A method for manufacturing a suction valve plate of a reciprocating piston compressor

A suction valve plate, reciprocating piston technology, applied in the field of refrigeration compressors, can solve the problems of difficulty in further improving the COP of the compressor, large relative clearance, small gas transmission coefficient, etc., so as to improve the ability to resist fatigue damage and the clearance The effect of volume reduction and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

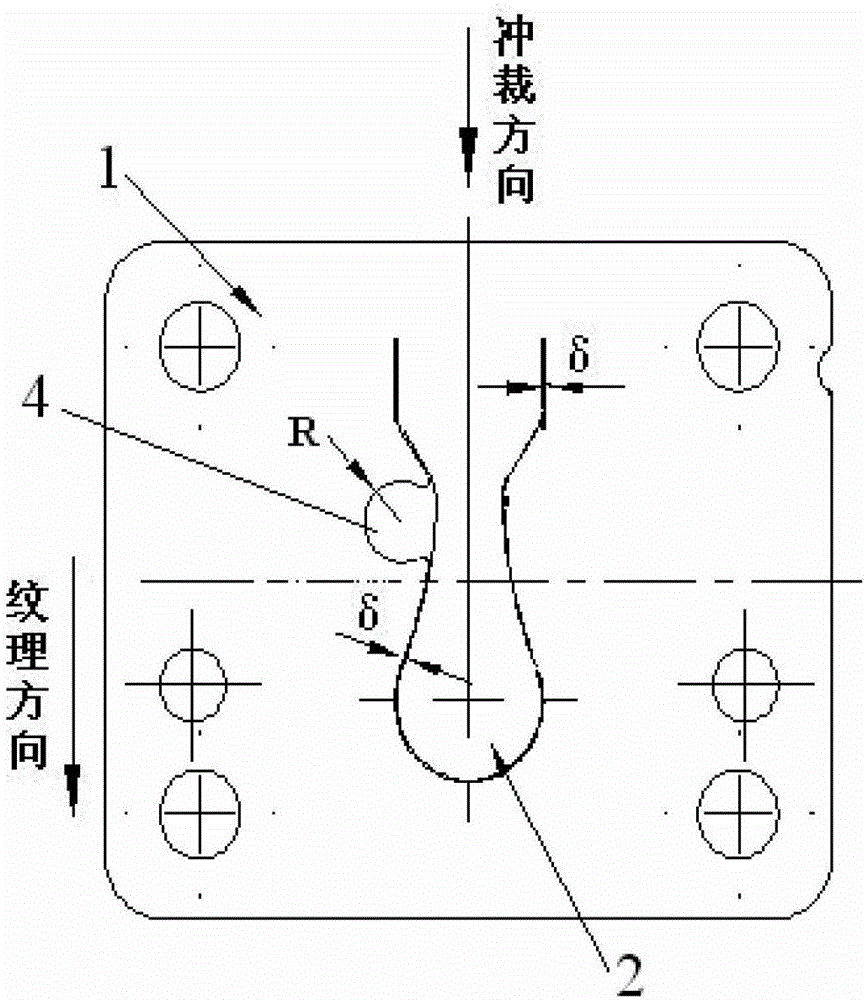

[0028] Such as figure 1 The structure of the present invention shown is a suction valve plate of a reciprocating piston compressor, which is used for a fully enclosed reciprocating piston refrigeration compressor, and is provided with a valve plate body 1, a suction valve reed 2 and an exhaust hole 4.

[0029] In order to solve the problems existing in the prior art and overcome its defects, realize the invention purpose of improving the gas transmission coefficient of the suction valve plate, improving the COP and compressor efficiency, and improving the reliability of the suction valve plate, the technical scheme adopted by the present invention is:

[0030] For the suction valve plate of the reciprocating piston compressor of the present invention, the gap between the suction valve reed 6 and the valve body 1 is δ≤0.4mm; the radius of the exhaust hole 4 is R3.

[0031] The longitudinal direction of the suction valve reed 2 is the punching direction, and the punching direct...

