Electronically controlled intelligent wave-absorbing coating material containing core-shell wave-absorbing particles

A wave-absorbing coating, core-shell technology, applied in the field of wave-absorbing materials, can solve the problems of lack of intelligence, narrow wave-absorbing frequency band, and small improvement space, and achieve the effect of efficiently regulating the absorption frequency and enhancing wave-absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

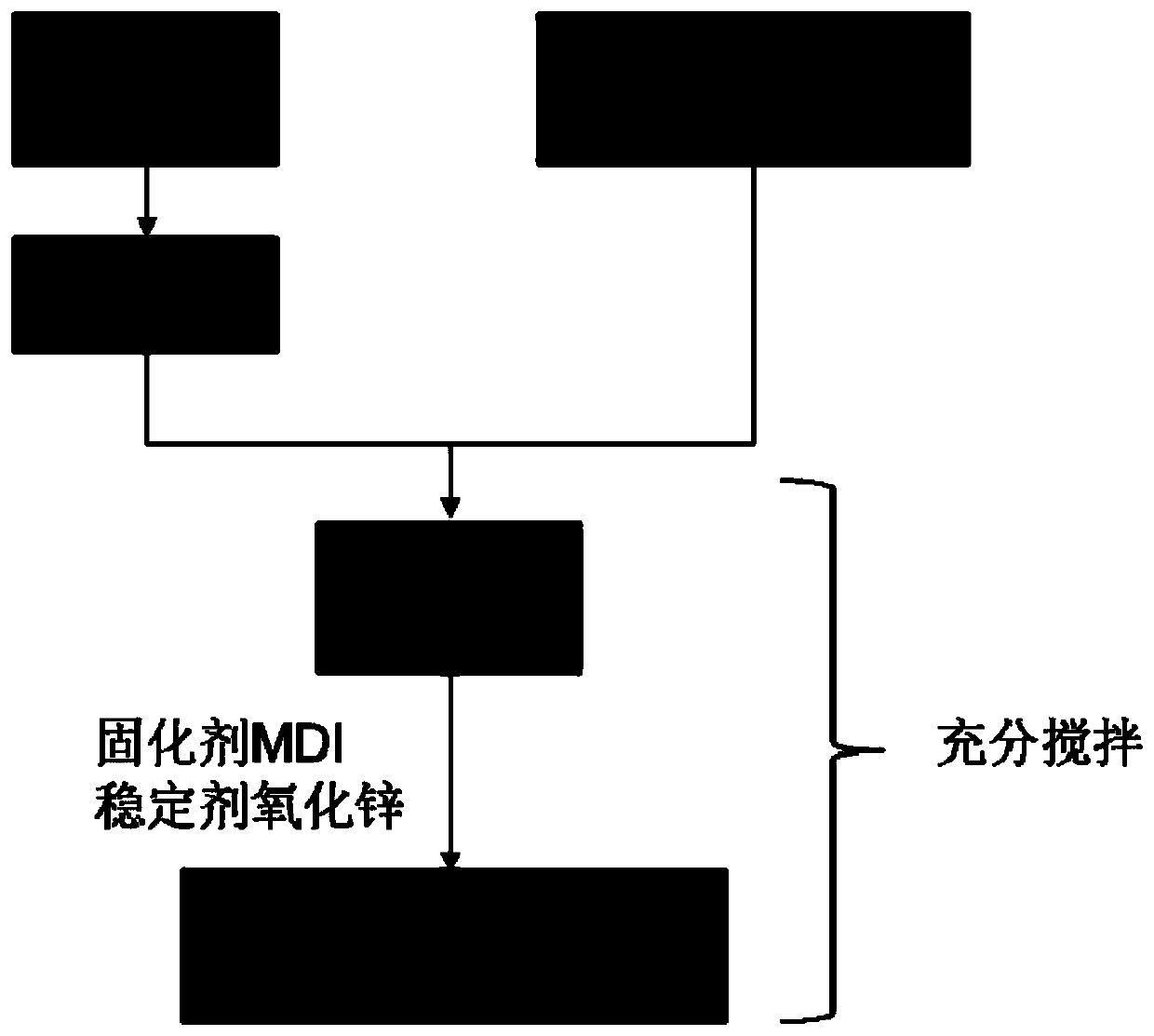

[0036] For the electronically controlled intelligent wave-absorbing coating material containing core-shell type wave-absorbing particles provided in this example, the raw materials of the wave-absorbing coating material include the following components by mass percentage: polyol 36.2%, core-shell type wave-absorbing particles 60%, diisocyanate 3.5%, stabilizer 0.3%;

