Method for testing air tightness of battery boxes

A technology for air tightness test and battery box, which is applied in the direction of using liquid/vacuum for liquid tightness measurement. Quantity and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

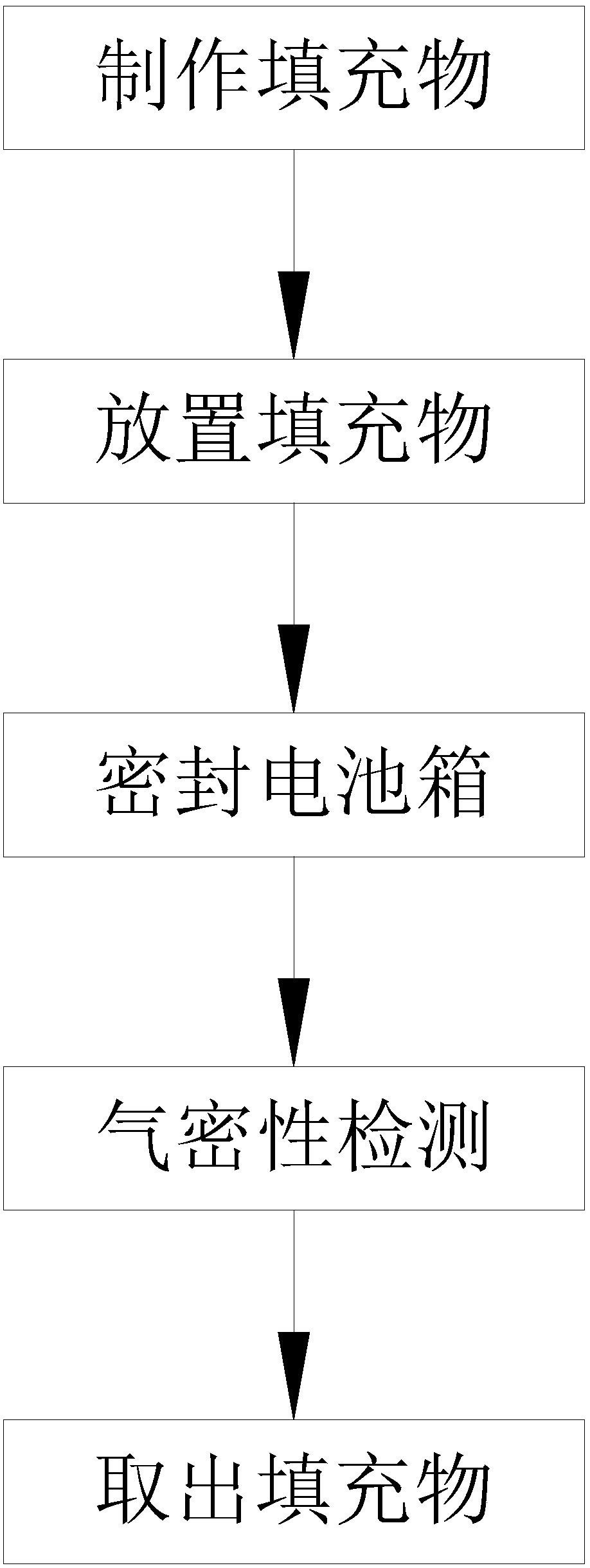

[0018] Such as figure 1 Shown is a method for testing the airtightness of a battery box, the method comprising the following steps:

[0019] (1) Making fillers: according to the size and quantity of battery modules in the battery pack, make fillers to replace the battery modules. The size of the fillers is similar to that of the battery modules. At the same time, the fillers are light and easy to handle , The characteristics of not releasing and absorbing gas, and the volume will not change due to changes in external pressure;

[0020] (2) Place filler: place filler in the battery box so that the proportion of space occupied by the filler in the battery box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com