Embodiment 2

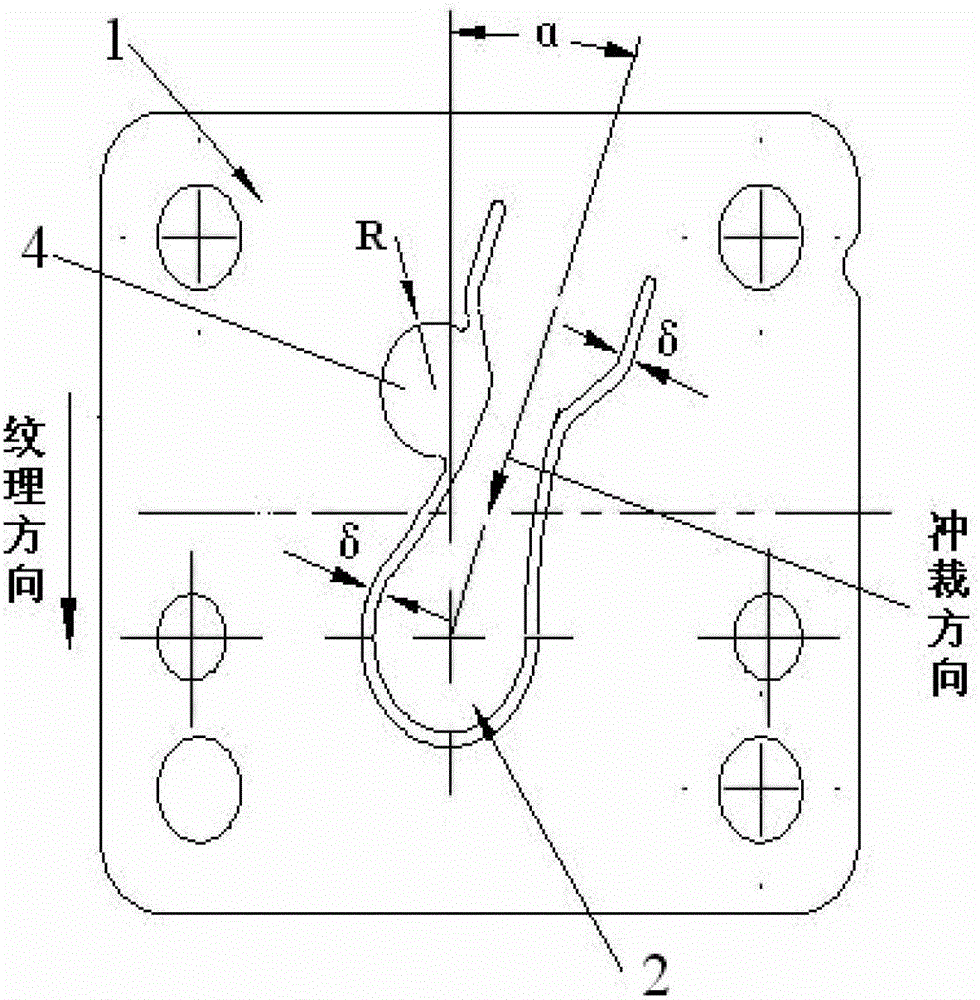

[0040] Such as figure 2 As shown, the punching direction in the first embodiment is changed to form this embodiment: that is, the included angle between the punching direction and the texture direction of the valve body 1 is 5°-20°. All the other technical solutions are the same as in Embodiment 1.

[0041] The material of the above-mentioned small gap suction valve plate of the present invention is Sandvik 20C carbon steel, and the reed position and the punching direction of the valve plate form an included angle of 5° to 20°. The same as in the first embodiment: the gap width of the suction valve plate is reduced from 0.4 to 0.5 mm in the prior art to 0.1 mm to 0.2 mm, even smaller than 0.1 mm; Air hole 4 is adjusted from R3.5 to R3.

