Method for determining uncertainty of flatness measurement result of flat plate under on-site environment

A technology of field environment and measurement results, applied in the field of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The invention provides a method for determining the uncertainty of the flatness measurement result of a flat panel in an on-site environment. The method comprises the following steps:

[0082] 1) Determine the level of the plate placed in the X and Y directions, determine the jump of the detection equipment value due to the vibration of the surrounding environment, and determine whether the composite uncertainty includes the uncertainty component caused by the level of the plate and the surrounding vibration according to the measurement results .

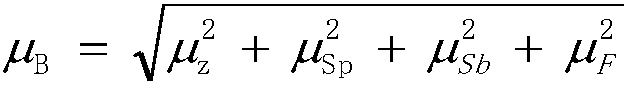

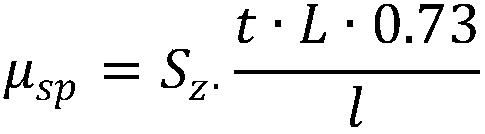

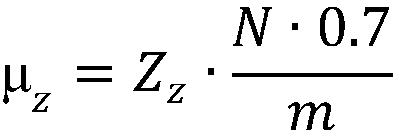

[0083] 2) Determine the uncertainty component calculation formula caused by the system effect to calculate the B-type uncertainty component of the flatness measurement result of the plate to be tested in the field environment where μ z Uncertainty component introduced for environmental vibration, μ Sp Uncertainty component introduced for the horizontal case, μ Sb Uncertainty component introduced by the measuring device, μ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap