A photoresist soft drying device

A photoresist and soft-baking technology, applied in optics, optomechanical equipment, instruments, etc., can solve the problems of insufficient exhaust capacity, residual photoresist, soft-bake exhaust alarm and downtime, etc., to avoid exhaust downtime , Increase the exhaust pressure, improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are only for reference The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention. In the figures, structurally similar elements are denoted by the same reference numerals.

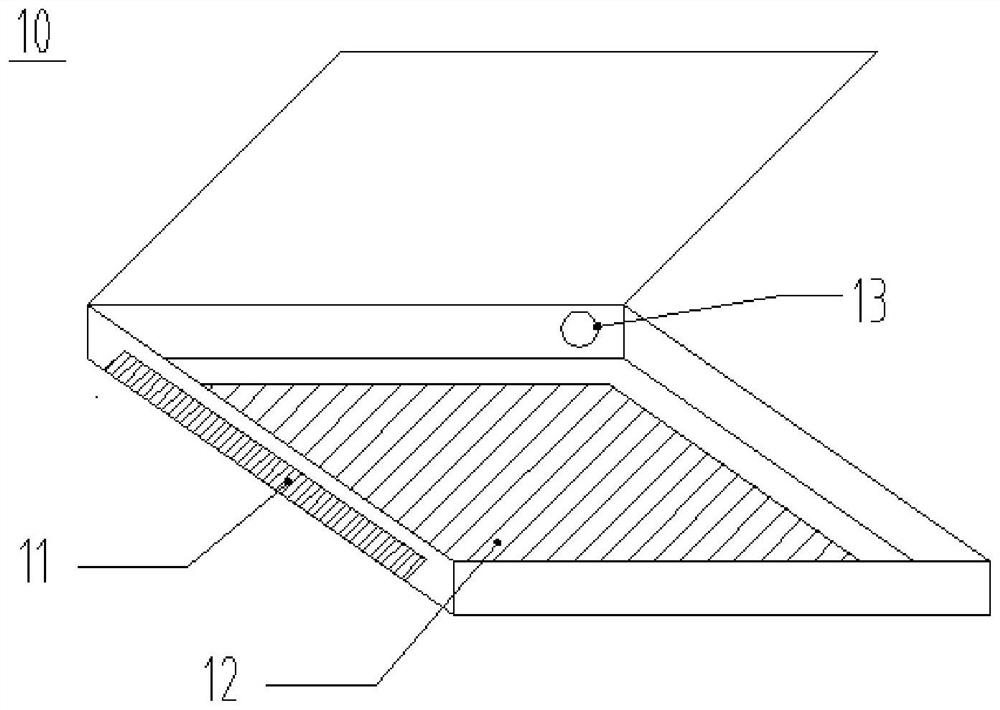

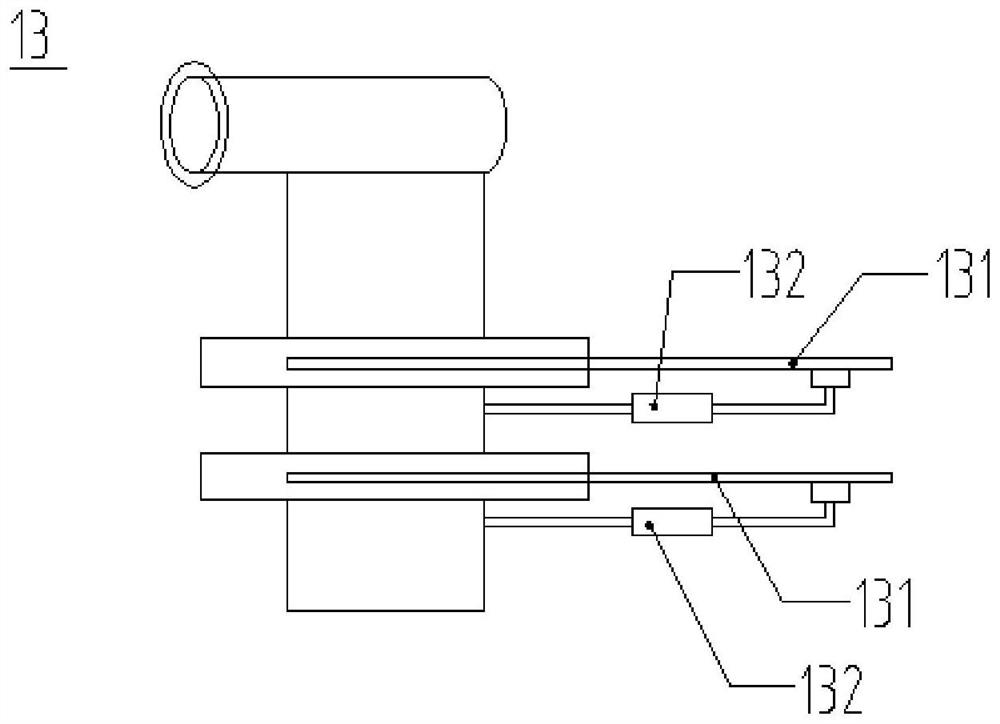

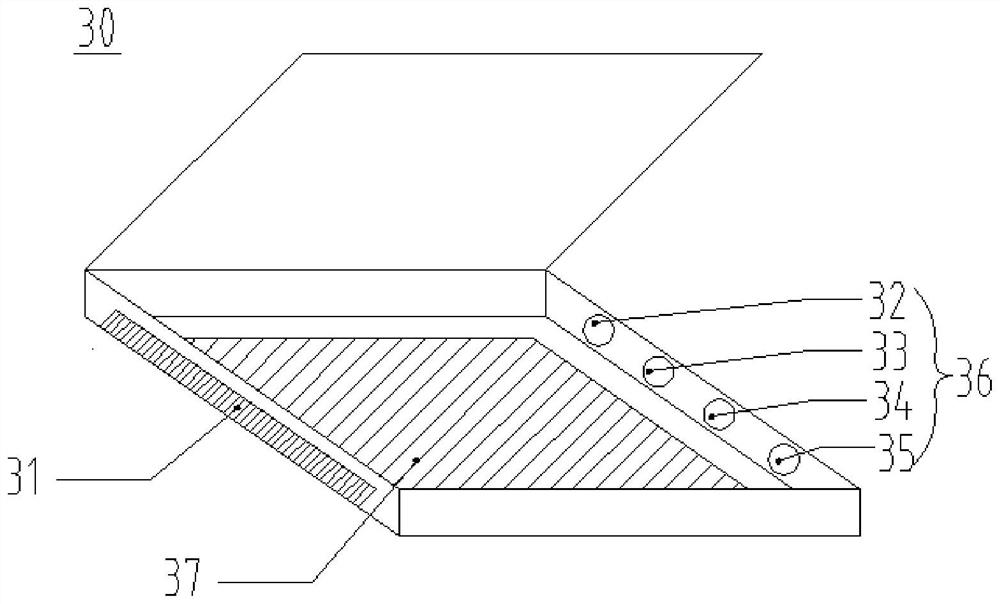

[0030] Such as figure 1 As shown, it is a schematic structural diagram of a photoresist soft-baking device in the prior art. The device includes a chamber 10, a hot air knife 11 is provided at the left end of the chamber 10, and a row of The gas port 13 and the substrate 12 coated with photoresist are placed in the chamber 10 . Such as figure 2 As shown, it is a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com