Polished Dust Hood

A dust hood, dry polishing technology, used in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of dust reflux and unsatisfactory dust collection efficiency, and achieve airflow flow Smooth, anti-regurgitation, combined with a gentle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

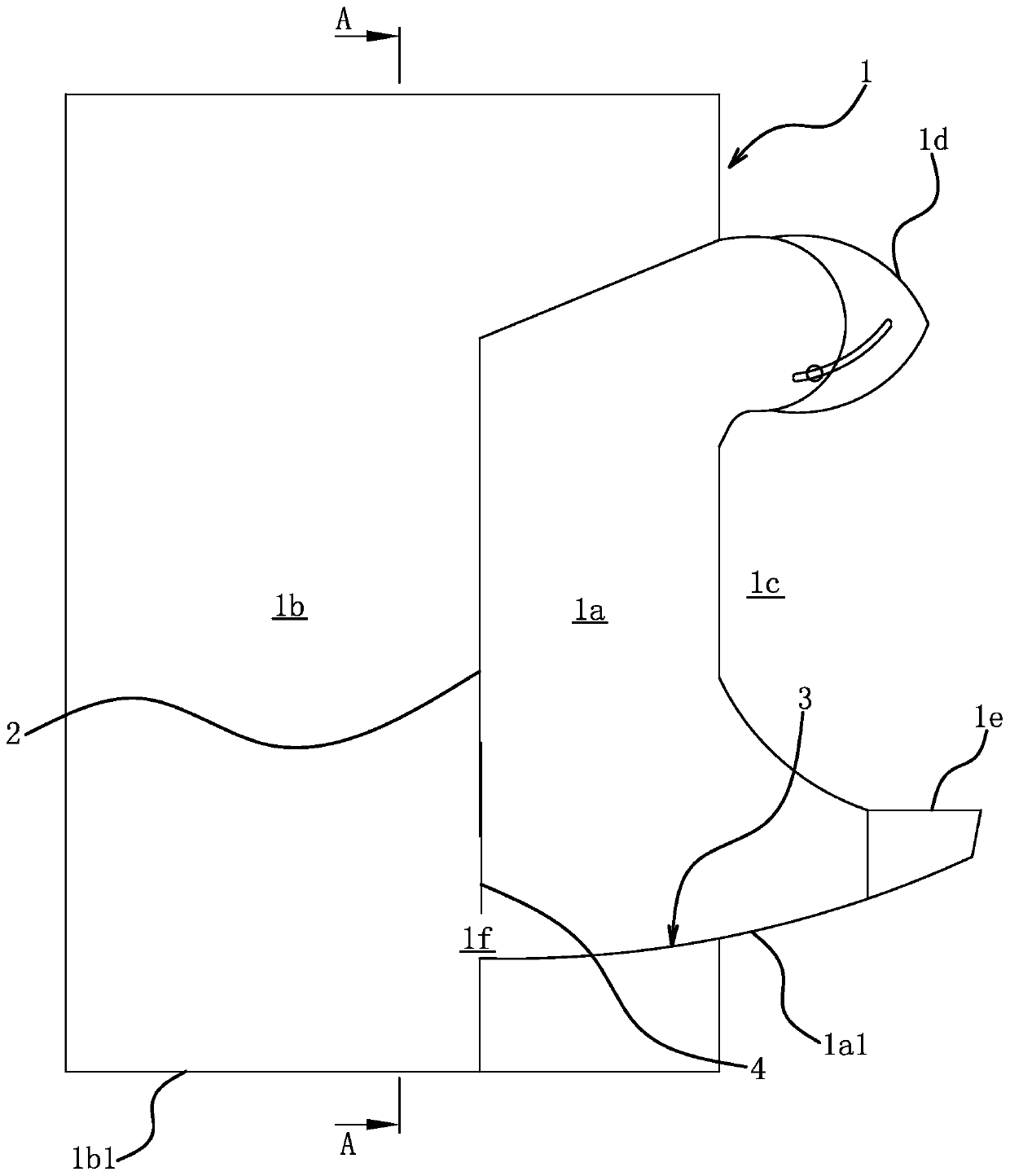

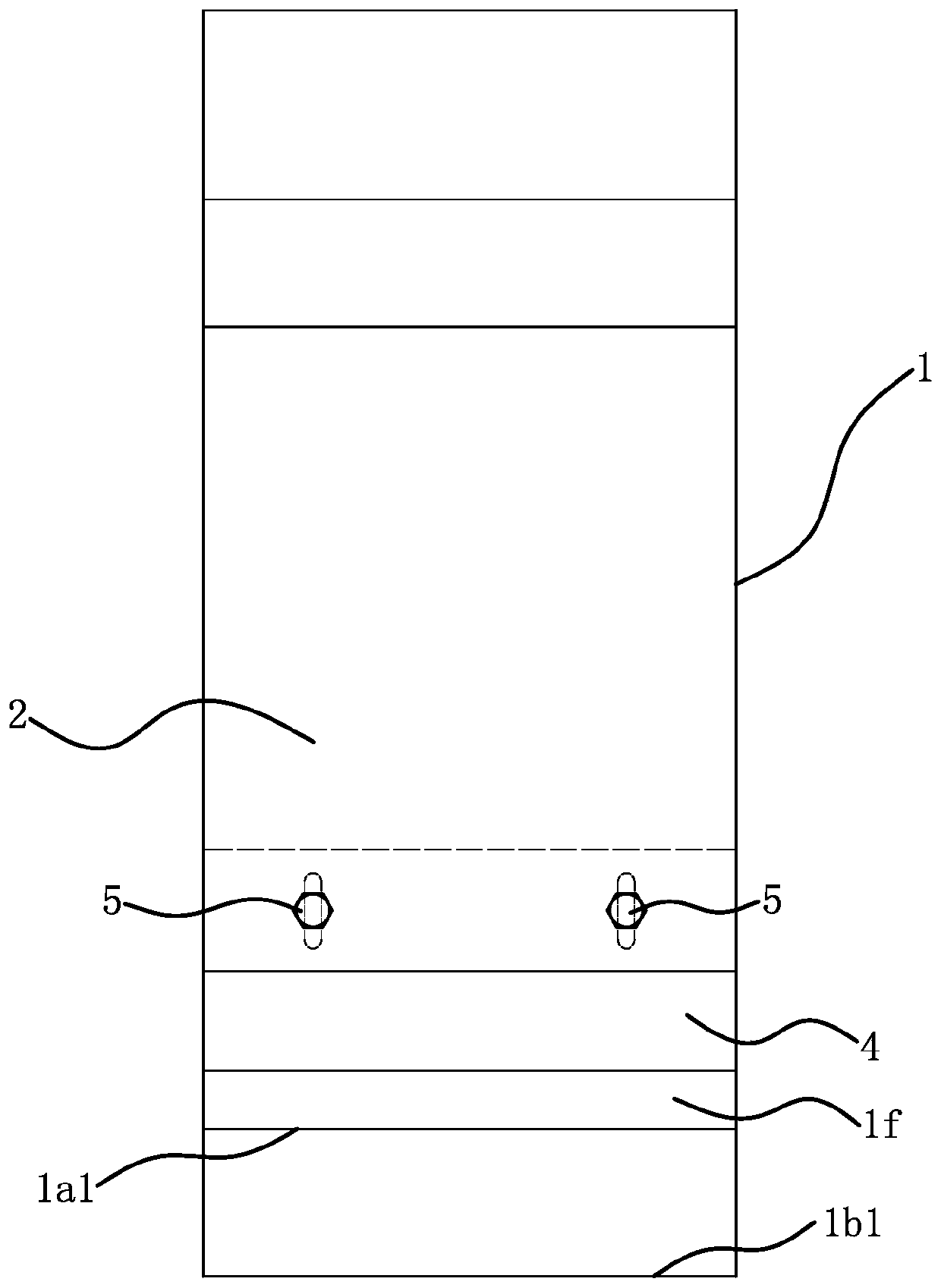

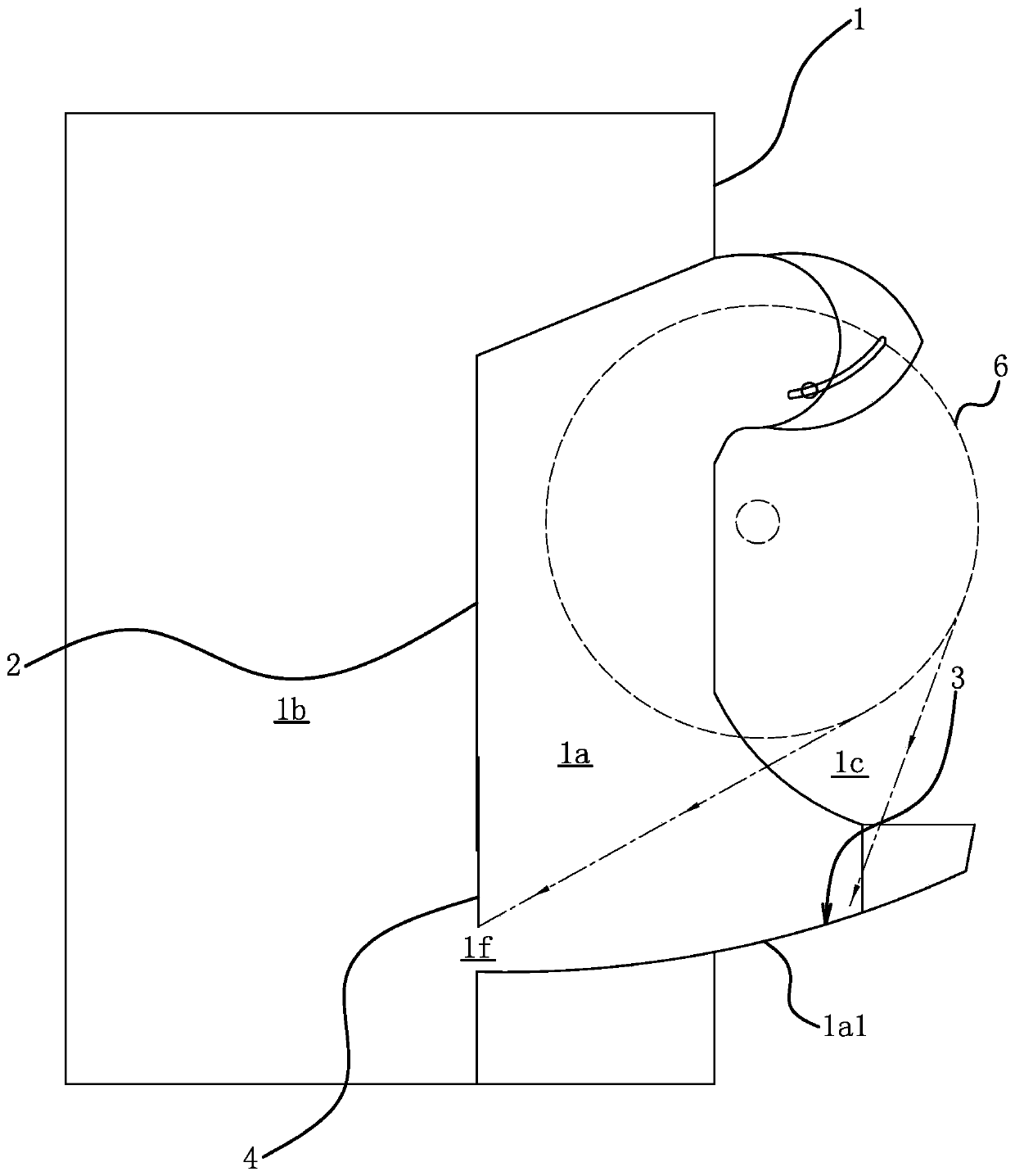

[0024] Such as figure 1 and figure 2 As shown, the polishing dust collection cover includes a cover body 1 and a partition 2, and the cover body 1 is in the shape of a box, that is, roughly in the shape of a cuboid.

[0025] The bottom of the partition 2 is arranged vertically, and the two side edges and the top edge of the partition 2 are sealed and fixedly connected with the wall of the cover body 1, thereby dividing the inner cavity of the cover body 1 into a grinding operation chamber 1a and a dust settlement chamber 1b, The grinding operation chamber 1a is located on the front side of the dust