Anti-blocking device for filtering secondary cooling water of continuous casting machine

A technology of secondary cold water and continuous casting machine, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of single water flow channel, filter failure, nozzle blockage, etc., to achieve convenient operation and maintenance, guarantee Quality, the effect of eliminating clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

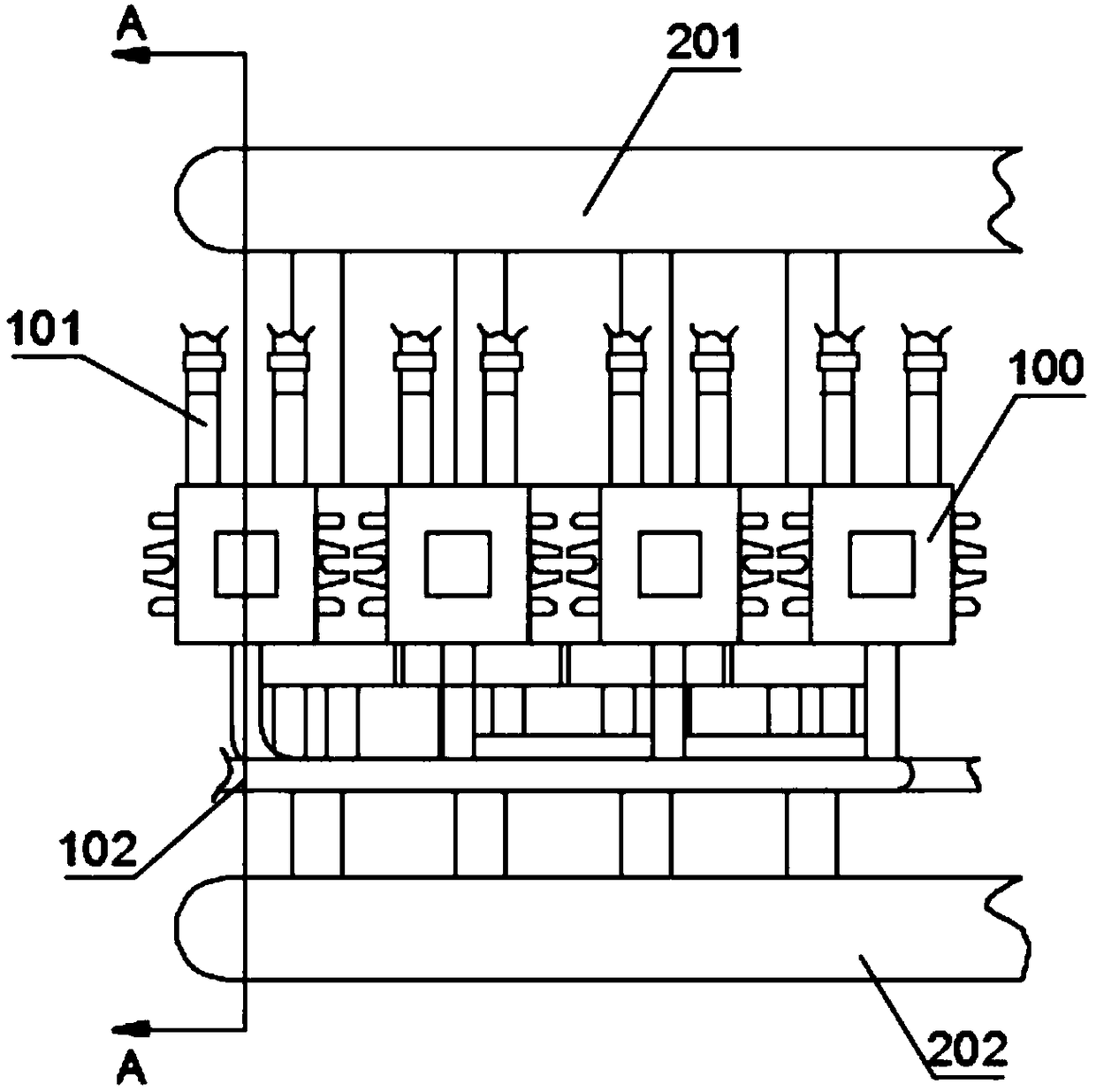

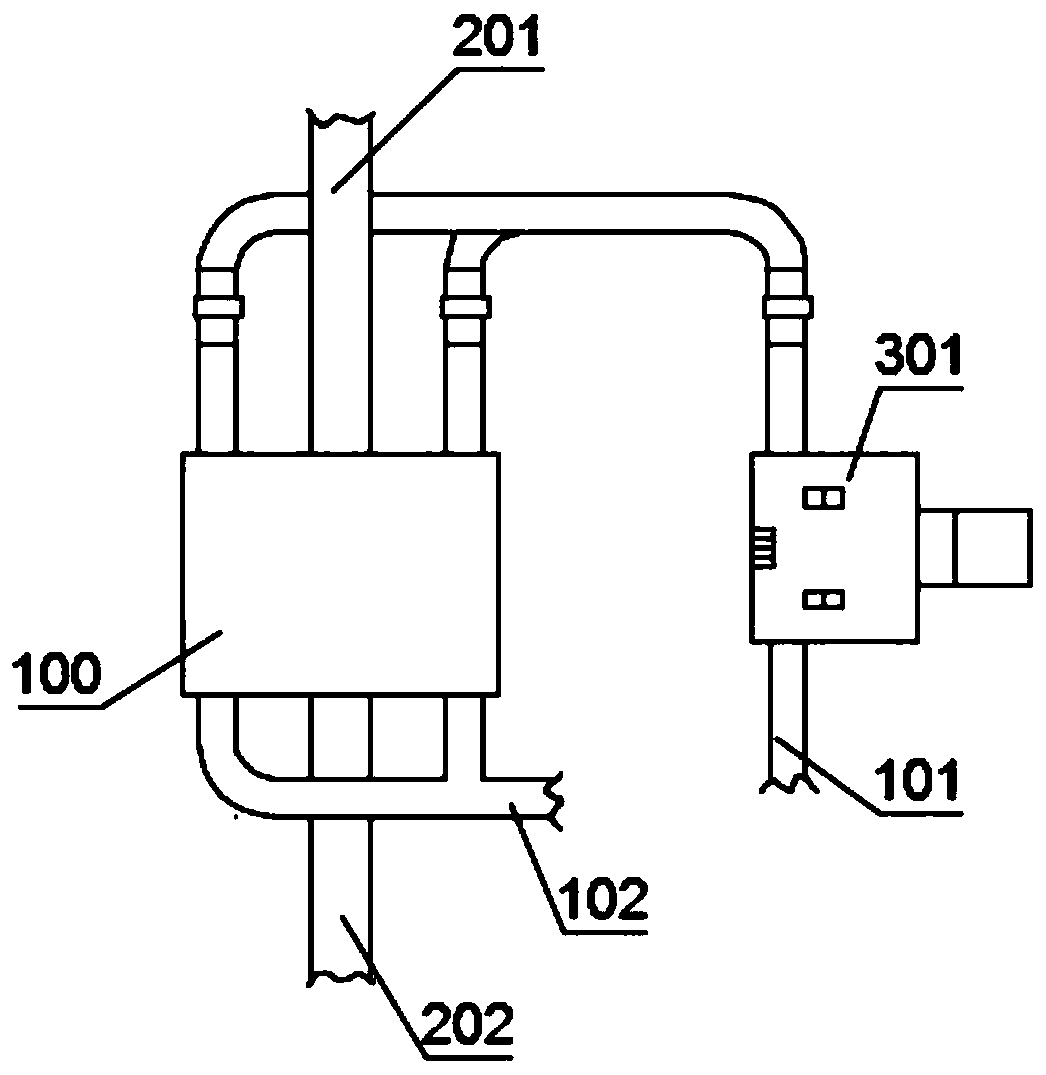

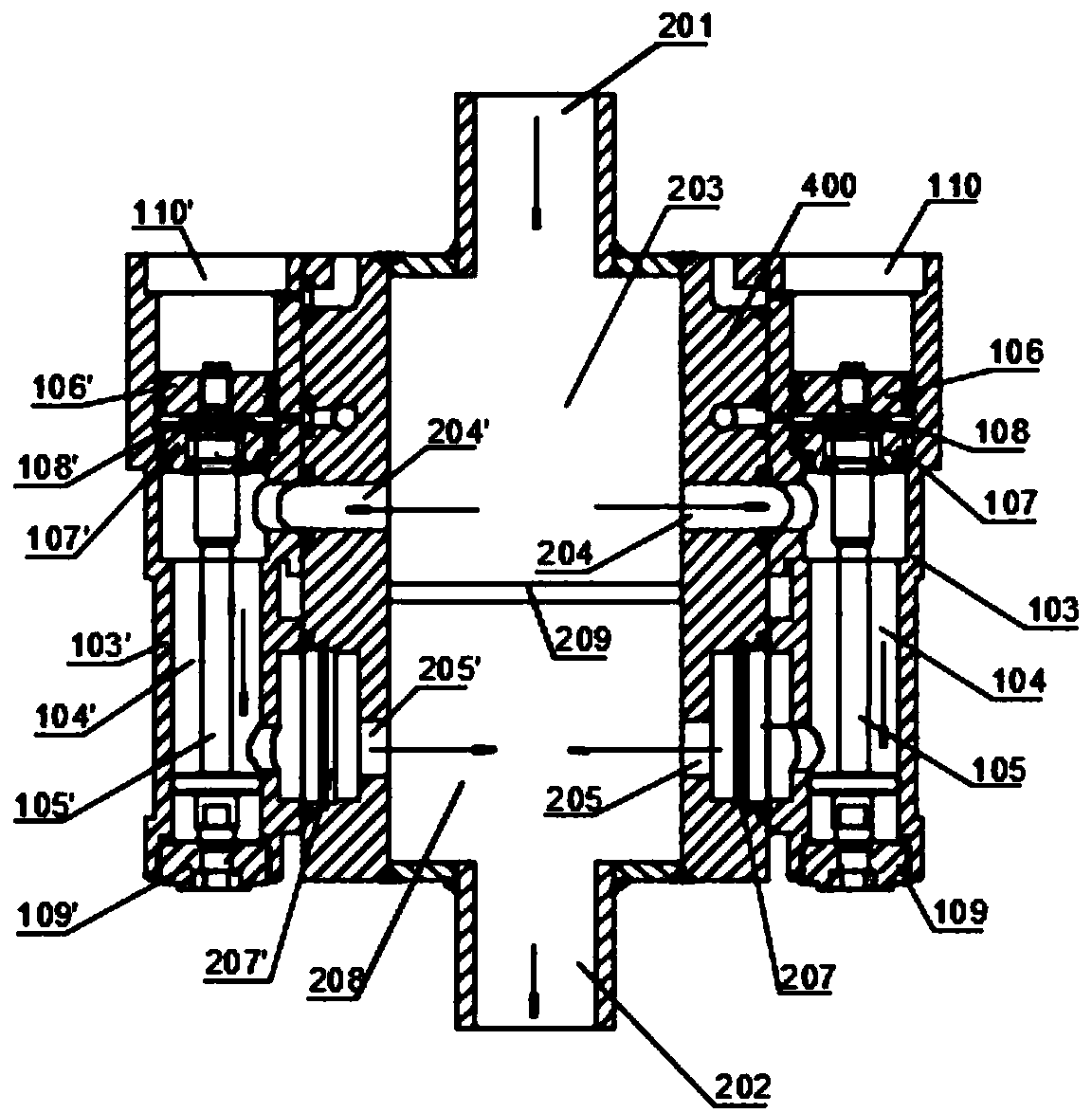

[0033] combine Figure 1 to Figure 3 As shown, in the normal filtering state of the secondary cooling water filter and anti-blocking device of the continuous casting machine, the main body of the right cylinder 105 is tightly connected with the inner wall of the right movable cavity 104 through the right guide seal sleeve 107, and is connected through the right first Circlip 108 limits the position of right guide sealing sleeve 107;

[0034] The right cylinder 105 drives the right movable rod 106 to move downward, so that the lower end of the right movable rod 106 is connected with the second right plug 109, so that the right movable cavity 104 is sealed;

