Gas-liquid separation device for mass transfer exchange

A gas-liquid separation device, mass transfer and exchange technology, applied in the direction of combination device, separation method, dispersed particle separation, etc., can solve the problems of small air flow velocity, short service life, easy clogging, etc., and achieve sufficient turbulence and separation of droplets Good effect, good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that the features in the various embodiments of the present invention may be combined with each other in the absence of explicit limitation or conflict. The present invention will be described in detail below with reference to the accompanying drawings and examples.

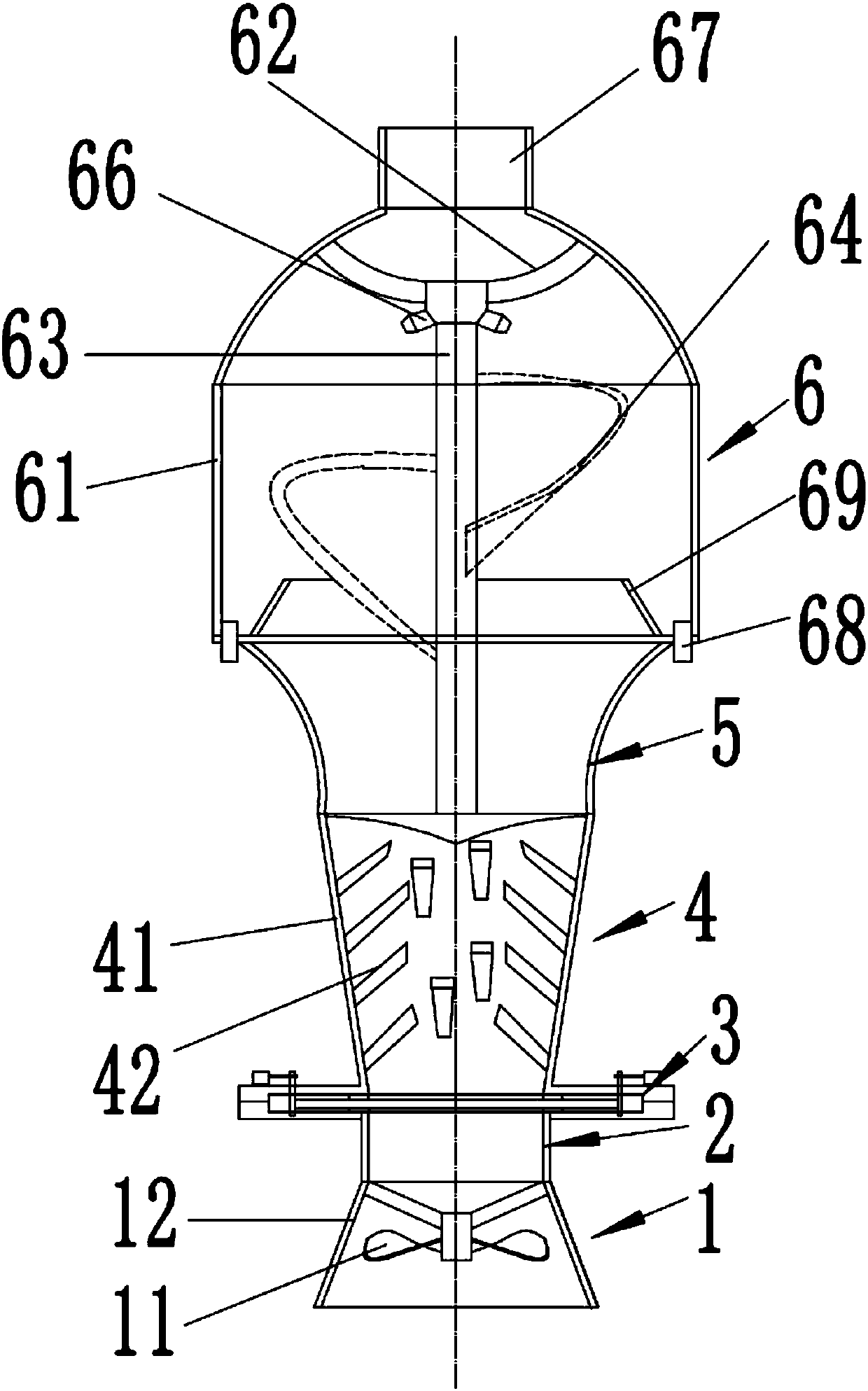

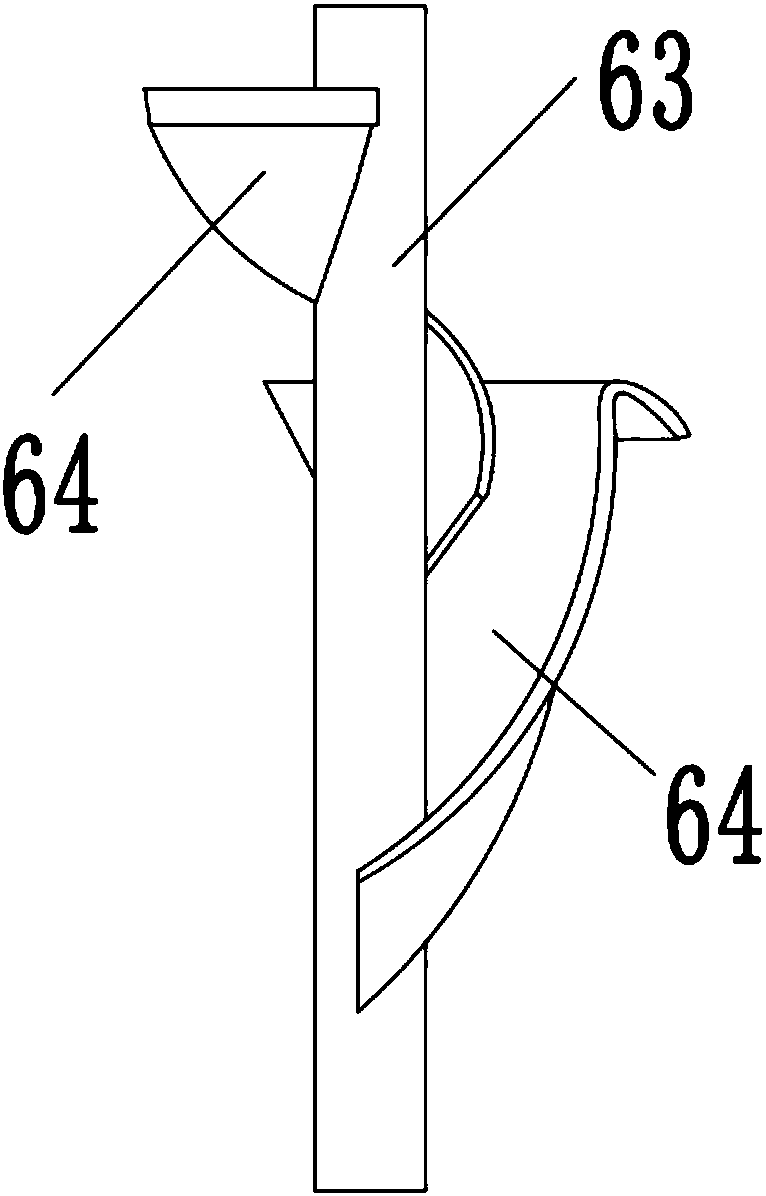

