Hydraulic elevating device for iron tower

A technology of hydraulic lifting and iron tower, applied in the direction of lifting device, lifting frame, etc., can solve the problems of limited hydraulic lifting space, time-consuming and laborious scheduling and transfer, increase construction cost, etc., to reduce costs, use less tools, and avoid lateral sliding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

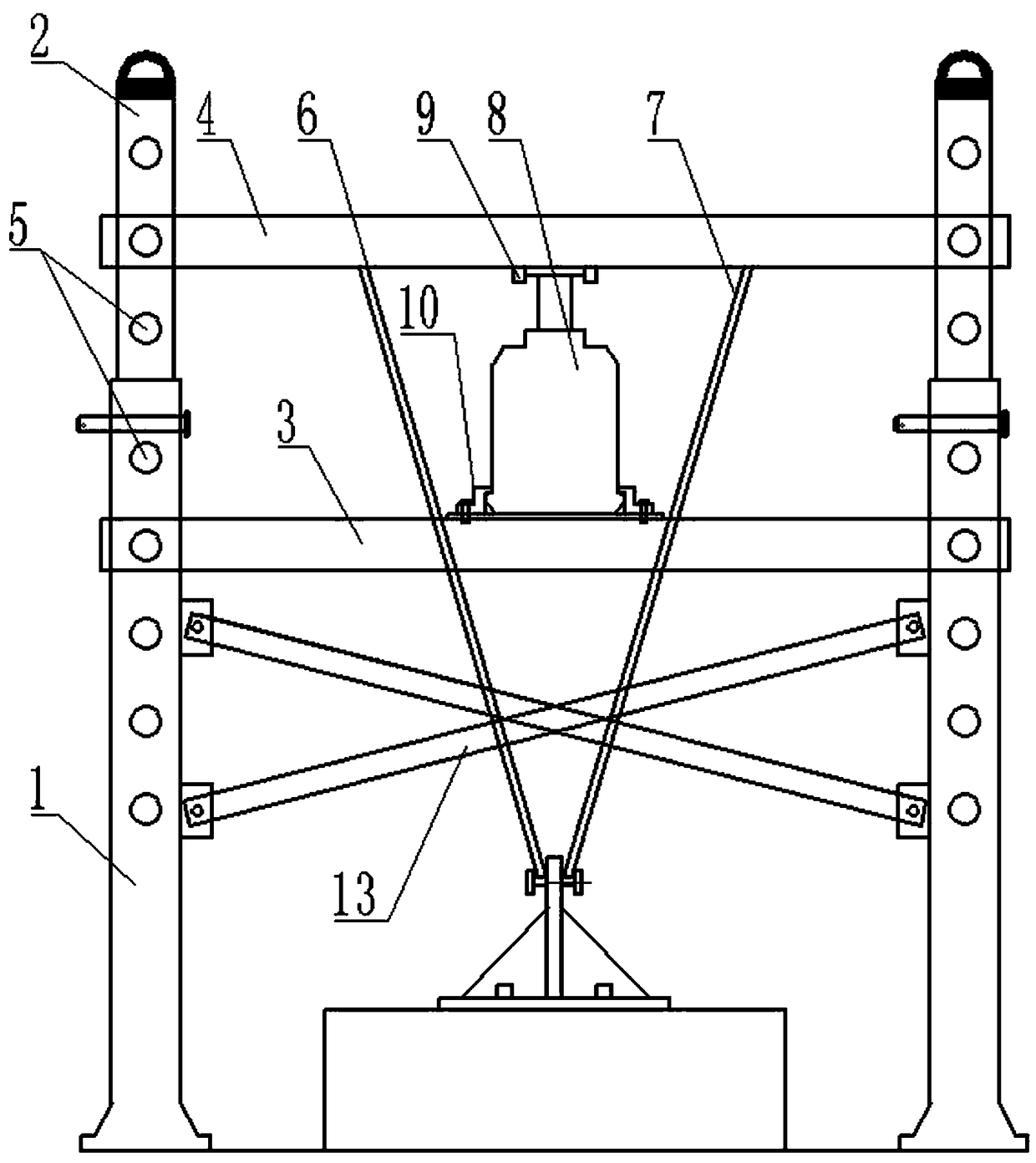

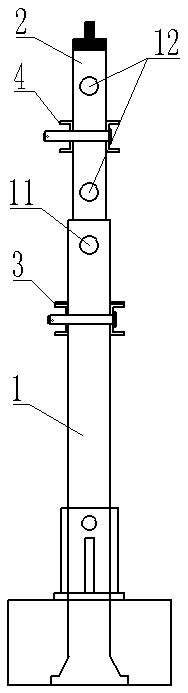

[0011] A hydraulic lifting device for an iron tower, comprising two base frames 1, the base frame 1 is equipped with a telescopic frame 2; Mounting holes 12 are arranged at intervals on the sides. Two stabilizing bars 13 are arranged crosswise between the corresponding underframes 1, the lower support beam 3 is installed on the underframe 1, the upper support beam 4 is installed on the telescopic frame, the upper support beam 4 and the lower support beam 3 are fixed through pin holes, and the upper support The first tie plate 6 and the second tie plate 7 are hinged on the upper beam 4, the hydraulic jack 8 is set on the lower support beam 3, the anti-slip base matching the bottom of the hydraulic jack 8 is fixedly installed on the top surface of the lower support beam, and the bottom surface of the upper support beam is fixed Install the anti-off cap 9 matched with hydraulic jack 8 piston rods.

[0012] During the lifting operation, the bottom frame 1 is fixed on the iron tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com