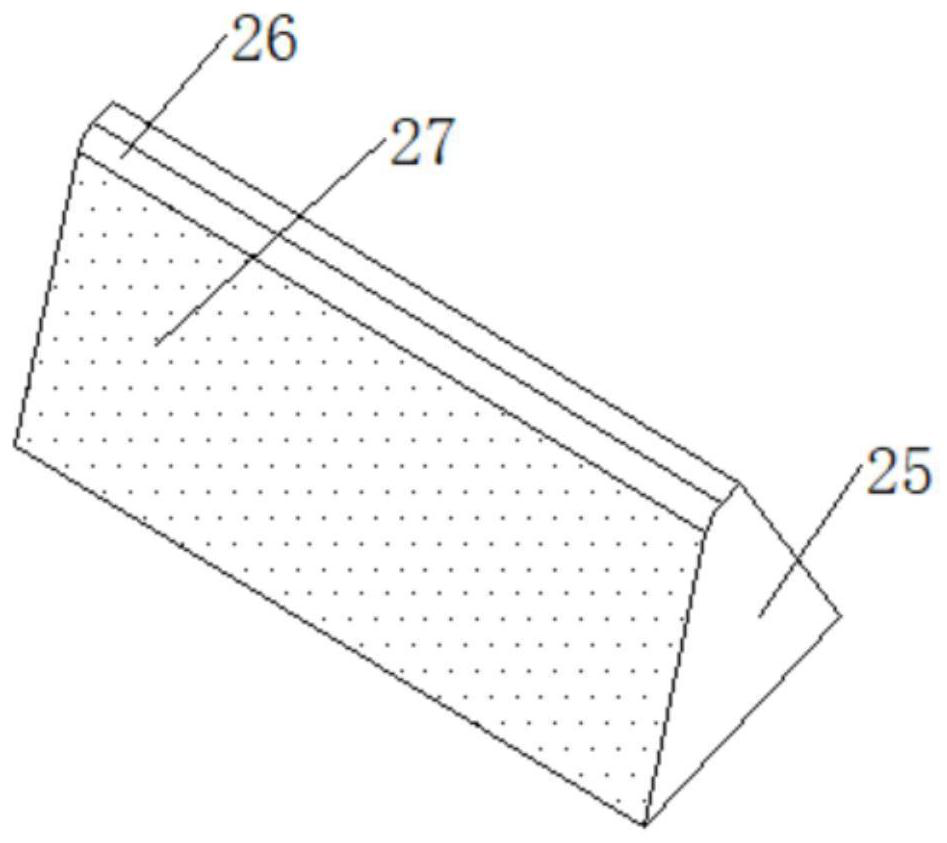

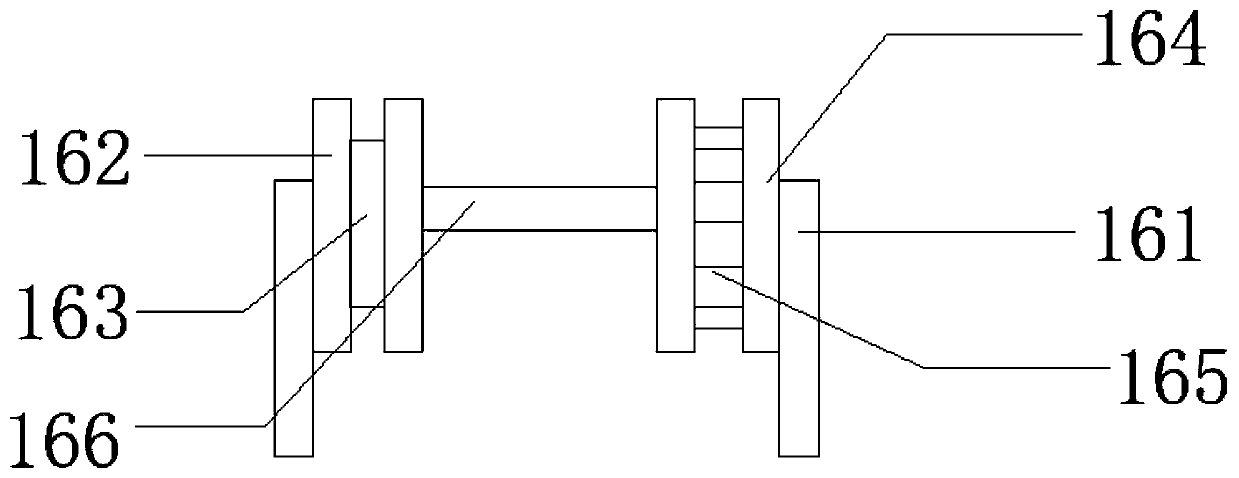

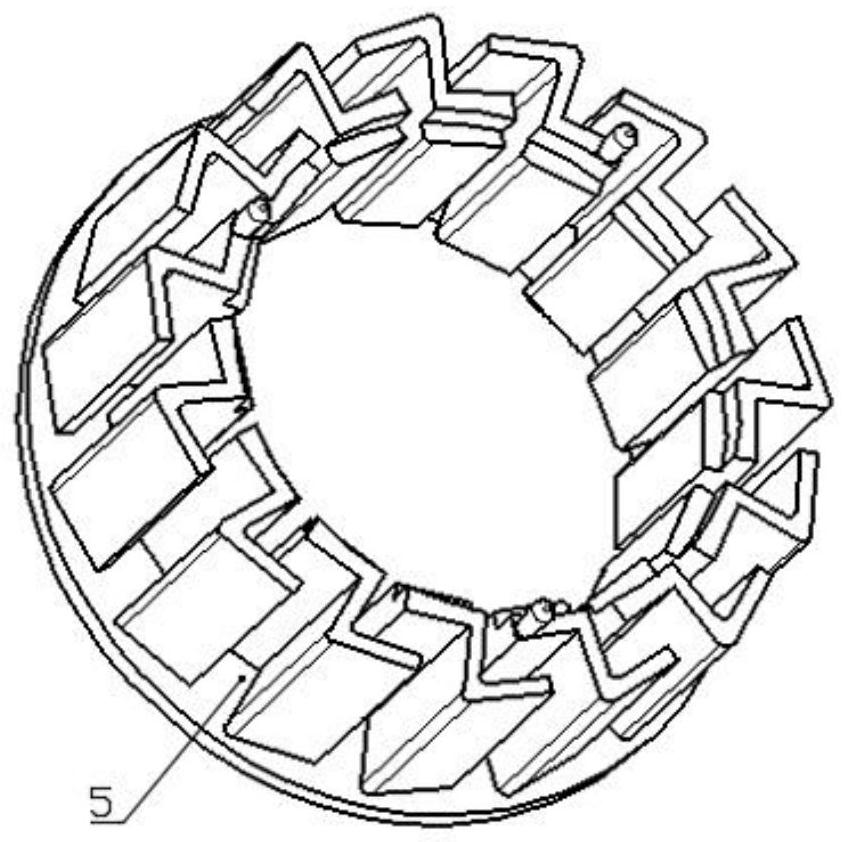