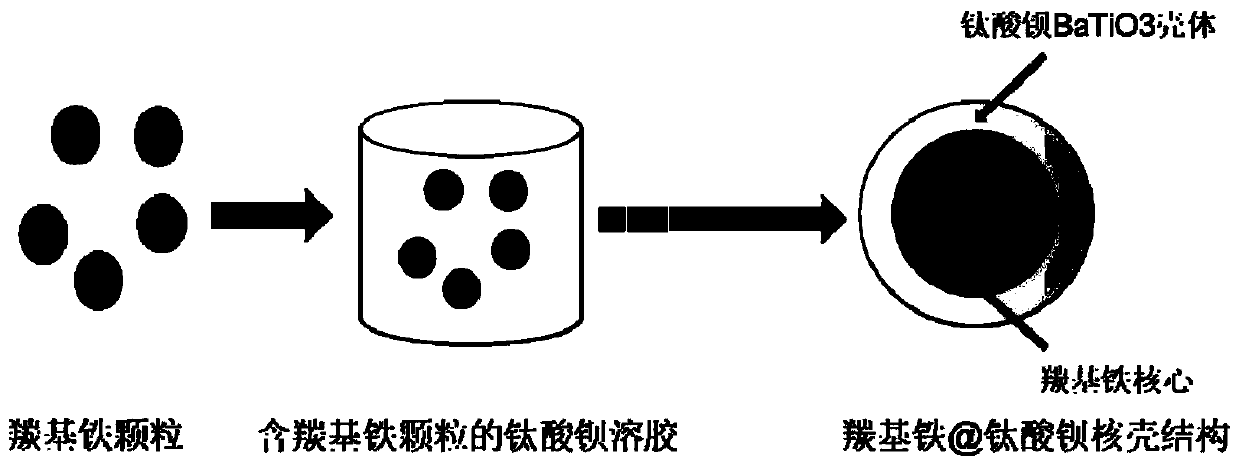

[0037] Among them: the core-shell type wave-absorbing particles are composed of barium titanate and carbonyl iron powder, with carbonyl iron powder as the core and barium titanate as the shell; the carbonyl iron powder is spherical, and its average particle size is 6μm (see Figure 4 ); the polyol is castor oil; the diisocyanate is diphenylmethane diisocyanate MDI; the stabilizer is zinc oxide.

