Wind generator stator core pressing device

A technology for wind turbines and stator cores, applied in electromechanical devices, manufacturing stator/rotor bodies, electrical components, etc., can solve problems such as high processing costs, high production management costs, and high mold investment costs, and achieve guaranteed control, Reduce cost and solve the effect of not tight pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

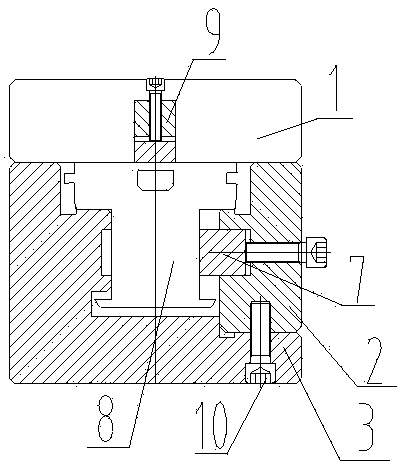

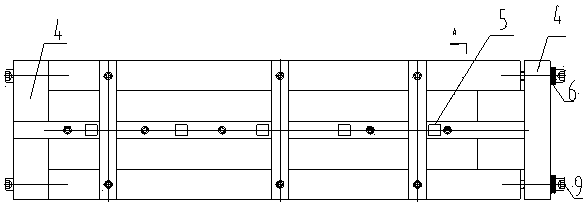

[0016] Example 1, such as Figure 1-4 , including internal press-fit side plate 2, press-fit base 3, external press-fit end plate 4, top slider 5, spring 6, side slider 7, closed punch 8, screw rod 9, screw 10, external The press-fit end plate 4 is in contact with the side of the closed punch 8, the inner press-fit cover 1 is in contact with the upper surface of the closed punch 8, and the inner press-fit cover 1 and the closed punch 8 are connected by a screw. Locking 9, the right side of the closed punch 8 is provided with a side slider 7, and the closed punch 8 is provided with a top slider 5, which ensures that the closed punch 8 does not shift axially and radially, and ensures that each The laminations are overlapped and aligned, and pressed without gaps. The side slider 7 runs through the right surface of the press-fit side plate 2. The press-fit side plate 2 and the press-fit base 3 are fixed with screws 10. The external press-fit end plate 4 Adopt screw rod locking 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com