Controllable solid phase micro-extraction handle

A controllable, extraction technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of limited types of solid-phase microextraction handles and high prices, and achieve improved performance and utilization, low cost, and easy replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

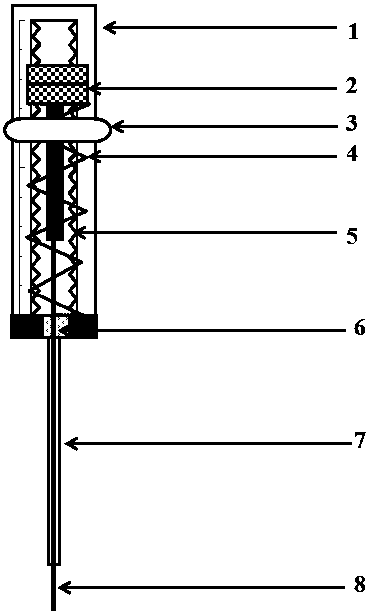

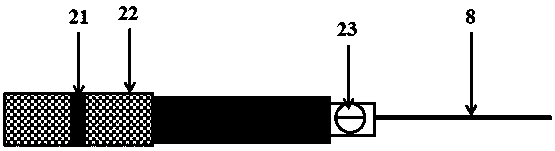

[0029] Such as figure 1 As shown, the controllable solid-phase microextraction handle includes a handle barrel 1, a metal sleeve 7 and an extraction probe 8 with stainless steel wire or silicon oxide as the support material. The handle barrel 1 is provided with a positioning ring 3, and is embedded with a push button 2 arranged on the zigzag guide rail 5; the lower end of the handle barrel 1 is provided with a metal sleeve fixing bracket 6, and the metal sleeve fixing bracket 6 and the metal sleeve 7 connected; the bottom end of the push button 2 is connected with the metal sleeve fixing support 6;

[0030] Wherein: the bottom end of the push button 2 is connected with the metal sleeve fixing bracket 6 through the spring 4 .

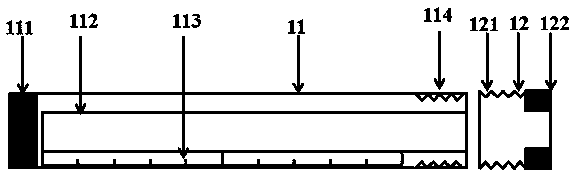

[0031] The handle barrel 1 comprises an upper half 11 and a lower half 12 connected together (see figure 2 ), the upper half 11 is provided with a scale line 113, one end of which is provided with a guide rail fixing groove 111, and a push button slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com