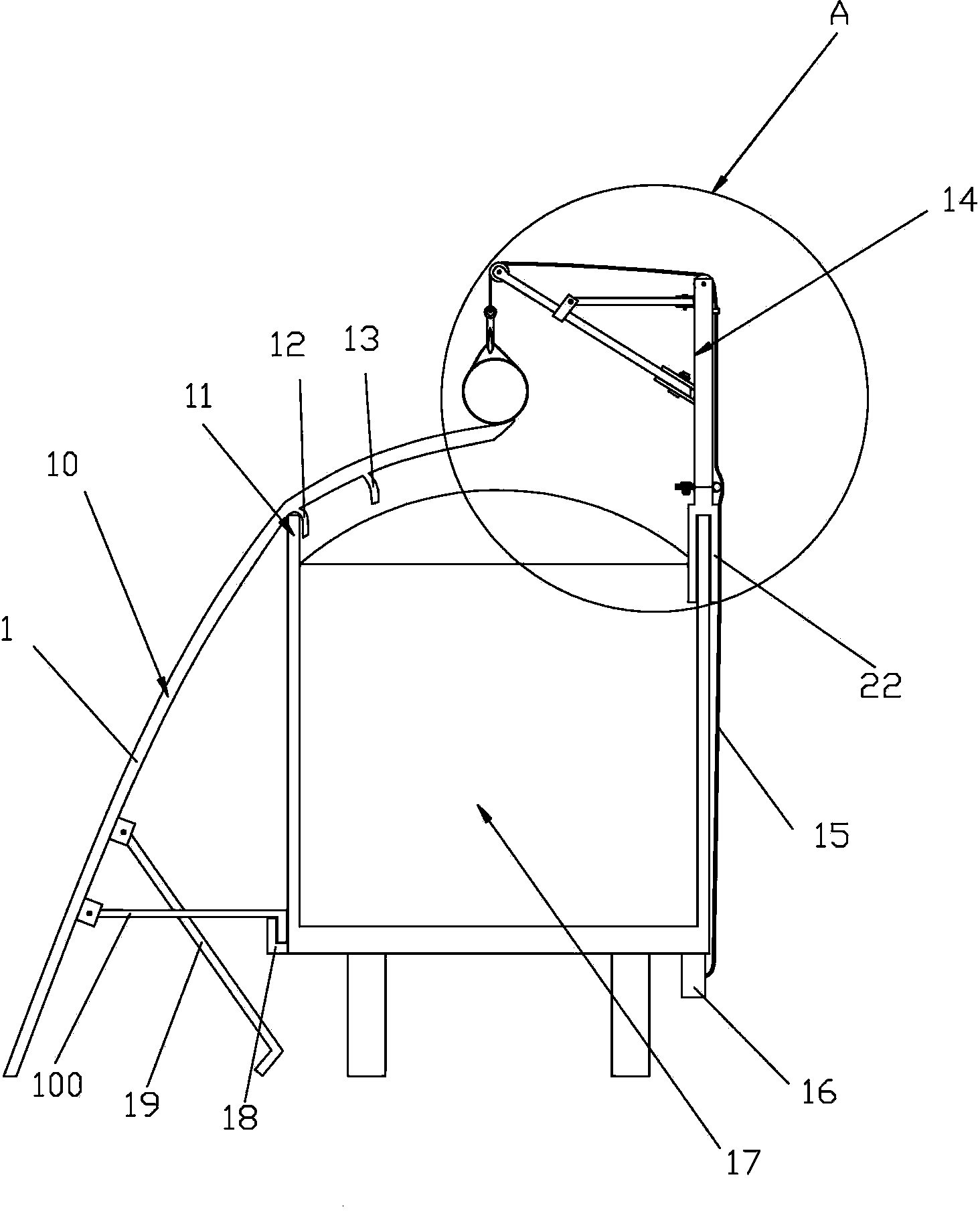

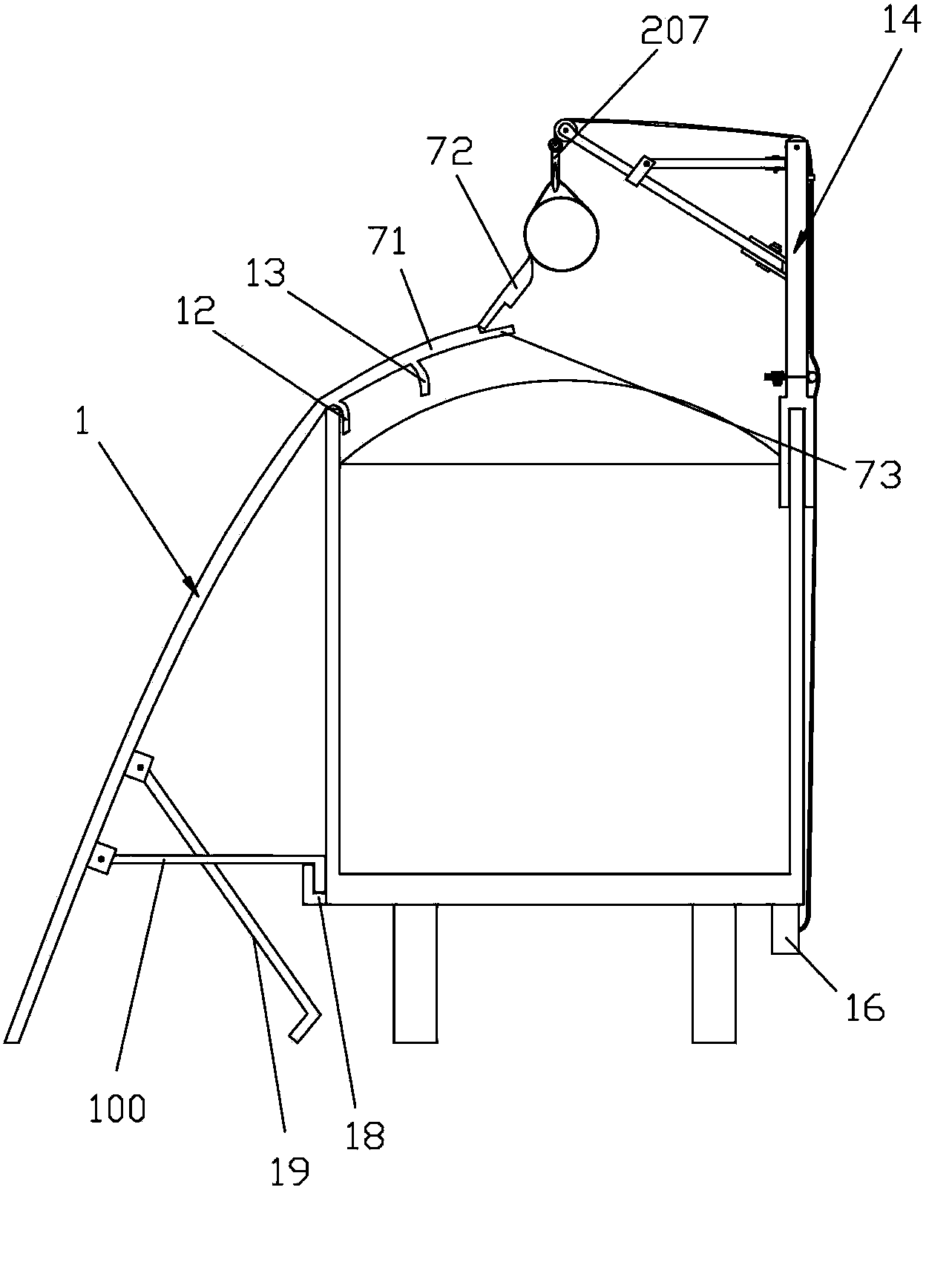

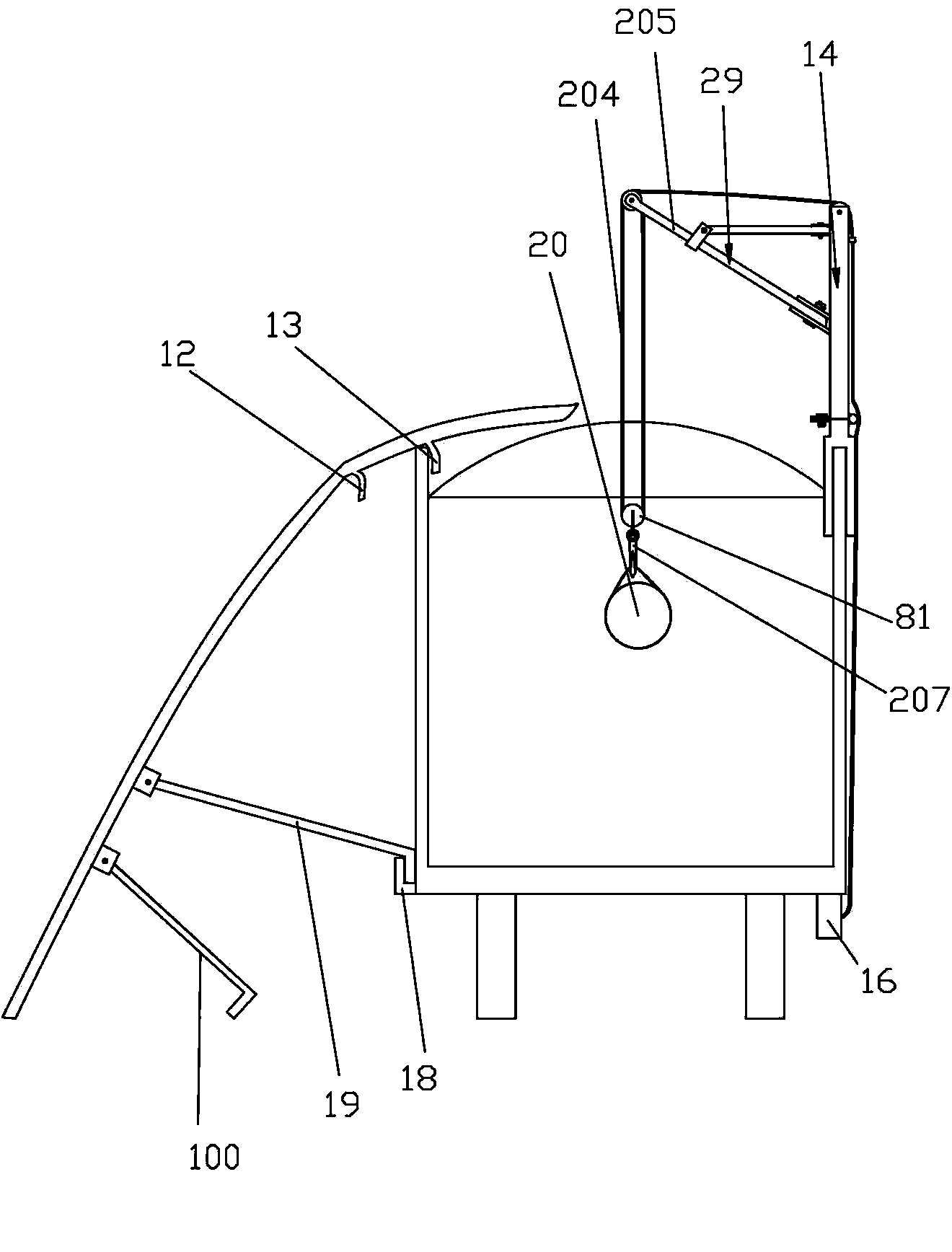

A hanging transport device for gear quenching

InactiveCN108557650BPut in accurately and stablyTimely automatic removalFurnace typesHeat treatment furnacesQuenchingMachining

