Material crushing system provided with dust collecting device

A crushing system and vacuum device technology, applied in grain processing, food science, cocoa, etc., can solve problems such as unsmooth feeding, material blockage, low processing efficiency, etc., to prevent left and right swinging, prevent material congestion, and reduce vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

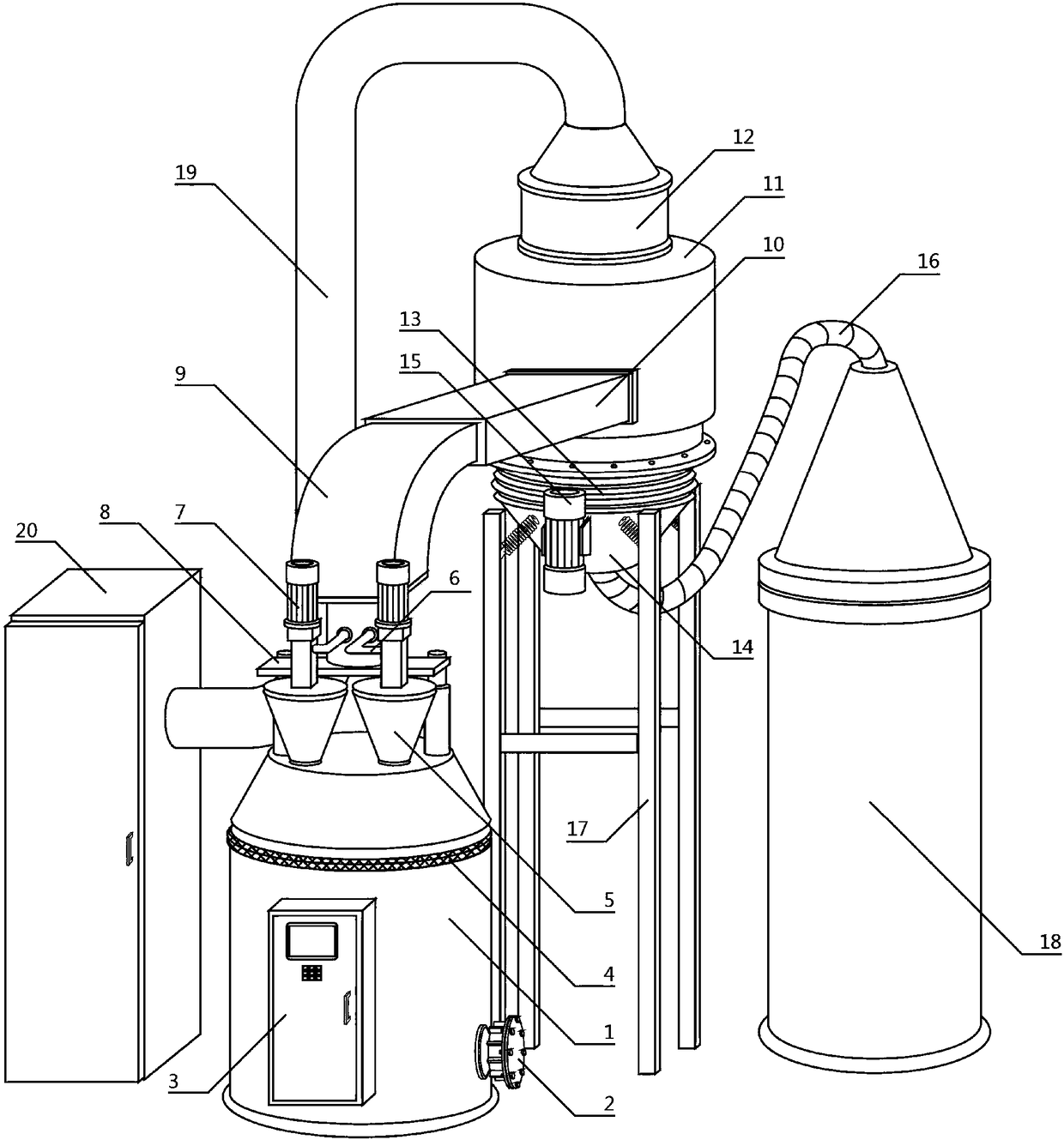

[0024] Such as figure 1A material crushing system with a dust suction device is shown, which is characterized in that it includes a material storage cabin 1, several material extraction buffer cabins 5, a feed support 8, a sealed conveying channel 9, a material extractor 10, and a crushing cabin 11 , dust conveyor 12, buffer channel 13, vibrating hopper 14, support frame 17, material collection cabin 18, dust conveying channel 19 and dust adsorption cabin 20, described material storage cabin 1 is also provided with feeding blue plate 2, airtight door 3 and screen 4, the feeding blue pan 2 is located on one side of the storage cabin 1, the feeding blue pan 2 is fixedly connected with the storage cabin 1, and the sealing door 3 is located on the side of the feeding blue pan 2 On one side, the airtight door 3 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com