Multi-channel air suction mute cavity

A silent cavity and multi-channel technology, applied in the direction of liquid displacement machinery, variable displacement pump components, machines/engines, etc., to achieve the effects of reducing noise, increasing gas transmission coefficient, and improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

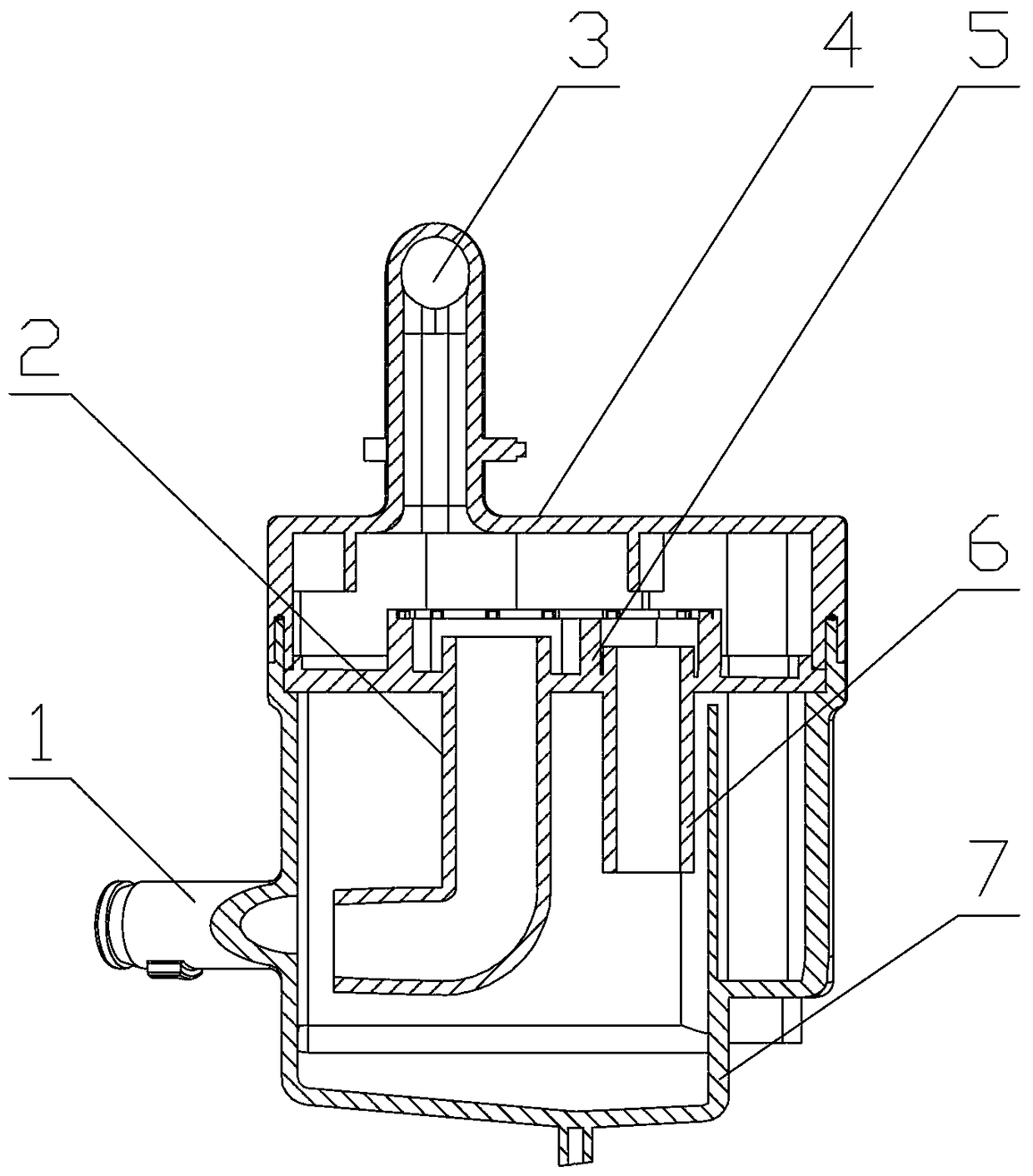

[0019] Example 1: see figure 1 , which is a direct suction double-communication pipe type suction muffler chamber, which includes an upper quiet room 4 and a lower quiet room 7 and a communication mechanism 5 installed between the two rooms, and the upper quiet room 4 is equipped with The air outlet 3 and the lower silent chamber 7 are provided with an air inlet 1, especially: a U-shaped main communication channel 2 and a secondary communication channel 6 are designed on the communication mechanism 5, and the inner diameter of the U-shaped main communication channel 2 is φ10-φ12mm , the specific option is φ8mm, the wall thickness is 4.5-5mm, the specific option is 1mm, the total length is 33-35mm, the specific option is 30mm; the inner diameter of the secondary communication channel 6 is φ8.5-φ10mm, the specific option is φ5mm, the wall thickness is 4.5 -5mm, specifically 2mm is optional, the total length is 26-30mm, specifically 16mm is optional. (The specific value of each ...