The invention discloses a hanging transportation device for gear quenching, and relates to the field of chain transmission machining production devices. A supporting control moving box is included, and a heat isolating and heat insulating outer frame is arranged outside the supporting control moving box; the inner wall of the supporting control moving box divides the interior of the supporting control moving box into a first supporting rotating power box and a second supporting rotating power box through an independent dividing plate; and an adjusting control box is inset and connected to theinner wall of the top end of one side of the independent dividing plate, and the two ends of the adjusting control box are located in the first supporting rotating power box and the second supportingrotating power box correspondingly. By performing unified hanging transportation on gears, the space utilizing rate in a workshop is increased; meanwhile, the gears can be transported in time quantitatively, and the gears can be accurately and stably placed into a quenching furnace due to automatic lifting; and after quenching ends, the gears can be automatically taken out in time, and it is achieved that the production efficiency of the gears is improved.

Owner:TAIZHOU HONGXIN CRANKSHAFT

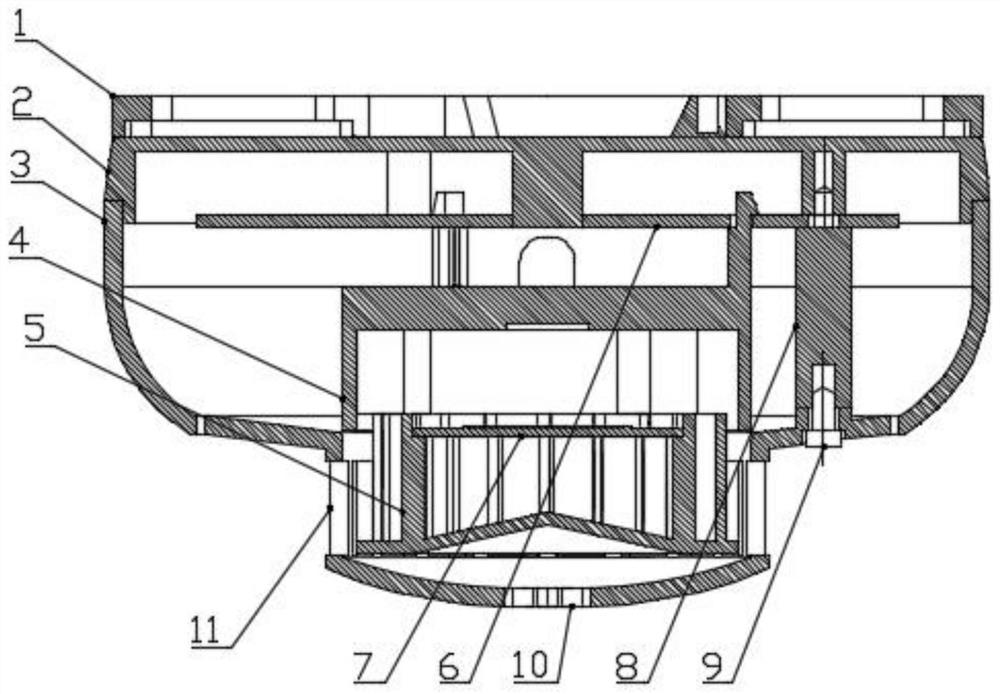

Anti-condensation structure of smoke detector

PendingCN114778388AAvoid standing waterSlide down smoothlyMeasurement apparatus housingsMaterial analysisSmoke detectorsStructural engineering

The invention discloses an anti-condensation structure of a smoke detector, and relates to the technical field of fire detection equipment, the anti-condensation structure comprises an upper cover body and a lower cover body, the port of the upper cover body and the port of the lower cover body are connected in a buckling manner, the joint is sealed by a spigot, the side wall, close to the bottom, of the lower cover body is provided with an open drainage through hole, and the open drainage through hole is communicated with the upper cover body and the lower cover body. The bottom of the lower cover body is of an arc curved surface structure, a water outlet is formed in the lowest position of the curved surface, a shell is defined by the upper cover body and the lower cover body, a smoke sensing chamber and a circuit board are arranged in the shell, the smoke sensing chamber comprises a smoke sensing detection lower chamber and a smoke sensing detection upper chamber, and the circuit board is arranged between the upper cover body and the lower cover body and detachably fixed. The smoke sensing detection upper chamber is connected with the circuit board in an abutting mode, the smoke sensing detection lower chamber is arranged opposite to the arc curved surface of the lower cover body, and the smoke sensing detection lower chamber is of a labyrinth structure. The structure is simple, water drops can be effectively prevented from entering the shell, the water drops in the shell can be quickly led out, and the phenomenon of condensation is prevented.

Owner:中城佳旭(北京)科技发展有限公司

a carrier

InactiveCN105083957BReduce frictionReduce frictional resistanceConveyor partsEngineeringSliding contact

The invention discloses a carrying device and a logistics sorting device using the carrying device. A frame body is connected under the pallet of the carrying device, and the frame body is provided with sliding rollers extending forward and backward, and the right side of the frame body is hinged on the pallet around the axis of the front and rear colors, and there is a gap between the left side of the frame body and the outriggers. When the pallet is tilted, the frame body drives the sliding roller to expose the jacking structure above the pallet. In this way, after the carrier device arrives at the sorting port, as the tray tilts, the outriggers and the tray will rotate relative to each other around the axis extending forward and backward. until the pallet is tilted in place, the sliding roller will be completely exposed from the top surface of the pallet driven by the frame body, so that the top surface of the pallet can contact the goods through the roller surface of the sliding roller, so as to reduce the distance between the carrier and the goods. The contact area between them also reduces the friction force on the goods during the process of tipping out, and reduces the friction resistance of the goods sliding down from the pallet.