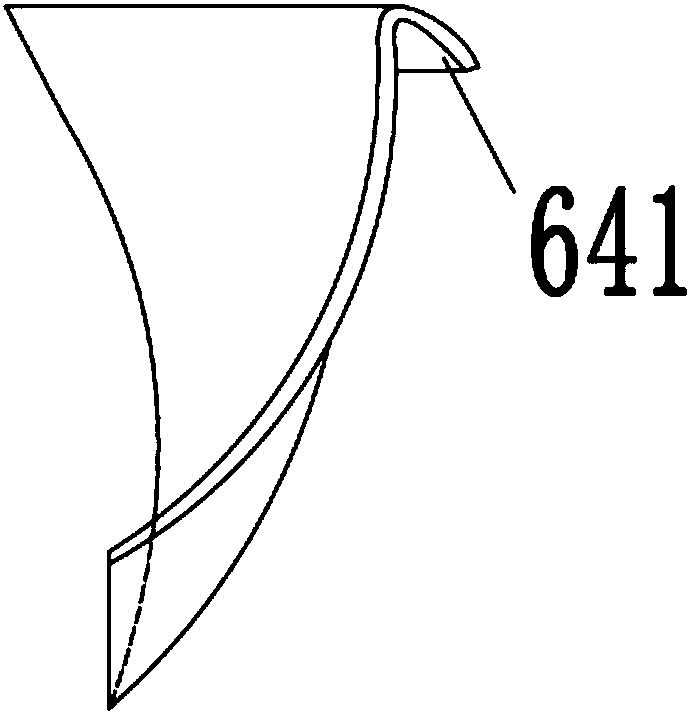

[0028] refer to Figure 1 to Figure 6 ,Such as figure 1 A gas-liquid separation device for mass transfer and exchange is shown, including a turbulent flow section, a swirl layer section 4 and a gas-liquid separation section 6 arranged in sequence. The turbulent flow section is tubular as a whole, and the turbulent flow section includes The inlet compression part 1, the throat part 2 and the barrier device 3 are arranged in sequence, the diameter of the flared pipe 11 of the inlet compression part 1 gradually expands along the axial direction of the inlet compression part 1, and the throat part 2 is Straight pipe, the small end of the inlet compression part 1 is fixedly connected with o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com