Large-torque self-locking steering engine

A technology of locking the steering gear and high torque, which is applied in the direction of steering mechanism, power amplification, steering steering with rudder, etc., to achieve the effect of light weight and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

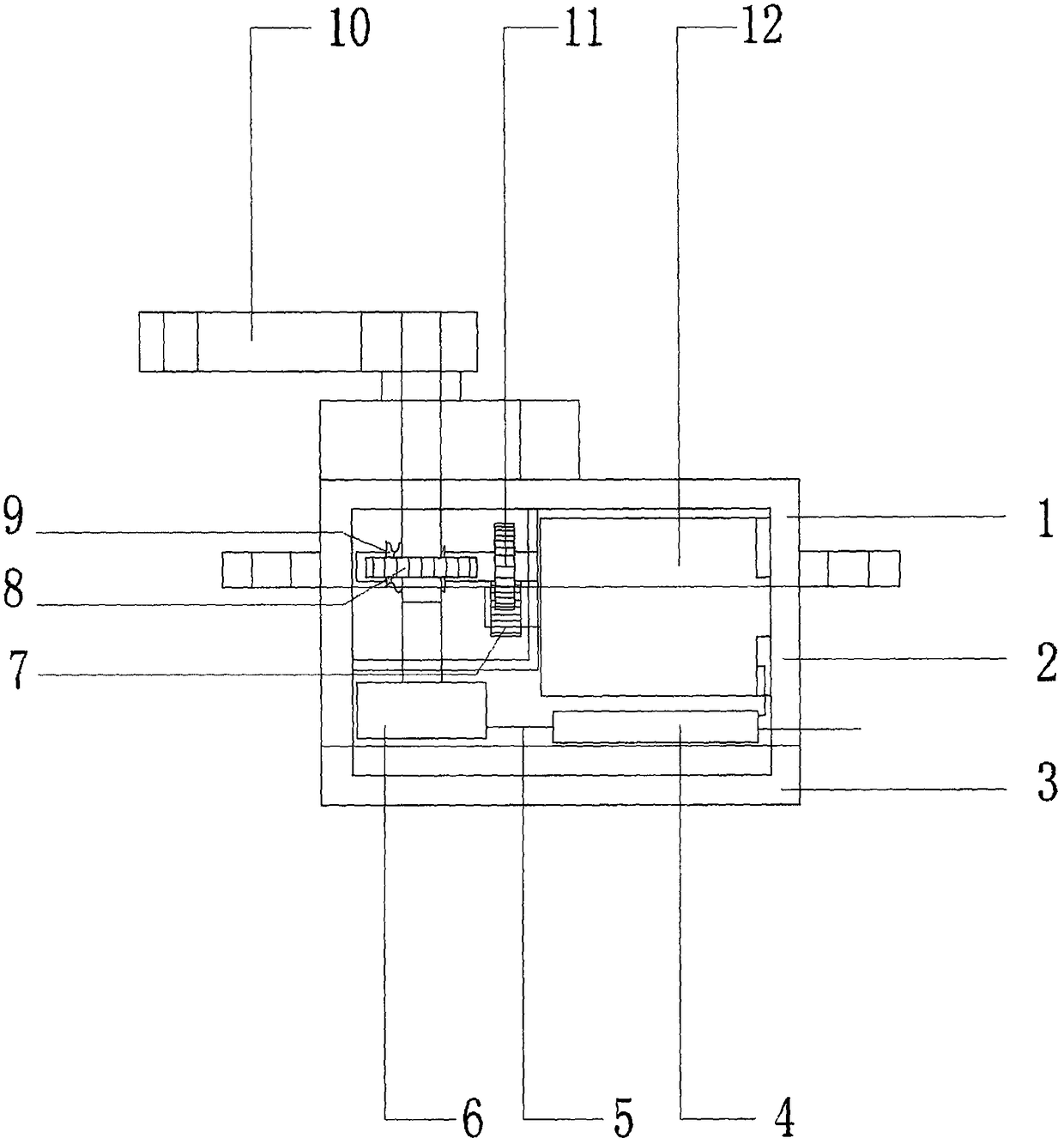

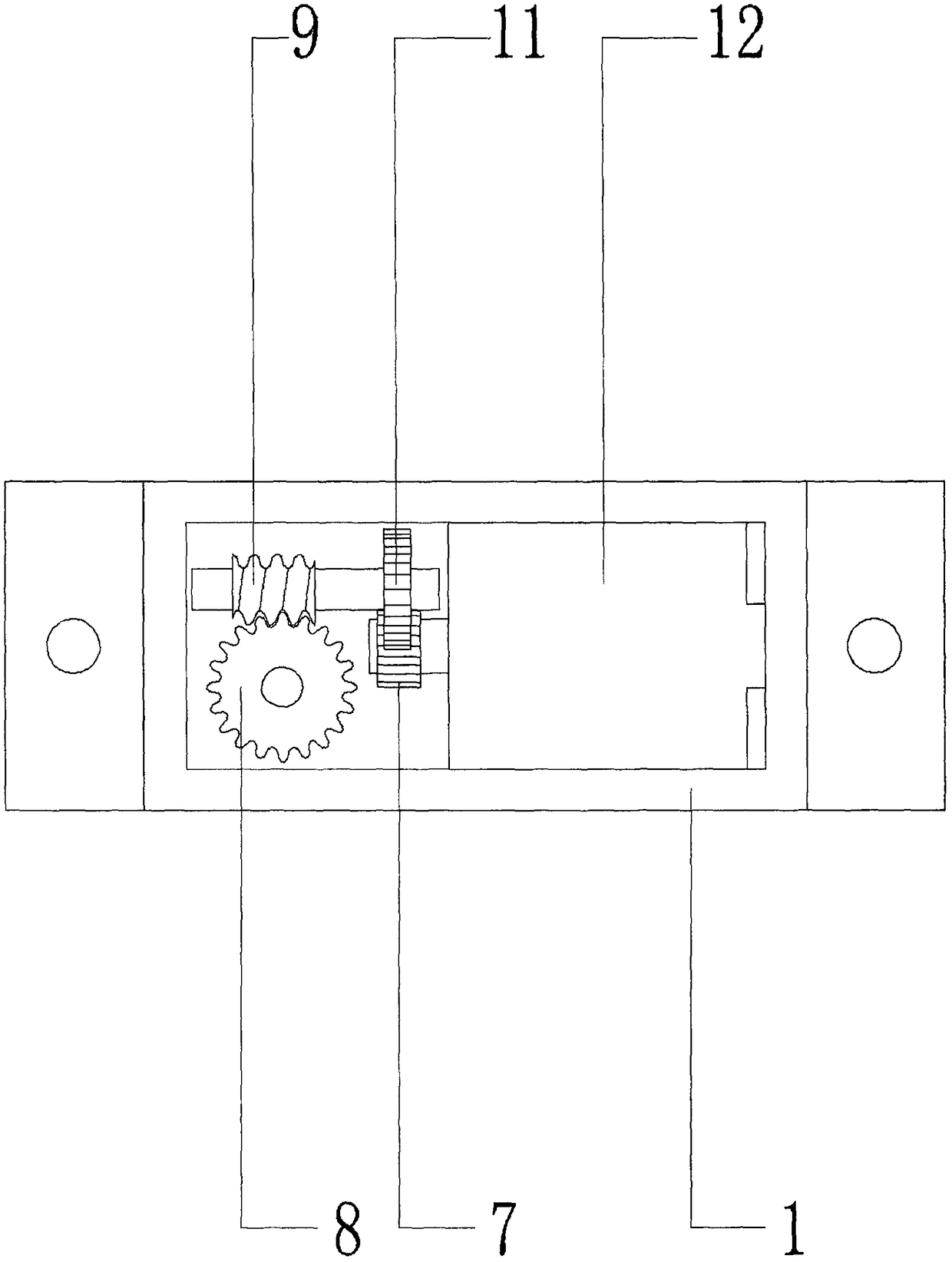

[0010] exist figure 1 Middle is the front view of the steering gear of the present invention. A closed cavity formed by the upper shell (1), the middle shell (2) and the lower shell (3) forms a complete shell. The control circuit (5) separated from the control circuit board (4) in this shell is respectively connected to the angle sensor (6) and the motor (12), and the rotation of the main shaft of the motor (12) drives the motor drive gear (7) on it. , the motor driving gear (7) drives the worm connecting gear (11) meshing with it, the worm connecting gear (11) is coaxial with the worm gear (9), and the worm gear (9) and the output gear (8) The shaft of the output gear (8) is connected with the angle sensor (6), and when the output gear (8) rotates to a certain angle, the angle sensor (6) senses the position information and feeds back to the control circuit Control the stall of motor (12) in plate (4), control the travel position that is connected to output shaft gear (8) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com