Owner:HENAN UNIV OF SCI & TECH

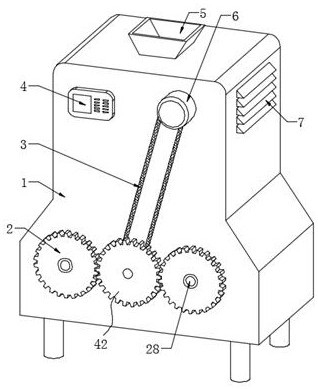

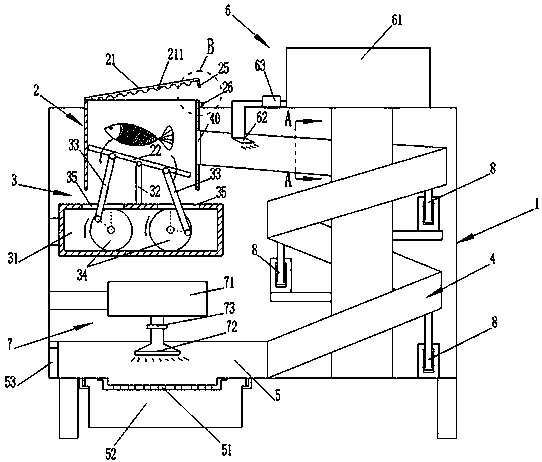

A garden pond feed throwing equipment

ActiveCN109601455BCan't throw awayRealize automatic throwingClimate change adaptationPisciculture and aquariaWater filterWater source

The invention relates to a feed throwing device, in particular to a garden pond feed throwing device. The technical problem is: to provide a garden pond feed throwing device which can realize automatic feed throwing, can save trouble, and has low cost. The technical solution is: a garden pond feed throwing equipment, including a feed throwing box, a driving mechanism, a large gear, a small gear, a first water wheel, a first flat belt, a connecting rod, a first gear, a first pulley, and a mounting seat etc.; the upper part of the feed throwing box has a storage tank, the lower part of the feed throwing box has a water filter tank, and the right side of the front wall in the water filter tank is provided with a drive mechanism, and a large gear is installed on the parts of the drive mechanism. The invention puts it at the water source interface by the staff, the water flowing into the water filter tank makes the feed intermittently fall into the parabolic frame, and the rod is knocked to make the parabolic frame move up and down, and the feed is thrown into the pond, which can realize automatic throwing Feed, no need to manually throw the feed, which can save trouble.

Owner:山东梵音生物科技有限公司

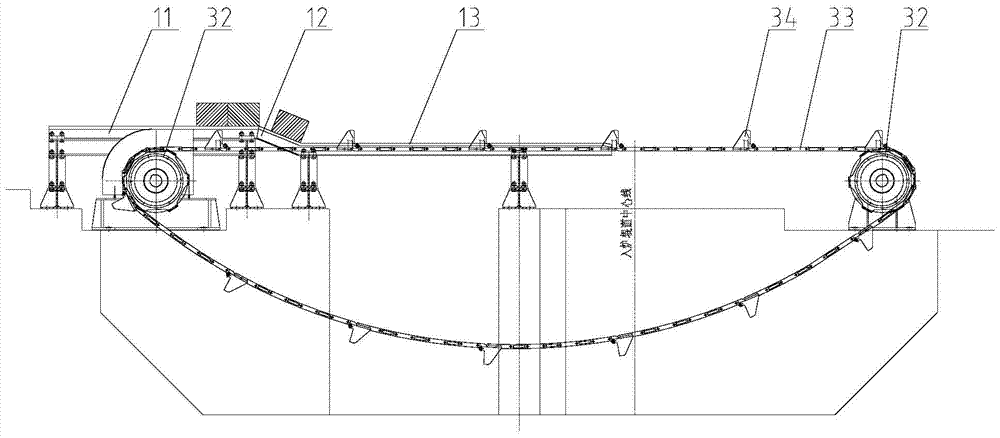

A front feeding device for a section steel heating furnace

The invention relates to a feeding device in front of a shaped steel heating furnace, which includes a stepped platform, a steel pushing device and a chain transmission device. The stepped platform is composed of an upper platform, a transition platform and a lower platform, wherein the lower platform is a The side is close to the section steel furnace roller table, and the steel pushing device is set on one side of the upper platform, which is composed of a steel push drive device, a gear, a rack and a steel push rod; A plurality of chains can be driven by the chain drive device and the sprocket along the lower platform to the side of the furnace entering roller table, and chain claws are uniformly arranged on the chains. The present invention can realize the functions of separating steel and traversing the profiled steel billet. The steel is divided by the steel pushing device. The blank is slid from the upper platform to the lower platform through the transition step, and then driven by the chain claw driven by the chain to move laterally to the profiled steel into the furnace. On the roller table; compact structure, small space occupation, stable and reliable transmission, flexible and accurate operation, high feeding efficiency, meeting process requirements; light equipment, easy maintenance.

Owner:鞍钢集团工程技术有限公司

Drying device for starch production

ActiveCN114593565AEasy to joinAvoid clumpingChemical industryDrying gas arrangementsProcess engineeringStarch production

The invention relates to the technical field of starch drying, in particular to a drying device for starch production, which comprises a drying box and further comprises a first partition plate, a second partition plate and a third partition plate, the stirring barrel is connected with the drying box and the first partition plate; the flow guide part is positioned in the drying box, and is matched with the stirring barrel; the drying mechanism is connected with the drying box, the first partition plate and the stirring barrel; wherein the drying mechanism comprises a hot air assembly, a crushing assembly and an equipartition assembly, the equipartition assembly comprises a driving unit, a hot air plate, a rotating cylinder and a containing groove, the drying device for starch production is novel in structure, easy to operate and high in automation degree, the situation that starch is stacked during drying, and then the drying effect is reduced can be avoided, and the drying efficiency is improved. The efficiency of drying work can be improved, and the phenomenon of caking of starch is avoided.

