Feeding system of solid polyolefin catalysts

A polyolefin catalyst and feeding system technology, applied in the field of olefin polymerization, can solve the problems of long catalyst feeding process, increased production cost, unstable feeding, etc., to avoid sticking or bridging, save production costs, and facilitate maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

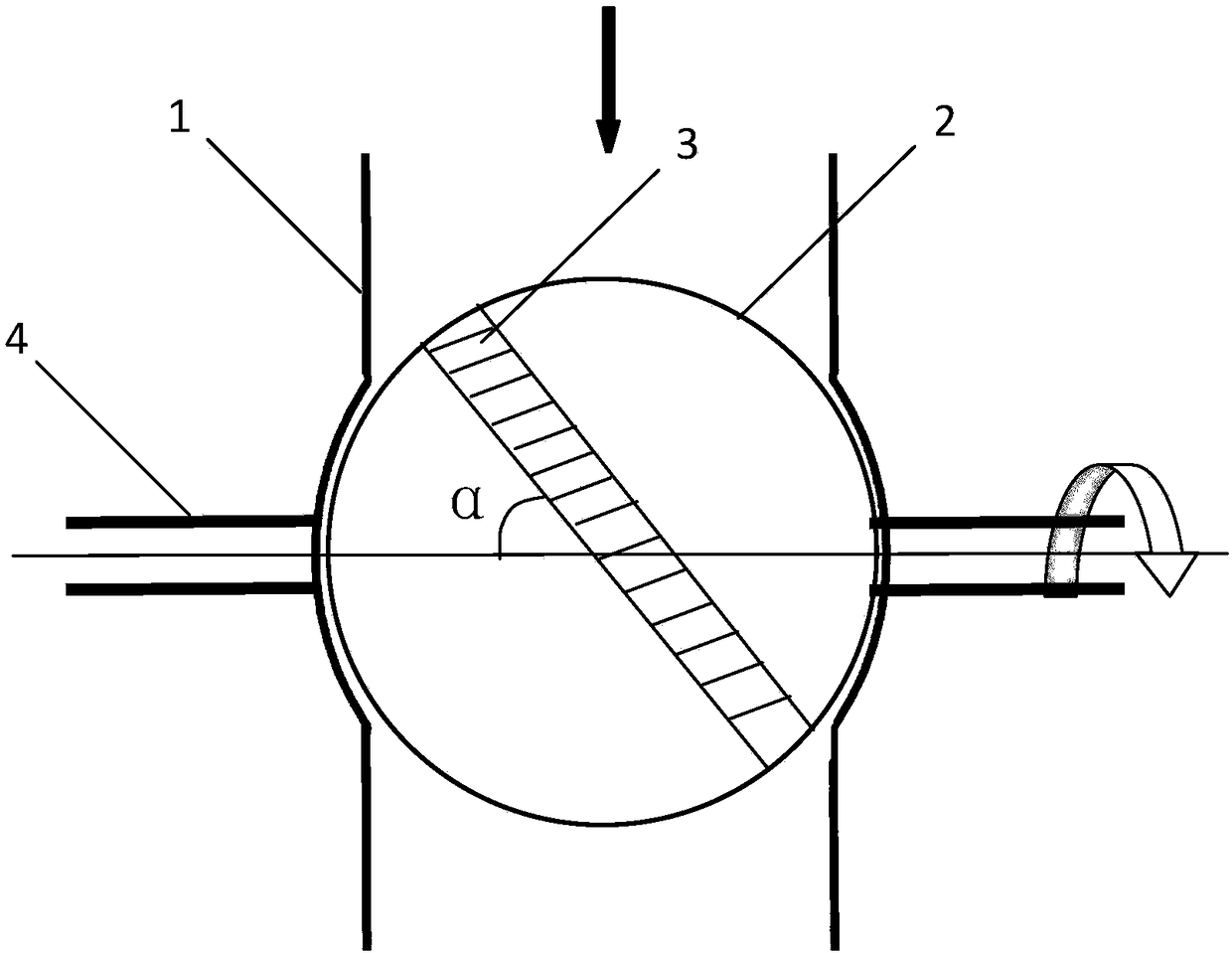

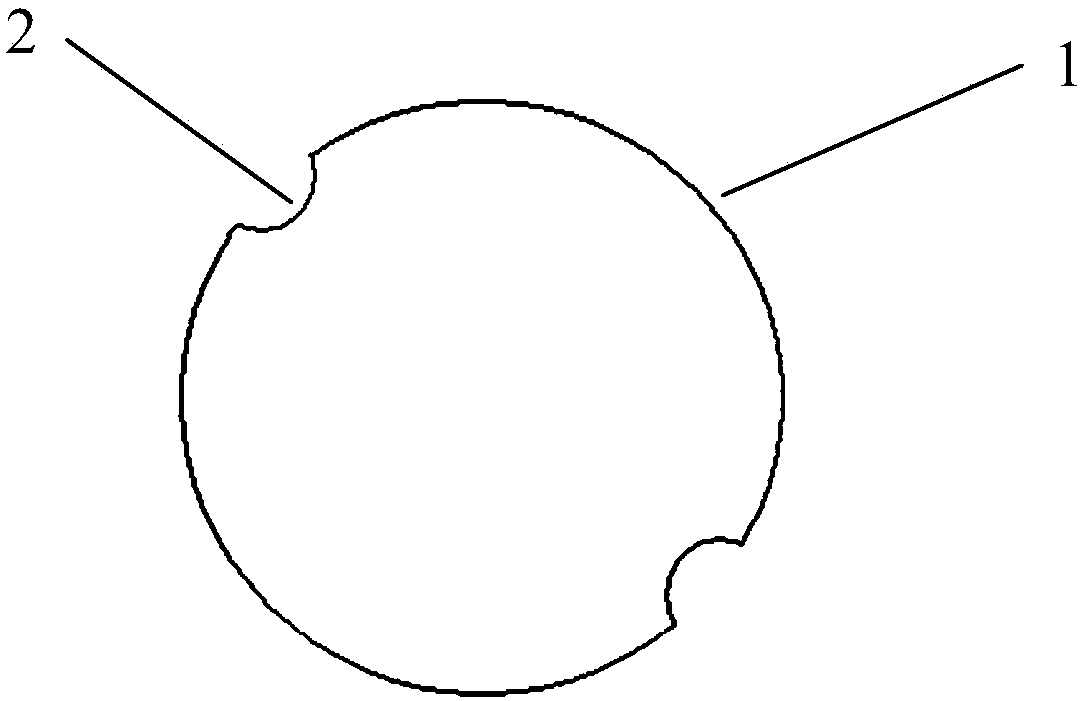

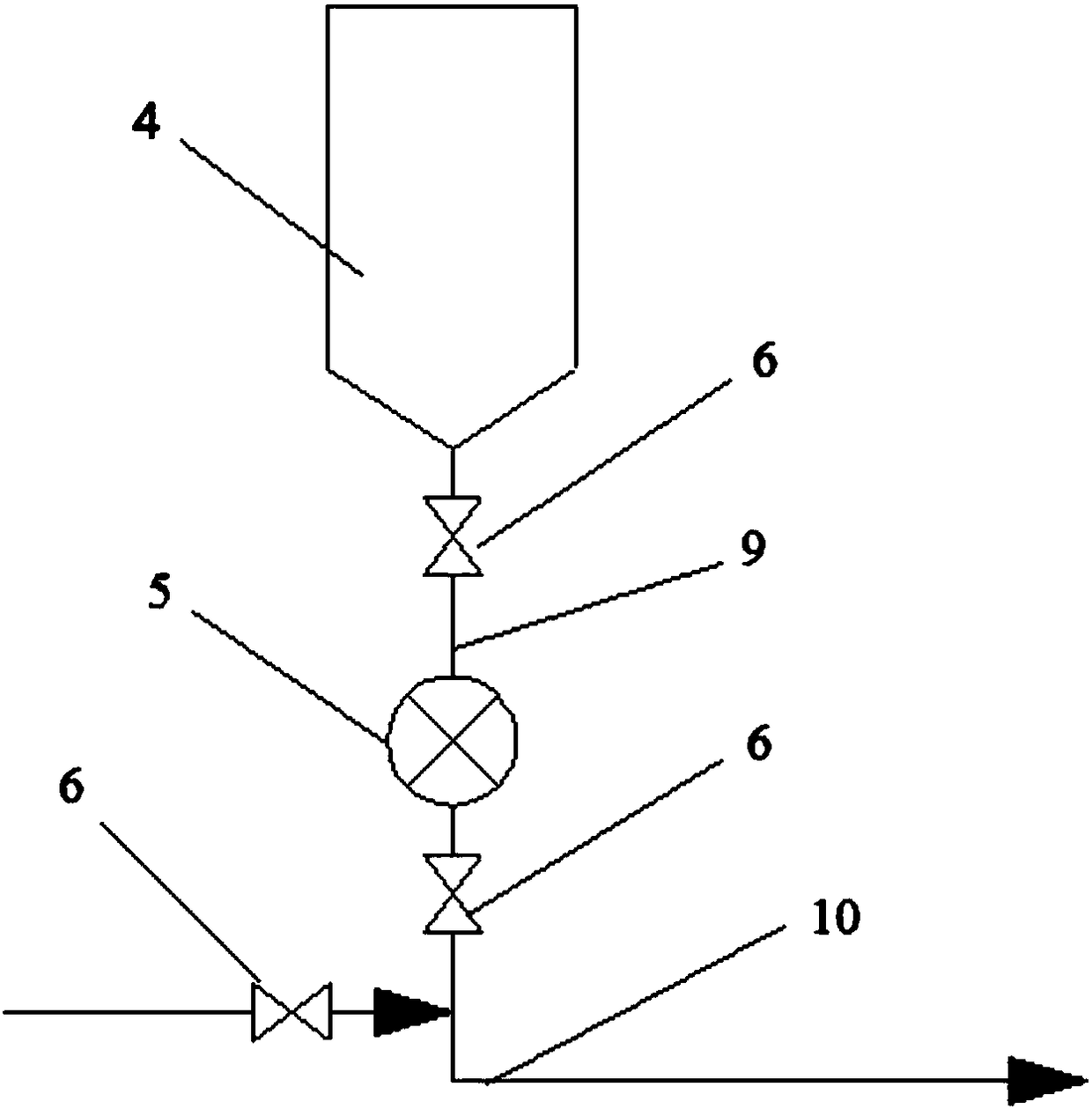

[0059] Determine that the angle between the direction of a circle of grooves 3 on the surface of the spherical body 2 and the transverse axis is 15°C, and use the invalid Ti-based catalyst to accurately measure and calibrate the different rotation speeds of the spherical body 2. The specific process is to rotate the spherical body 2 The speed is set to 2 rpm, 4 rpm, 6 rpm, 7 rpm, 8 rpm, 9 rpm, 10 rpm, 12 rpm, 14 rpm, 16 rpm, 20 rpm, 30 rpm, measure the amount of catalyst feed in 5 minutes, 10 minutes, 15 minutes, 30 minutes, 1 hour, and take the average value, and then draw the The relationship curve between the amount of material and the rotation speed of the sphere 2, and