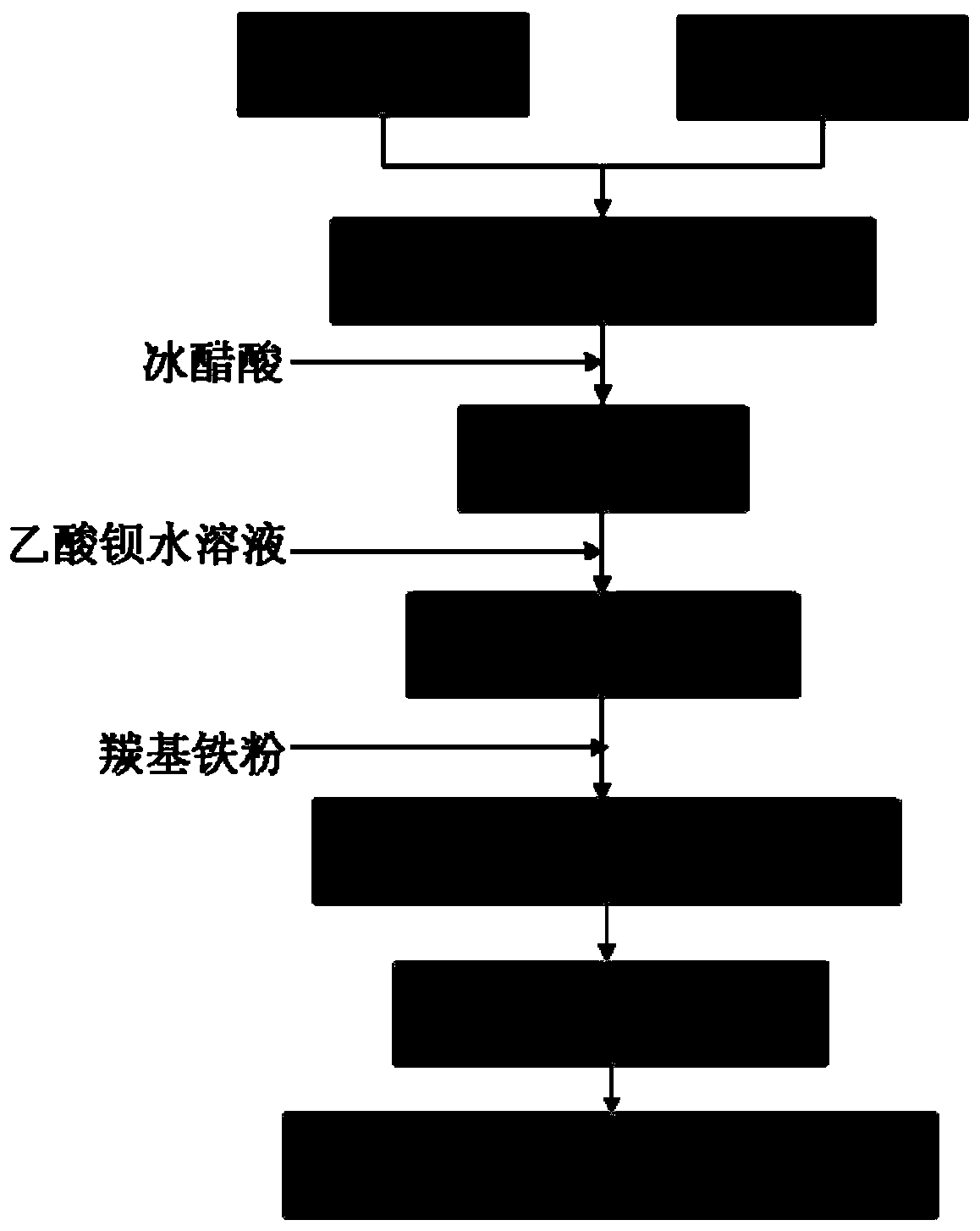

[0038] In this embodiment, the preparation method of the core-shell type wave-absorbing particles includes the following steps (for the preparation flow chart, see figure 1 , the schematic diagram of the preparation pr...

Embodiment 2

[0047] The electronically controlled intelligent wave-absorbing coating material containing core-shell type wave-absorbing particles provided in this example, the raw materials of the wave-absorbing coating material include the following components by mass percentage: polyol 14%, core-shell type wave-absorbing particles 80%, diisocyanate 5.7%, stabilizer 0.3%;

[0048] Among them: the core-shell type wave-absorbing particles are composed of barium titanate and carbonyl iron powder, with carbonyl iron powder as the core and barium titanate as the shell; the carbonyl iron powder is spherical, and its average particle size is The polyol is castor oil; the diisocyanate is diphenylmethane diisocyanate MDI; the stabilizer is zinc oxide.

[0049] In this embodiment, the preparation method of the core-shell type wave-absorbing particles includes the following steps:

[0050] (1) According to the molar ratio of butyl titanate and barium acetate as 1:1, take the aqueous solution of bar...

Embodiment 3

[0057] The electronically controlled intelligent wave-absorbing coating material containing core-shell type wave-absorbing particles provided in this example, the raw materials of the wave-absorbing coating material include the following components by mass percentage: polyol 75%, core-shell type wave-absorbing particles 22%, diisocyanate 2.9%, stabilizer 0.1%;

[0058] Among them: the core-shell type wave-absorbing particles are composed of barium titanate and carbonyl iron powder, with carbonyl iron powder as the core and barium titanate as the shell; the carbonyl iron powder is spherical, and its average particle size is The polyol is castor oil; the diisocyanate is diphenylmethane diisocyanate MDI; the stabilizer is zinc oxide.

[0059] In this embodiment, the preparation method of the core-shell type wave-absorbing particles includes the following steps:

[0060] (1) According to the molar ratio of butyl titanate and barium acetate as 1:1, take the aqueous solution of bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com