Self-installed camera

A camera and self-installation technology, applied in image communication, TV, color TV, etc., can solve the problems of reducing work efficiency, dust ingress, camera damage, etc., and achieve the effect of reducing work steps, improving work efficiency, and reducing filling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

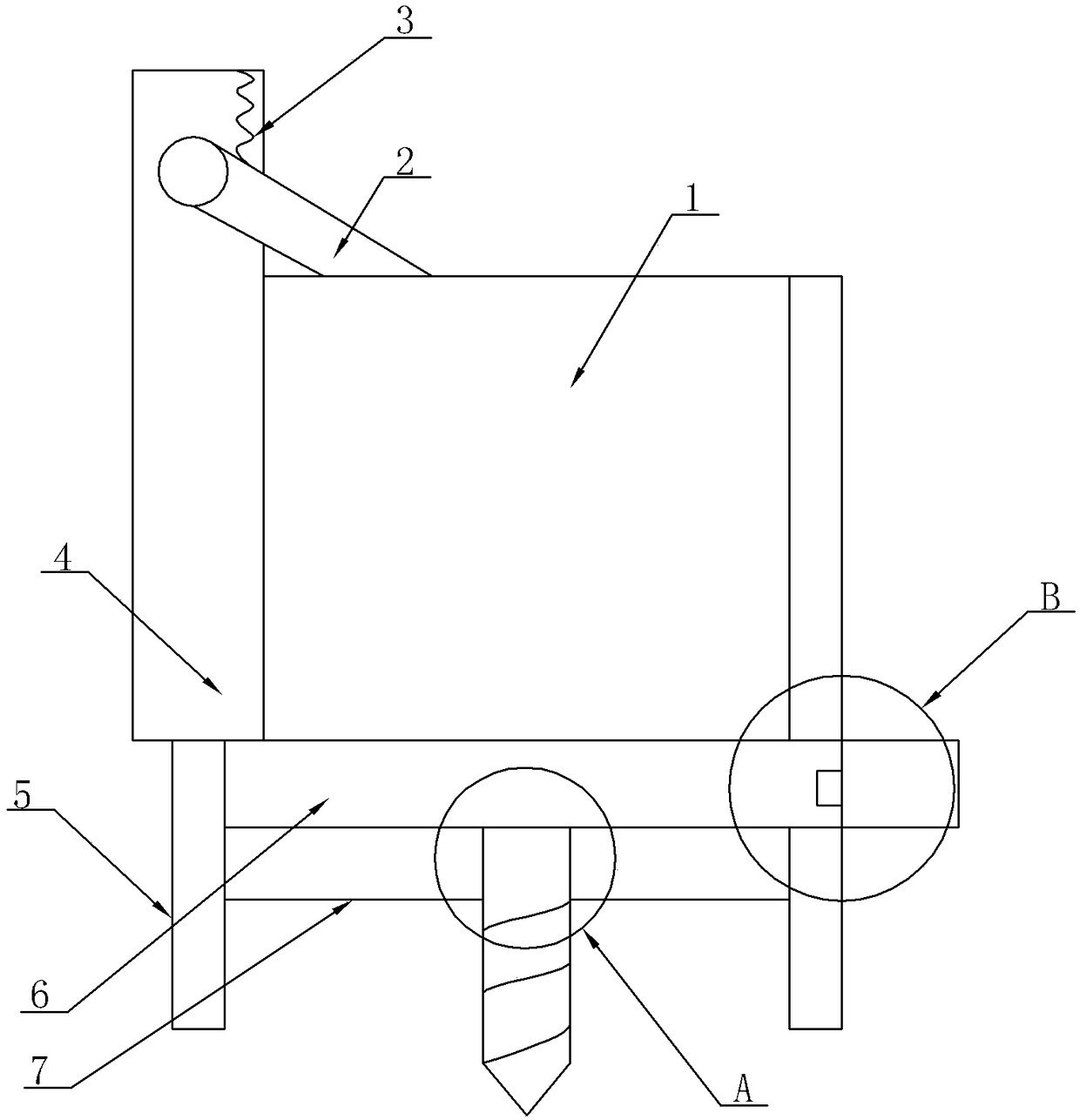

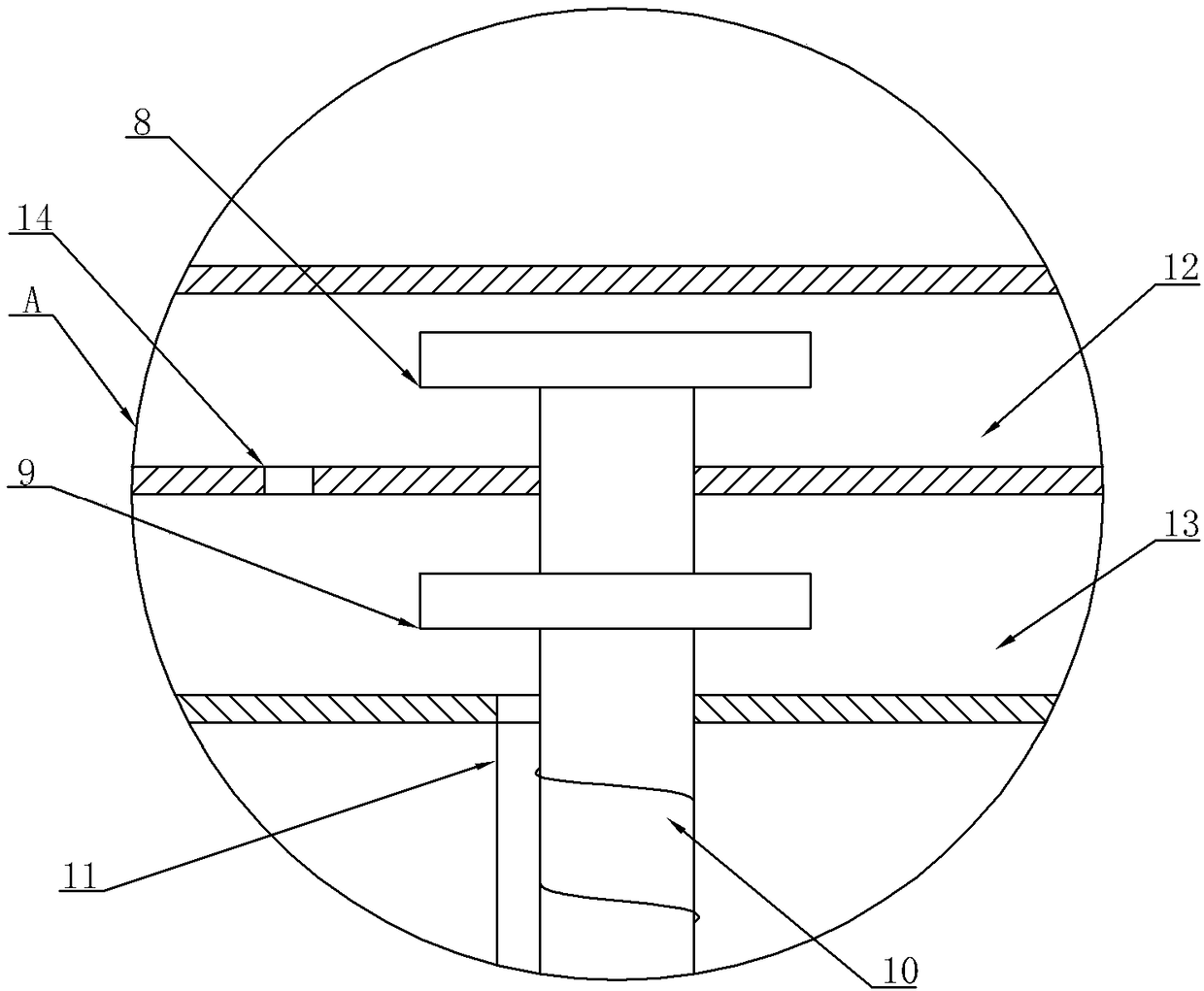

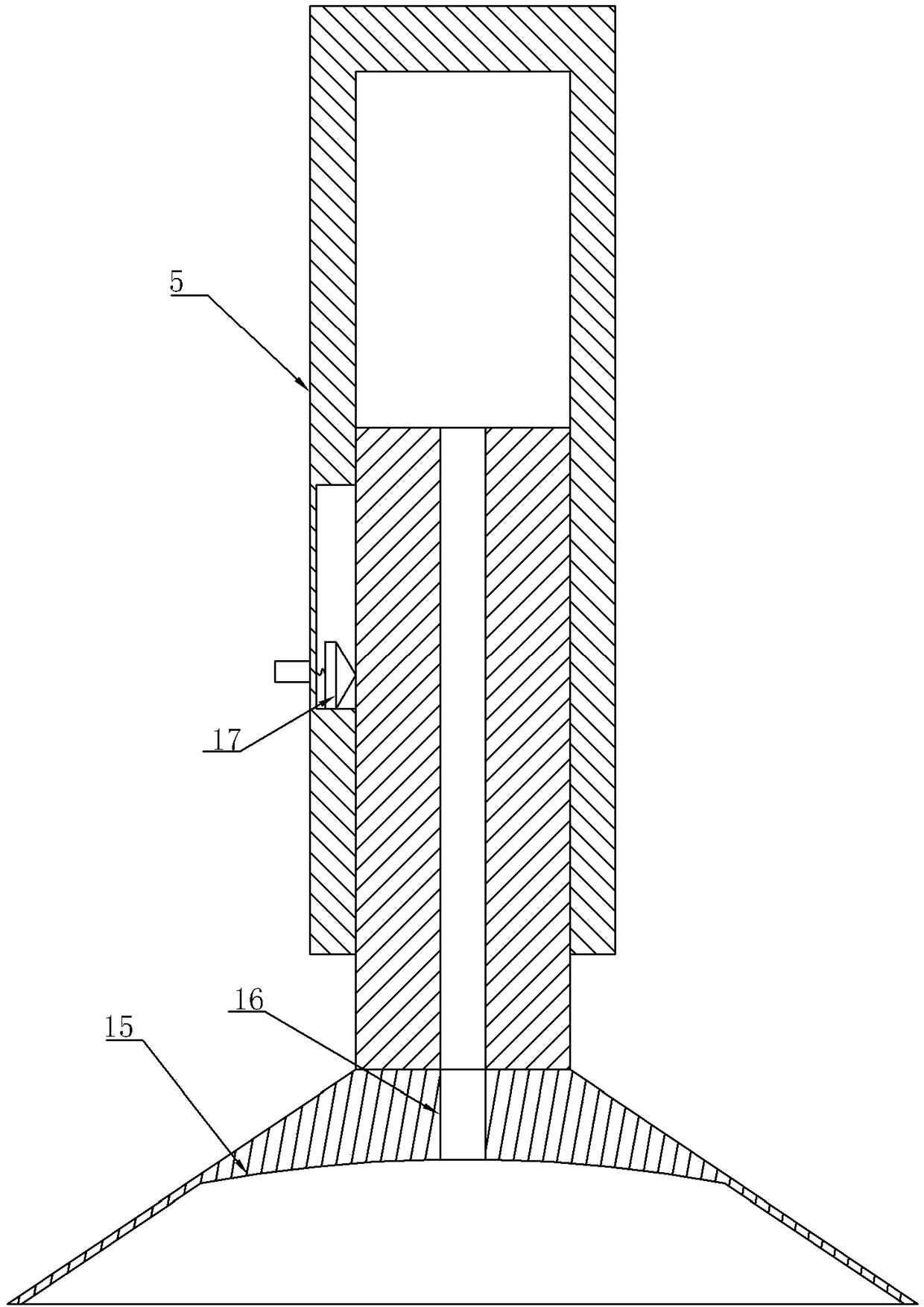

[0027] As attached figure 1 , Attached figure 2 , Attached image 3 And Figure 4 As shown, a self-installing camera includes a camera 1, a high-pressure air box 4 and a support frame 19. The high-pressure air box 4 is mounted on the support frame 19 and is detachably connected to the support frame 19. The camera 1 is fixed on the support frame 19 by fastening bolts. The high-pressure air box 4 is provided with a spring 3 and a compression rod 2. The compression rod 2 is hinged with the high-pressure air box 4, and one end of the spring 3 is fixed on the high-pressure air box 4. The other end of the spring 3 is fixed on the compression rod 2. The spring 3 pushes the compression rod 2 to rotate on the high-pressure air box 4. The compression rod 2 can further compress the camera 1 on the support frame 19 under the squeeze action of the spring 3 on. Both sides of the support frame 19 are fixed with a fixed rod 5, the fixed rod 5 includes an inner rod and an outer rod sleeved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com