An environment-friendly hydrocarbon mixed refrigerant replacing r134a and its application

A mixed refrigerant, environmentally friendly technology, applied in heat exchange materials, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of compressor discharge temperature without any improvement, GWP value not reaching EU standards, Can not be completely replaced and other problems, to achieve the effect of reducing irreversible loss, low adiabatic index, and reducing exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] R1270 and R600a, which are commonly used in the field of refrigerants and have a purity of more than 99.99wt%, are fully physically mixed with R1270 and 64% R600a with a mass percentage of 36% in the liquid phase.

Embodiment 2

[0030] R1270 and R600a, which are commonly used in the field of refrigerants and have a purity of more than 99.99wt%, are fully physically mixed with R1270 and 63% R600a with a mass percentage of 37%.

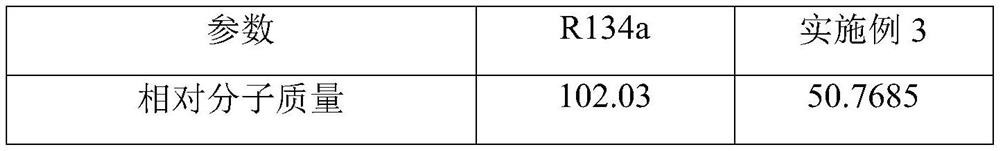

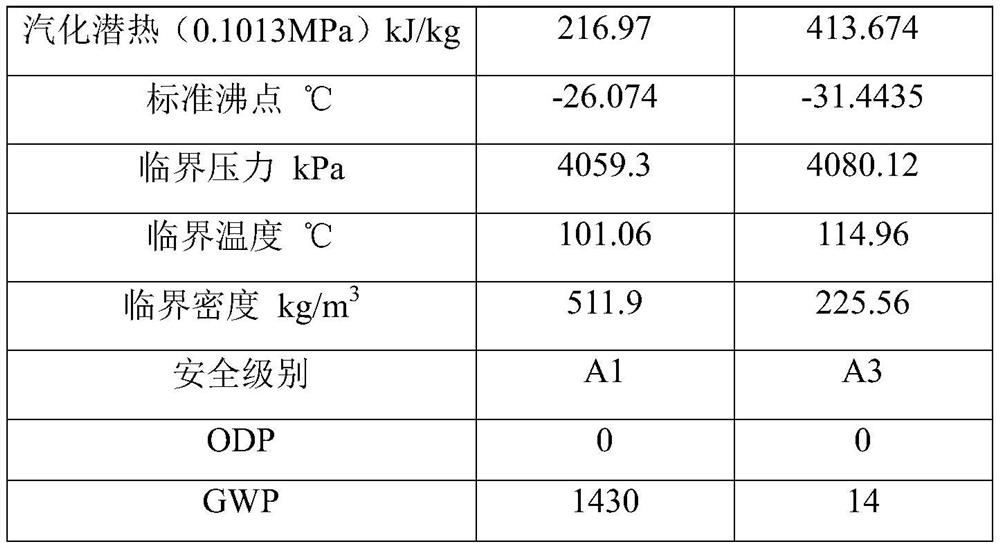

Embodiment 3

[0032]R1270 and R600a, which are commonly used in the field of refrigerants and have a purity of more than 99.99wt%, are fully physically mixed with R1270 and 62% R600a with a mass percentage of 38% in the liquid phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com