Composite pump with small pump conducting strong flow return and big pump conducting small-quantity ejection

A compound pump, large pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of reducing and losing a large number of injection channels and a small amount of injection channels, such as backflow prevention and blockage, to reduce manufacturing costs, The effect of reducing wear and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

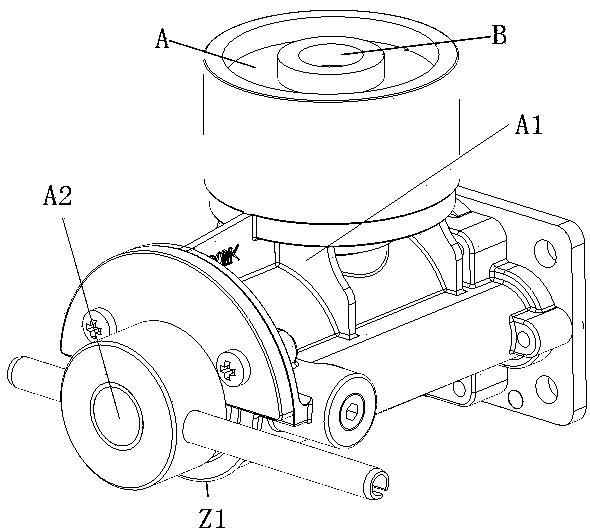

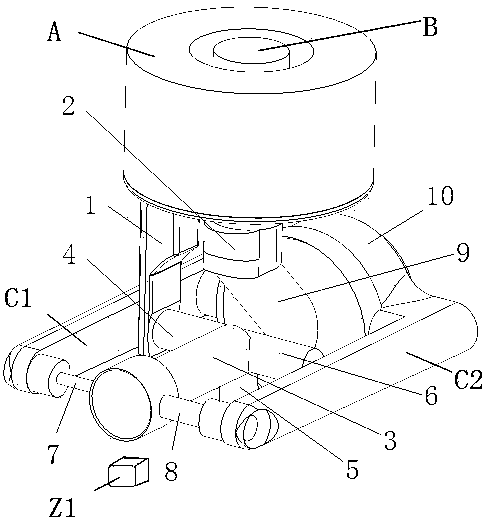

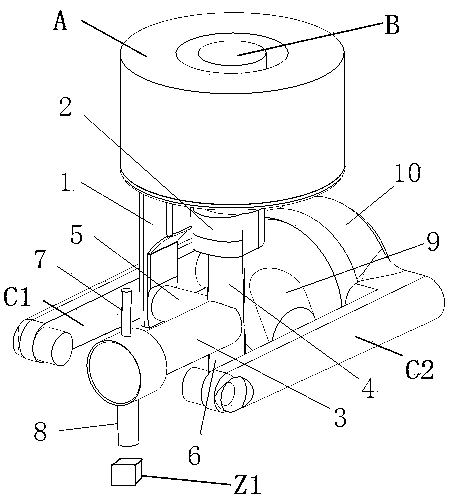

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0053] Such as Figure 6-9 As shown, the small pump has strong backflow and the large pump injects a small amount of compound pump. The valve body A1 is provided with a large pump inlet and outlet 11 and a small pump inlet and outlet 12. The axial channel 13 of the valve core A2 is provided with a first radial channel 14. , the second radial channel 15 and the third radial channel 16, one end of the axis channel 13 of the spool A2 is also provided with a first injection channel 17 and a second injection channel 18, the diameter of the first injection channel 17 Greater than the diameter of the second injection channel 18, the other end of the spool A2 is provided with an inclined channel 19, and one end of the inclined channel 19 is connected to the color paste barrel inlet and outlet 20, wherein, when the pump valve is in the initial position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com