Full-automatic pill making machine

A pill making machine, fully automatic technology, applied in the direction of making medicines into special physical or ingestible devices, etc., can solve the problems of wasting labor, time-consuming and labor-intensive, and can not guarantee uniform powdering and powdering dosage, etc. good powder effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

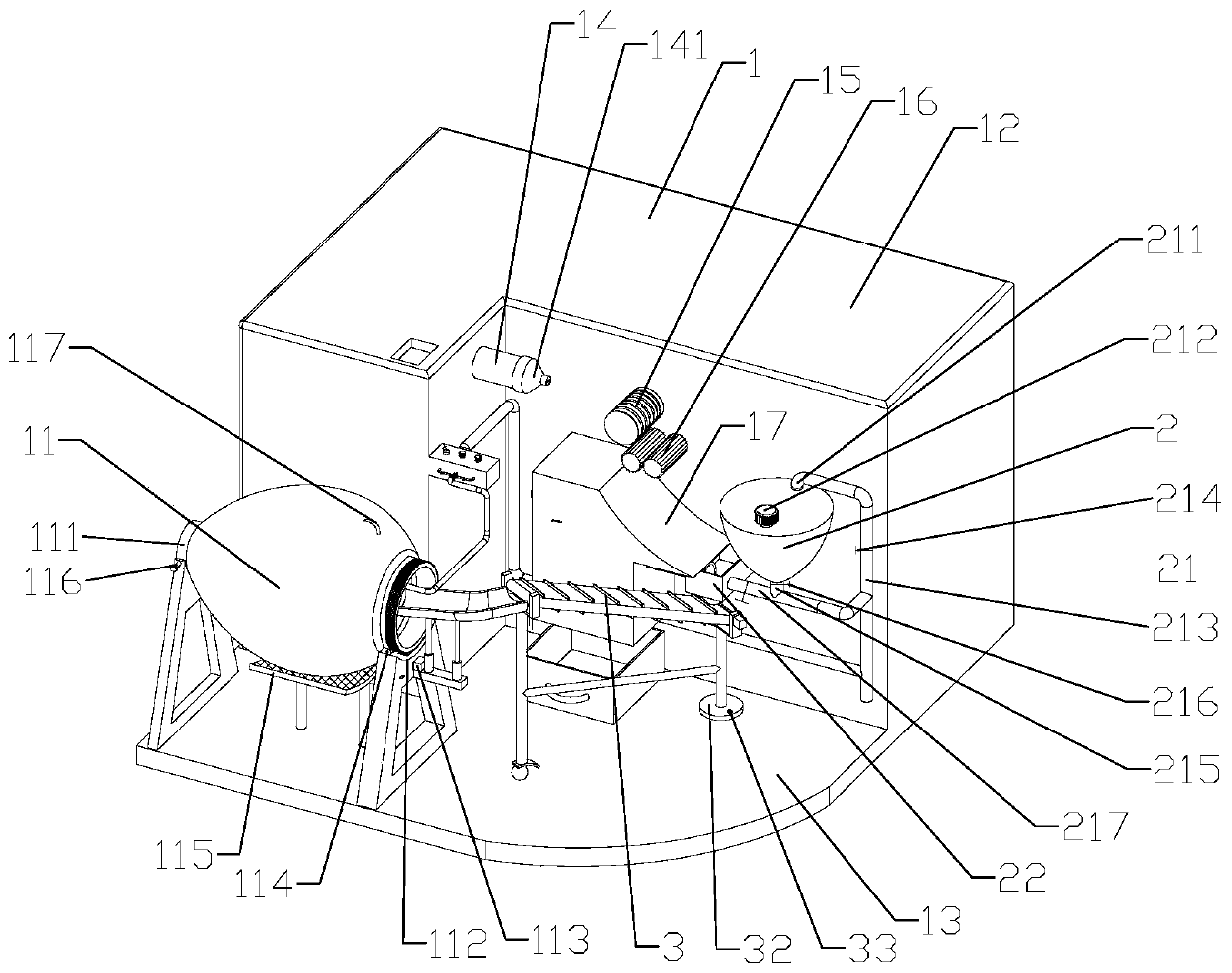