determine its relationship formula. Obtain the relationship curve or relational expression between the amount of catalyst feed and the rotation speed of the sphere 2, and the amount of catalyst feed can be accurately measured and controlled by adjusting the rotation speed of the sphere. The rotation of the ...

Embodiment 2

[0063] Determine that the angle between the direction of a circle of grooves 3 on the surface of the spherical body 2 and the transverse axis is 20°C, and use the invalid Cr-based catalyst to accurately measure and calibrate the different rotation speeds of the spherical body 2. The specific process is to rotate the spherical body 2 The speed is set to 2 rpm, 4 rpm, 6 rpm, 7 rpm, 8 rpm, 9 rpm, 10 rpm, 12 rpm, 14 rpm, 16 rpm, 20 rpm, 30 rpm, measure the amount of catalyst feed in 5 minutes, 10 minutes, 15 minutes, 30 minutes, 1 hour, and take the average value, and then draw the The relationship curve between the amount of material and the rotation speed of the sphere 2, and determine its relationship formula. Obtain the relationship curve or relational expression between the amount of catalyst feed and the rotation speed of the sphere 2, and the amount of catalyst feed can be accurately measured and controlled by adjusting the rotation speed of the sphere. The rotation of the ...

Embodiment 3

[0067] Determine that the angle between the direction of a circle of grooves 3 on the surface of the spherical body 2 and the transverse axis is 30°C, and use the spent metallocene catalyst to accurately measure and calibrate the different rotation speeds of the spherical body 2. The specific process is to rotate the spherical body 2 The speed is set to 2 rpm, 4 rpm, 6 rpm, 7 rpm, 8 rpm, 9 rpm, 10 rpm, 12 rpm, 14 rpm, 16 rpm, 20 rpm, 30 rpm, measure the amount of catalyst feed in 5 minutes, 10 minutes, 15 minutes, 30 minutes, 1 hour, and take the average value, and then draw the The relationship curve between the amount of material and the rotation speed of the sphere 2, and determine its relationship formula. Obtain the relationship curve or relational expression between the amount of catalyst feed and the rotation speed of the sphere 2, and the amount of catalyst feed can be accurately measured and controlled by adjusting the rotation speed of the sphere. The rotation of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap