A support structure and method for an thermal insulation outer guard plate at an expansion joint

A technology for supporting structures and outer guard plates, applied in the direction of thermal insulation, building thermal insulation materials, building components, etc., can solve the problems of difficult construction, waste of steel, and lower thermal insulation performance of thermal insulation materials, so as to shorten the installation period, simplify installation and save energy. The effect of steel and artificial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific examples.

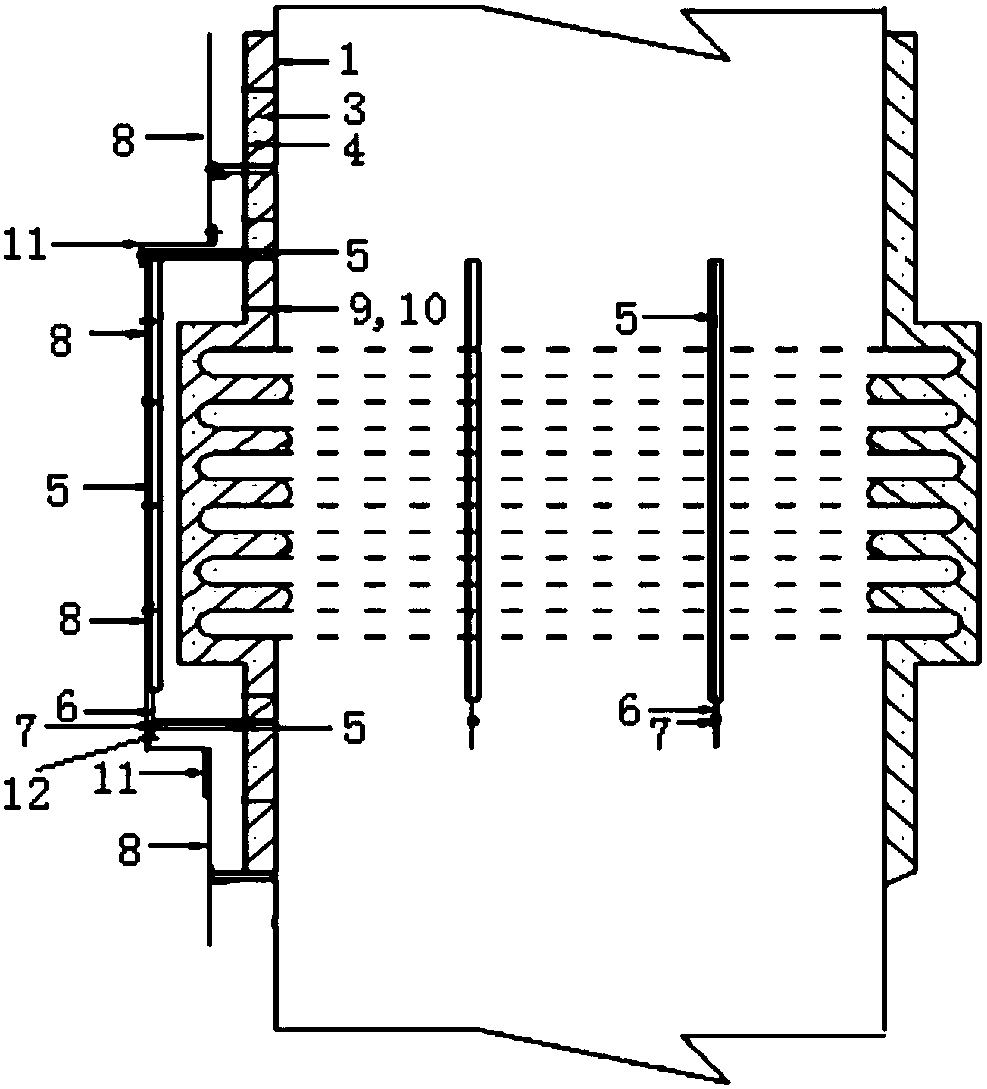

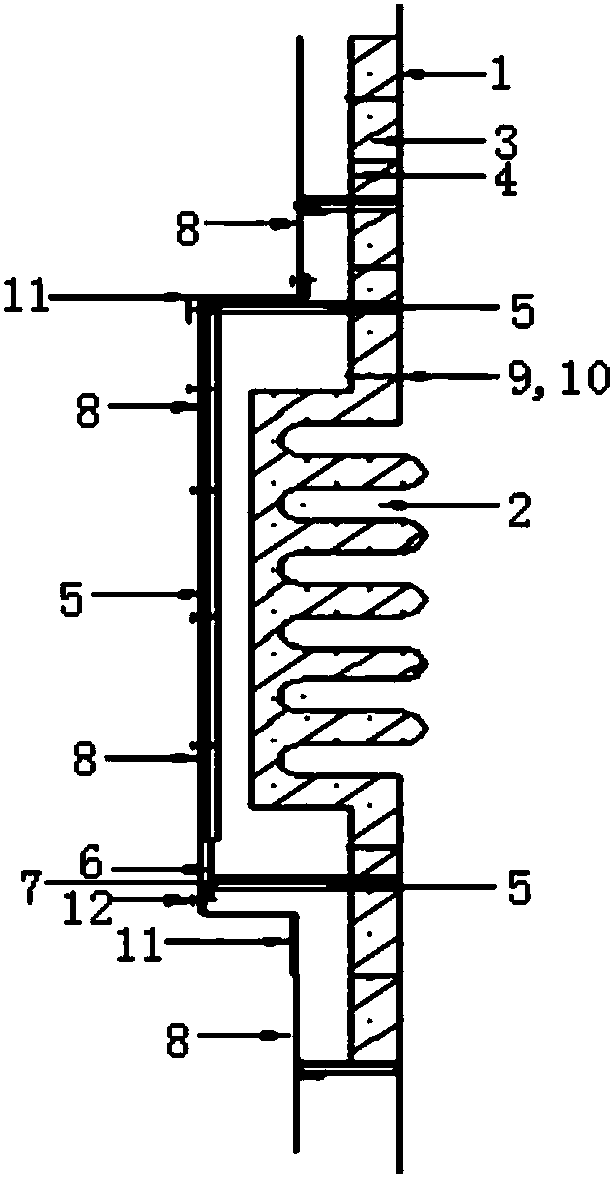

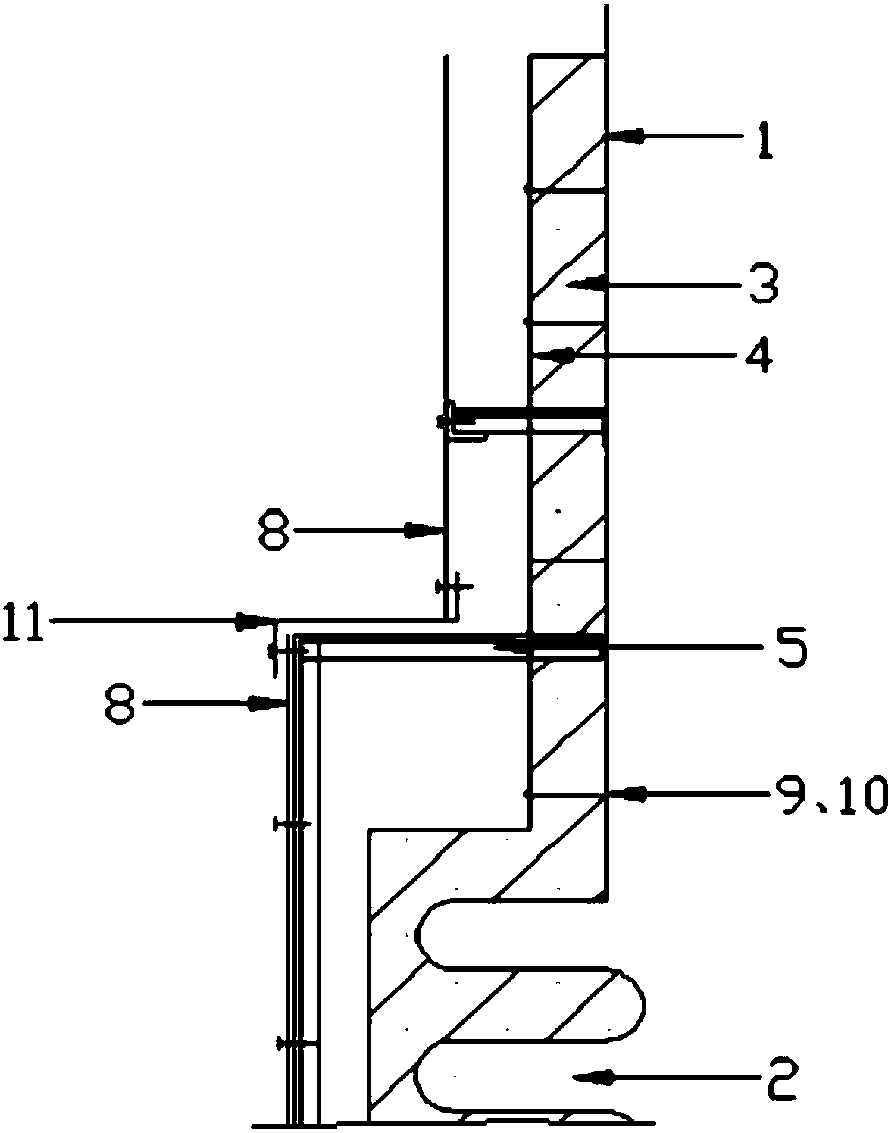

[0037] Such as Figure 1 to Figure 4 As shown, a construction plan for the support structure of the thermal insulation outer shield at the expansion joint, including several supports, the outer shield 8, the limit support 7 and the sliding end guide rod 6, one end of the support is fixed on the expansion On the housing at one end of section 2, the other end of the support member is fixedly connected with the sliding end guide rod 6;

[0038] The limit support 7 is fixed on the housing at the other end of the expansion joint 2, a guide hole is set on the limit support 7, and the free end of the sliding support 6 is inserted into the guide hole; the outer guard plate 8 is installed on the outer surface of the support plate.

[0039] The surface of the guide hole is smooth, and the outer surface of the sliding end guide rod 6 is smooth.

[0040] The length of the outer guard p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com