Medicine bottle packaging box mold

A technology for packaging boxes and medicine bottles, which is applied in the field of molds, can solve the problems of large volume occupation, broken medicine bottles, inconvenient demoulding of medicine bottle packaging boxes, etc., and achieves the effect of high placement stability and convenient molding and demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

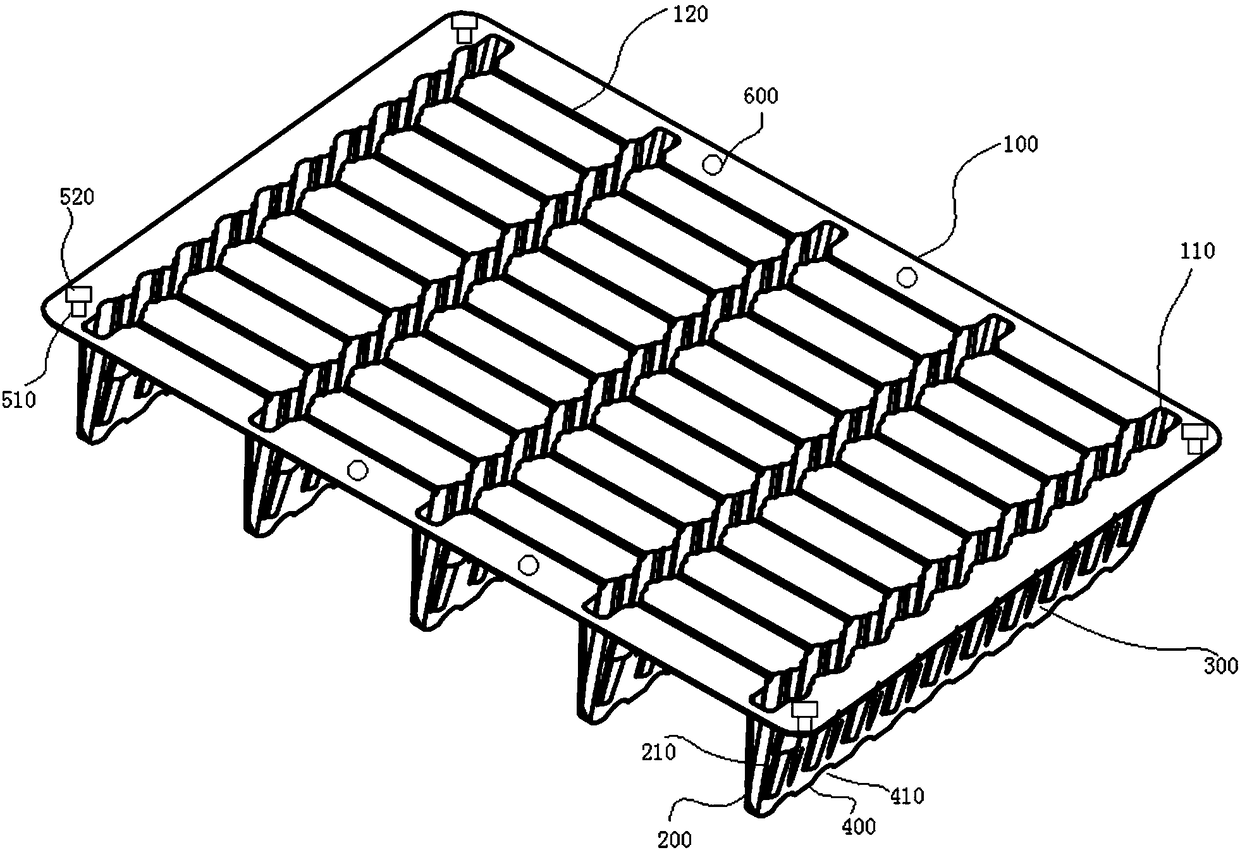

[0017] see figure 1 , the medicine bottle packaging box mold provided by the present invention includes a molding template 100 .

[0018] Forming template 100, which is the forming carrier of the present application, is specifically a rectangular stainless steel panel, and a corrosion-resistant layer is also provided on the stainless steel panel to prevent the forming template 100 from easily deforming when viewed from above after long-term use.

[0019] A plurality of forming holes 110 are arranged at regular intervals on the forming template 100 , and a plurality of carriers 200 are arranged at regular intervals on the bottom surface of the forming template 100 .

[0020] The cross-section of the carrier 200 is in the shape of an isosceles tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com