Diamond wire removal machine and application method thereof

A technology of diamond wire and waste wire machine, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. The effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

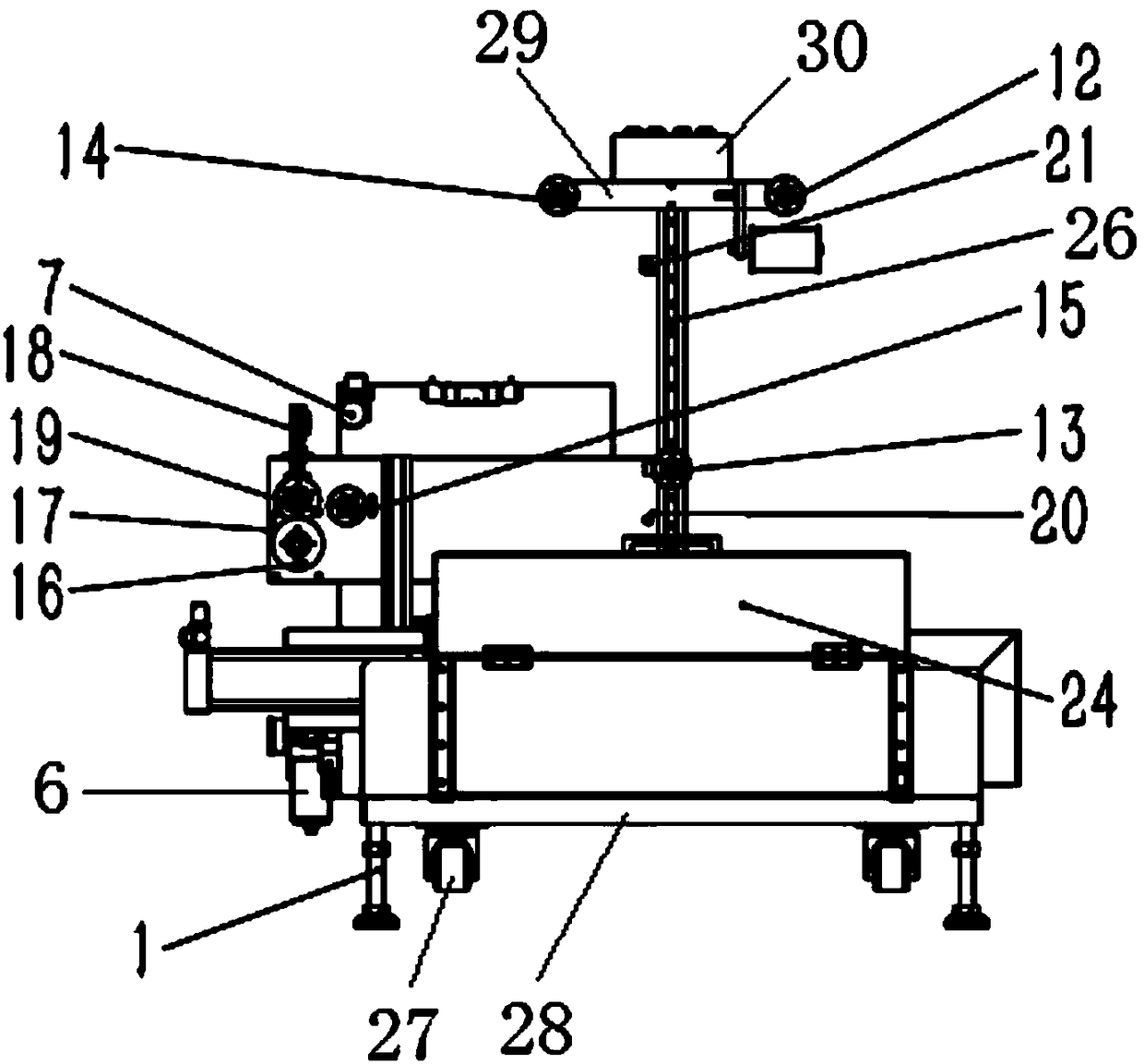

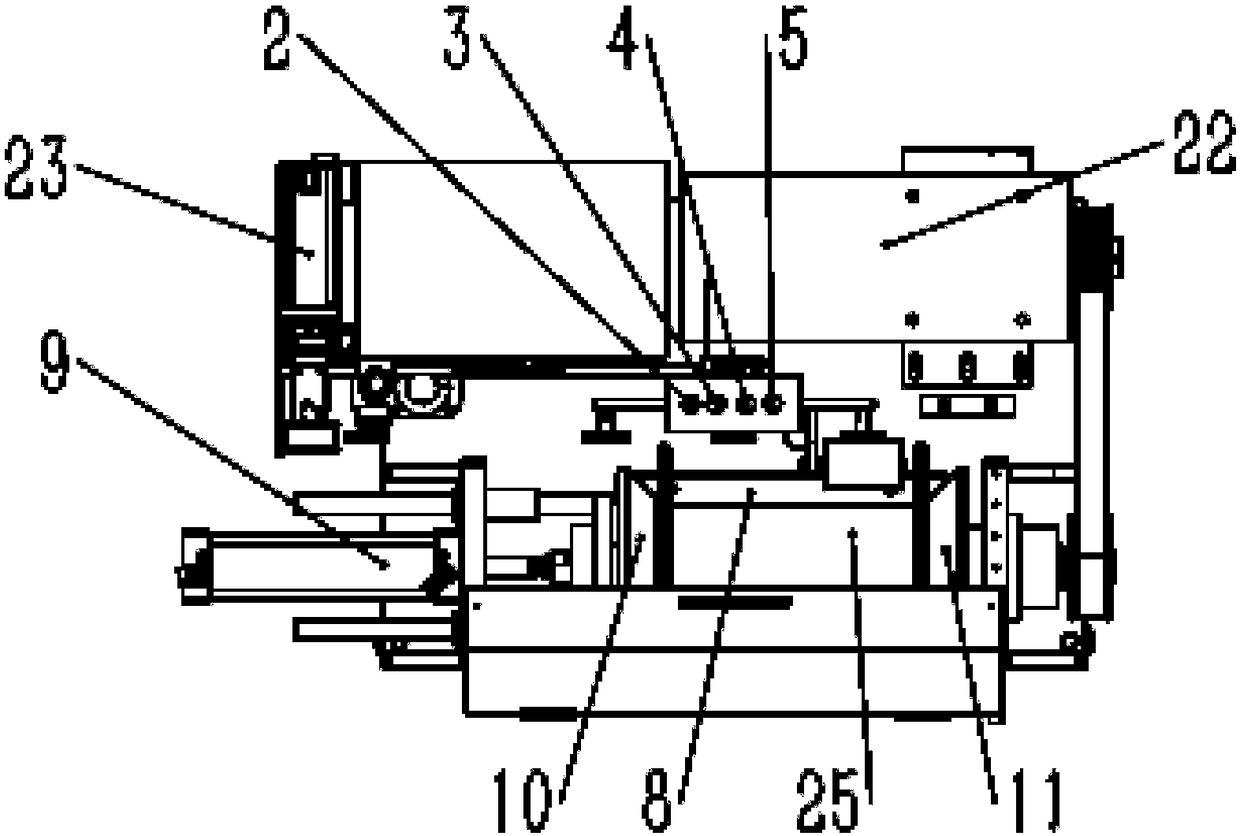

[0032] The diamond wire waste wire machine of the present embodiment, as figure 1 with 2 Shown, comprise frame 28, I-shaped wheel drive device, diamond wire lead-out device and switch device 30, I-shaped wheel drive device, diamond wire lead-out device are arranged on frame 28, switch device 30 is arranged on the diamond wire lead-out device top;

[0033] The I-shaped wheel driving device includes a large clamping cylinder 9, a V-shaped support plate 8, a top wheel 10, a fixed wheel 11, and an I-shaped wheel rotating motor 22. The top wheel 10 and the fixed wheel 11 are arranged symmetrically, and the fixed wheel 11 and the frame 28 Fixed connection, the top wheel 10 can slide back and forth along the direction of the fixed wheel 11 and is set on the frame 28, the V-shaped support plate 8 is arranged below between the top wheel 10 and the fixed wheel 11, and the clamping large cylinder 9 is close to the top wheel 10 is arranged to drive the top wheel 10 to slide back and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com