Method for processing excess tape of communication IC metal-based carrier board

A technology of metal base and carrier board, which is applied in the cleaning/polishing, photolithography/patterning, patterning and photolithography of conductive patterns, etc., to achieve the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

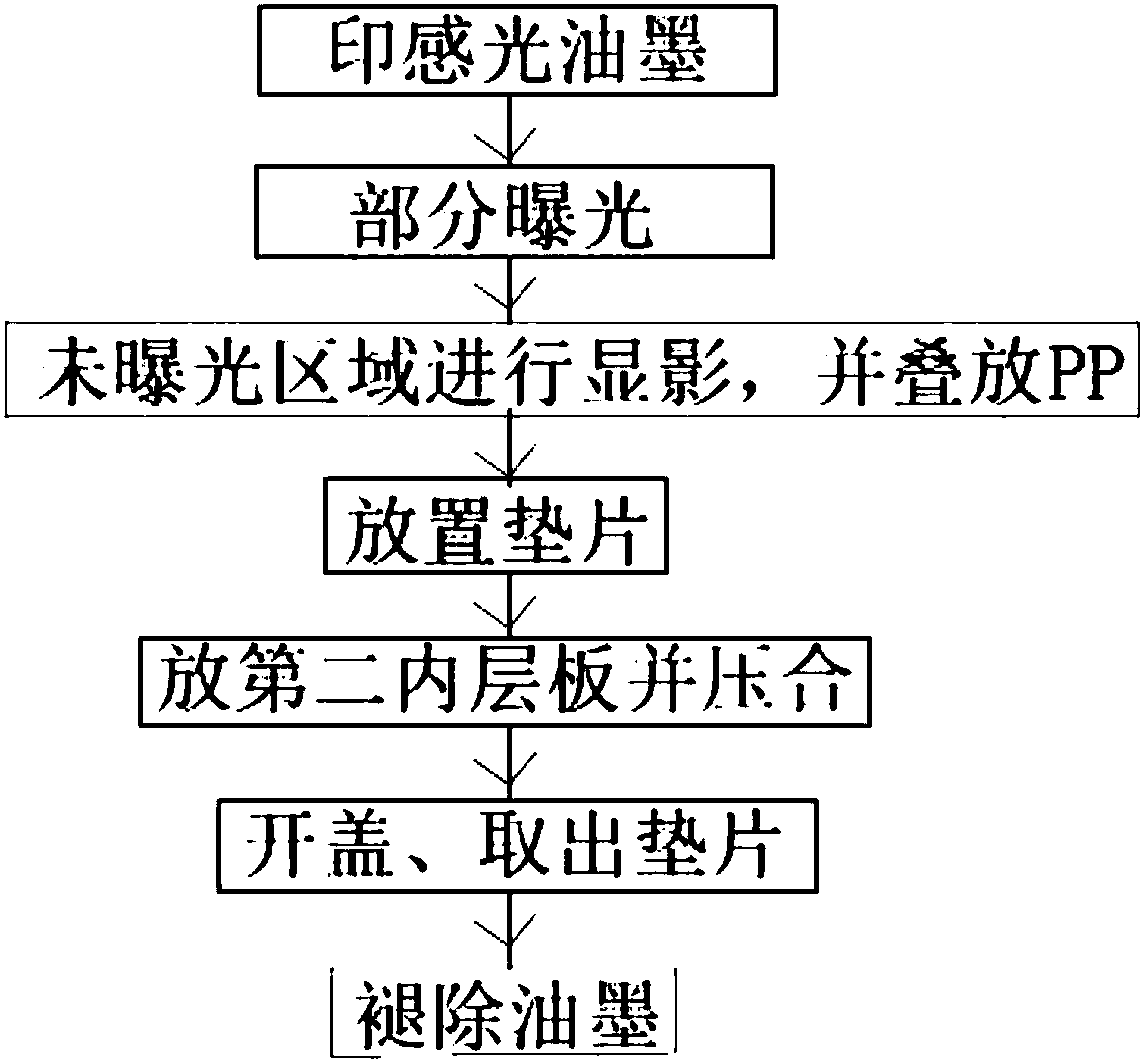

[0020] see figure 1 , the preferred embodiment of the present invention provides a kind of method for solving the residual glue of IC metal-based carrier board used for communication, comprising the following steps: then exposing the ink in the region that needs to be grooved on the first inner layer board, so that the ink occurs Optical reaction; then developing the ink in the unexposed area on the first inner layer plate to remove the ink through a chemical reaction, removing the ink in the unexposed area through a chemical reaction, and stacking PP on the developed area, Make the PP powder produced during the pressing process fall on the ink; then place a gasket in the area where the PP is not stacked, and play a supporting role in the second inner layer board pressing process; then place the PP and the gasket Place the second inner layer board on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com