A built-in sncr spray gun

A built-in, spray gun technology, used in spray devices, liquid spray devices, separation methods, etc., can solve problems such as difficulty meeting process requirements, increasing boiler volume, and heavy spray gun weight, saving consumption, reducing operating volume, and reducing Effects of steps and actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

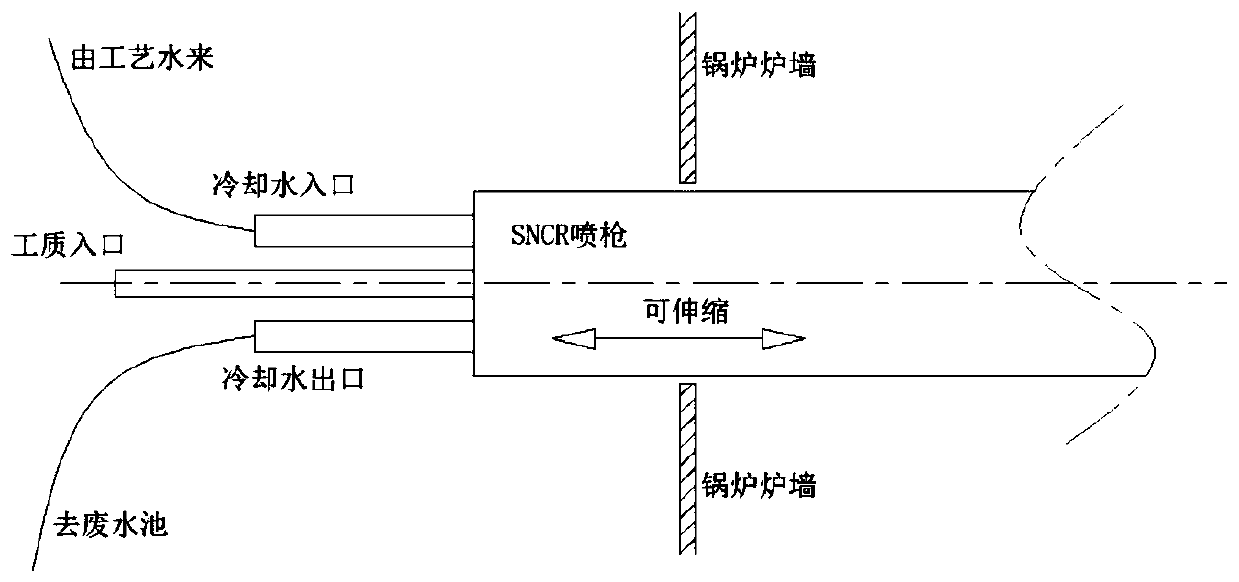

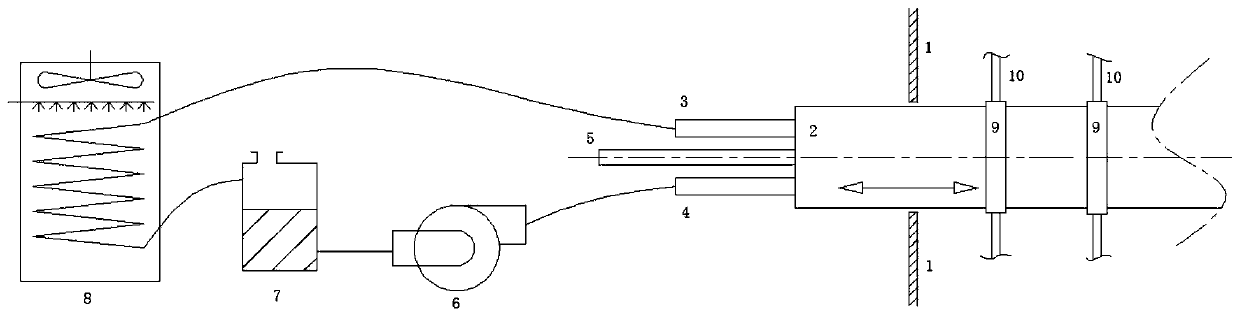

[0021] The present invention as figure 2 As shown, it includes the SNCR spray gun body 2 inserted into the boiler furnace from the boiler furnace wall 1. The SNCR spray gun body 2 is provided with a connected evaporative cooling medium outlet 3 and an evaporative cooling medium inlet 4; A plurality of tube clips 9 on the body 2, and an evaporative cooling medium with a boiling point lower than 100°C circulating between the evaporative cooling medium outlet 3 and the evaporative cooling medium inlet 4; the outside of the tube clips 9 is fixed on the corresponding heating surface 10 in the furnace Above; the gap between the pipe clamp 9 and the SNCR spray gun body 2 can ensure the free expansion of the SNCR spray gun body 2 after being heated; the evaporative cooling medium entering the evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com