[0035] Similarly, the main body of the left cylinder 105' is tightly connected with the inner wall of the left movable cavity 104' through the left guide seal sleeve 107', and the left guide seal sleeve 107' is limited by the left first retaining spring 108';

[0036] The left cylinder 105' drives the left movable rod 106'...

specific Embodiment approach 2

[0041] combine figure 1 , figure 2 and Figure 4 As shown, when a secondary cold water filter and anti-blocking device of a continuous casting machine of the present invention performs online backwashing of the right anti-blocking block, the right cylinder 105 drives the right movable rod 106 to move upward, and the lower end of the right movable rod 106 is connected to the right second blocking head 109 separation;

[0042] Further, the right movable rod 106 moves upward to the top of the right water outlet hole 205, so that the water flowing in from the right water inlet hole 204 cannot flow to the right water outlet hole 205;

[0043] The water flow enters the raw water chamber 203 through the water inlet pipe 201, and flows into the left movable cavity 104' through the left water inlet hole 204', and then flows into the clean water chamber 208 from the left water outlet hole 205', and then flows into the right water chamber through the right water outlet hole 205. In t...

specific Embodiment approach 3

[0044] combine figure 1 , figure 2 and Figure 5 As shown, when a secondary cold water filter and anti-blocking device of a continuous casting machine of the present invention performs online backwashing of the left anti-blocking block, the left cylinder 105' drives the left movable rod 106' to move upward, and the lower end of the left movable rod 106' is aligned with the left The second plug 109' is separated;

[0045] Further, the left movable rod 106' moves upward to the top of the left water outlet hole 205', so that the water flowing in from the left water inlet hole 204' cannot flow to the left water outlet hole 205';

[0046] The water flow enters the raw water chamber 203 through the water inlet pipe 201, and flows into the right movable cavity 104 through the right water inlet hole 204, and then flows into the clean water chamber 208 from the right water outlet hole 205, and then flows into the left movable cavity through the left water outlet hole 205'. cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com