Variable speed control method for preventing wire sliding in downward preparation of detonating fuse

A detonating cord, sliding wire technology, applied in non-electric variable control, speed/acceleration control, control/regulation system, etc., can solve problems affecting product quality, sliding wire, reducing production efficiency, etc., to avoid the sliding wire problem , the acceleration time is short, the effect of keeping the work efficiency unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

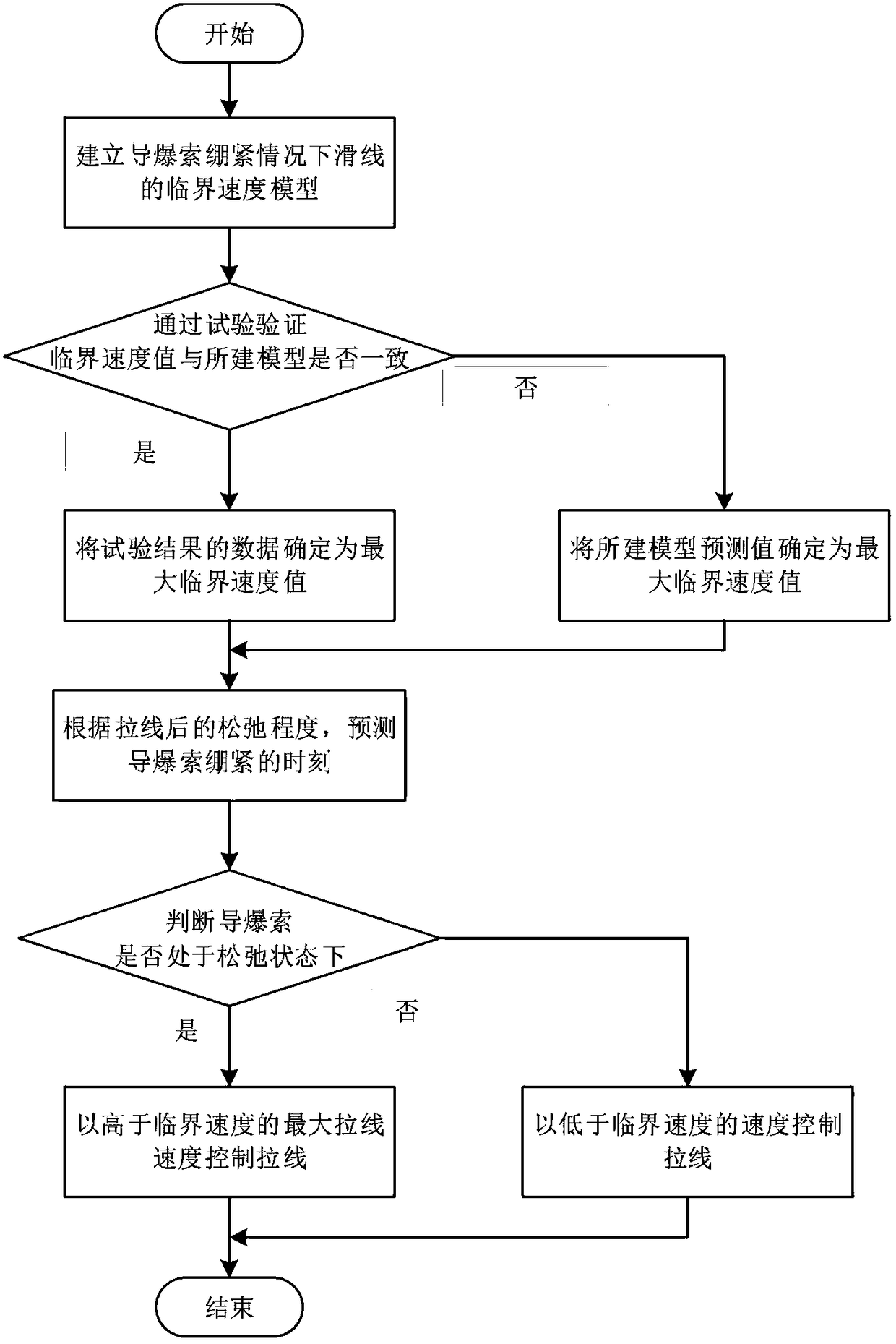

[0016] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

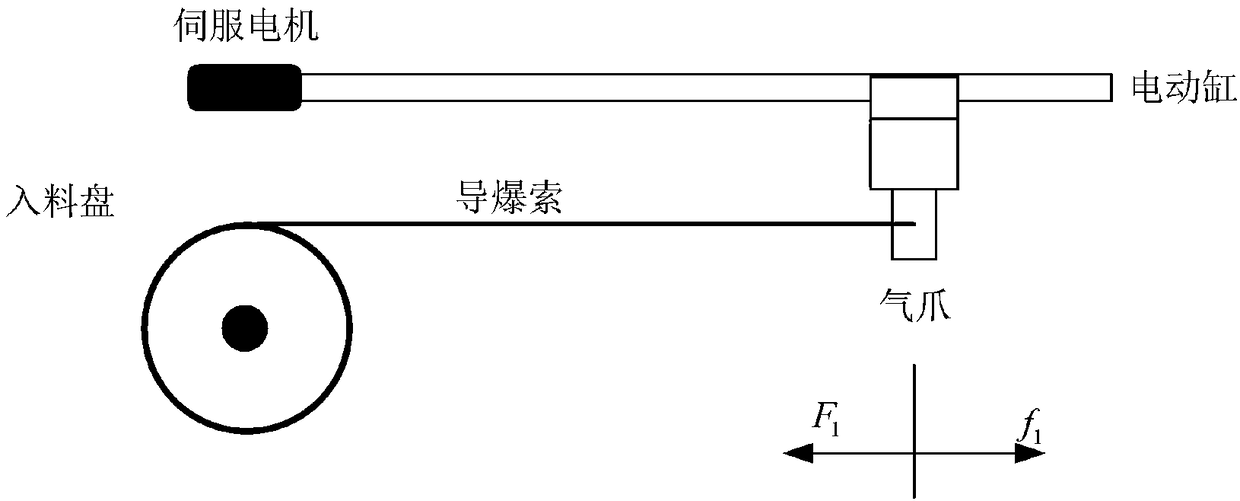

[0017] figure 1 It is a model diagram for preventing the problem of sliding wires from occurring according to the present invention, and the quality of the wire-guy claws is M 1 , and the mass of the incoming disk is M 2 , the wire velocity before the detonating cord is taut is V 1 , the wire velocity after the detonating cord is tensioned is V 2 , the gas source pressure is P 0 , the friction coefficient of air gripper is μ 1 , the friction coefficient of the feeding tray is μ 2 , the detonating cord tightening time is Δt, and the contact area between the air claw and the detonating cord is S 1 . The maximum friction force of the air gripper is f 0 , the actual friction force during the motion is f 1 , the friction force overcome by the starting of the feeding tray is F 1 .

[0018] m 1 V 1 2 =(M 1 +M 2 )V 2 2 +F 1 V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com