Simulation experiment method of acidizing production stimulation under temperature and pressure of 7 cm diameter core formation

A simulation experiment and core technology, which is applied in the simulation experiment field of acidification stimulation under temperature and pressure of 7 cm diameter core formation, can solve problems such as difficult seepage capacity, unsuitable for sandy conglomerate experiment, and inability to judge the impact, and achieve the effect of increasing representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

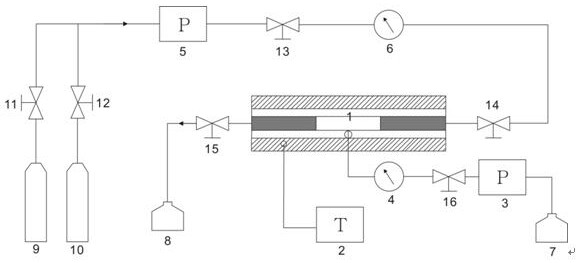

[0025] Example 1 Simulation Experimental Method for Acidizing Production Stimulation under Temperature and Pressure of 7 cm Diameter Core Formation

[0026] The structure of the device used in the experiment is as follows figure 1 Shown, comprise the brine container 9, acid solution container 10, reactor 1, sample bottle 8 that are connected together successively; The pipeline that described brine container 9, acid solution container 10 is connected with reactor 1 is provided with and is used for making solution Reach the internal pressure pump 5 and pressure gauge B 6 of the reaction kettle 1, and the electric furnace and the temperature controller 2 for self-heating are arranged around the reaction kettle 1. The reaction kettle 1 is externally connected with a pressure gauge A 4 , a ring pressure pump 3 and a liquid supply container 7 . Valves (11, 12, 13, 14, 15, 16) are arranged on the liquid supply pipeline.

[0027] The reaction kettle is made of alloy materials resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com