A structure for reducing mhd pressure drop in liquid cladding

A cladding, liquid technology, applied in the field of structure to reduce the pressure drop of liquid cladding MHD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

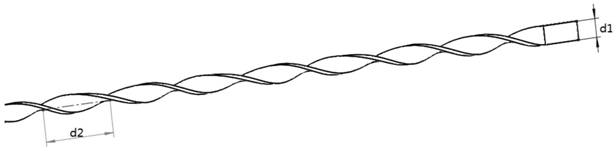

[0026] A structure for reducing the pressure drop of the liquid cladding MHD according to the present invention will be described in detail below with reference to the drawings and specific embodiments.

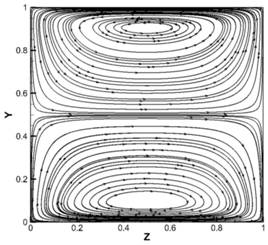

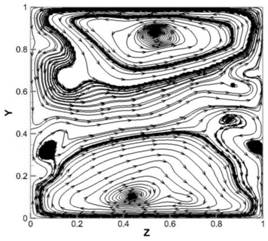

[0027] like figure 1 and figure 2 As shown, when the liquid metal inlet flow rate in the pipeline is low, the flow state in the pipeline is laminar flow, and the corresponding induced current distribution is symmetrical up and down (such as figure 1 shown), it is easy to form a consistent Lorentz force that hinders the forward flow of liquid metal, making the MHD pressure drop in the liquid cladding pipe obvious; when the disturbance metal strip is set on the pipe wall, the liquid metal in the pipe can be In the case of low inlet velocity, the flow is fully turbulent, and the induced current distribution is much more chaotic than that of laminar flow (such as figure 2 Shown), so that a consistent Lorentz force that hinders the forward flow of liquid metal cannot be formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com