example 2

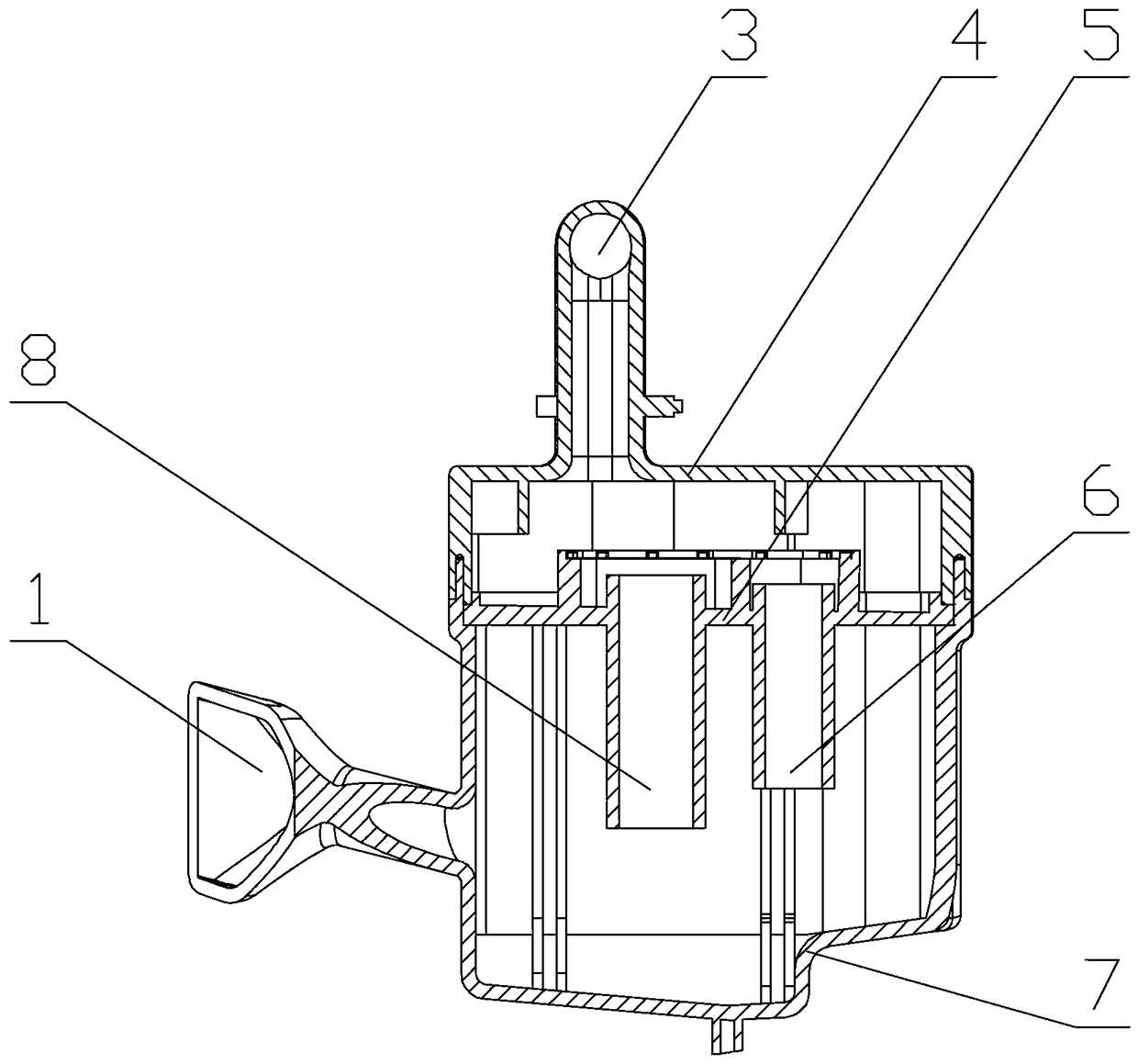

[0020] Example 2: see figure 2 , which is a semi-direct suction three-communication pipe-type suction muffler chamber, which consists of an upper quiet room 4, a lower quiet room 7 and a communication mechanism 5 installed between the two rooms, and there is a The air outlet 3, the lower silent room is provided with an air inlet 1, especially: a horizontal pipe, a vertical pipe type main communication channel 8 and two auxiliary communication channels 6 are designed on the communication mechanism 5 (two auxiliary communication channels 6 Front and back arrangement, one shown in the figure), the inner diameter of horizontal pipe and vertical pipe type main communication channel 8 is φ10mm, the wall thickness is 3mm, the total length is 20mm, and the inner diameter of two auxiliary communication channels 6 is φ4mm, and the wall thickness is 2mm , the total length of each secondary communication channel is 15mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com