Convenient power cable device

A power cable and convenient technology, which is applied in the field of convenient power cable devices, can solve problems such as consuming manpower and time, reducing corporate profits, and affecting the process of winding wires, so as to reduce manual operations and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

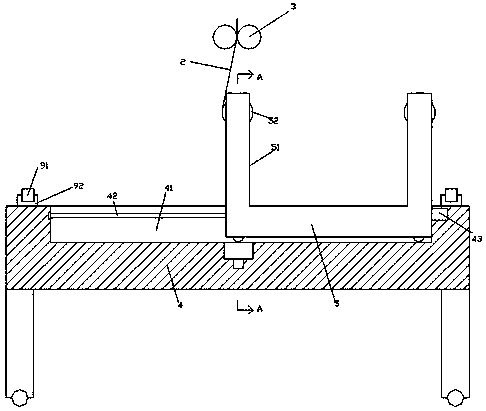

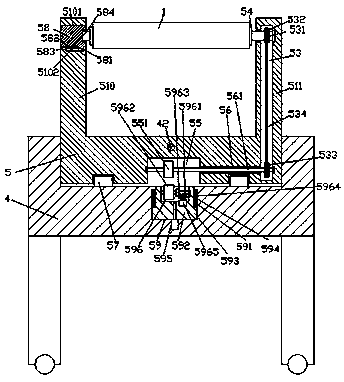

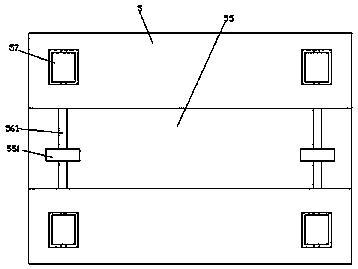

[0025] like Figure 1-Figure 6 As shown, a convenient power cable device of the present invention includes a base 4 and a clamp 3 arranged above the top of the base 4 and arranged opposite to the left and right, and the bottom of the base 4 is fixedly installed around the base 401, The bottom of the foot column 401 is provided with casters 402, the base 4 is provided with a first guide groove 41, and the first guide groove 41 slides and fits to connect the base 5, and the first guide groove 41 The middle part of the bottom is provided with a first sliding groove 59, the front and rear sides of the first sliding groove 59 are symmetrically provided with a second guiding groove 591, and the first sliding groove 59 is provided with a first sliding block 592 The front and rear sides of the bottom of the first sliding block 592 are respectively provided with first guide blocks 593 extending into the second guide grooves 591 on the front and rear sides, and the middle position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com