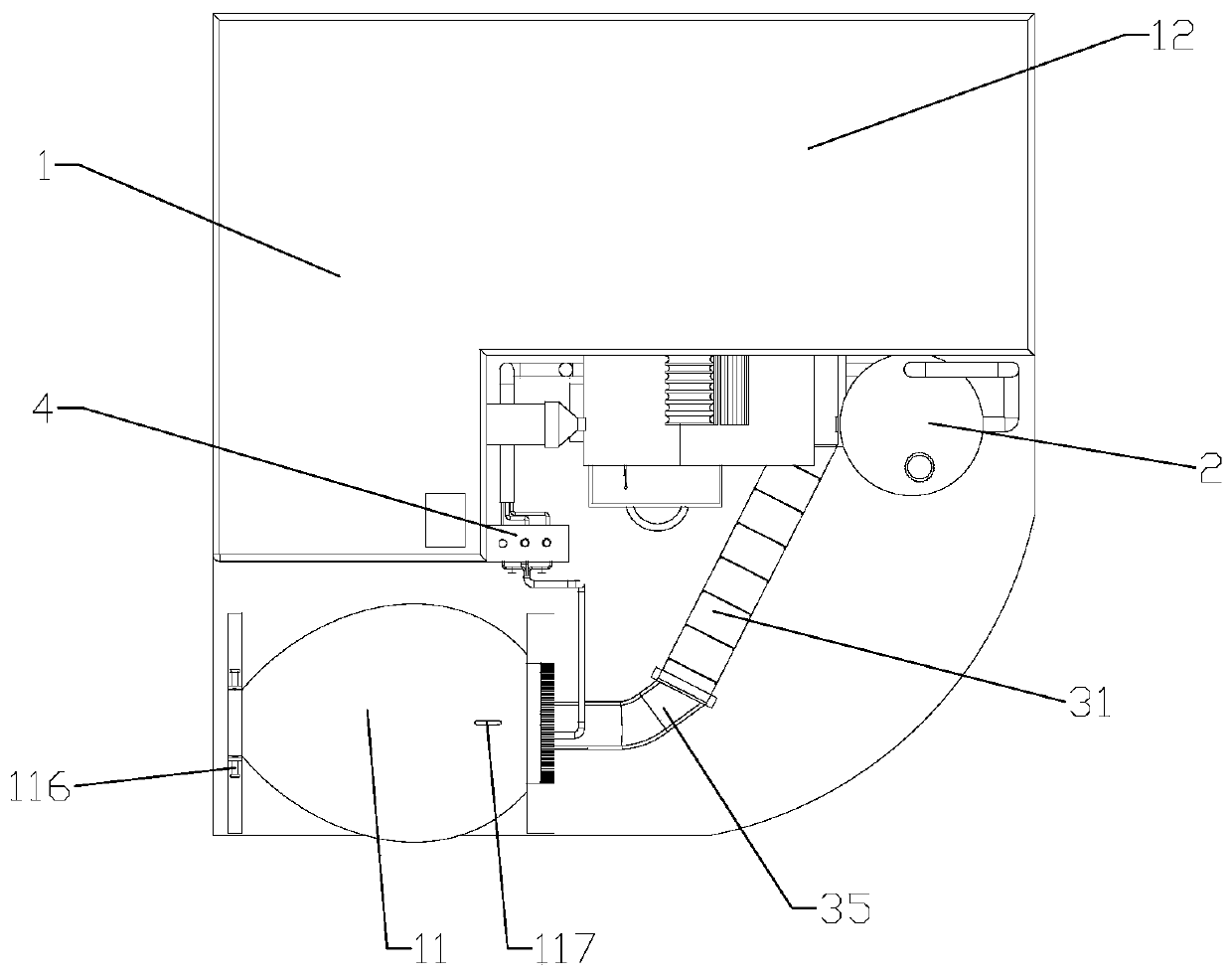

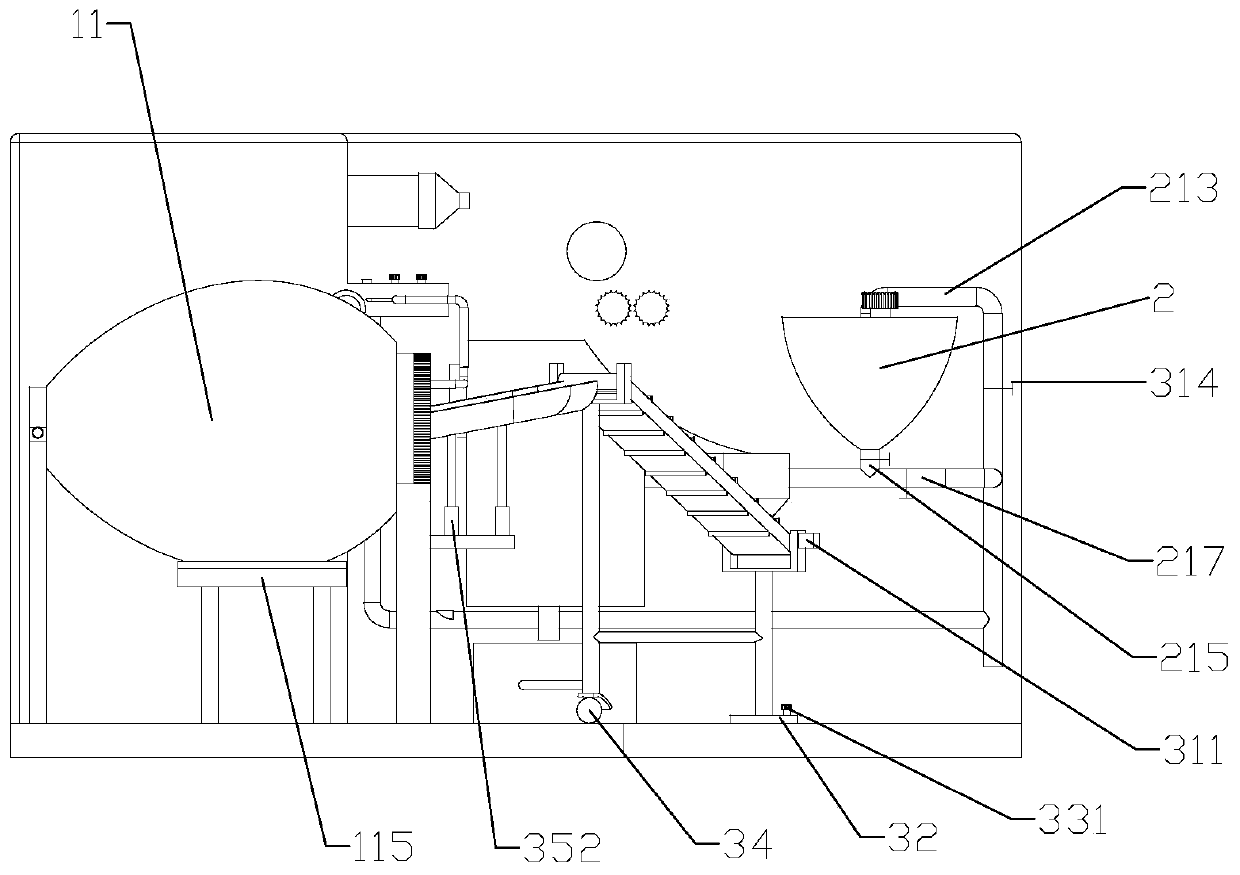

[0047] as attached figure 1 to attach Figure 21 Shown, a kind of full-automatic pill making machine, it comprises pill making machine 1 and coating machine pan body 11, and pill making machine 1 includes body 12, base 13, extruding strip outlet 14, transition wheel 15 and pill extruding roller 16 , Extrusion outlet 14 is provided with outlet 141 by screw thread detachable connection, outlet 141 has multiple models, can make pills of different diameters. The below of pill extruding roller 16 is provided with inclined slide plate 17 (namely figure 1 The right side of the Chinese medicine powder collection box 23 is inclined to form an arc-shaped landslide).

[0048] The automatic pill making machine also includes a powder spreading device 2 , a pill conveying mechanism 3 and a polishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com