Owner:SHANDONG SHENZHOU XIANGYU TECH GRP

Circulating heated shrimp cooking equipment

ActiveCN109077216BCook thoroughlyReduce contact areaSteam cooking vesselsFood sciencePrawnProcess engineering

The invention discloses a circulating heating shrimp cooking equipment, which comprises a frame, a cooking device and a heating device. The cooking device includes a cooking chamber, a conveying device, a sliding material board, a shrimp cooking pond, a steam delivery pipe and a steam nozzle. The bottom of the cooking chamber is provided with a boiled shrimp pond, and the conveying device includes a first conveyor belt, a second conveyor belt, a third conveyor belt and a first driving device, and the third conveyor belt is arranged in the shrimp boiled pond , the first drive device drives the first conveyor belt and the third conveyor belt to rotate clockwise, the first drive device drives the second conveyor belt to rotate counterclockwise, and the cooking chamber is inside the first The steam delivery pipe is provided between the conveyor belt and the second conveyor belt and between the second conveyor belt and the third conveyor belt, and several steam nozzles are arranged on the steam delivery pipe. The device can solve the technical problems of low energy utilization rate and insufficient cooking of prawns.

Owner:北海市海庆兄弟水产有限公司

Plant cultivation component and cultivation method

InactiveCN109618729BSlide down smoothlyAchieve removalTilling equipmentsCereal cultivationAgricultural engineeringElectric machinery

Owner:原晓玲

Activated carbon crushing device with drying function

InactiveCN109647605AImprove drying efficiencyEfficient dryingDrying gas arrangementsDrying machines with non-progressive movementsActivated carbonEngineering

The invention discloses an activated carbon crushing device with a drying function. The activated carbon crushing device comprises a frame (1). The frame (1) is provided with a feeding channel (2). Anupper layer crushing mechanism, a lower layer crushing mechanism and a drying mechanism are sequentially arranged from top to bottom in the frame (1), wherein the upper layer crushing mechanism is used for crushing activated carbon raw materials, the lower layer crushing mechanism is used for crushing the activated carbon raw materials, and the drying mechanism comprises a drying platform (4). The inner bottom end surface of the frame (1) is provided with a drying motor (5). The inner wall of the frame (1) is provided with a plurality of air blowing pipes (6) provided with air blowing openings (7). The air blowing pipes (6) are externally connected with a blasting air blowing device and a heating device through pipelines. The frame (1) is also provided with an air outlet (3) in one side of the feeding channel (2). The activated carbon crushing device with the drying function is simple in structure and high in crushing efficiency, and crushing and drying procedures can be carried out in the same equipment.

Owner:宁波越茂活性炭有限公司

Hanger for metal pipe and vehicle with hanger

Owner:GOOMAX METEL CO LTD FUJIAN

Fish scale removing machine and use method thereof

PendingCN107668163AGood effectAvoid accumulationFish washing/descalingClimate change adaptationEngineeringMechanical engineering

Owner:辛幼霞

A cargo moving device for storage

ActiveCN109532979BChange the damagePlay the role of limiting and preventing fallingSupporting partsHand carts with multiple axesHydraulic cylinderEngineering