settling chamber 1b. There is a polishing operation port 1c on the front side wall of the polishing operation chamber 1a. In order to ensure the dust collection efficiency, there is a brim part 1d above the polishing operation port 1c, and a forehead part 1e below the polishing operation port 1c; the top of the partition 2 can be opposite The bottom is inclined or the top of the ...

Embodiment 2

[0032] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 6 As shown, the bottom plate 1a1 of the grinding operation chamber 1a is arranged obliquely and has a non-arc shape; the bottom plate 1a1 of the grinding operation chamber 1a does not form the wind guide surface 3; Can be water. The air guide surface 3 is formed by the gap between the top surface of the liquid medium 9 and the lower edge of the dividing plate 2 by the air flow; that is, the fan 7 runs in the cover body 1 to form an air flow from the polishing control port 1c to the air vent, and the liquid level of the liquid medium 9 Under the action of the airflow, the arc-shaped wind guiding surface 3 is naturally formed.

[0033]By adjusting the height of the shutter 4 and the liquid level of the liquid medium 9, the positio...

Embodiment 3

[0036] The structure and principle of this embodiment are basically the same as that of Embodiment 2, and the basic similarities will not be redundantly described, and only the differences will be described. The differences are as follows: Figure 7 As shown, a horizontally arranged rotating shaft 10 is arranged in the dust settling chamber 1b, and the rotating shaft 10 is connected to the side wall of the dust settling chamber 1b through bearing rotation. There are multiple blades 11 installed on it, and when the rotating shaft 10 rotates, the blades 11 stir the liquid medium 9 to generate water spray and water mist, which can be integrated into the airflow generated by the fan, and when the airflow contains dust, the water spray and water mist The combination of mist and dust realizes wet dust removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com