Environmental testing device applied to complex stress condition

An environmental test device, a technology of complex stress, applied in the testing of machine/structural components, measuring devices, vibration testing, etc., can solve problems such as inability to achieve, and achieve the effects of convenient operation, reasonable design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

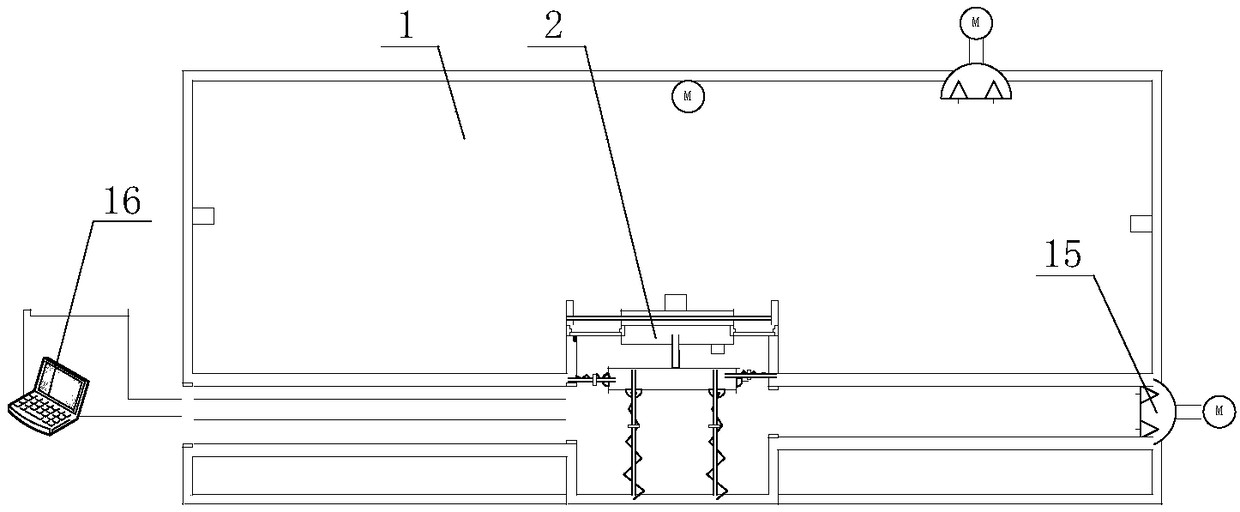

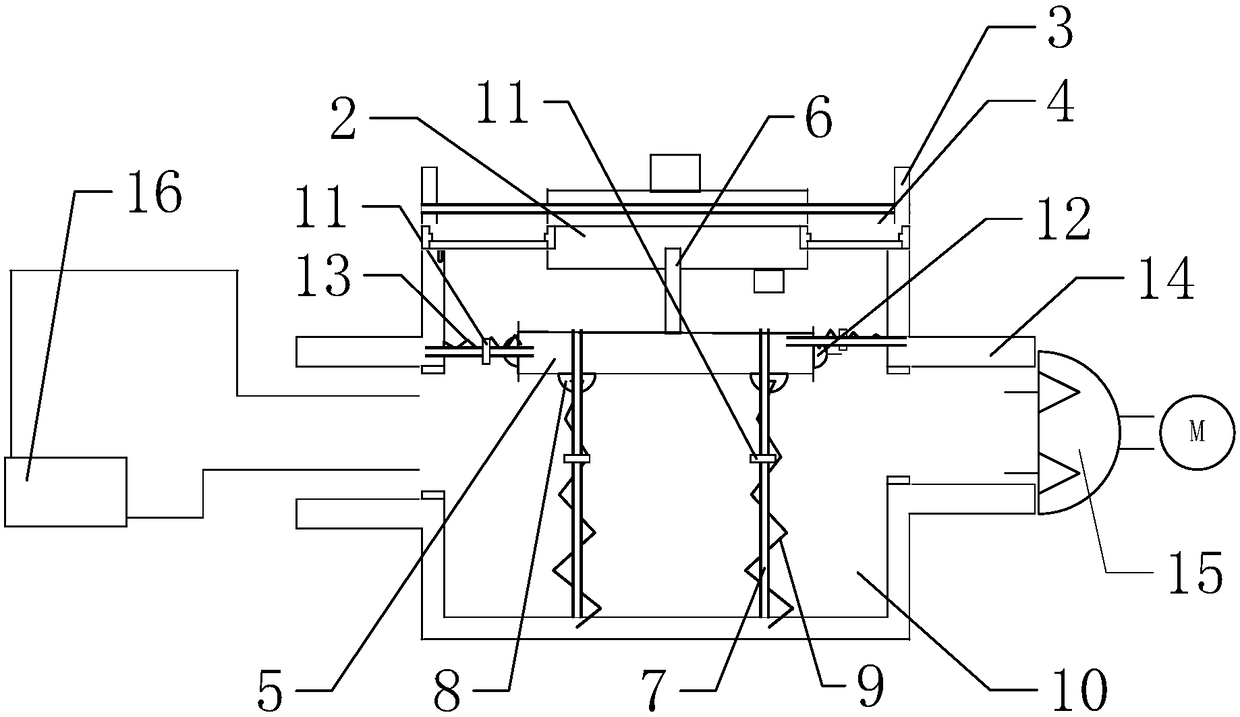

[0029] An environmental test device suitable for complex stress conditions, such as figure 1 As shown, it includes an environment-strengthening box body 1 with a mounting opening, an equipment installation base 2 arranged at the position of the installation opening in the environment-enhancing box body 1, an installation fixture 3 arranged around the installation opening, the inner ring and the equipment installation base The seat 2 is sealed and connected, and the outer ring is sealed and connected with the mounting fixture 3. The elastic sealing ring 4 is provided with a vibration generation system that drives the equipment installation base 2 to vibrate outside the environment-strengthening box 1 .

[0030] In this embodiment, the vibration generation system includes a vibration base 5, one end of which is fixed on the vibration base 5, and the other end is fixed on the transmission rod 6 on the equipment installation base 2, which is arranged on the vibration base 5 to driv...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that this embodiment further optimizes the structure of the vibration generation system, and the specific settings are as follows:

[0041] The outer ring of the elastic sealing ring 4 is sealingly connected with the top end of the mounting fixture 3, and the vibration base 5 is arranged at the bottom position of the mounting fixture 3, such as figure 1 and figure 2 shown. Moreover, in this embodiment, the guide rod 7 and the inner pipe are provided with limit nuts 11, which can effectively avoid damage to the elastic sealing ring 4 due to excessive vibration exceeding the elastic deformation of the elastic sealing ring 4 .

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that a ventilation cooling device 15 is also added in this embodiment, and the specific settings are as follows:

[0044] The insulation box 10 is provided with a heat insulation isolation tube 14 communicating with the interior of the isolation box 10 , and a ventilation cooling device 15 is installed on the insulation box 14 .

[0045] Moreover, the structure of the limiting device in this embodiment is different. In this embodiment, the limiting device includes a spherical groove arranged on the bottom surface of the isolation box 10, and a hinged ball arranged in the spherical groove and hinged to the bottom surface of the isolation box 10 is fixed on the hinge. A horizontal channel on the ball, the pulley slides inside the horizontal channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com