Owner:周永俊

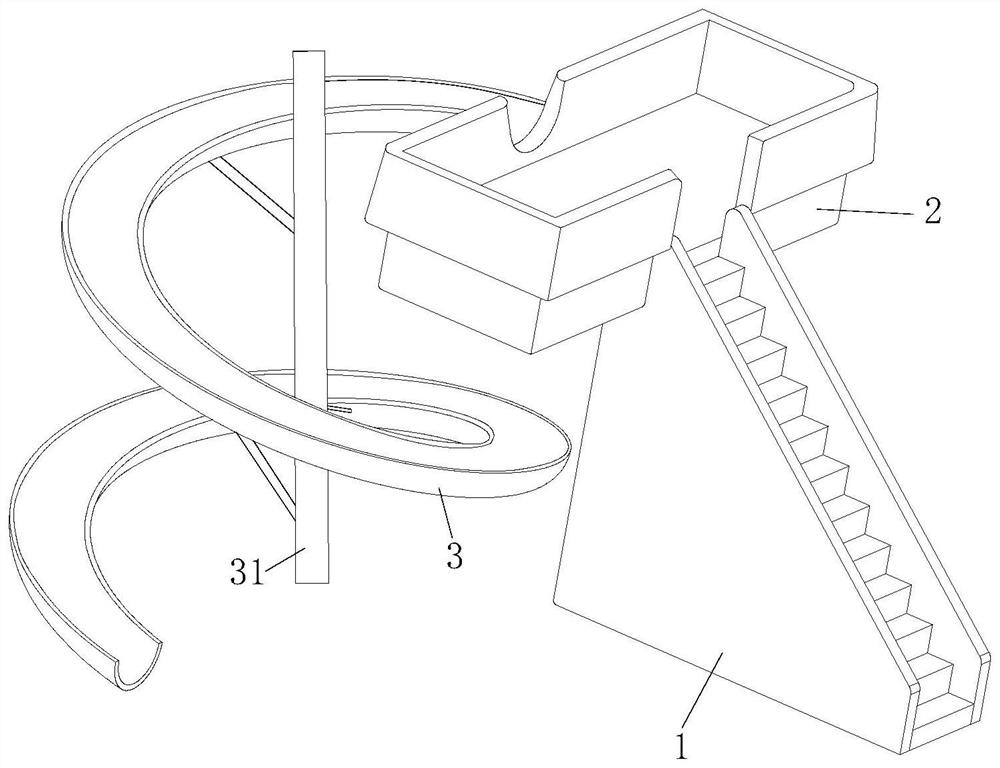

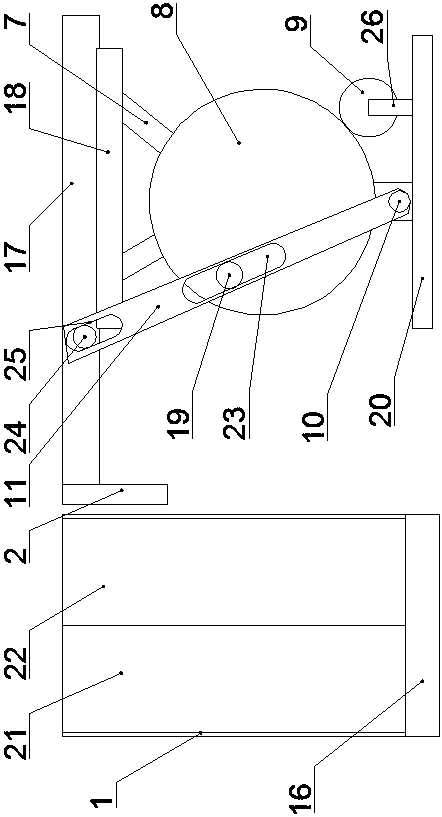

Multi-layer children's spiral slide and its processing technology

ActiveCN113856212BShock mitigationReduce impactHelter-skeltersClassical mechanicsMechanical engineering

The invention relates to the technical field of amusement equipment, in particular to a multi-layer spiral slide for children, comprising: a slide frame, a platform, a support rod and a slide track; the slide frame is vertically and fixedly installed on the ground, and one end of the slide frame is provided with a stair step; the platform One end of the slideway is fixedly connected with the other end of the slide frame; one end of the slideway is fixedly connected with the other end of the platform, and the other end of the slideway extends to the ground and is fixedly installed on the ground; it also includes: a buffer device, which is located at the exit of the slideway and connected with the slide Road connection, used to alleviate the impact of children when they slide down; in the invention, the multi-layer spiral slide for children uses the buffer device, so that when the child approaches the exit of the slide, the buffer device will be triggered, and the buffer device can relieve the impact of the child's slide. Force, so that the impact force of the child's slide can be reduced, so that the child will not rush out of the slideway, so that the safety of the child itself and the child who may be located at the exit of the slideway is guaranteed.

Owner:华东游乐设备有限公司

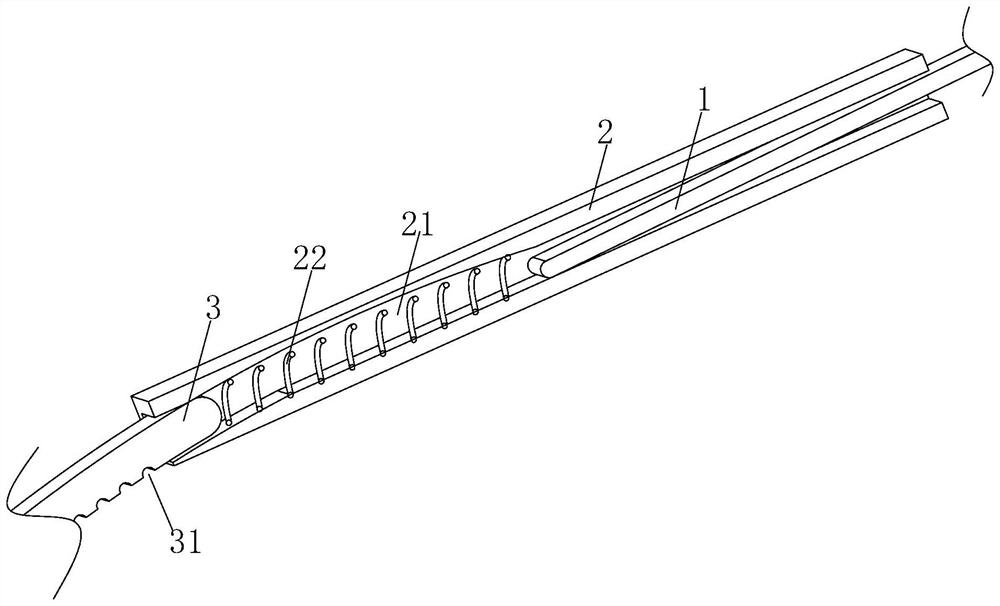

Production output device for precision frames used for diodes

The invention discloses a production output device for precision frames used for diodes. The device comprises a conveying device and a pushing device, wherein the conveying device comprises a first bottom plate which is horizontally arranged in a front-and-back direction, a baffle plate is arranged on the front end face of the first bottom plate, and a slideway plate is arranged above the first bottom plate, wherein the front end of the slideway plate is lower than the rear end of the slideway plate; a first guide column and a second guide column are vertically arranged on the surface of the slideway plate in a front-and-back interval mode, wherein the lower end of the first guide column and the lower end of the second guide column are both suspended, a first compressed spring is arrangedon the first guide column in a penetrating mode, and a second compressed spring is arranged on the second guide column in a penetrating mode; and the lower ends of the first compressed spring and thesecond compressed spring are both fixed on the upper surface of the first bottom plate. The production output device for the precision frames used for the diodes is simple and ingenious in structure,capable of being used for effectively avoiding accumulation of the precision frames used for the diodes under cooperation with a conveyor belt so as to avoid the phenomena that the precision frames used for the diodes are damaged and fractured and terminals are damaged due to the fact that the precision frames used for the diodes are accumulated, capable of greatly improving the yield of the precision frames used for the diodes, and capable of reducing the production cost.

