Undercarriage structure of aerial helicopter model

A technology for helicopters and landing gear, applied in toy planes, entertainment, toys, etc., can solve the problems of poor applicability, lack of secondary auxiliary buffer, etc., and achieve good buffer protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

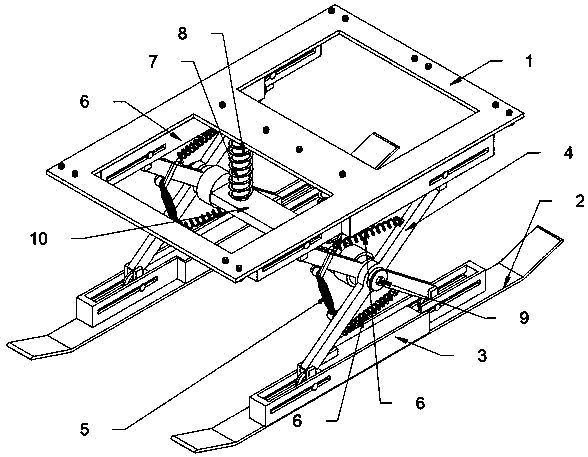

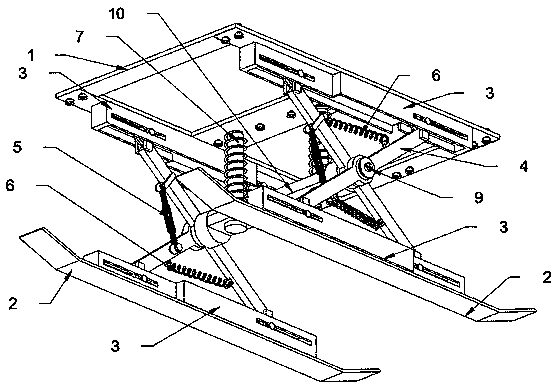

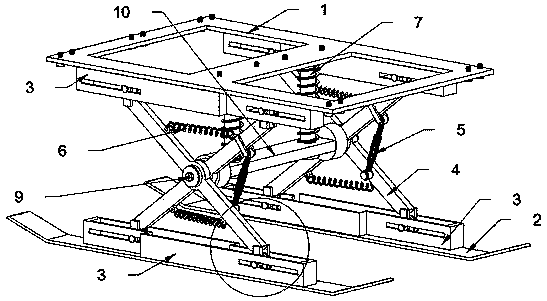

[0038] as attached figure 1 to attach Figure 8 Shown:

[0039] The invention provides a landing gear structure of an aviation helicopter model aircraft, which includes a locking positioning frame 1, a support plate 2, a positioning chute 3, a support rod 4, a gasket ring 401, a double-headed locking screw rod 5, and a tension spring 6. The sliding support shaft 7, the buffer spring 8, the locking limit plate 9, the main support plate 10 and the pulley 11, the locking and positioning frame 1 is arranged in a Japanese shape as a whole, and the bottom of the supporting plate is connected to the center by a symmetrical welding hanger. There are two sliding support shafts 7, and a positioning chute 3 is welded on the bottom of the left and right side plates; two circular mounting seats are welded symmetrically on the left and right sides of the main support plate 10, and the two places On the circular mounting seat, there is an insertion shaft that is welded to the outside; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com