Eccentric positioning platform

A positioning platform and eccentric technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of high production cost, slow platform positioning speed, etc., and achieve the effect of saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

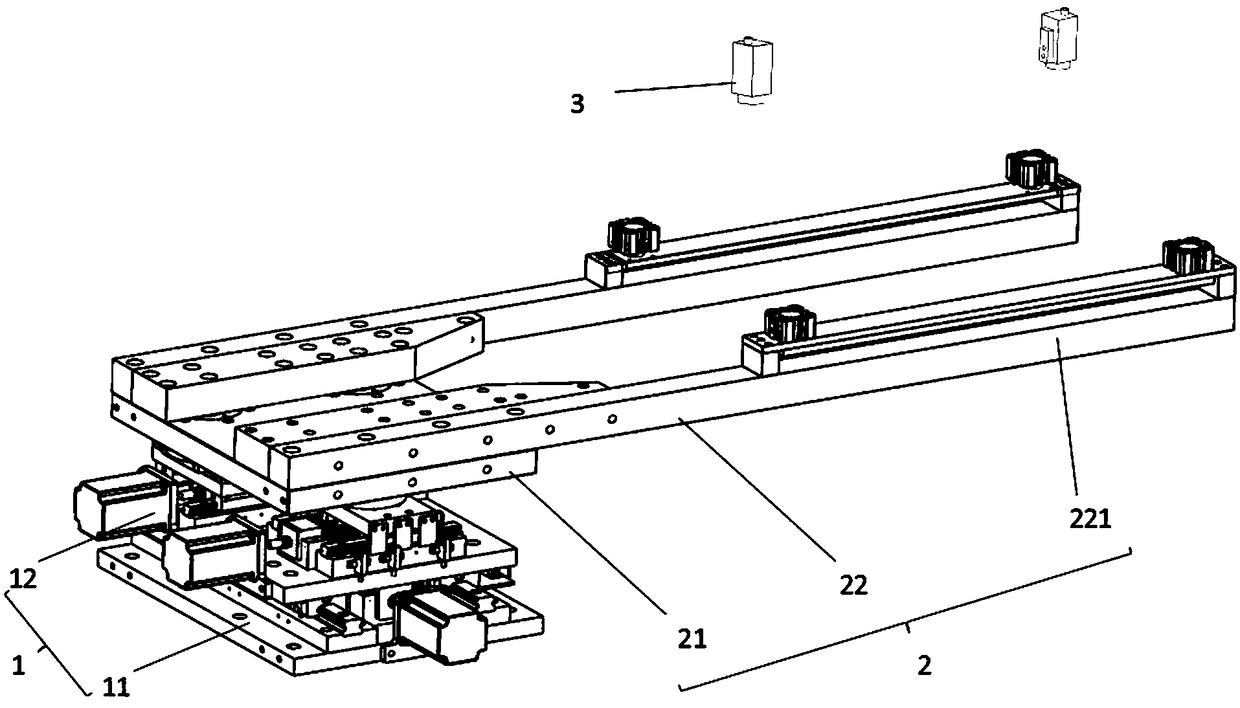

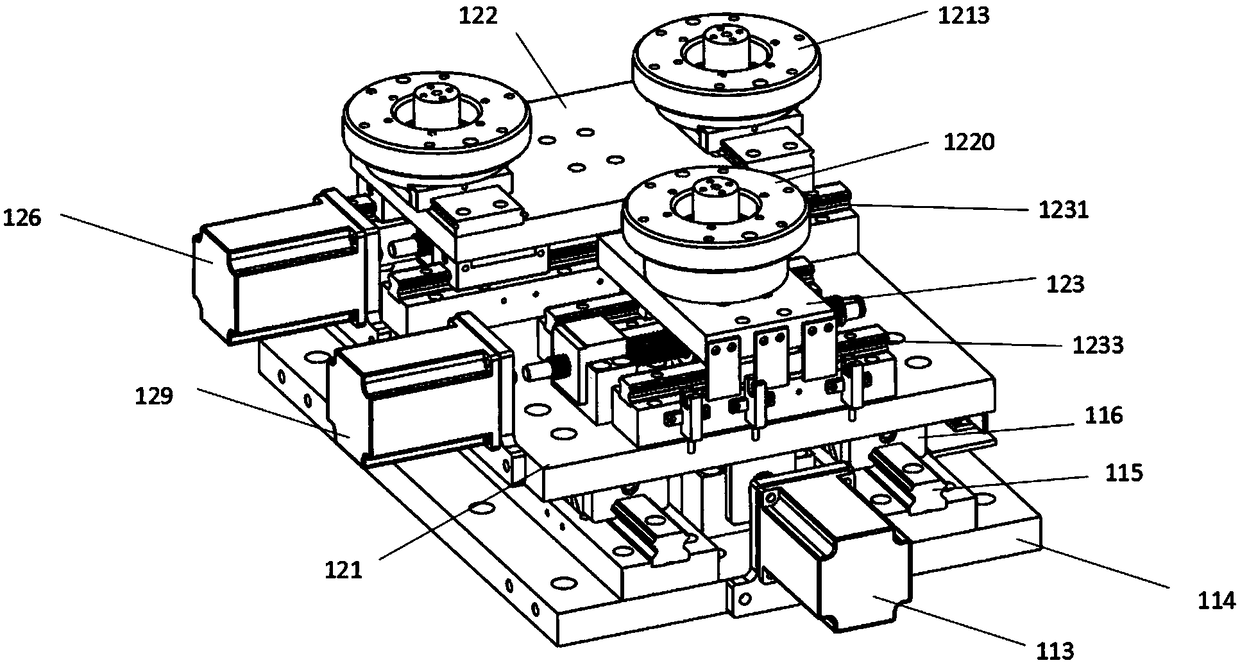

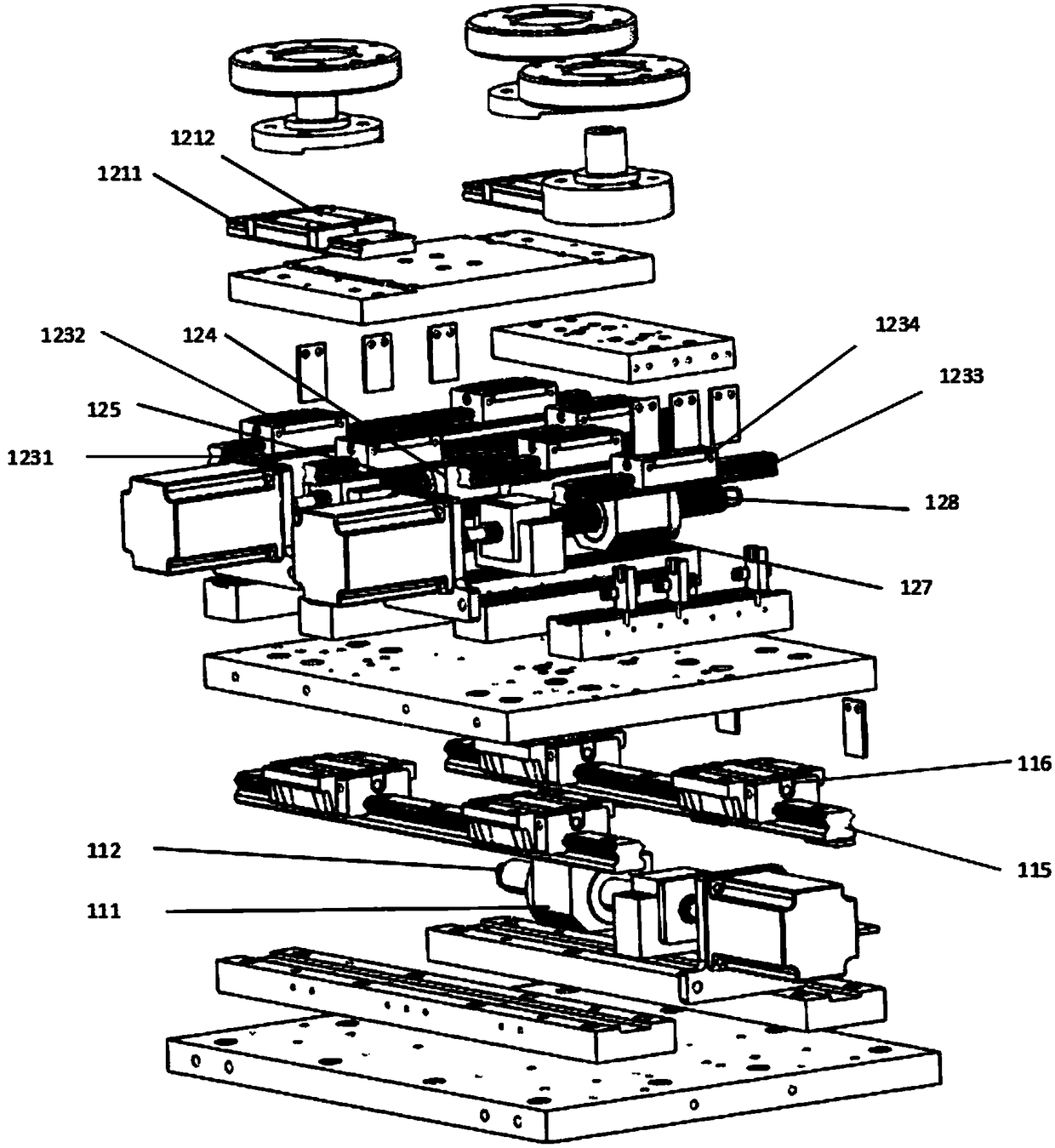

[0024] Such as figure 1 As shown, it is a kind of eccentric positioning platform provided by the present invention, which is used for processing and positioning of workpieces, including positioning driving device 1, workpiece support platform 2, controller and CCD camera 3 electrically connected with the controller (in the figure The support structure of the camera is omitted), wherein the workpiece support platform 2 is installed on the positioning drive device 1 . The positioning driving device 1 includes a translation positioning mechanism 11 that drives the workpiece support platform 2 to perform left and right translational motions and a side deviation correction mechanism 12 that drives the workpiece support platform 2 to perform left and right deflection movements. The support plate 21 directly above and the support arms 22 arranged in parallel and spaced apart, one end of the two support arms are respectively fixed on the support plate 21, and the other ends jointly fo...

Embodiment 2

[0033] Such as Figure 5 As shown, the difference between the present embodiment and the first embodiment is that the CCD camera 3 of the present embodiment (the supporting structure of the camera is omitted in the figure) is arranged below the bearing end 221, and the CCD camera takes pictures of the workpiece from below the workpiece and The difference between the position of the workpiece and the reference position is calculated, and the rest are the same as those in Embodiment 1, and will not be repeated here.

[0034] The eccentric positioning platform provided by the embodiment of the present invention can identify the deviation between the workpiece and the reference position by photographing the workpiece on the workpiece loading end with a CCD camera. The controller controls the positioning drive device to drive the workpiece support platform to move, and the workpiece support platform is positioned in translation Driven by the mechanism and the side deviation correct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com