Owner:DAYA SEMICON

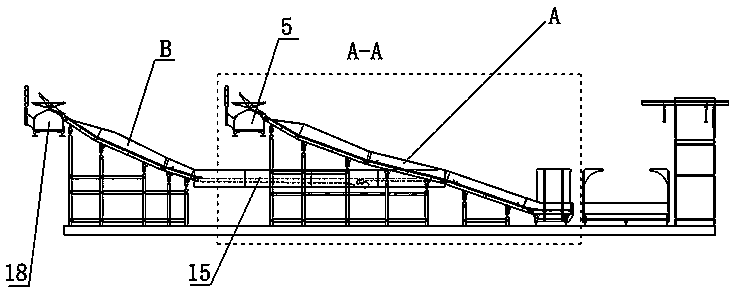

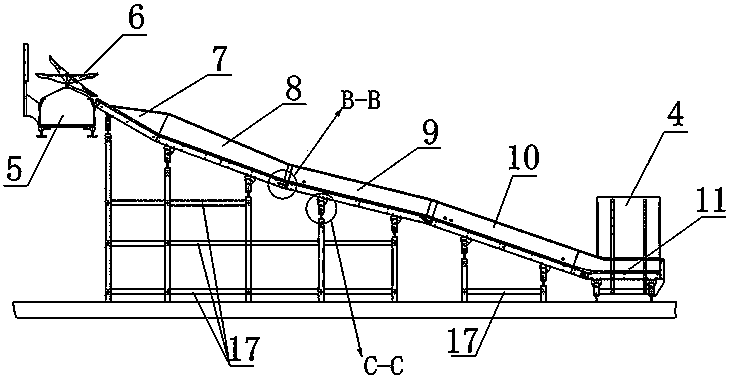

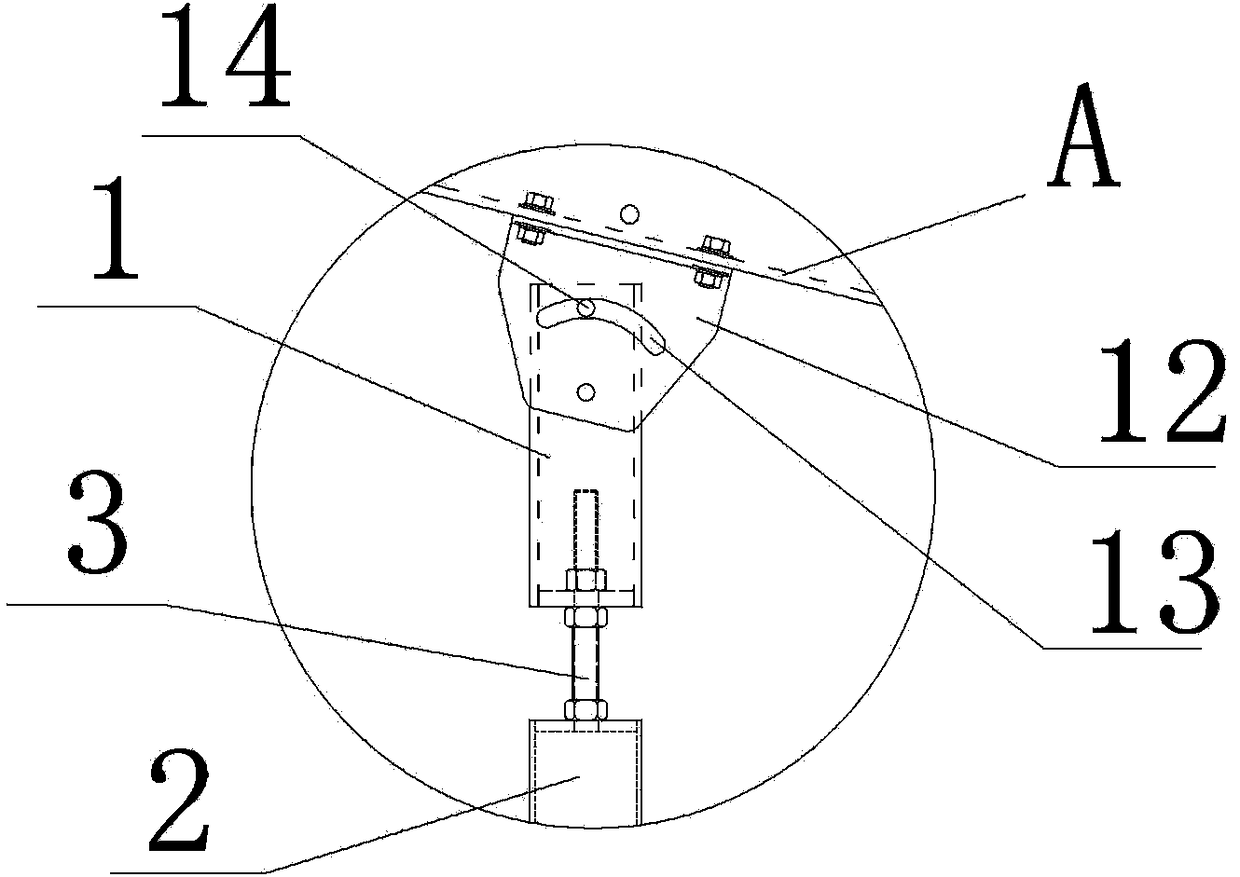

An adjustable double chute for airline luggage bags

The invention discloses adjustable double sliding troughs used for aviation luggage bags. The adjustable double sliding troughs comprise the sliding trough A, the sliding trough B, upper supporting rods, lower supporting rods and connecting rods. The sliding trough A is connected with a near bar-code separating machine which is close to a safety detection device, the sliding trough B is connected with a distant bar-code separating machine which is away from the safety detection device, and the near bar-code separating machine and the distant bar-code separating machine are each provided with luggage overturning plates. The sliding trough A and the sliding trough B each comprise a receiving section, an accelerating section and a buffering section. The sliding trough A further comprises a self-sliding section and a catching section. All the connected sections of the sliding trough A are connected movably and arranged at a certain inclination angle, and all the connected sections of the sliding trough B are connected movably and arranged at a certain inclination angle. Hinging heads, the upper supporting rods, the connecting rods and the lower supporting rods are sequentially arranged under the sliding trough A and the sliding trough B correspondingly, and the bottom ends of the lower supporting rods are fixed to the ground. The adjustable double sliding troughs used for the aviation luggage bags have the beneficial effects that the luggage bag separating efficiency is high, and damage caused by collision of the luggage bags is reduced.

Owner:MEISHAN DEXIN AVIATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com