Improved bridge producing and manufacturing equipment

A technology for manufacturing equipment and bridges, which is applied in the field of improved manufacturing equipment for bridges, can solve problems such as low painting efficiency, complex structure, and impact on human health, and achieve the effects of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

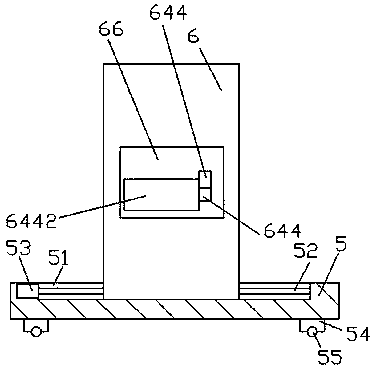

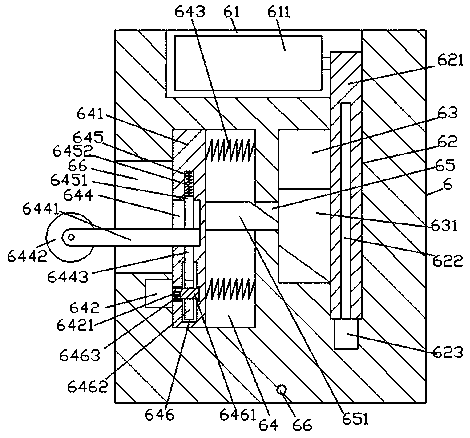

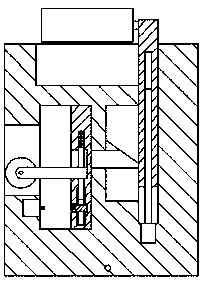

[0015] Such as figure 1 , figure 2 and image 3 As shown, an improved bridge production and manufacturing equipment of the present invention includes an installation base frame 5 and a production main frame 6. A slideway 51 extending forward and backward is arranged in the upper end surface of the installation base frame 5, and the production main frame 6 slides Fittingly installed in the slideway 51, the production main frame 6 is provided with a through hole 66 that penetrates front and back, and a threaded post 52 is installed in the through hole 66, and the threaded post 52 The front end face is rotationally connected with the front end wall of the slideway 51, and the rear end face of the stud-shaped column 52 is connected with the power fit with the main driving machine 53, and the outer surface of the main driving machine 53 is fixed on the rear end wall of the slideway 51. , the top end surface of the production main frame 6 is provided with a first embedding cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com