High efficient water heater capable of making full use of biomass fuels

A biomass fuel and water heater technology, applied in the direction of solid fuel combustion, combustion equipment, water heaters, etc., can solve the problem of underutilization of biomass energy, unsatisfactory heat preservation effect, limited heat contact area, etc. problems, to achieve the effect of easy collection of slag and ash, full and complete combustion, and fast fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

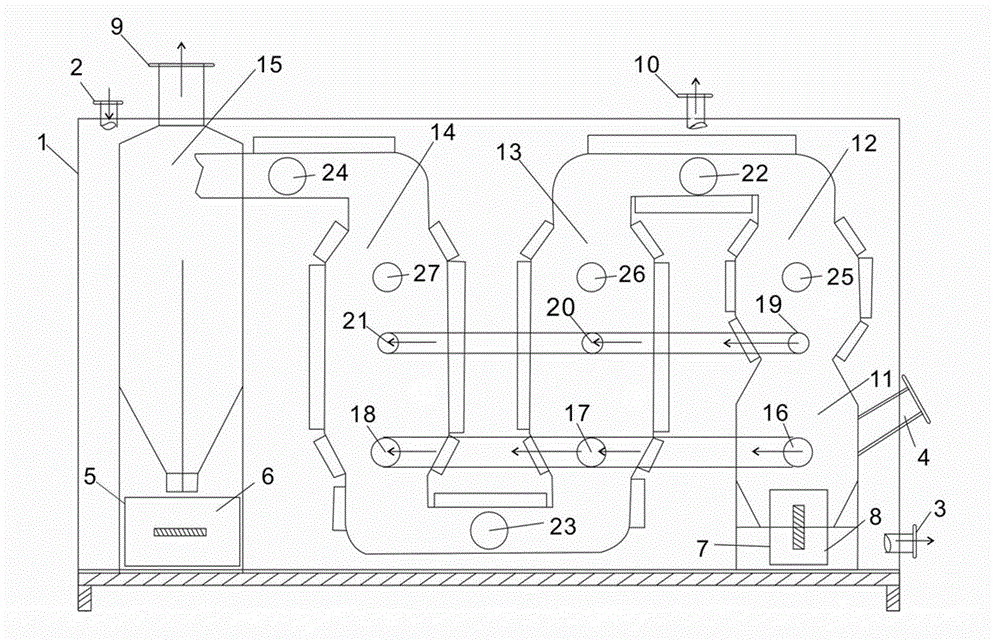

[0029] See figure 1 .

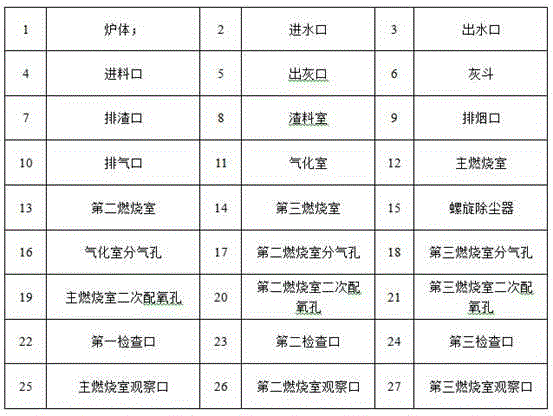

[0030] For the convenience of description, first list the corresponding relationship between the numbers marked in the figure and each component

[0031] as follows:

[0032]

[0033]The high-efficiency hot water heater fully utilizing biomass fuel of the present invention includes a furnace body 1, a water inlet 2, a water outlet 3, a material inlet 4, an ash outlet 5, an ash hopper 6, a slag outlet 7, and a slag material chamber 8 , smoke exhaust port 9, exhaust port 10, gasification chamber 11, combustion chamber, the key lies in one gasification chamber 11 and three combustion chambers (12, 13, 14), spiral dust collector 15, ash hopper 6, slag The material chamber 7 and the pipes and parts connected to the combustion chamber are all arranged in the furnace body 1 that can be filled with water. The upper section of the main combustion chamber 12 is conical, the middle section of the main combustion chamber 12 is cylindrical, and the lower sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com