[0042] Through design improvement, the relative clearance volume c=0.045 is reduced to c=0.03, the volume coefficient λv increases, the pressure coefficient λp increases due to the reduction of the relative clearance volume c and the increa...

Embodiment 3

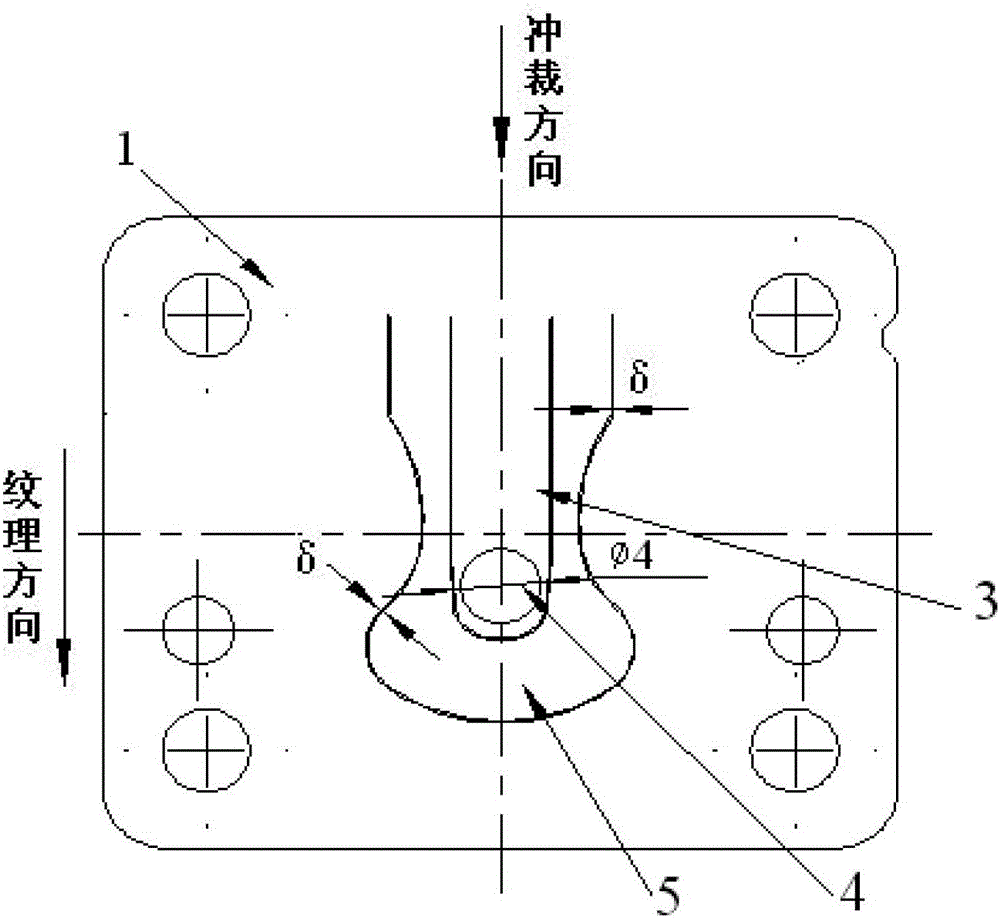

[0046] The carbon steel strip Sandvik20C in Embodiment 1 or Embodiment 2 is replaced to form this embodiment, that is, the material of the above-mentioned suction valve plate is changed to spring steel strip 7C27Mo2. All the other technical solutions are the same as those in Embodiment 1 or Embodiment 2.

[0047]Martensitic stainless steel 7C27Mo2 has extremely high fatigue strength under bending and impact stress, and high residual compressive stress on the surface. This determines that the tensile stress on the punching edge of the valve plate is changed into compressive stress after punching and rolling, which greatly enhances the fatigue strength of the valve plate and the straightness of the valve plate; the fatigue strength of the valve plate and the After the flatness of the valve is increased, the lift of the valve plate can be increased, the airflow loss of the valve plate can be reduced, the efficiency of the compressor can be improved, the air transmission coefficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com